Ford industrial engine parts are known for their reliability, performance, and versatility across various applications, from construction to agriculture. However, like any mechanical system, these engines can wear down over time, requiring parts replacement and maintenance to keep them running efficiently. Sourcing the right parts is crucial for the longevity and performance of your Ford industrial engine parts. This article provides tips for sourcing and replacing parts, helping you make informed decisions that will benefit your engine’s performance and lifespan.

Understanding Ford Industrial Engines

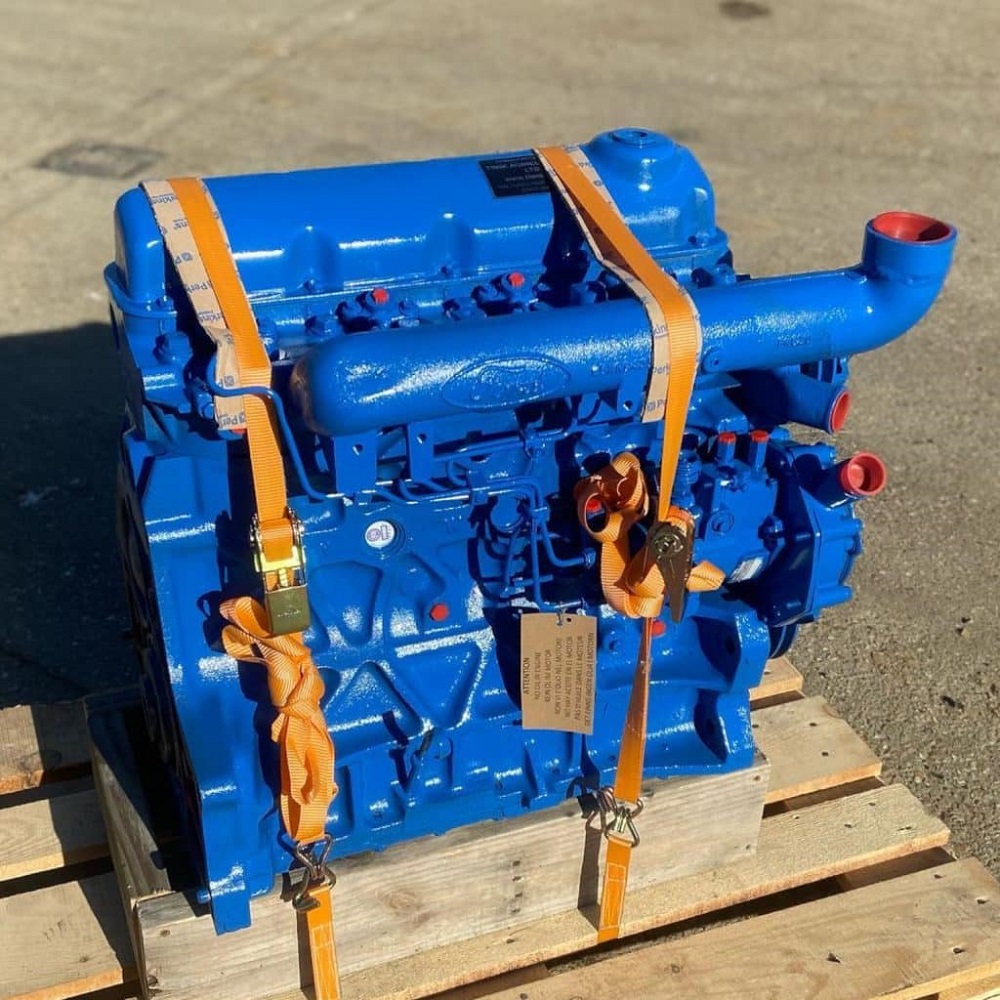

Overview of Ford Industrial Engines

Ford industrial engines are designed for heavy-duty applications and have been utilized in various sectors such as construction, agriculture, and manufacturing. Known for their robustness, these engines often feature advanced technology that enhances fuel efficiency and reduces emissions. Many models are available, each tailored to specific industrial needs.

The engines are equipped with durable components designed for high performance and prolonged service life. This means that not only do these engines deliver power, but they also require careful selection of replacement parts to ensure they operate at peak efficiency. Understanding the specifications and features of your engine model is the first step toward successful maintenance.

Different Engine Models

Ford has produced numerous industrial engine models over the years, each with unique specifications and components. Common models include the Ford 4D and 6D series, recognized for their adaptability and performance in tough working conditions. Each engine type may require specific parts, so knowing which model you are dealing with is critical.

Before sourcing parts, refer to the engine’s documentation or identification tags. This information helps you identify the engine model, serial number, and other details essential for selecting the correct components. Having this knowledge will save you time and prevent the frustration of ordering the wrong parts.

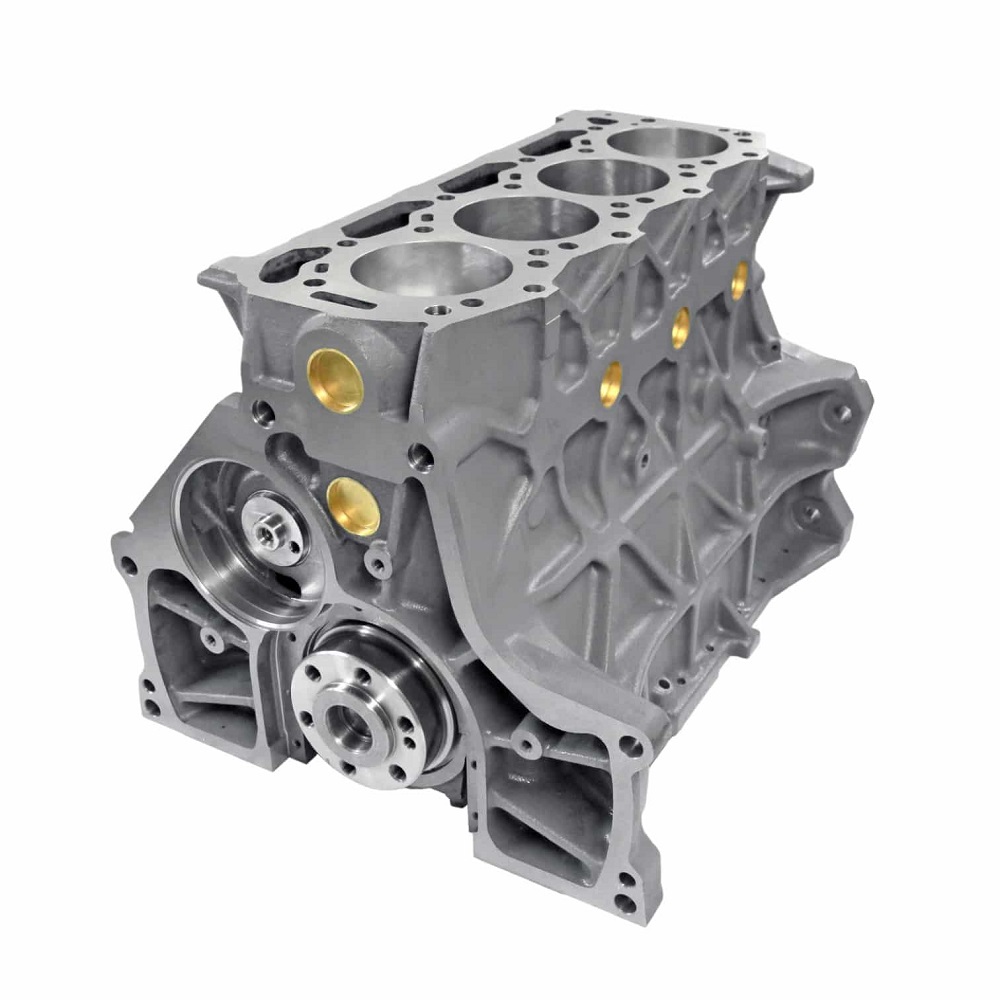

Identifying the Required Parts

Conducting a Thorough Inspection

When considering parts replacement for your Ford industrial engine, a thorough inspection is crucial. Begin by visually assessing the engine’s components, including the air filter, oil filter, spark plugs, hoses, and belts. Look for signs of wear and tear such as cracks, fraying, or corrosion.

Additionally, consider consulting maintenance logs to identify any recurring issues. These records can provide valuable insight into which parts need attention. For example, if certain components are frequently being replaced, that may indicate a persistent issue affecting performance. A comprehensive evaluation will help you create a list of necessary parts for replacement.

Using Manufacturer Guidelines

Manufacturer guidelines often contain valuable information regarding parts specifications and replacement procedures. Ford provides detailed service manuals for their engines, which outline the tools and methods required for each specific model. These manuals can often be found online or purchased, and they offer the most accurate information regarding parts replacement.

Following manufacturer guidelines can ensure that you use OEM (Original Equipment Manufacturer) parts. These parts are designed specifically for Ford industrial engines, ensuring a proper fit and compatibility. Using OEM parts can also protect your engine warranty, which is a significant consideration, especially for newer models.

Sourcing Ford Industrial Engine Parts

Authorized Dealers and Distributors

One of the most reliable ways to source Ford industrial engine parts is through authorized dealers and distributors. These sources are directly linked to Ford and usually have access to the latest parts and components. By purchasing from authorized dealers, you can ensure that you receive genuine parts that meet the original specifications.

Working with authorized dealers also provides the added benefit of professional support. Their staff is generally well-versed in the nuances of Ford industrial engines and can assist in identifying the right parts for your needs. Whether you’re looking for specific components or need advice on a particular issue, these experts can guide you in the right direction.

Online Retailers and Marketplaces

Online retailers and marketplaces are increasingly popular options for sourcing Ford industrial engine parts. Websites such as Amazon, eBay, and specialized automotive platforms offer a wide selection of engine components. When using online retailers, it’s crucial to evaluate seller ratings and read customer reviews to ensure quality.

Additionally, many online retailers provide detailed specifications for each part, making it easier to confirm compatibility with your engine model. However, be cautious with unknown third-party sellers and ensure you’re purchasing from a reputable source. Lower prices may often indicate lower quality or counterfeit products.

Considering Aftermarket Parts

Benefits of Aftermarket Parts

Aftermarket parts provide a viable alternative to OEM components. Many aftermarket manufacturers create parts that can be more affordable while still offering satisfactory quality. These parts undergo rigorous testing and quality control, making them suitable for various applications.

Using aftermarket parts can be particularly advantageous if OEM options are limited or if you are looking to enhance your engine’s performance beyond the standard specifications. Some aftermarket parts may offer improved durability, specific tuning options, or enhancements in efficiency.

Challenges with Aftermarket Parts

However, it is essential to be aware of potential downsides when using aftermarket parts. Compatibility can be an issue, and not all aftermarket parts meet the same quality standards as OEM components. It’s critical to do thorough research on manufacturers to ensure you choose reputable companies known for their reliability and customer service.

Some aftermarket parts may not have the same warranty coverage or support as OEM parts. This situation can be problematic if an issue arises after installation. Therefore, make an informed decision based on your engine’s needs and the reputation of the parts manufacturer.

Ensuring Correct Installation of Parts

The Importance of Proper Installation

Once you have sourced the appropriate parts, proper installation is crucial for performance and longevity. Incorrectly installed parts can lead to engine inefficiencies, premature wear, or even complete failure. It’s essential to follow manufacturer guidelines during the installation process.

If you’re not confident in your ability to install the parts yourself, consider hiring a professional mechanic. Trained technicians possess the necessary experience and tools to perform installations correctly. They can also identify any additional issues that may require attention, ensuring that your engine operates optimally.

Utilizing the Right Tools

If you decide to perform the installation yourself, make sure you have the right tools for the job. Using appropriate tools reduces the risk of damaging parts during the replacement process. You may need common tools for engine part replacement, including socket sets, torque wrenches, and specialty tools specific to the component you are replacing.

Read the service manual carefully to identify the necessary tools and techniques for the installation process. By following the correct procedures, you can help guarantee that you do the job right, which enhances the reliability and lifespan of your Ford industrial engine parts.

Maintaining Your Engine and Parts

Regular Maintenance Practices

Regular maintenance is necessary for maximizing the performance and longevity of your Ford industrial engine parts. Ensure you adhere to the manufacturer’s recommended service intervals for oil changes, filter replacements, and inspections. Consistent upkeep can prevent premature wear and extend the life of your engine.

Incorporate routine checks of key components such as belts, hoses, and the fuel system. Any signs of damage or wear should be addressed promptly to prevent further issues. Keeping an eye on these elements can save time and money by avoiding more extensive repairs in the future.

Utilizing Engine Diagnostics

Modern Ford industrial engine parts often come equipped with advanced diagnostic tools that can help identify issues before they escalate. Utilizing these diagnostic systems can provide detailed insights into engine performance, allowing you to pinpoint potential problems early. Regularly checking these diagnostics can help you stay proactive in maintaining the overall health of your engine.

Consider investing in diagnostic software or tools specifically designed for Ford engines. These resources can enhance your ability to monitor performance and troubleshoot issues effectively. By being proactive with maintenance and diagnostics, you can ensure optimal operation of your engine for years to come.

Making Informed Choices for Your Ford Engine

Recap of Key Insights

In conclusion, understanding the components of your Ford industrial engine parts is essential for effective maintenance and part replacement. Knowing how to source the right parts, be they OEM or aftermarket, plays a significant role in performance and reliability. Before making any purchases, identify your engine model, thoroughly inspect components, and follow best practices for sourcing and installation.

Looking Ahead

As technology continues to advance in the automotive industry, so will the methods and practices for maintaining and repairing engines. Staying informed about new developments and innovations will empower you to be proactive in maintaining your Ford industrial engine. Whether you’re a seasoned mechanic or a first-time owner, these tips will help ensure that your engine remains reliable, efficient, and ready for any task at hand.

Investing time in understanding your engine, its parts, and proper maintenance will contribute to the longevity of your Ford industrial vehicle. By making informed choices and adhering to best practices, you can enjoy the full capabilities of your engine and get the most out of it throughout its lifespan.

Leave a Reply