Overview of Diesel Engine Maintenance

Proper maintenance of diesel engine parts is critical to ensure long-term performance and efficiency. A diesel engine’s robust design requires regular attention to keep it running smoothly. Key maintenance tasks include regular oil changes, filter replacements, and fuel system cleanings. These help prevent the buildup of contaminants that can degrade engine components.

Preventative maintenance for diesel engine parts also involves inspecting systems such as the cooling and exhaust. This helps catch problems early, reducing repair costs and downtime. It is vital to follow the manufacturer’s maintenance schedule closely and use high-quality parts. Skilled technicians should perform more complex tasks to ensure quality workmanship.

Adhering to a regimented maintenance schedule enhances the lifespan of diesel engine parts. It also maximizes fuel efficiency, which can lead to significant cost savings. In the long run, well-maintained diesel engines are more reliable, have better resale value, and offer increased safety on the road. Regular maintenance is not just about addressing current issues but also about preventing future problems and ensuring optimal engine performance.

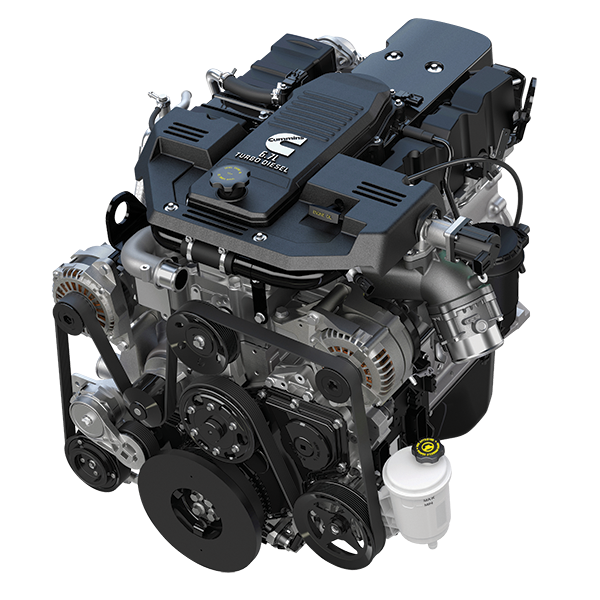

Key Diesel Engine Parts and Their Functions

Understanding the key components of a diesel engine is crucial for proper maintenance. Each part plays a vital role in the overall functionality and efficiency of the engine. Here, we will discuss some of the essential diesel engine parts and their functions:

- Fuel Injector: The fuel injector delivers diesel to the combustion chamber. Precise fuel injection is key for engine performance.

- Turbocharger: This component increases engine power by forcing more air into the combustion chamber for a more intense burn of fuel.

- Air Intake System: It supplies clean air to the engine, which mixes with the fuel for combustion. Regular filter changes keep airflow unrestricted.

- Cooling System: It keeps the engine from overheating. Coolant levels and radiator condition are crucial.

- Exhaust System: Takes away combustion byproducts. A functioning exhaust is essential for engine health and environment safety.

- Battery: Provides the electrical power needed to start the engine and powers electrical components when the engine runs.

- Alternator: Charges the battery while the engine runs, ensuring the battery remains fully charged.

- Oil Filter: Removes contaminants from engine oil to prevent wear and tear on moving parts.

Each of these components must work seamlessly to maintain an efficient diesel engine. Regular checks and maintenance ensure they function correctly and last longer. Skipping maintenance on these parts can lead to reduced efficiency and eventual engine failure.

Regular Maintenance Schedule for Diesel Engine Components

Keeping up with a regular maintenance schedule is vital for the longevity and efficiency of diesel engine parts. To ensure optimal performance of a diesel engine, here’s what you should incorporate in your maintenance routine:

- Oil Change: Replace the engine oil regularly. This is essential to lubricate moving parts and prevent wear.

- Filter Replacement: Change the oil filter, air filter, and fuel filter as recommended by the manufacturer to prevent blockages and maintain engine cleanliness.

- Fuel System: Inspect and clean the fuel injectors to ensure efficient fuel delivery and combustion. Check for any signs of damage or wear.

- Cooling System: Monitor coolant levels and inspect the radiator and hoses for leaks or corrosion. Replace coolant as per the schedule to prevent overheating.

- Air Intake System: Keep the air intake system clear. Replace air filters to ensure there is no restriction in airflow to the engine.

- Exhaust System: Check the exhaust system for blockages or leaks which can impact engine performance and emissions.

- Electrical Components: Test the battery and alternator regularly to ensure they provide consistent electrical supply.

- Visual Inspections: Look for any signs of damage, leaks, wear, or unusual noises during operation that can indicate potential issues.

Always refer to the diesel engine’s owner manual for the precise intervals for each of these tasks. Following the specified intervals will help catch minor issues before they turn into major repairs. Moreover, maintenance logs should be kept up-to-date as they are crucial when assessing the health of diesel engine parts over time.

Troubleshooting Common Diesel Engine Problems

Even well-maintained diesel engines can encounter issues. Being able to quickly identify and address common problems can save time and money. Here are frequently reported diesel engine problems and how to troubleshoot them:

- Hard Starting or No Start: This may be due to low quality fuel, drained batteries, or clogged fuel filters. Check the battery charge and replace filters if necessary.

- Poor Fuel Economy: If the engine consumes more fuel than usual, inspect the air and fuel filters. Also, check for potential leaks in the fuel system.

- Exhaust Smoke: Excessive smoke can indicate a variety of problems. Black smoke often points to incomplete combustion, white smoke could suggest coolant leaks, and blue smoke often signals oil burning.

- Power Loss: Loss of engine power might stem from issues with the turbocharger, air intake system, or dirty fuel injectors. Inspect these components for damage or blockages.

- Engine Overheating: Make sure to check the coolant level and ensure the cooling system is working correctly. Look for leaks or clogs in the radiator and hoses.

- Increased Oil Consumption: This can be a sign of worn-out engine parts. Investigate the possibility of oil leaks or the need for more frequent oil and filter changes.

- Excessive Noise: Knocking or tapping sounds may mean combustion problems or damaged bearings. An immediate inspection is advisable to prevent further damage.

Regularly monitoring your diesel engine’s performance can help you catch these problems early on. Perform visual checks and listen for unusual noises to detect issues before they escalate. Always refer to your engine’s manual and consult a professional when needed to maintain your diesel engine’s health and efficiency.

Best Practices for Cleaning and Maintaining Diesel Parts

For optimal diesel engine performance, keeping engine parts clean and well-maintained is a must. Here are best practices to keep in mind:

- Routine Cleaning: Dirt and debris accumulation can impair engine parts. Regular cleaning prevents build-up and ensures smooth operation. Wipe down accessible parts with a clean rag and use approved cleaning solutions for tougher grime.

- Lubrication: Apply lubricant to moving parts as needed. This reduces friction and wear, prolonging part life. Always use lubricants that meet your engine’s specifications.

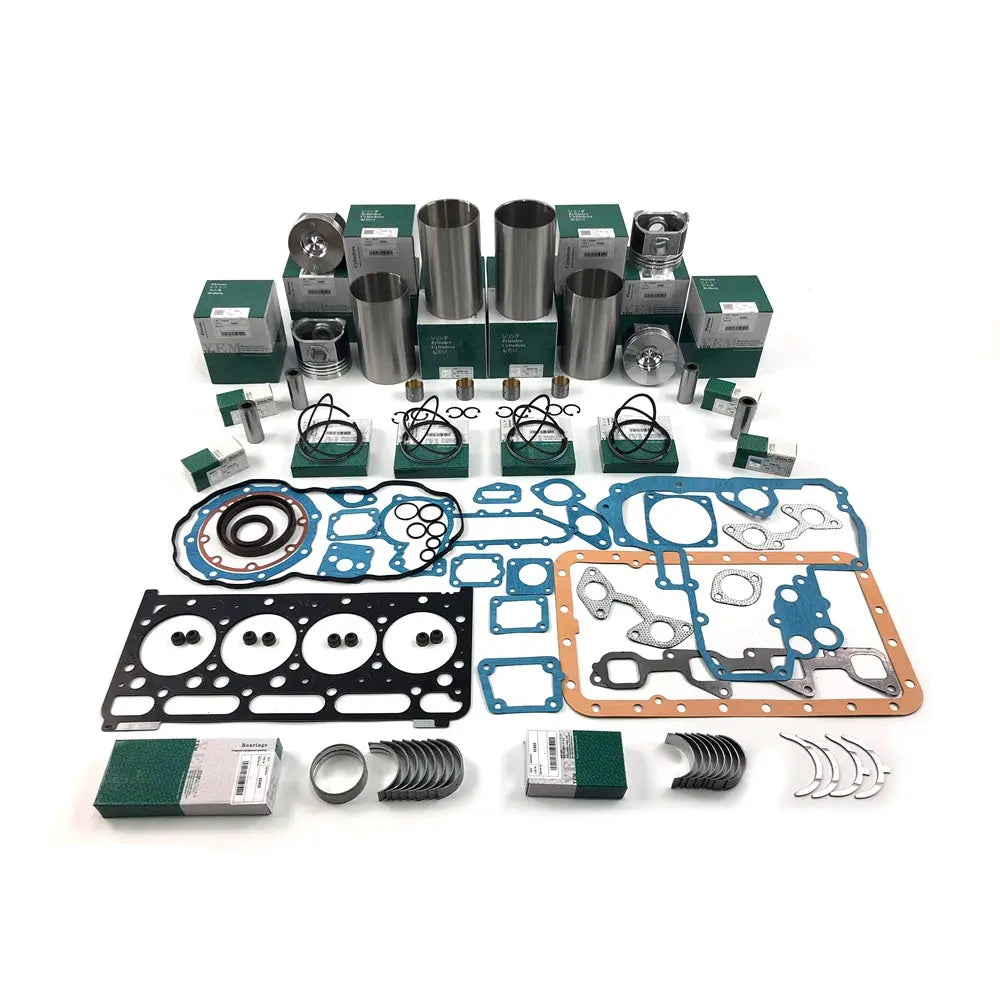

- Inspect Seals and Gaskets: Check for leaks or damage regularly. Replace worn out seals to prevent fluid loss and potential contamination.

- Use Quality Fuel: Contaminated or low-grade fuel can harm diesel engine parts. Invest in high-quality diesel to protect and maintain your engine’s efficiency.

- Corrosion Prevention: Protect metal parts from rust and corrosion. Apply anti-corrosion sprays or coatings where appropriate. Keeping parts dry where possible is also vital.

- Avoid Short Runs: Short engine runs don’t let the engine reach optimal operating temperature. This can cause unburned fuel to accumulate and oil to dilute, hampering parts’ functionality.

- Handle with Care: When disassembling engine parts for maintenance, handle them with caution. Avoid using excessive force that might cause damage. Store parts in a clean, dry place when not installed.

- Professional Cleaning: Certain parts like fuel injectors may need specialized cleaning equipment. Consider having these cleaned by professionals.

Maintaining diesel engine parts is not just about cleaning; it’s about consistent care and attention to detail. By following these best practices, you safeguard the engine’s efficiency and longevity.

The Role of Fuel Quality in Diesel Engine Health

Fuel quality is fundamental to maintaining diesel engine health. Poor fuel can cause a multitude of problems, from clogging and corrosion to inefficient combustion. Let’s delve into why fuel quality matters and how it affects the key diesel engine parts:

- Clean Combustion: High-quality diesel ensures clean combustion. It prevents deposit build-up in the combustion chamber and on fuel injectors.

- Reduced Wear: Cleaner fuel reduces wear on engine parts. This is because it contains fewer contaminants that can erode components.

- Efficient Fuel Injection: Fuel that meets engine specifications helps maintain precise fuel injection. This is crucial for engine performance and fuel efficiency.

- Prevents Clogging: Quality diesel has fewer impurities. This means less risk of clogging filters and fuel lines.

- Preserves Fuel System Health: A healthy fuel system is less prone to leaks and failures. High-grade diesel protects this system by not introducing harmful materials.

To ensure you’re using the right diesel for your engine, always source fuel from reputable providers. Check the cetane number, which indicates fuel combustion quality. Also, follow your vehicle manufacturer’s guidelines for the correct fuel type. Regularly using quality diesel can lead to fewer engine problems, lower maintenance costs, and a longer engine life.

Upgrading Diesel Engine Parts for Improved Performance

For better diesel engine performance, upgrading specific parts can be highly effective. Upgrading goes beyond routine maintenance. It introduces newer or better-performing parts into your diesel engine. This can lead to greater power, increased fuel efficiency, and improved overall engine response. Focus on these key upgrades for enhanced performance:

- High-Performance Air Filters: These provide better airflow to the engine. More air means more power.

- Upgraded Fuel Injectors: Better injectors improve fuel delivery. This leads to a more efficient burn and more power.

- Turbochargers: Installing a larger or more efficient turbocharger can significantly boost engine power.

- Performance Chips and Programmers: These adjust the engine’s electronic functions. They optimize fuel use and power output.

- Exhaust Systems: A high-flow exhaust system reduces back pressure. It allows the engine to breathe better.

- Improved Cooling Systems: Keeping your engine cooler helps preserve the life of its parts. It also enhances performance.

Make sure to consult experts when upgrading diesel engine parts. They can advise on compatibility and installation. Quality upgrades, when done right, will not only improve performance but also add to the durability of your engine. Always remember, upgrading is an investment in your engine’s future capabilities and endurance.

The Importance of Professional Maintenance and Diagnosis

Professional maintenance is key to keeping diesel engine parts running at peak condition. Experts with the right tools and knowledge can spot issues that might go unnoticed. In-depth diagnostics can prevent costly future repairs by catching problems early. Regular check-ups by professionals ensure every part functions well together.

With professional diagnosis, you avoid guesswork. Trained technicians use advanced equipment to find exact problems. They offer solutions that are precise and tailored to your engine’s needs. Skilled mechanics also help to maintain your engine’s warranty. They follow manufacturer guidelines during service.

Professionals also give advice on how to best care for your diesel engine parts. They inform you when to schedule next maintenance based on how you use your engine. During professional maintenance, technicians might also update you on new techniques or products. This helps improve your engine’s performance over time.

Always choose certified professionals for diesel engine maintenance. It saves time and money down the line. With their aid, you can extend the life of your engine. You also keep it running efficiently, which reduces your fuel costs. Trust in their expertise for an engine that stays reliable on the road.

The Role of Professional Maintenance

Seeking Expert Assistance

While performing regular maintenance is essential for the health of your diesel engine, seeking professional assistance is equally important. Trained mechanics have the expertise and tools necessary to perform in-depth inspections and maintenance tasks that may be challenging for an average owner.

Consider scheduling periodic professional maintenance, especially for complex systems like the fuel and exhaust. Routine inspections by a mechanic can identify potential issues before they escalate into major problems, saving you money in the long run.

Keeping Maintenance Records

Maintain thorough records of all maintenance performed on your diesel engine. Documenting oil changes, part replacements, and inspections helps keep track of the engine’s history. This information can be invaluable for future maintenance and repairs, allowing mechanics to understand the engine’s condition.

Keeping a maintenance log also helps ensure that you adhere to recommended service intervals. Regular upkeep and detailed records enhance the engine’s reliability and performance while maximizing its lifespan.

Ensuring Efficiency and Longevity

In conclusion, maintaining diesel engine parts is vital for ensuring efficiency and longevity. Each part of the engine plays a crucial role, and neglecting any component can lead to reduced performance and costly repairs. By following the outlined maintenance practices—such as regular inspections, proper lubrication, and professional assistance—owners can significantly improve the overall health of their engines.

Diesel engines are designed to last, but they require dedication and attention from their owners. Implementing these maintenance tips will not only enhance engine performance but also contribute to a more enjoyable driving experience. Embrace a proactive approach to diesel engine maintenance, and you will reap the rewards of a reliable, efficient, and powerful machine for years to come.

Leave a Reply