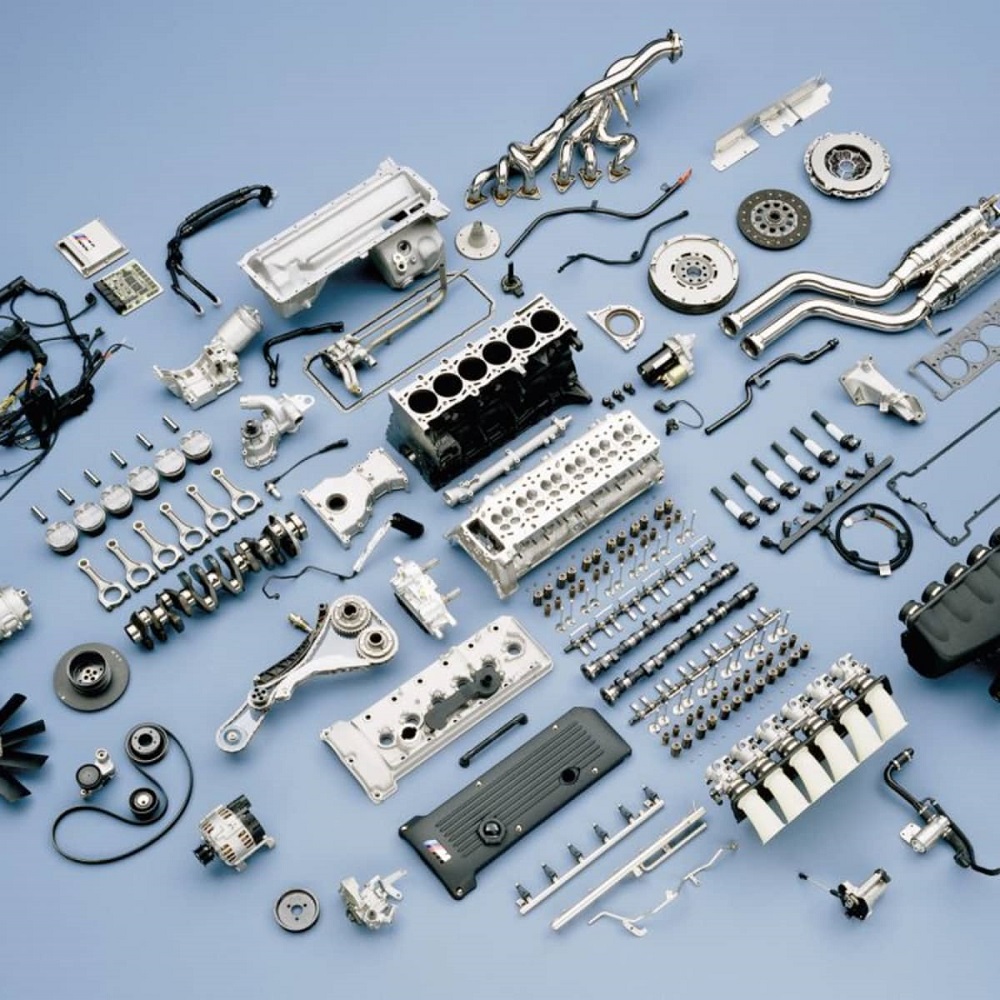

An engine’s performance and longevity depend heavily on its internal components. These parts work together to ensure that combustion occurs efficiently and that power is generated smoothly. Understanding the role of each internal engine part is crucial for anyone who owns a vehicle or is interested in automotive mechanics. This article will explore the key internal engine parts, their functions, and how they contribute to reliable engine operation.

The Basics of Internal Combustion Engines

Understanding Internal Combustion Engines

Internal combustion engines (ICE) convert fuel into mechanical energy through combustion. In these engines, the fuel-air mixture ignites within a confined space, producing high-pressure gases that push against components to generate power. Various parts work together fluidly to ensure the engine functions correctly.

The engine block serves as the core structure housing several essential components. It houses the cylinders, where combustion occurs, and provides a mounting point for other vital parts. Motorists should understand the basics of the combustion process to appreciate the importance of the internal parts.

Different Types of Internal Combustion Engines

There are mainly two types of internal combustion engines: gasoline and diesel engines. Gasoline engines typically use spark plugs to ignite the air-fuel mixture. In contrast, diesel engines rely on compression to ignite the fuel. Although the core concept is the same, the internal components can differ significantly.

For instance, diesel engines often utilize stronger materials to withstand higher levels of pressure. Additionally, while both types of engines utilize pistons and crankshafts, diesel engines usually have larger and more robust components. Understanding these differences helps in recognizing how individual parts contribute to engine performance.

Pistons: The Heart of the Engine

The Role of Pistons

Pistons are key components that reside within the cylinders of an internal combustion engine. They are cylindrical pieces that move up and down in response to combustion gases. When the fuel-air mixture ignites, the resulting pressure forces the piston down, creating the power stroke.

Pistons also play a crucial role in compressing the fuel-air mixture prior to ignition. This compression increases efficiency and power output. Properly functioning pistons are essential for maintaining engine performance, as their ability to withstand intense pressure and withstand wear and tear is vital.

Materials and Design Considerations

Most pistons are made of aluminum or a high-strength aluminum alloy. These materials provide the necessary strength while keeping the weight low. The design of the pistons can also impact performance. Some performance pistons feature special coatings to reduce friction and enhance durability.

When upgrading at the pistons level, it is critical to ensure they are compatible with the engine’s specifications. Installing the correct pistons can result in improved efficiency and power. Aftermarket options are often available for performance enthusiasts looking to enhance engine capability.

Crankshafts: Converting Motion

The Function of Crankshafts

The crankshaft is another vital internal engine parts. It converts the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. As the pistons push down, the crankshaft rotates, transferring power to the transmission.

Crankshafts are responsible for balancing the engine. An imbalanced crankshaft can lead to excessive vibrations, reducing engine life. This is particularly important in high-performance engines, where a finely tuned crankshaft contributes to smooth operation.

Construction and Balancing

Crankshafts are typically made from forged steel or cast iron, as these materials can withstand high stresses and impact loads. The design incorporates counterweights to help balance the rotating assembly. Proper balancing involves precise engineering, as even minor imbalances can cause vibrations that affect engine performance.

When upgrading the crankshaft, careful consideration must be given to the engine’s intended use. High-performance crankshafts are often available with increased strength and reduced weight. This combination can lead to improved throttle response and overall engine efficiency.

Connecting Rods: Bridging the Gap

The Importance of Connecting Rods

Connecting rods play a crucial role in linking the pistons to the crankshaft. They transmit the force generated by combustion from the piston to the crankshaft, ensuring that motion is effectively transferred. This function makes them vital for the engine’s overall operation.

Connecting rods must withstand significant stress as they transfer forces back and forth with each engine cycle. The durability and strength of connecting rods are essential for reliable engine function, especially in high-performance applications where forces are amplified.

Materials and Upgrading Options

Most connecting rods are constructed from forged steel or aluminum, which provides a good balance of strength and weight. Performance engines often utilize lightweight materials to enhance responsiveness. When upgrading connecting rods, it is crucial to ensure compatibility with both the pistons and the crankshaft.

Performance connecting rods may feature advanced designs that contribute to overall engine efficiency. These upgrades can stabilize the engine during high-rpm operation, improving power delivery and performance. Investing in high-quality connecting rods can lead to a significant improvement in engine reliability and performance.

Cylinder Heads: Controlling Airflow and Combustion

The Function of Cylinder Heads

Cylinder heads are critical components that cover the top of the engine cylinders. They house essential components such as valves and spark plugs. The cylinder head plays a major role in controlling the airflow into the combustion chamber, which is necessary for proper combustion.

Cylinder heads determine how efficiently the engine breathes. An upgraded cylinder head can improve airflow, resulting in better engine performance, especially at high RPMs. Proper ventilation allows the engine to extract maximum power from the combustion process.

Choosing the Right Cylinder Head

When selecting a cylinder head, it is essential to consider its design and materials. High-performance cylinder heads are often made of aluminum due to their lightweight and thermal conductivity. These heads can also feature larger valves to improve airflow and increase engine efficiency.

It’s important to pair the right cylinder head with compatible valves, camshafts, and intake systems. The holistic approach to upgrading these components leads to optimized performance. Many aftermarket options are available for various engine types, providing opportunities for enhanced power and efficiency.

Valves and Timing Components

The Role of Valves

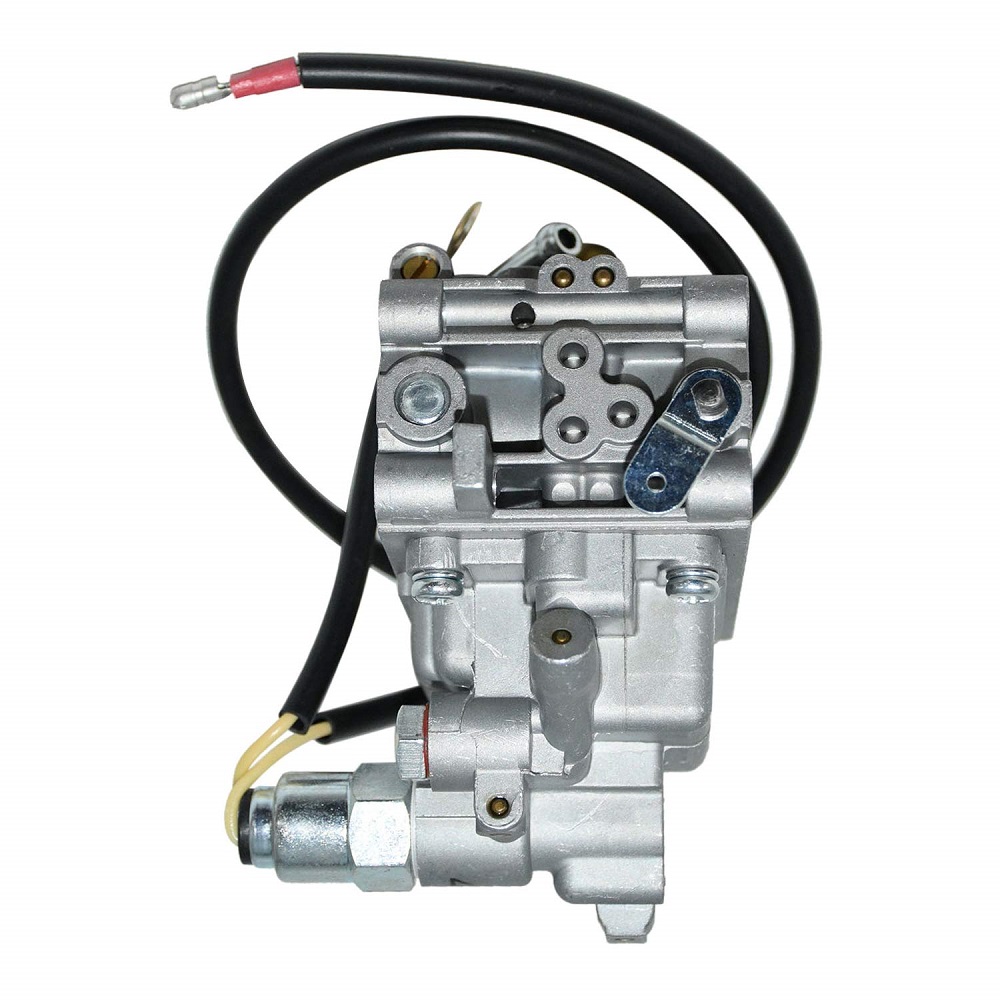

Valves control the intake of air and fuel and the expulsion of exhaust gases from the cylinders. Generally, there are two types of valves: intake and exhaust. Intake valves allow the air-fuel mixture to enter the combustion chamber, while exhaust valves let out burnt gases after combustion.

Maintaining proper valve function is crucial for optimal engine performance. Worn or damaged valves can result in poor combustion, loss of power, and increased emissions. Regular inspections and replacements can help maintain engine efficiency.

Timing Components for Precision

Timing components, including the timing belt or chain, synchronize the opening and closing of the valves with the pistons’ movements. A well-timed engine ensures that the combustion process occurs smoothly and efficiently.

Using high-quality timing belts and chains can prevent catastrophic engine damage. Failure of these components can lead to severe engine problems, including bent valves and damaged pistons. Upgrading to durable, performance-oriented timing components can improve the overall reliability of the engine and maximize performance.

Maintaining and Upgrading Internal Engine Components

Routine Maintenance Practices

Regular maintenance is essential for ensuring that all internal engine parts function reliably. Routine oil changes, frequent inspections, and timely replacements of worn components can extend the engine’s life. Regularly checking the quality of engine oil helps maintain optimal lubrication and reduces wear on internal components.

Engine performance can also be affected by the quality of the fuel used. Using high-quality, suitable fuel for your engine type can improve combustion efficiency. Additionally, addressing potential issues like vacuum leaks and ensuring proper ignition timing are critical for maintaining reliable operation.

Considerations for Upgrades

When planning upgrades to internal engine parts components, it’s essential to take a comprehensive approach. Each part must be compatible with others for improved performance. For example, an upgraded intake system should complement the chosen exhaust system and be suited for the selected camshaft.

Seeking advice from automotive professionals or reputable performance shops can provide valuable guidance on which upgrades make sense for your specific engine type and application. Thorough research ensures that your investment enhances the engine’s performance without compromising its reliability.

Ensuring Reliable Engine Function

In conclusion, internal engine parts are the foundation of reliable engine function. From pistons and crankshafts to valves and cylinder heads, each component plays a critical role in the overall performance and efficiency of the engine. By understanding the functions of these vital parts, vehicle owners can make informed decisions about upgrades and maintenance.

Regular maintenance should not be overlooked, as it is key to maximizing performance and lifespan. When upgrading internal components, choosing high-quality parts and ensuring compatibility is essential. By taking a thoughtful approach to engine care and improvement, you can enjoy a reliable and powerful vehicle that meets your performance needs and expectations.

Ultimately, investing in both the understanding of internal engine components and their proper upkeep can significantly enhance the driving experience. A well-functioning engine not only provides dependable transportation but also contributes to the joy of driving. By prioritizing reliable engine function, you can ensure that your vehicle performs at its best for years to come.

Leave a Reply