When it comes to machinery and heavy-duty vehicles, having a reliable engine is crucial for optimal performance. Perkins engines are well-known in various industries, including agriculture, construction, and power generation. These engines offer reliable performance and durability, making them a popular choice worldwide. However, understanding more about Perkins engine parts and their compatibility is essential for maximizing performance and longevity. In addition, some users may also find themselves interested in other engine parts, such as Loncin 196cc engine parts, as they often have applications in similar equipment. In this article, we will delve into the world of Perkins engine parts, focusing on compatibility, potential upgrades, and what to consider when replacing or enhancing your engine components.

The Perkins Engine Overview

Evolution and Use

Perkins engines have a rich history that dates back to 1932. Originally based in Peterborough, England, the Perkins company developed engines that quickly became synonymous with reliability and performance. Today, Perkins engines are found in a wide variety of applications, from agricultural tractors to construction equipment. They are celebrated for their fuel efficiency, low emissions, and ease of maintenance.

Over the years, Perkins has introduced numerous enhancements to their engine designs. Technological advancements have allowed them to maintain their status as a leader in the industry. As users rely on Perkins engines for their operations, understanding their components becomes essential for ongoing maintenance and repairs.

Key Features of Perkins Engines

Perkins engines come in various models and configurations, making them suitable for different applications. Common features include a reputation for superior torque and power delivery, which are crucial for heavy-duty work. Many of these engines are also designed to operate under challenging conditions, ensuring they can handle the rigors of various industrial tasks.

The engines are known for being easy to maintain, which is a significant benefit for operators. Perkins has developed their engines with user-friendly accessibility in mind. This design consideration allows for simpler replacements and repairs. By understanding engine parts and their compatibility, operators can ensure that they maintain high performance over the years.

Understanding Perkins Engine Parts

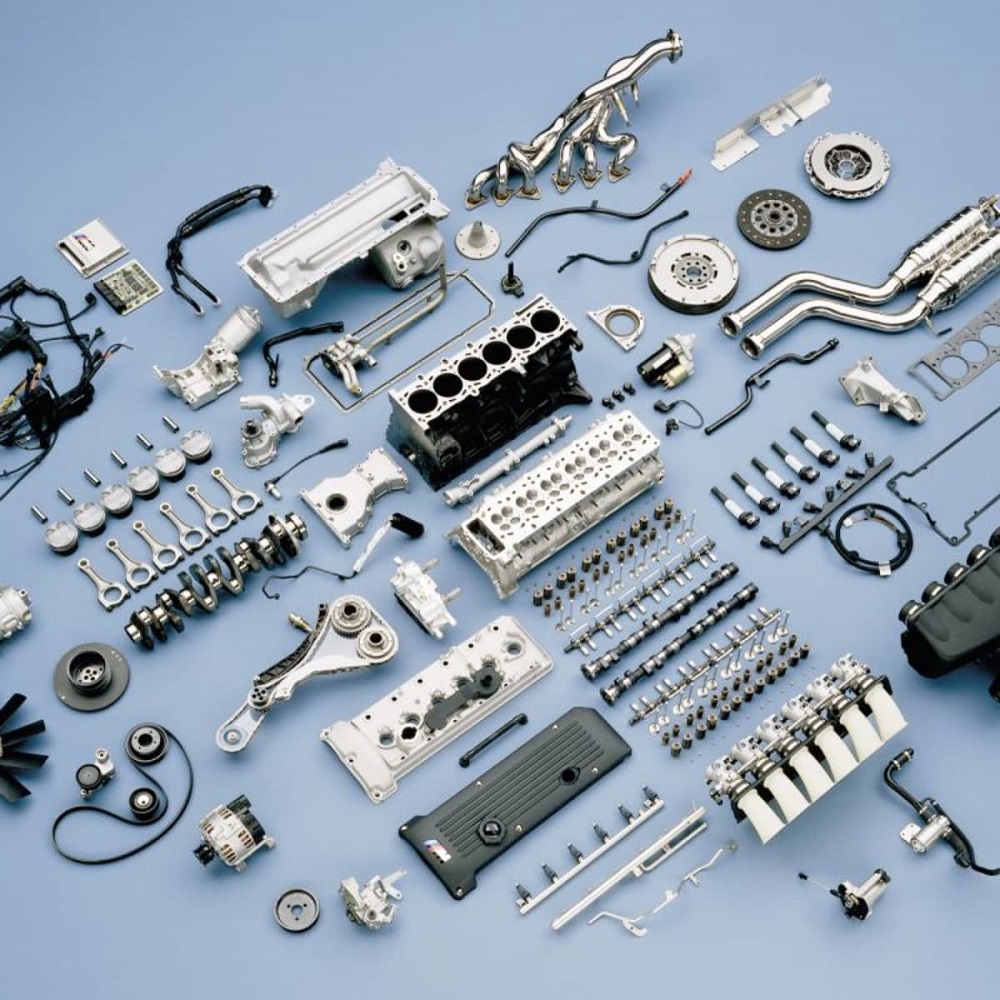

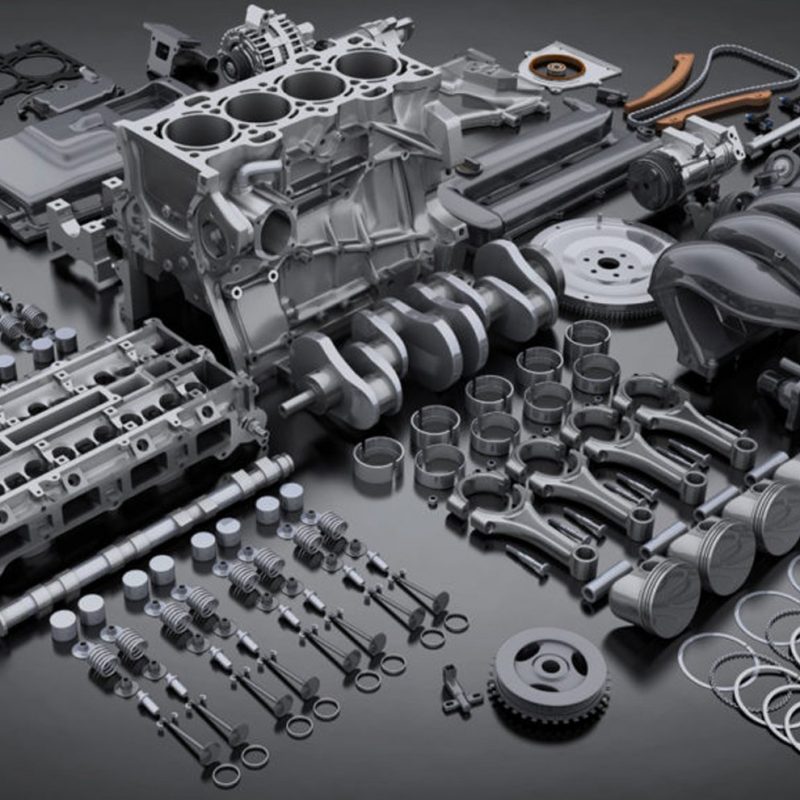

Types of Components

Perkins engines consist of several critical components that contribute to their overall functionality. These parts can be categorized into various systems, including the fuel system, cooling system, exhaust system, and electrical system. Each of these components plays a vital role in ensuring that the engine operates efficiently and effectively.

- Fuel System: This system includes injectors, fuel pumps, and filters. These components work together to deliver the right amount of fuel to the engine, ensuring that it runs smoothly. Any issues in the fuel system can lead to reduced performance and increased emissions.

- Cooling System: The cooling system consists of the radiator, water pump, and thermostat. These parts manage the engine temperature, preventing overheating and maintaining optimal operating conditions. A malfunction in the cooling system can cause significant damage to the engine.

- Exhaust System: The exhaust system includes components like exhaust manifolds, turbochargers, and mufflers. This system is responsible for directing exhaust gases away from the engine. Proper functioning of the exhaust system is essential for performance and compliance with emission standards.

- Electrical System: This system encompasses the starter, alternator, and battery. These parts provide the necessary electrical power to start the engine and maintain its operation. Electrical issues can significantly impact performance and reliability.

Authentic vs. Aftermarket Parts

When considering Perkins engine parts, users often face the choice between authentic and aftermarket options. Authentic parts are produced by Perkins and are guaranteed to meet the manufacturer’s specifications. They usually come with a warranty and are designed specifically for compatibility with Perkins engines.

On the other hand, aftermarket parts are often cheaper and can be made by third-party manufacturers. While some aftermarket parts can offer good value, others may not meet the same quality standards as authentic components. Therefore, it is crucial to research and choose reputable suppliers to ensure the reliability of aftermarket parts.

Compatibility of Perkins Engine Parts

Factors to Consider

When replacing or upgrading parts in a Perkins engine, compatibility is a crucial issue. Different engine models and configurations may have specific requirements. It is important to understand the specifications for each engine to make the right choice when selecting replacement parts.

- Engine Model: Every Perkins engine has a designated model number that indicates its specifications and capabilities. When purchasing replacement parts, always verify they match the engine model in question.

- Year of Manufacture: Manufacturing years can impact part compatibility as designs may change over time. Certain parts might have been updated or improved in newer models, making older parts incompatible with newer engines.

- Application Specifics: Depending on the application, certain parts may need to be tailored to specific operating conditions or performance requirements. For instance, components for engines used in construction may differ from those used in agriculture.

Importance of Correct Fit

The correct fit of engine parts is vital for optimal performance. Ill-fitting components can lead to inefficiencies, increased wear, and potentially serious engine damage. For example, improperly matched fuel injectors can lead to poor fuel delivery, impacting overall engine performance. Similarly, a cooling system component that doesn’t fit correctly may not function effectively, leading to overheating.

Ensuring correct compatibility means consulting manufacturer specifications and possibly working with a knowledgeable technician or mechanic. They can provide guidance on finding compatible parts and ensuring seamless integration into the engine.

Upgrading Perkins Engine Parts

Benefits of Upgrades

Upgrading engine parts can bring several benefits, ranging from increased performance to enhanced fuel efficiency. Upgrades may involve improving specific components, such as the turbocharger, air filters, or exhaust systems. These enhancements can lead to a more responsive engine and a better overall driving experience.

- Boosted Performance: Upgrading parts can result in better acceleration and power delivery, making machines better suited for heavy workloads. Higher-quality components, such as performance injectors or high-flow air filters, can maximize engine capabilities.

- Improved Fuel Efficiency: Many modern replacement parts are designed with efficiency in mind. Upgrading components such as the fuel pump or injectors can ensure optimized fuel delivery, potentially saving money on fuel costs.

- Better Emissions Control: Regulations regarding emissions are tightening worldwide. Upgrading parts, such as the exhaust system, can help maintain compliance while improving environmental performance.

Choosing the Right Upgrades

When considering upgrades, it is essential to choose parts that are designed for your specific Perkins engine model. Researching reliable suppliers and reading reviews on aftermarket performance parts can help in making informed decisions. Be sure to consult professionals if needed for personalized recommendations and installation assistance.

In some cases, it may also be beneficial to upgrade multiple components at once for a synergistic effect. For example, if an upgraded turbocharger is installed, it may be wise to also consider modifying the exhaust system to handle increased airflow.

Maintenance Best Practices

Regular Inspections

Regular maintenance is vital for the longevity and performance of Perkins engines. This includes conducting frequent inspections of all crucial components. Check for signs of wear and tear, such as leaks, cracks, or unusual noises. Early detection of potential problems can prevent costly repairs down the road.

- Fluid Levels: Always monitor fuel, oil, and coolant levels. Maintaining proper fluid levels is essential for optimal engine performance. Low levels can lead to serious problems, including overheating or inadequate lubrication.

- Parts Replacement: Replace parts based on manufacturer recommendations, especially those that experience routine wear, such as oil filters, air filters, and fuel injectors. Regular replacements help maintain engine efficiency and functionality.

Professional Servicing

Engaging professional services for regular maintenance and repairs is a smart choice for engine longevity. Certified technicians familiar with Perkins engines can provide valuable insights and service tailored to your specific needs. They can conduct thorough inspections, replace parts, and perform repairs as necessary.

Additionally, utilizing professional services ensures that any replacement parts used meet quality standards set by Perkins. This practice minimizes the risk of compatibility issues, helping maintain performance over time.

Sourcing Perkins Engine Parts

Authorized Dealers vs. Online Suppliers

Finding genuine Perkins engine parts is crucial for maintaining optimal performance. Authorized dealers are often the best source for authentic parts, as they guarantee compatibility and quality. They usually have access to the latest parts and can provide professional guidance when selecting what to purchase.

However, many online suppliers also sell Perkins parts, often at competitive prices. It is crucial to vet these suppliers carefully to ensure they offer genuine components. Always look for retailers with positive reviews, clear return policies, and good customer service.

Local Salvage Yards

For those on a budget, local salvage yards can be an excellent resource for used Perkins engine parts. Many salvage yards sell quality parts at a fraction of the new prices. While buying used parts comes with risks, thorough inspections can help determine their condition and suitability. Ensure any used parts you consider are still functional and compatible with your specific engine model.

This approach can be a cost-effective way to acquire essential components while being environmentally friendly by recycling parts.

The Future of Perkins Engines

Innovations and Developments

As technology continues to evolve, Perkins is dedicated to enhancing its engines and components. Developments in efficiency and emissions reduction are at the forefront of these efforts. The company continuously works to refine its technology to meet changing regulations and customer demands.

Investments in research and development are likely to yield significant advancements in engine performance and durability. With a focus on the future, Perkins aims to stay at the cutting edge of the industry, ensuring that their engines remain relevant and efficient for years to come.

Keeping Up with Trends

For aspiring and current Perkins engine users, staying informed about industry trends and new developments is essential. Following industry publications, attending trade shows, and participating in communities related to Perkins engines can provide valuable insights. Networking with other operators can also foster the exchange of knowledge regarding parts, maintenance, and upgrades.

By understanding both the current landscape and future trends, users can better prepare for shifts in technology and ensure that their engines remain reliable and competitive.

Maximizing Perkins Engine Performance

In summary, understanding Perkins engine parts and their compatibility is essential for anyone relying on these powerful machines. From knowing what components work best for your specific engine model to considering potential upgrades, detailed knowledge leads to better performance and longevity.

Engaging in regular maintenance and sourcing authentic parts can help users get the most from their Perkins engines. Whether you’re dealing with heavy machinery or agricultural vehicles, maintaining your engine efficiently ensures reliability and productivity.

By keeping an eye on industry innovations and trends, you can improve your understanding and capabilities as a user. As you explore replacements and upgrades, you empower your equipment to perform at its best, turning potential challenges into a seamless operation. Investing time in understanding and maintaining your Perkins engine will pay off in enhanced efficiency and long-term reliability.

Leave a Reply