Cummins engines are well-known for their durability and performance. They are used in a variety of applications, including trucks, buses, and industrial machinery. When it comes to maintaining and repairing these engines, having a clear understanding of their components is essential. A Cummins engine parts diagram provides valuable insights into the functionality of various parts and their relationships. This article explores the importance of engine diagrams for DIY repairs, the key components typically found in Cummins engines, and tips for using these diagrams effectively.

The Importance of Engine Diagrams

Understanding the Layout

A Cummins engine parts diagram serves as a visual reference that outlines the organization and arrangement of various components. For DIY enthusiasts, this is particularly beneficial. Understanding the layout of parts helps in diagnosing issues and identifying which components may need attention or replacement.

For instance, if a Cummins engine is experiencing performance problems, a repair technician can use an engine diagram to trace fuel lines or wiring connections. This visual guide can highlight potential problem areas, making it easier to pinpoint exactly where the issue lies. With a clear diagram, the complexities of an engine become more manageable.

Streamlining the Repair Process

Apart from diagnosis, engine diagrams streamline the repair process. Knowing the exact location and function of each part allows for more efficient repairs. Technicians can plan their approach, gather necessary tools, and execute repairs in a logical sequence. This organization reduces the likelihood of errors and can expedite the time it takes to complete a repair.

Saving time and minimizing mistakes ensures that repairs are both efficient and effective. With a grateful attitude towards the benefits of an organized approach, DIY enthusiasts can tackle engine repairs with greater confidence.

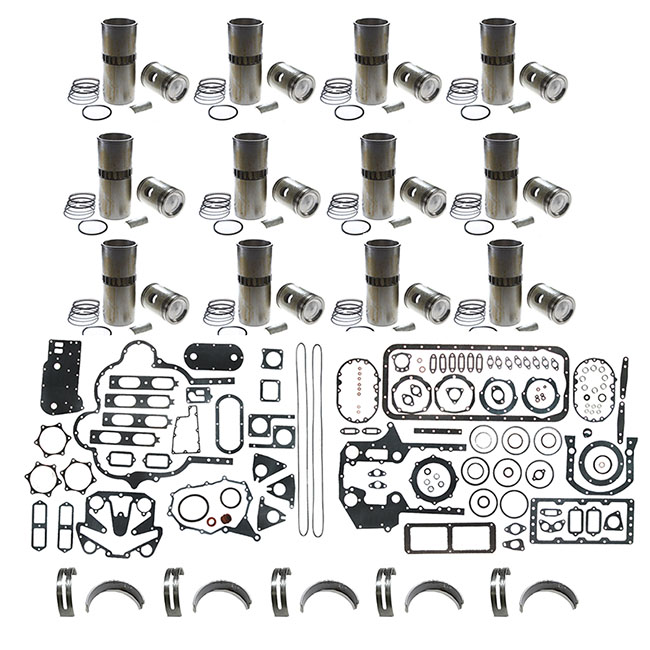

Key Components of a Cummins Engine

Engine Block and Cylinder Head

The engine block is the core of any engine, including Cummins engines. It houses the cylinder bores, crankshaft, and pistons, making it a crucial component for proper engine function. The cylinder head, mounted to the top of the engine block, contains the intake and exhaust valves and provides pathways for air and fuel to enter while allowing exhaust gases to escape.

In a Cummins engine, the interaction between the engine block and cylinder head is essential for combustion. A clear understanding of these two components allows for assessments of issues like blown gaskets or warped heads, which can lead to reduced engine performance. Often indicated in diagrams, these components are fundamental in understanding engine operation.

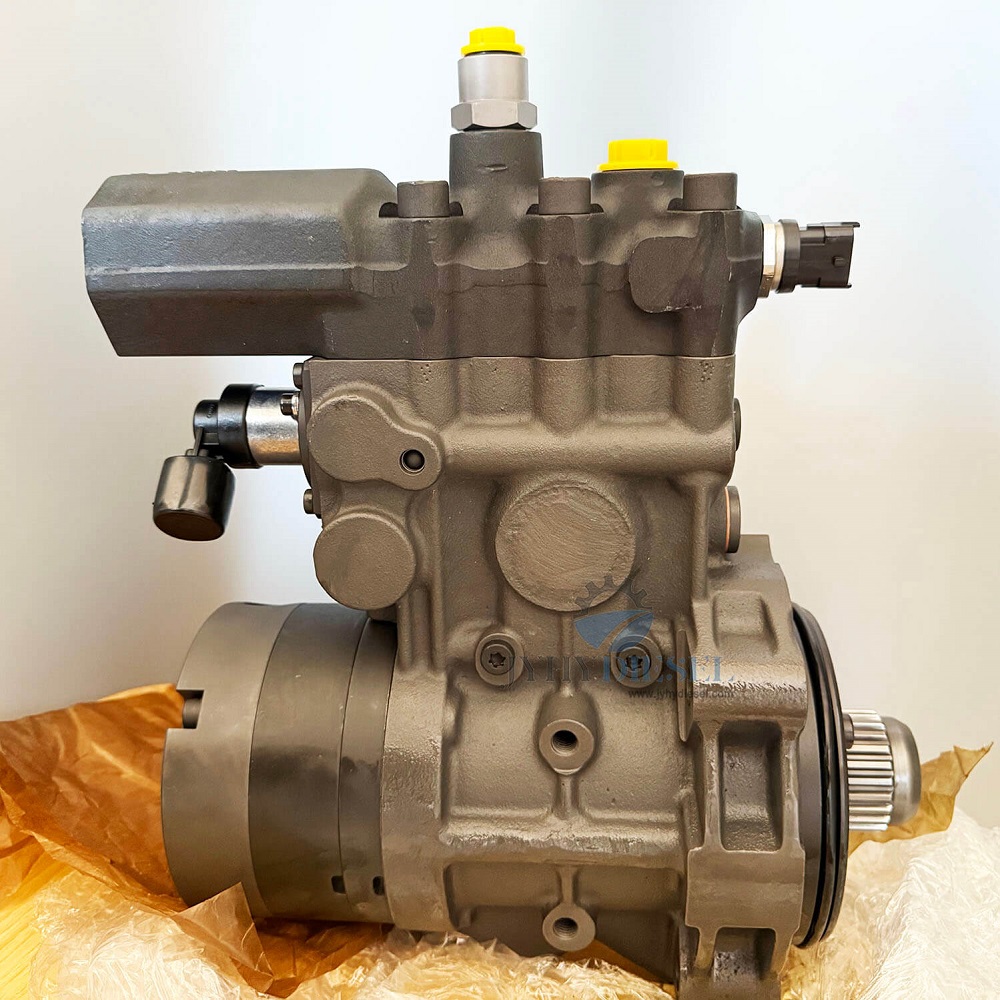

Fuel System Components

The fuel system in a Cummins engine includes essential parts such as the fuel pump, fuel injectors, and fuel filters. The fuel pump delivers fuel from the tank to the injection system, ensuring that the engine receives an adequate supply of fuel. Fuel injectors then deliver the fuel into the combustion chamber at precise timings and amounts.

Over time, these components can wear down or become clogged. Understanding how they fit into the overall fuel system is crucial for diagnosing fuel-related issues. A comprehensive parts diagram will illustrate how these components are connected, allowing DIY enthusiasts to identify potential problems and perform necessary repairs or replacements effectively.

Common Issues Addressed Through Diagrams

Engine Overheating

One common issue with diesel engines, such as those manufactured by Cummins, is overheating. This can be caused by a variety of factors, including faulty thermostats, malfunctioning water pumps, or blocked cooling passages. A detailed Cummins engine parts diagram allows users to locate the cooling system components quickly.

By pinpointing parts like the radiator, coolant hoses, and water pump, users can troubleshoot overheating issues more effectively. For example, they can check if the water pump is functioning correctly or whether any hoses are damaged or blocked. Understanding the layout through diagrams can help diagnose the root cause of overheating issues.

Misfiring or Poor Performance

Misfiring or a general lack of engine performance can be frustrating issues for diesel engine owners. The causes may range from fuel system problems to electrical faults. Using an engine part diagram helps mechanics trace fuel lines, injector assemblies, and ignition components.

With a diagram, mechanics can easily verify whether electrical connections are secure, fuel injectors are clean, or fuel lines have leaks. This precision is essential in addressing performance issues, ensuring the engine runs smoothly and efficiently. The ability to visualize connections can significantly reduce the troubleshooting time required.

Utilizing Diagrams for Repairs

Step-by-Step Repair Processes

When conducting repairs, having a step-by-step approach is vital. With a Cummins engine parts diagram, DIY mechanics can create a clear plan for the repair process. They can outline the sequence of tasks, such as removing components, replacing parts, and reassembling the engine.

For instance, when replacing the fuel injectors, the diagram will indicate the required steps, such as disconnecting the fuel lines and unbolting the injectors. Following this organized approach prevents losing track of components and minimizes the risk of error. Documenting each step helps during reassembly, ensuring everything is returned to its rightful place.

Gathering Necessary Tools

Understanding the components through a parts diagram also assists in gathering the necessary tools before starting repairs. When mechanics can visualize the arrangement of parts, they can determine which sockets, wrenches, and specialized tools are needed to complete the job. This preparation reduces time spent searching for tools during repairs.

Preparing a checklist of required tools—and sharing it with team members—will facilitate a smoother repair process. Being adequately equipped is key to ensuring that repairs progress without unnecessary delays.

Safety Considerations During Repairs

Using Proper Safety Gear

Safety should always be a priority when conducting engine repairs. When working on diesel engines, mechanics should wear appropriate personal protective equipment (PPE). Safety glasses, gloves, and protective clothing help ensure that workers remain safe from debris, hot fluids, and other potential hazards.

Engine components can be heavy, and using appropriate lifting equipment is essential for safely removing parts such as the engine block or cylinder head. Before starting any repair, reviewing safety guidelines is crucial to prevent accidents or injuries during the process.

Working in a Well-Ventilated Area

Because diesel engines emit exhaust fumes, performing repairs in a well-ventilated area is vital. Lack of ventilation can lead to the accumulation of harmful gases, which pose health risks. Ensuring adequate airflow minimizes exposure to these fumes, allowing mechanics to work safely.

If working indoors, opening windows and using fans can create cross-ventilation. Similarly, taking regular breaks outdoors can help mechanics avoid prolonged exposure to exhaust gases. Prioritizing safety enhances the repair experience and contributes to successful outcomes.

Where to Find Quality Engine Diagrams

Official Manuals and Resources

The most reliable source for Cummins engine diagrams is the official service manual. These manuals contain detailed diagrams, specifications, and repair instructions for specific engine models. Many manufacturers, including Cummins, provide online access to these resources, ensuring that DIY enthusiasts have the information they need.

Supplementing official manuals with additional resources can be beneficial. Online forums and websites dedicated to diesel engines often feature discussions, tips, and shared diagrams. Joining these communities can enhance knowledge and provide support from fellow enthusiasts.

Dealer Assistance

If individuals find it challenging to locate relevant diagrams, reaching out to authorized Cummins dealers can provide additional guidance. Dealers have access to technical resources and can assist in finding the right diagrams based on engine models. Engaging with professionals ensures access to accurate and up-to-date information.

Building relationships with local distributors can also yield additional resources and support for repairs. Many dealers are willing to offer advice on common repairs, which could prove invaluable for DIY mechanics working on their engines.

Empowering DIY Mechanics Through Knowledge

In conclusion, understanding the Cummins engine parts diagram is essential for anyone wanting to perform DIY repairs. The insights gained from these diagrams provide a foundation for effective troubleshooting and repairs. Knowing the relationships between components improves problem diagnostics and repair efficiency.

By understanding the critical components of a Cummins engine and utilizing diagrams effectively, DIY enthusiasts can confidently tackle repairs. From identifying issues to gathering necessary tools, these diagrams streamline the entire process. Prioritizing safety measures during repairs further enhances the experience and promotes successful outcomes.

As you explore the world of Cummins engines, the value of engine diagrams cannot be overstated. They empower individuals with the knowledge needed to maintain their engines properly. Investing the time and effort to understand these diagrams ultimately leads to greater confidence in repairing and maintaining Cummins engines. By embracing this knowledge, you embrace the art of effective and rewarding engine repair.

Leave a Reply