Small engines are at the heart of many tools and machines we use every day, from lawn mowers to generators. The efficient operation of these engines relies on numerous components, collectively known as rotary small engine parts. Understanding these parts and their functions is crucial for anyone looking to improve performance, ensure longevity, and conduct effective repairs. This article will explore the key components of rotary small engines, their roles in enhancing efficiency, and practical tips to maintain them for prolonged use.

Introduction to Rotary Small Engines

Understanding Rotary Small Engines

Rotary small engine parts are typically defined as engines with a displacement of less than 20 horsepower. These engines are used in various applications, including lawn care, construction, and agricultural tasks. Their compact size and robust performance make them ideal for powering handheld tools and machinery.

The most common type of rotary small engine is the two-stroke or four-stroke engine. Two-stroke engines are lighter and simpler, while four-stroke engines are known for their fuel efficiency and lower emissions. Understanding these distinctions is important when choosing equipment for specific tasks. Knowing about the engine’s design can help users grasp how rotary motion translates into the power needed for various applications.

Importance of Engine Parts

The performance and longevity of a rotary small engine are heavily influenced by its individual parts. Each component has a specific role, contributing to the engine’s overall functionality. When all parts are working well together, the engine operates efficiently and effectively. If any part is damaged or not functioning correctly, it can lead to decreased performance, increased fuel consumption, or even engine failure.

For instance, parts such as the carburetor, ignition system, and oil system are crucial for the engine’s function. Understanding how these parts interact allows for better maintenance practices, ensuring that the engine runs smoothly over time. Overall, knowledge of engine parts empowers users to make informed decisions about repairs and upgrades.

Key Components of Rotary Small Engines

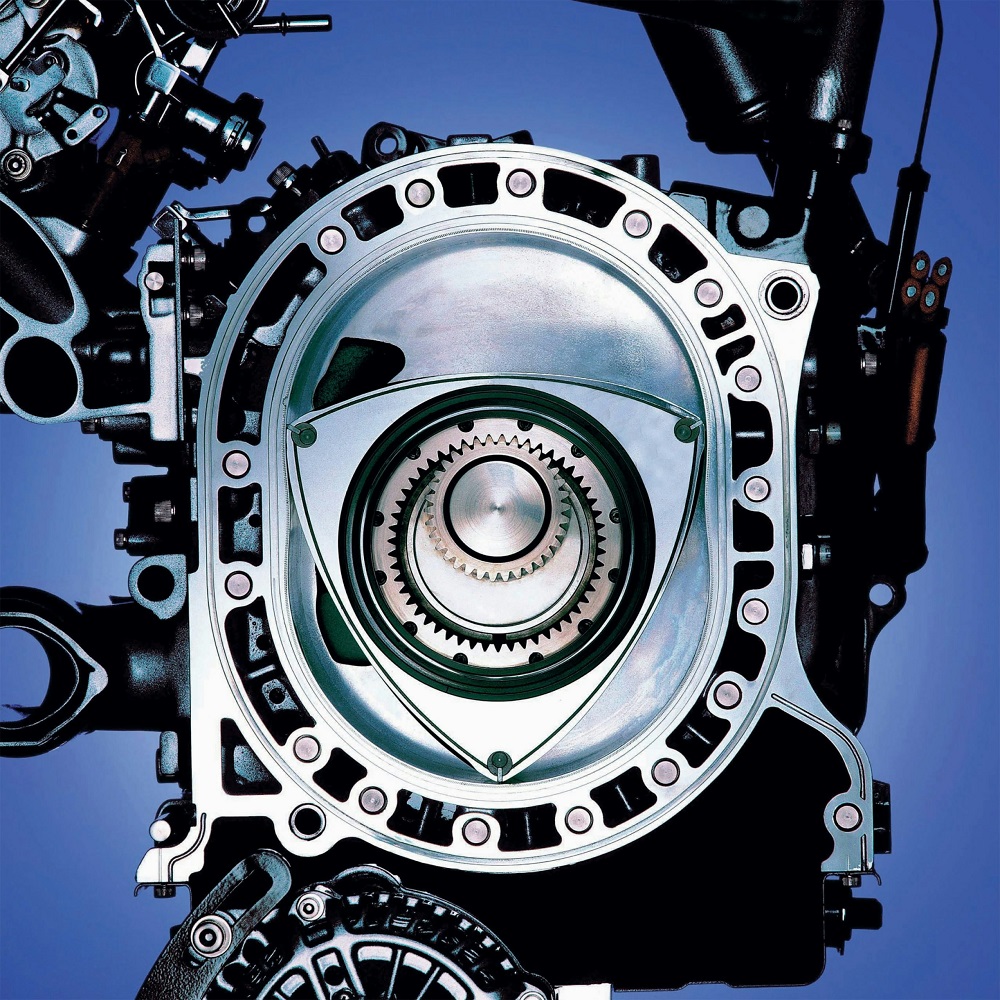

Engine Block and Cylinder

At the core of every rotary small engine lies the engine block. It houses critical components like the cylinders, where fuel combustion occurs. The engine block is primarily made from durable materials like aluminum or cast iron to withstand the high temperatures and pressures generated during operation.

Cylinders can be either vertical or horizontal, depending on the engine’s design and intended application. The vertical cylinders are often used in smaller equipment, providing a compact layout. In contrast, horizontal cylinders are typically found in larger machines, offering better balance and power delivery. Understanding the configuration of your engine block and cylinders is essential for identifying specific issues.

Pistons and Crankshaft

Pistons move within the cylinders, driven by the combustion of air-fuel mixtures. They create power by transferring energy through their movement, which is critical for engine operation. Mounted at the top of the pistons are piston rings, which help seal the combustion chamber and minimize oil consumption. Damaged or worn piston rings can lead to reduced efficiency and increased emissions.

The crankshaft converts the linear motion of the pistons into rotational motion. This rotation ultimately powers the machinery connected to the engine. Ensuring that both the pistons and crankshaft are in good condition is vital for maintaining engine performance. If either part experiences wear or damage, it can significantly affect power output and overall engine efficiency.

Fuel System Components

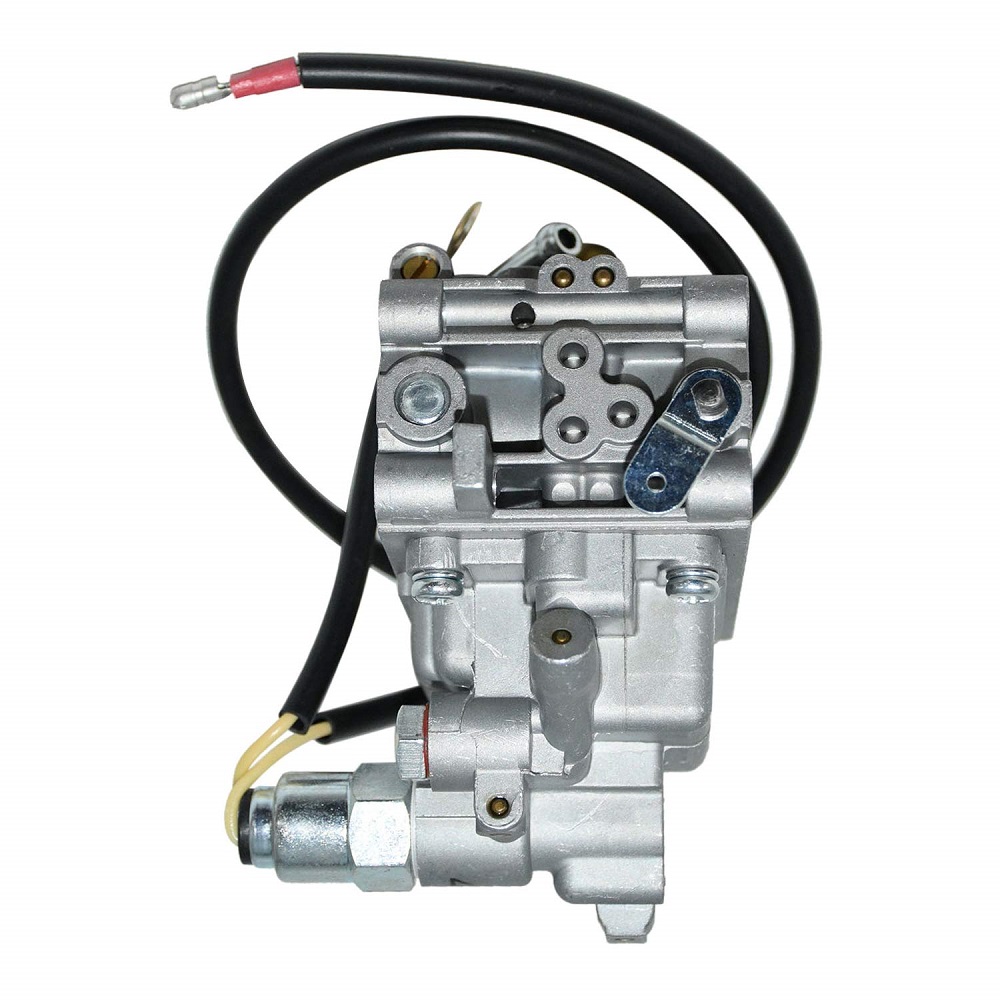

Carburetor Functionality

The carburetor is a critical component of the fuel system. It mixes air and fuel in the correct proportions before sending it to the engine for combustion. A well-functioning carburetor is essential for efficient engine performance. Issues such as clogs or wear can lead to problems like rough idling, stalling, or poor acceleration.

Regular maintenance of the carburetor is essential. Cleaning the carburetor and ensuring proper adjustments can improve fuel efficiency and performance. If the engine seems to be running poorly, inspecting the carburetor should be a top priority for any DIY mechanic.

Fuel Filter

The fuel filter is another important part of the fuel system. Its primary role is to trap dirt, debris, and contaminants before they can reach the engine. A clean fuel filter ensures that the engine receives the proper fuel mixture, which is crucial for optimal performance.

Replacing the fuel filter according to the manufacturer’s recommendations is essential for maintaining fuel system health. Clogged filters can restrict fuel flow, leading to performance issues. By keeping the fuel filter clean, you help ensure that the engine runs smoothly and efficiently.

Ignition System Essentials

Spark Plug

The spark plug is key to the ignition system, creating the spark needed to ignite the air-fuel mixture within the engine’s cylinder. Proper functioning of the spark plug is crucial for starting the engine and maintaining efficient combustion. A worn or faulty spark plug can lead to misfiring, reduced power, and increased emissions.

Regular inspection and replacement of spark plugs are vital. If your engine exhibits signs of difficulty starting or poor acceleration, it may be time to check the spark plug for wear or buildup. Keeping the spark plug in good condition is a straightforward way to enhance engine reliability.

Ignition Coil

The ignition coil converts battery voltage into the high voltage needed to fire the spark plug. Without a functioning ignition coil, your engine will not start or run properly. Ensuring that the ignition coil functions correctly is essential for the ignition system.

Routine testing of the ignition coil can help identify issues before they become serious. If you notice starting difficulties or inconsistent performance, the ignition system, including the ignition coil and spark plug, should be inspected. A properly functioning ignition system enhances the overall efficiency of your rotary small engine parts.

Cooling System Components

Cooling Options

Rotary small engines can utilize either air-cooled or liquid-cooled systems to regulate temperature. Air-cooled engines rely on fans and the ambient airflow to dissipate heat generated during operation. Conversely, liquid-cooled engines use a coolant to take heat away from the engine and circulate it back through the radiator to release heat.

If your rotary engine operates in high-temperature environments, proper cooling is crucial. Air-cooled systems are easier to maintain, while liquid-cooled systems tend to handle prolonged use and heavy loads better. Understanding which cooling system your engine uses can help you select the best maintenance practices.

Maintaining the Cooling System

Regardless of the cooling system, regular maintenance is essential for ensuring effective heat regulation. For air-cooled engines, keeping cooling fins clean and unobstructed is vital. Accumulation of debris can hinder airflow, leading to overheating and potential engine damage.

For liquid-cooled engines, regularly checking coolant levels and inspecting hoses for leaks is important. If the coolant level is low or leaks are present, it can lead to overheating and serious damage to internal engine components. By maintaining the cooling system, you help ensure the longevity and reliability of your rotary small engine parts.

Lubrication System Importance

Oil Pump and Oil Filter

The lubrication system is another critical aspect of rotary small engine parts. The oil pump circulates oil throughout the engine, reducing friction between moving parts and preventing wear. Without proper lubrication, the engine’s components can overheat and fail.

The oil filter is essential for removing contaminants from the oil, ensuring that only clean oil circulates. Regular oil changes and filter replacements are vital for maintaining the health of the lubrication system. Neglecting to service these components can result in reduced engine performance and a higher risk of breakdowns.

Oil Types and Quality

Understanding the type of oil recommended for your rotary small engine is also essential. Different oils have varying viscosities and properties, influencing engine performance and longevity. Checking the owner’s manual can guide you in selecting the right oil type, whether it is synthetic, conventional, or a blend.

Using high-quality oil suitable for your specific engine type can enhance performance and overall efficiency. A clean and properly lubricated engine will operate more smoothly, reducing wear and extending its lifespan. Keeping oil in good condition is a straightforward yet critical task for DIY engine maintenance.

Maximizing Performance and Longevity

In conclusion, understanding rotary small engine parts and their functions is crucial for anyone looking to boost efficiency and longevity. Key components, such as the engine block, carburetor, ignition system, and lubrication components, all play a significant role in maintaining engine performance. Regular maintenance and inspections can prevent common issues and extend the life of your engine.

By keeping a close eye on the health of each component and performing routine upkeep, you can improve your rotary small engine’s efficiency and reliability. Whether you use your engine for personal projects or professional tasks, proper care is essential. Armed with knowledge and maintenance tips, you can enjoy greater confidence in your machinery while ensuring optimal performance.

Applying these insights not only benefits your rotary small engine parts but also delivers peace of mind. The more informed you are about your engine, the better prepared you will be to address any issues. Ultimately, focusing on the key components of rotary engines allows you to get the most out of your equipment, ensuring that it serves you well for years to come.

Leave a Reply