Vanguard engines are known for their durability and high performance in various applications, ranging from lawn care equipment to industrial machinery. When it comes to the performance of these engines, the quality and functionality of their parts make a significant difference. Understanding Vanguard engine parts and their roles can help users maintain and enhance the performance and reliability of their engines. In this article, we will explore key Vanguard engine parts components, their functions, maintenance tips, and how they contribute to overall engine performance.

Overview of Vanguard Engines

History and Application

Vanguard engines, manufactured by Briggs & Stratton, have a long history of powering outdoor and industrial equipment. These engines are designed to provide reliable performance for various applications, including mowers, generators, and pressure washers. Their robust design allows them to operate efficiently in demanding environments, making them a popular choice among professionals and DIY enthusiasts.

The versatility of Vanguard engine parts makes them suitable for numerous tasks. Whether used in residential lawn care or commercial landscaping, these engines are built to last. Understanding the components that make up Vanguard engines is essential for anyone looking to optimize their performance and extend their lifespan.

Engine Design and Functionality

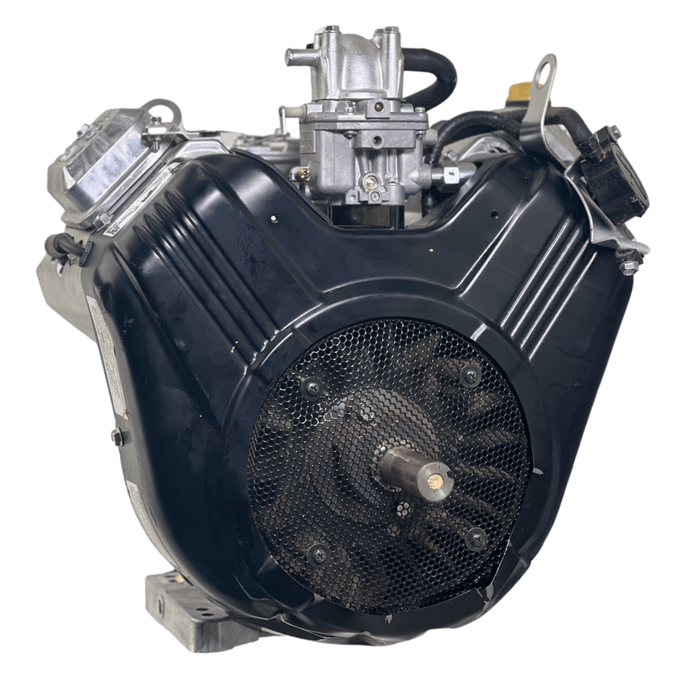

Vanguard engines are typically offered in both air-cooled and liquid-cooled designs. The choice between these systems often depends on the specific application and intended use. Air-cooled engines are lightweight and easy to maintain, making them ideal for smaller equipment. In contrast, liquid-cooled engines offer superior thermal efficiency and are better suited for larger, more intensive applications.

Both designs prioritize efficiency and power. The engineering behind these engines includes features that minimize fuel consumption while maximizing output. This focus on performance ensures that Vanguard engine parts can handle tough jobs while maintaining reliability over the long term.

Key Engine Components

Engine Block

The engine block is the heart of any engine, including Vanguard engine parts. It houses critical components such as cylinders, pistons, and crankshafts. The design of the engine block determines the engine’s overall size, weight, and performance characteristics. Vanguard engines feature blocks designed for durability, often using cast iron or aluminum alloys to withstand high pressures and temperatures.

A robust engine block can significantly impact the longevity of the engine. Regular inspection of the block for cracks, leaks, or signs of wear is essential for maintaining engine performance. Keeping the block in good condition helps ensure that the engine operates smoothly and reliably.

Pistons and Crankshaft

Pistons play a vital role in converting the energy from fuel combustion into mechanical power. Located within the cylinders, they move up and down in response to pressure from burning fuel. The movement of the pistons drives the crankshaft, which transfers this energy to the rest of the engine components. Vanguard engines typically use forged aluminum pistons, providing strength and light weight for improved performance.

The crankshaft is responsible for turning the linear motion of the pistons into rotational motion. A well-designed crankshaft reduces vibration and enhances overall engine efficiency. Ensuring that both the pistons and crankshaft are in good working order is crucial. Signs of wear, such as unusual noises or excessive vibrations, should be addressed immediately to avoid costly repairs.

Fuel and Air Systems

Carburetor and Fuel Delivery

The carburetor plays a critical role in mixing fuel and air to create the right mixture for combustion. Vanguard engine parts often utilize high-performance carburetors designed for efficiency and responsiveness. Proper tuning of the carburetor can significantly affect engine power and fuel efficiency.

Regular maintenance checks on the carburetor ensure smooth operation. This includes cleaning the jets and adjusting the mixture as necessary. If you notice that the engine is running poorly or misfiring, it may be time to inspect and service the carburetor to maintain optimal performance.

Air Filter

The air filter is another essential component of the fuel and air system. It filters out dirt, debris, and other contaminants that could harm the engine. A clean air filter ensures that the engine receives an adequate supply of clean air, which is vital for optimal combustion. Vanguard engines typically use foam or paper filters, each with varying characteristics and maintenance needs.

Regularly checking and replacing the air filter is crucial. A clogged air filter can restrict airflow, leading to decreased engine performance and increased fuel consumption. Keeping the air filter clean and in good condition helps the engine run efficiently and prolongs its lifespan.

Ignition System Components

Spark Plug

The spark plug ignites the air-fuel mixture in the combustion chamber, allowing the engine to run. In Vanguard engines, the quality and type of spark plug significantly influence performance. High-quality spark plugs provide a consistent spark, which leads to smoother engine operation and fuel efficiency.

Regular inspection of the spark plug is key to maintaining engine performance. Checking for signs of wear, such as carbon buildup or corrosion, will help identify when it needs to be replaced. A well-maintained spark plug ensures consistent ignition and contributes to overall engine reliability.

Ignition Coil

The ignition coil supplies the necessary voltage to the spark plugs. It converts the battery’s low voltage into the high voltage needed to create a spark. If the ignition coil fails, the engine may not start or could run poorly. Vanguard engines are designed with durable ignition coils that provide reliable performance over time.

Routine checks of the ignition system can help prevent ignition-related issues. If you experience starting difficulties or notice engine misfires, inspecting the ignition coil along with the spark plugs is advisable. Prompt attention to these components can prevent further complications and keep the engine running smoothly.

Cooling and Lubrication Systems

Cooling System

Keeping the engine cool is essential for performance and longevity. Vanguard engine parts typically use an air-cooled or liquid-cooled system to regulate temperature. Air-cooled systems rely on fans and the natural flow of air to dissipate heat. Liquid-cooled systems use coolant to absorb heat from the engine and dissipate it through a radiator.

Regularly checking the cooling system for leaks or blockages is important. In liquid-cooled engines, monitor the coolant level and quality. For air-cooled engines, ensuring the cooling fins are clean and unobstructed will promote effective cooling. Proper maintenance of the cooling system reduces the risk of overheating and related damage.

Lubrication System

The lubrication system ensures that all moving parts within the engine receive adequate oil to reduce friction and wear. Vanguard engines typically utilize a pressurized oil system, which circulates oil through the engine automatically. High-quality engine oil enhances performance and protects components from damage.

Routine oil changes are essential for maintaining engine health. Over time, engine oil can break down and become contaminated. Following the manufacturer’s recommendations for oil changes and using the proper oil type will help keep the engine clean and functioning properly.

Importance of Routine Maintenance

Regular Inspections

Routine maintenance and inspections are key to keeping Vanguard engines running smoothly. Regular checks on parts like the air filter, spark plugs, and oil levels can help prevent unexpected issues and improve engine performance. Understanding the intervals for servicing various components is crucial for maintaining the longevity of the engine.

Creating a maintenance schedule tailored to the specific engine model can be beneficial. This schedule should include checks for wear and tear, fluid levels, and component functionality. By staying proactive, you can avoid more serious problems and costly repairs.

Keeping Records

Keeping records of maintenance and repairs is vital for the long-term care of your Vanguard engine. Documenting what has been checked and replaced offers insight into the engine’s performance and health. This information can be invaluable when troubleshooting issues or seeking assistance from professionals.

Moreover, having a clear maintenance history can enhance resale value if you decide to sell your equipment. Knowing that an engine has been well-maintained and cared for often provides buyers with confidence in their purchase.

Maximizing Performance and Reliability

In conclusion, understanding Vanguard engine parts and their functions is essential for anyone looking to enhance performance and reliability. From the engine block to the ignition system, each component plays a critical role in ensuring smooth operation. Regular maintenance and adherence to care guidelines can significantly extend the lifespan of your engine and improve performance.

A proactive approach to maintenance, including routine inspections and record keeping, offers peace of mind. As you become more familiar with your Vanguard engine, you will gain confidence in your ability to perform DIY repairs. This knowledge not only saves you money but also enhances your skills as a mechanic.

Investing time in understanding your Vanguard engine will lead to a more satisfying and efficient experience, whether you are mowing the lawn or powering heavy machinery. By providing regular attention and care, you can rely on the exceptional performance and durability that Vanguard engines are known for, ensuring they serve you well for years to come.

Leave a Reply