Komatsu is a renowned brand in the heavy machinery industry, known for building durable and reliable equipment. Komatsu machines are often used in construction, mining, and various industrial applications. The engine is the heart of any machinery, and understanding the key parts of Komatsu engines can greatly assist operators and technicians in maintaining and troubleshooting equipment. This article will provide a comprehensive overview of the essential Komatsu engine parts machinery, their functions, and tips for identifying them.

The Importance of Understanding Engine Parts

Why Engine Parts Matter

Understanding the engine parts of your Komatsu machinery is crucial for maintaining optimal performance. Each component of the engine plays a specific role in ensuring the machinery operates efficiently. If one part fails or is not functioning properly, it can lead to decreased performance or even complete engine failure. Regular maintenance and knowledge of engine parts can save time and repair costs in the long run.

Proper identification of engine parts also allows for quicker troubleshooting. When you know how the parts work together, diagnosing issues becomes more manageable. This knowledge can significantly reduce downtime, which is vital in industries where efficiency is key. Therefore, familiarizing yourself with Komatsu engine parts can lead to better handling and maintenance of the machinery.

Overview of Komatsu Engines

Komatsu manufactures a variety of engines for its machinery, including diesel engines and hybrid engines. Diesel engines are most common in heavy equipment and are designed for high performance under demanding conditions. They are built to provide durability and fuel efficiency, making them suitable for rigorous applications. Understanding the fundamental components of these engines will help ensure they continue to run effectively over time.

The engines produced by Komatsu vary by machinery type and purpose. Different models may have distinct parts, but there are common components found across many of them. Being familiar with these universal parts will be beneficial regardless of the specific Komatsu machine you are working with.

Key Engine Components

Cylinder Block and Head

One of the most important components of a Komatsu engine is the cylinder block. The cylinder block houses the cylinders where combustion takes place. It is a fundamental structure that supports other engine parts, such as the crankshaft and camshaft. The durability of the cylinder block is crucial as it withstands immense pressure and temperature during engine operation.

Similarly, the cylinder head plays a vital role in the engine’s performance. It covers the cylinder block and contains the intake and exhaust valves. The cylinder head is essential for controlling the airflow into and out of the cylinders, impacting engine efficiency and power. Both the cylinder block and head must be regularly inspected for damage and leaks to ensure the engine operates smoothly.

Pistons and Connecting Rods

Pistons are the moving components within the cylinders, playing a significant role in converting fuel energy into mechanical work. As the fuel combusts, it pushes the piston down, creating the power needed to turn the crankshaft. High-quality pistons are vital for maintaining performance and preventing wear.

Connected to the pistons are the connecting rods. These rods link the pistons to the crankshaft, transferring the linear motion of the pistons into rotational motion. Any issues with these connecting rods, such as bending or breaking, can lead to catastrophic engine failure. Regular checks on the pistons and connecting rods can help avoid such problems.

Fuel and Air System Parts

Fuel Injectors and Pump

The fuel injectors and pump are integral to the fuel system of Komatsu engine parts. The pump is responsible for transporting fuel from the tank to the injectors. Once the fuel reaches the injectors, they spray it directly into the combustion chamber precisely and at the right timing. This process ensures that the engine receives the necessary amount of fuel for optimal performance.

Clogged or malfunctioning fuel injectors can lead to poor engine performance, increased emissions, and higher fuel consumption. Regular maintenance of the fuel system, including cleaning and inspecting the injectors and pump, is essential for keeping the engine running smoothly.

Air Filter and Turbocharger

The air filter protects the engine from dirt and debris. It ensures that clean air enters the combustion chamber. A clogged air filter can restrict airflow, leading to decreased engine power and efficiency. Regularly checking and replacing the air filter is vital for optimal engine performance.

Turbochargers are also crucial for enhancing engine performance. They compress incoming air, allowing more air into the combustion chamber and improving power output. Turbocharged engines can produce more horsepower without significantly increasing fuel consumption. Ensuring proper functioning of the turbocharger is key to maintaining peak engine performance.

Cooling and Lubrication Components

Radiator and Coolant

The radiator is part of the engine’s cooling system and plays a crucial role in maintaining optimal engine temperatures. It removes excess heat generated during operation, preventing the engine from overheating. The coolant within the radiator circulates through the engine, absorbing heat and cooling it in the radiator.

Regularly checking the radiator for leaks and maintaining the proper coolant levels is vital. An overheating engine can cause severe damage, increasing repair costs and downtime. Getting your cooling system serviced regularly helps prevent overheating issues and ensures longevity.

Oil Pump and Oil Filter

The oil pump circulates oil throughout the engine, lubricating moving parts to reduce friction. Proper lubrication is essential for preventing wear and ensuring smooth operation. The oil filter cleans the oil, removing contaminants and debris before it circulates back into the engine.

It is crucial to maintain both the oil pump and filter to ensure an engine runs efficiently. Regular oil changes and filter replacements are necessary to keep the oil clean and reduce the risk of engine wear. Checking the oil level regularly can help catch potential issues before they escalate.

Electrical System Components

Alternator and Battery

The electrical system in a Komatsu engine is essential for starting the engine and powering various components. The alternator generates electricity while the engine runs, charging the battery and powering electrical systems such as lights and gauges.

A failing alternator can lead to battery drain, making it impossible to start the engine. Regular checks of the electrical system, including the alternator and battery, are vital. If you notice dimming lights or difficulty starting the engine, these components may need inspection.

Starter Motor

The starter motor is responsible for initiating the engine’s operation. When you turn the ignition key, the starter motor engages, turning the engine over and allowing it to start. A malfunctioning starter can cause starting issues, leading to frustration and downtime.

Testing the starter motor’s functionality is crucial. If there is a clicking sound when you turn the key or if the engine does not start, it may point to a starter issue. Regular maintenance checks on the electrical components can help prevent unexpected problems.

Maintenance Tips for Engine Parts

Regular Inspections

Conducting regular inspections of the engine’s key parts is essential for maintaining functionality. This includes checking for leaks, wear, and any signs of damage. Look for corroded connectors, cracks in components, and check fluid levels carefully. Addressing issues early can prevent more extensive and costly repairs later.

Utilizing a comprehensive maintenance schedule can help ensure that no part is overlooked. Keeping track of service intervals can assist in developing a routine that protects the engine’s longevity. Consistent care is vital for preventing breakdowns and enhancing machinery performance.

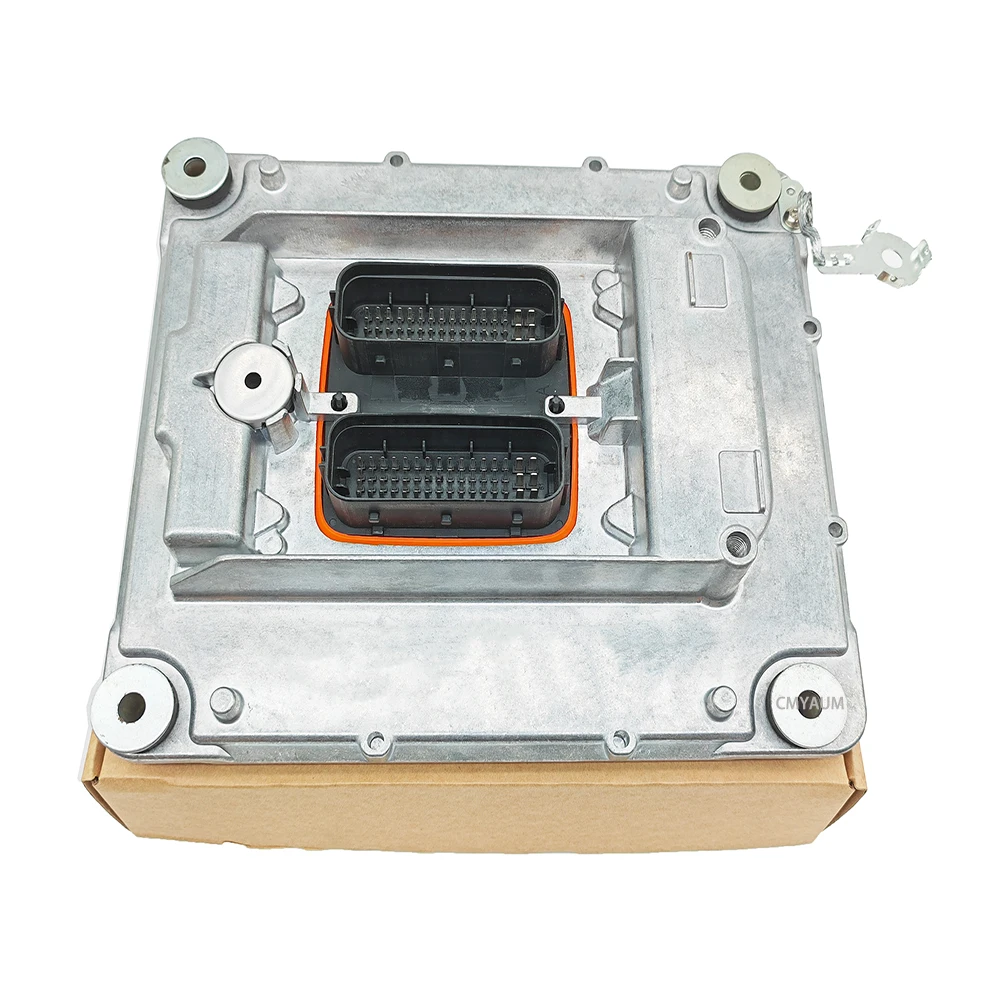

Utilizing Quality Replacement Parts

When replacing any engine parts, it is important to use quality components. Sourcing genuine Komatsu engine parts ensures compatibility and reliability. Using substandard or generic parts can lead to poor performance and potential failure. Always consult your machine’s manual for recommended parts and specifications.

Establishing a partnership with reputable suppliers can help ensure that you always have access to quality parts. Having the right tools and equipment for repairs and replacements is also crucial for ensuring that maintenance tasks are completed efficiently and effectively.

Enhancing Efficiency with Knowledge

Understanding the Komatsu engines parts is essential for optimizing performance and ensuring the longevity of your machinery. By familiarizing yourself with components such as the cylinder block, fuel system, cooling system, and electrical parts, you can quickly identify and address potential issues.

Regular maintenance, inspections, and the use of high-quality parts are integral to keeping your engine in top condition. With proactive care, you can enhance the efficiency and reliability of Komatsu machinery, minimizing downtime and maximizing productivity.

By investing time in understanding and maintaining your engine, you will not only prolong its life but also enhance your confidence in operating your equipment. The knowledge of Komatsu engine parts will serve you well, leading to better performance and an overall smoother experience in managing your machinery.

Leave a Reply