As you cruise down the road, the wind in your hair and the engine humming beneath you, a sense of freedom and adventure fills the air. But amidst the thrills of driving, it’s crucial to remember the importance of safeguarding your beloved machine, especially its undercarriage. This is where the unsung hero of the vehicle, the engine under cover, comes into play.

I. Introduction

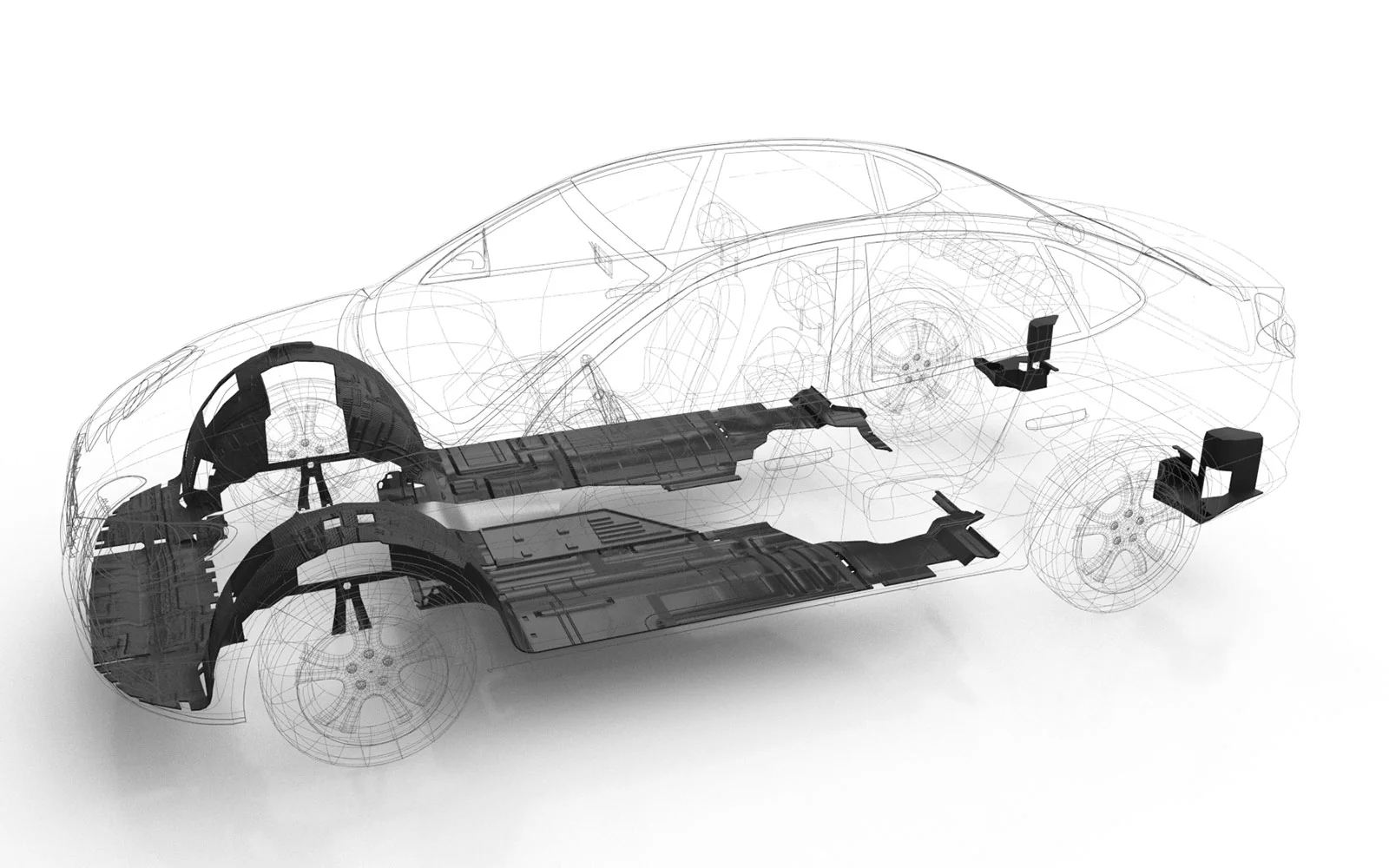

Often overlooked amidst the car’s exterior, the engine under cover, also known as a skid plate, splash shield, or lower engine cover, plays a vital role in protecting the undercarriage from the harsh elements and road hazards. This unsung hero acts as a silent guardian, shielding the engine, transmission, and other vital components from harm.

A. Defining the Engine Under Cover

The engine under cover is a protective panel typically made of plastic or metal that is mounted underneath the vehicle’s engine compartment. It acts as a barrier, deflecting debris, rocks, and other objects that could damage the engine, transmission, exhaust system, and other components.

B. Significance of the Engine Under Cover

The engine under cover serves several critical functions:

-

Protection from Debris and Road Hazards: It shields the undercarriage from flying rocks, gravel, and other debris that could cause damage to vital components.

-

Prevention of Fluid Leaks: It helps prevent leaks from the engine, transmission, and other components by deflecting water, mud, and snow.

-

Aerodynamic Enhancement: It can improve aerodynamics by smoothing out the airflow under the vehicle, potentially increasing fuel efficiency.

-

Noise Reduction: It can reduce noise from the engine and transmission, contributing to a quieter ride.

C. Growing Importance of Engine Under Cover Maintenance

As modern vehicles become more sophisticated and operate at higher temperatures, the engine under cover’s role in maintaining vehicle health has grown increasingly crucial. Proper maintenance of the under cover helps prevent damage to the undercarriage, ensures optimal performance, and extends the lifespan of your vehicle.

II. Types of Engine Under Covers

A. Plastic Engine Under Covers:

Plastic engine under covers are lightweight, affordable, and easy to install. They are a popular choice for many vehicles due to their cost-effectiveness and ease of maintenance.

B. Metal Engine Under Covers:

Metal engine under covers, typically made from aluminum or steel, offer enhanced durability and protection against impacts. They are often preferred for vehicles that frequently travel off-road or in harsh conditions.

C. Aerodynamic Engine Under Covers:

Aerodynamic engine under covers are designed to optimize airflow under the vehicle, potentially improving fuel efficiency and reducing drag. They may feature vents, fins, or other aerodynamic elements.

III. Choosing the Right Engine Under Cover

When selecting an engine under cover for your vehicle, consider the following factors:

A. Compatibility with Your Vehicle Model: Ensure the chosen under cover is specifically designed for your vehicle model. Check the manufacturer’s specifications and compatibility charts to avoid fitment issues.

B. Material and Durability: Consider the material and durability of the under cover. Plastic offers a balance of weight and affordability, while metal provides enhanced strength and protection.

C. Protection Level: Evaluate the level of protection needed based on your driving habits and terrain. If you frequently travel off-road or in harsh conditions, a metal under cover might be a better choice.

D. Aerodynamic Benefits: If fuel efficiency is a priority, consider an aerodynamic under cover that can potentially improve airflow and reduce drag.

IV. Benefits of Maintaining a Properly Functioning Engine Under Cover

A properly functioning engine under cover offers several benefits:

A. Protects Vital Components: It safeguards the engine, transmission, exhaust system, and other vital components from damage caused by debris, rocks, and road hazards.

B. Prevents Fluid Leaks: It helps prevent leaks from the engine, transmission, and other components by deflecting water, mud, and snow.

C. Enhances Aerodynamics: It can improve aerodynamics by smoothing out the airflow under the vehicle, potentially increasing fuel efficiency.

D. Reduces Noise: It can reduce noise from the engine and transmission, contributing to a quieter ride.

E. Extends Vehicle Lifespan: By protecting the undercarriage and preventing damage, a well-maintained engine under cover can extend the lifespan of your vehicle.

V. Signs of a Damaged or Missing Engine Under Cover

Several signs can indicate a damaged or missing engine under cover:

A. Unusual Noises: If you hear scraping or banging sounds from underneath the vehicle, it could be a sign that the under cover is damaged or missing.

B. Fluid Leaks (Continued): A damaged or missing under cover can allow water, mud, and road debris to come into contact with engine and transmission components, potentially leading to leaks.

C. Increased Road Noise: Without the under cover to deflect noise from the engine and transmission, you might experience a noticeable increase in road noise in the cabin.

D. Visible Damage to the Undercarriage: If you crawl under your vehicle and visually inspect the undercarriage, you might see signs of damage to components like the oil pan or exhaust system due to missing or inadequate protection from an under cover.

VI. Replacing or Repairing a Damaged Engine Under Cover

Replacing a damaged engine under cover can be a straightforward process for mechanically inclined individuals. However, consulting your vehicle’s service manual for specific instructions is always recommended. Here’s a general outline of the process:

A. Safety Precautions:

- Park your vehicle on a level surface and engage the parking brake.

- Wear safety glasses and gloves to protect yourself from potential hazards during the process.

- Allow the engine and exhaust system to cool completely before starting any work. Hot components can cause burns.

B. Gathering Necessary Tools and Materials:

- Replacement engine under cover (ensure compatibility with your vehicle)

- Socket wrench set

- Phillips screwdriver (if applicable)

- Trim removal tool (if necessary for plastic clips)

- Jack and jack stands (if needed to raise the vehicle)

- Rags

C. Removing the Damaged Engine Under Cover:

- Locate the mounting bolts or clips that secure the under cover to the vehicle frame.

- Use the socket wrench or screwdriver to loosen the bolts or carefully remove any plastic clips with the trim removal tool.

D. Installing the New Engine Under Cover:

- Thoroughly clean the mounting points on the vehicle frame with a rag to remove any dirt or debris.

- Position the new under cover into place, aligning the mounting holes with those on the frame.

- Secure the under cover using the bolts or clips, tightening them gradually in a crisscross pattern to the recommended torque specifications using the socket wrench.

E. Final Checks and Adjustments:

- Double-check that all mounting bolts or clips are securely fastened.

- Visually inspect the under cover for proper alignment and ensure no gaps exist.

- Lower the vehicle from the jack stands (if used) and dispose of the old under cover responsibly.

VII. Preventive Maintenance for Your Engine Under Cover

Regular maintenance plays a crucial role in ensuring the proper functioning of your engine under cover:

A. Regular Inspections:

- During routine car washes or oil changes, take a moment to visually inspect the engine under cover for any signs of damage, cracks, or loose mounting hardware.

B. Cleaning:

- While the under cover protects the undercarriage from dirt and debris, it can accumulate over time. Periodically clean the under cover with a hose and mild soap solution to remove dirt buildup.

C. Tightening Mounting Hardware:

- Over time, vibrations can cause the mounting bolts or clips to loosen slightly. Re-tighten the hardware periodically to the recommended torque specifications to maintain a secure fit.

VIII. Additional Considerations

A. Aftermarket vs. OEM Engine Under Covers:

- Aftermarket engine under covers offer a wider variety of materials, styles, and potentially lower costs compared to OEM (Original Equipment Manufacturer) options.

- However, OEM under covers are guaranteed to fit your specific vehicle model perfectly and might be constructed with higher-quality materials.

B. Weight Considerations:

- When choosing a metal under cover, consider the added weight compared to a plastic counterpart. While metal offers superior protection, it can also add a few extra pounds to your vehicle, potentially affecting fuel efficiency slightly.

C. Environmental Impact:

- If you choose a plastic engine under cover, consider opting for recycled plastic materials to minimize environmental impact.

- Additionally, ensure proper disposal of your old under cover at a recycling facility whenever possible.

IX. The Future of Engine Under Covers

The world of engine under covers is constantly evolving, with advancements in materials and design shaping their future:

A. Lightweight and High-Strength Materials:

- The development of lightweight and high-strength composite materials like Kevlar or carbon fiber could lead to under covers that offer superior protection while minimizing weight.

B. Integrated Under Covers:

- Future under covers might be integrated with other undercarriage components like aerodynamic diffusers or belly pans, improving functionality and overall vehicle performance.

C. Self-Healing Materials:

- The concept of self-healing materials for engine under covers is being explored. These under covers could potentially repair minor scratches or cracks over time, reducing maintenance needs.

Leave a Reply