The engine block is often referred to as the heart of a vehicle. It houses crucial components essential for engine operation and power generation. Understanding the parts that constitute the engine block is vital for anyone interested in performing DIY repairs and maintenance. Whether you’re an experienced mechanic or a beginner, having a clear understanding of these components can simplify the repair process and save you significant time and money. This article aims to provide a comprehensive overview of engine block parts, their functions, and tips for identification.

Overview of the Engine Block

What is an Engine Block?

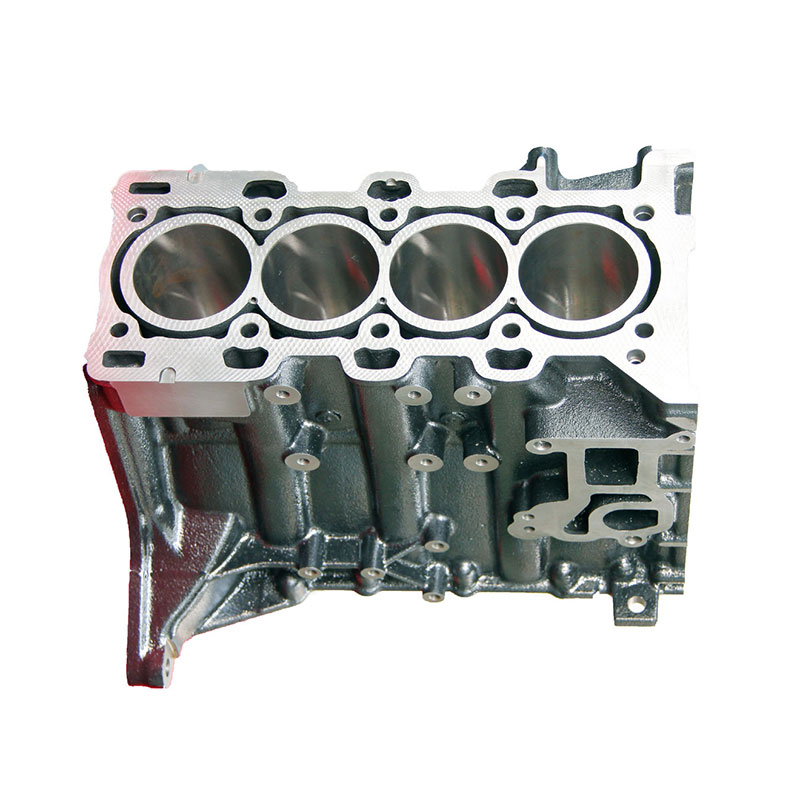

The engine block is a major component of an internal combustion engine. It serves as the core structure for various engine parts, including cylinders, pistons, crankshafts, and camshafts. Most engine blocks are made of cast iron or aluminum due to their strength, heat resistance, and overall durability. The choice of material can affect the weight of the engine and performance characteristics.

Engine blocks come in different configurations, such as inline or V-shapes. Inline engines have all cylinders arranged in a straight line, while V-shaped engines have cylinders arranged in two banks at an angle. Each configuration has its benefits and drawbacks that affect the engine’s performance, size, and efficiency. Understanding the specifics of your engine block configuration is essential for any maintenance or repair work.

Importance of the Engine Block in Vehicle Performance

The engine block plays a pivotal role in vehicle performance. It houses the cylinders where combustion occurs, converts fuel into mechanical energy, and supports various moving components. The strength and integrity of the engine block directly impact the engine’s efficiency and longevity. A well-maintained engine block can withstand extreme temperatures and pressures, which are common during engine operation.

Any damage to the engine block can lead to severe performance issues or engine failure. Issues such as cracks, warping, or corrosion can occur over time, especially in older engines or those exposed to harsh conditions. Regular inspections and a basic understanding of the engine block’s components can help identify potential problems before they escalate into costly repairs.

Key Components of the Engine Block

Cylinders and Cylinder Liners

The cylinders are cylindrical spaces within the engine block where pistons move up and down. Each cylinder is essential for the combustion process, as this is where the air-fuel mixture ignites to generate power. The number of cylinders can vary; common configurations include four-cylinder, six-cylinder, and eight-cylinder engines.

Cylinder liners, or cylinder sleeves, can be used to protect the cylinder’s interior from wear and tear. These liners can be replaced if they become damaged or worn out, allowing for a more straightforward repair process without needing to replace the entire engine block. Proper maintenance of the cylinders and liners can ensure efficient combustion and overall engine performance.

Pistons

Pistons are critical components that fit snugly within the cylinders. They are connected to the crankshaft via connecting rods. As the air-fuel mixture ignites in the cylinder, the resulting pressure forces the piston downward. This linear motion is then converted into rotational motion by the crankshaft, powering the vehicle.

The design of the piston plays a significant role in engine efficiency. Pistons are typically made from lightweight aluminum or specific alloy materials that can handle high temperatures and pressures. Each piston must create a strong seal within the cylinder to prevent blow-by, which can lead to reduced power and increased emissions. Regularly inspecting pistons for wear or damage is essential for maintaining engine health.

Crankshaft: Converting Linear Motion to Rotational Motion

Understanding the Crankshaft

The crankshaft is a vital component found within the engine block. It converts the linear motion created by the pistons into rotational motion. This rotational motion ultimately powers the vehicle by turning the wheels. The crankshaft is usually made from forged steel or high-strength cast iron, offering durability and resistance to bending under pressure.

In a V-engine configuration, the crankshaft may have a unique design to accommodate different cylinder layouts. Proper alignment and balance of the crankshaft are crucial for smooth engine operation. An unbalanced crankshaft can lead to excessive vibrations, which can cause damage to other engine components over time.

Maintenance of the Crankshaft

Regular maintenance and inspection of the crankshaft are necessary for optimal performance. Issues such as wear on the main and rod bearings can impact the crankshaft’s ability to function effectively. Keeping the engine properly lubricated helps minimize friction and wear on the crankshaft, extending its lifespan.

If repairs become necessary, such as crankshaft grinding or bearing replacement, specific tools and knowledge of the process are essential. While DIY fixes are possible, consulting a professional mechanic is advisable for complex issues or when precision is critical.

Cylinder Head: Governing Air and Fuel Flow

The Role of the Cylinder Head

You mount the cylinder head on top of the engine block, and it consists of various components that control the air and fuel entering the combustion chambers. It houses the intake and exhaust valves, spark plugs, and, in some designs, fuel injectors. The cylinder head ensures that the correct mixture of air and fuel enters the cylinders for combustion while allowing exhaust gases to exit efficiently.

A well-designed cylinder head enhances engine performance by optimizing airflow. The configuration of the intake and exhaust ports directly affects how efficiently air enters and exits the engine. Engine performance can significantly improve through advancements in cylinder head design, such as improved valve configurations and port shapes.

Signs of Cylinder Head Issues

Problems with the cylinder head can lead to severe engine issues, such as overheating, loss of power, or lower fuel efficiency. Common signs of cylinder head failure may include coolant leaks, persistent overheating, or visible damage such as cracks or warping. Regular inspections of the cylinder head can help identify these issues before they lead to more significant problems.

If cylinder head repairs are necessary, understanding the specific parts involved — such as valves, springs, and bolts — is essential for making informed decisions about repairs and replacements. Proper torque specifications during installation and maintenance will ensure that the cylinder head seals correctly and functions efficiently.

Fuel and Ignition Systems: The Heart of Combustion

Fuel Delivery System

The fuel delivery system is a vital part of the engine block framework. In most modern engines, this system includes fuel injectors that deliver fuel directly to the combustion chambers. Proper fuel delivery ensures that the right mixture of air and fuel ignites efficiently, producing the necessary power.

Fuel pressure regulators and filters are also critical components of the fuel system. The pressure regulator delivers fuel to the injectors at the correct pressure, while fuel filters prevent contaminants from entering the engine. Regular checks and replacements of these components can prevent clogged injectors or fuel lines, which can lead to poor performance.

Ignition System

The ignition system sparks the air-fuel mixture in the combustion chamber, starting the combustion process. Key components include spark plugs, ignition coils, and distributor systems. Spark plugs ignite the fuel-air mixture, while ignition coils provide the necessary voltage to produce a spark.

Regular maintenance of the ignition system is crucial for optimal engine performance. Worn or fouled spark plugs can lead to misfires, reduced power, and increased emissions. Inspecting and replacing ignition components as needed can help ensure reliable starts and efficient combustion.

Lubrication and Cooling Systems: Essential for Longevity

The Lubrication System

The lubrication system is integral to the engine block’s longevity and performance. By ensuring that all moving parts receive adequate lubrication, this system minimizes friction, reduces wear, and prevents overheating. Oil is circulated throughout the engine via an oil pump, reaching vital components such as the crankshaft, camshaft, and pistons.

Using the correct engine oil is essential for maintaining optimal performance. Low-viscosity oils can improve fuel economy but may not provide sufficient protection at high temperatures. Conversely, higher viscosity oils can offer better protection but may result in reduced fuel efficiency. Always consult the manufacturer’s specifications when selecting oil.

Cooling System Components

The engine cooling system works alongside the lubrication system to maintain optimal operational temperatures. Components such as the water pump, radiator, and thermostats regulate the engine’s temperature, preventing overheating during operation. The water pump circulates coolant throughout the engine block, absorbing heat and transferring it to the radiator.

Proper maintenance of the cooling system is essential. Checking coolant levels, inspecting hoses, and ensuring there are no leaks can help prevent overheating. Maintaining the engine’s temperature not only protects the engine block but also enhances overall performance.

Identifying Parts for DIY Repairs

Using Engine Block Diagrams

To effectively identify engine block parts, utilizing engine diagrams is invaluable. These diagrams provide clear illustrations of components, their locations, and how they interact with one another. Many repair manuals and online resources offer comprehensive diagrams for specific engine makes and models, making it easier for DIY enthusiasts.

Familiarizing yourself with these diagrams can enhance your ability to pinpoint issues and understand the assembly and disassembly process. Whether you are replacing components or conducting routine maintenance, having visual references simplifies repairs and minimizes errors.

Tips for Successful DIY Repairs

When undertaking DIY repairs, always follow best practices to ensure a successful outcome. Begin by gathering all necessary tools and components before starting the project. This preparation can help you avoid interruptions during repairs.

Be sure to take your time when disassembling engine components. Keeping track of parts, nuts, and bolts is crucial; it’s helpful to organize them in labeled containers as you work. Referencing your engine block diagram frequently can guide you during the repair process.

If you encounter difficulties or complex issues during repairs, do not hesitate to consult professional resources or mechanics. Their expertise can guide you in resolving specific concerns and ensuring that your engine operates optimally.

In conclusion, understanding the various parts of the engine block parts is essential for anyone interested in performing DIY repairs and maintenance. From the cylinders and crankshaft to the fuel delivery and ignition systems, each component plays a crucial role in engine performance. Utilizing engine diagrams will help facilitate effective identification and understanding of these parts, making your repair efforts more successful. By following proper maintenance practices, you can ensure the longevity and efficiency of your engine, enhancing your overall driving experience.

Leave a Reply