Introduction to Crankshaft Engines

Crankshaft engine are at the heart of modern mechanical systems. They convert energy into motion, powering countless machines. Their design is both intricate and highly efficient. Understanding these engines helps us appreciate their importance in today’s technology.

What is a Crankshaft Engine?

A crankshaft engine is a mechanical system that transforms energy into motion. It typically uses pistons and rods to create rotational movement. This rotation powers the engine’s connected systems. Crankshaft engines are commonly used in cars, trucks, and other machinery. Their design is compact and ideal for internal combustion engines.

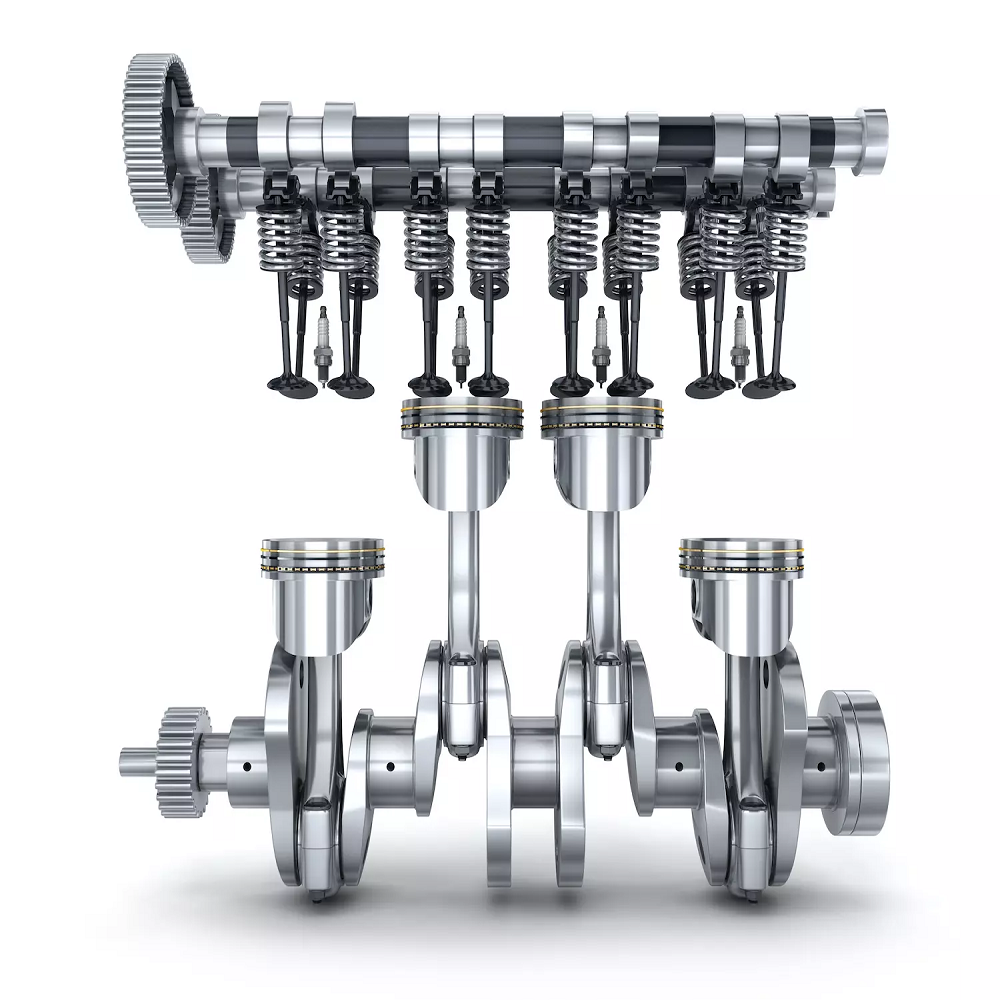

Key Components of a Crankshaft Engine

Several components work together to make crankshaft engines functional:

- Crankshaft: The central shaft that converts piston movement into rotation.

- Pistons: They move up and down, transferring energy to the crankshaft.

- Connecting Rods: These rods link the pistons to the crankshaft.

- Bearings: They support the crankshaft and reduce friction during rotation.

- Balancing Mechanisms: Counterweights ensure smooth operation by reducing vibrations.

Each component is crucial for efficiency. Together, they form the backbone of crankshaft engines, enabling reliable operation across various applications.

The Role of the Crankshaft in Engine Mechanics

The crankshaft is the backbone of any crankshaft engine. It plays a key role in converting energy and ensuring the engine’s successful operation. This robust mechanical component drives the functioning of connected systems and is integral to the engine’s core mechanics.

How the Crankshaft Converts Linear to Rotational Motion

The crankshaft transforms the linear motion of pistons into rotational motion. Pistons move up and down inside cylinders as the engine burns fuel. Connecting rods transmit this movement to the crankshaft, causing it to rotate. This rotation powers other engine parts, such as the camshaft and accessories. The design ensures a smooth and efficient transfer of energy.

Key points of this process include:

- Pistons produce linear motion through combustion.

- Connecting rods link pistons to the crankshaft.

- The crankshaft rotates, converting motion into usable energy.

This mechanism is fundamental to the operation of all crankshaft engines, whether in cars, trucks, or industrial machines.

Importance of Crankshaft in Internal Combustion Engines

In internal combustion engines, the crankshaft serves as a critical component. It receives energy from the combustion of fuel and translates it into motion. This motion drives the vehicle’s wheels or machinery. Without the crankshaft, internal combustion engines couldn’t function.

The crankshaft also contributes to:

- Engine power and efficiency.

- Smooth operation by balancing vibrations.

- Enabling effective timing mechanisms.

Its durability and precision are vital for the engine’s performance. In summary, the crankshaft is indispensable for transforming raw energy into mechanical action.

Types of Crankshaft Engines

Crankshaft engines come in various configurations to suit different needs. Each type offers unique design, efficiency, and performance characteristics.

Inline Engines

Inline engines arrange the cylinders in a straight line. They are simple and compact. These engines are easy to maintain and produce less mechanical noise. Inline engines are often used in smaller cars, motorcycles, and machinery. Their straightforward design helps reduce manufacturing costs and repair complexities.

Advantages of inline engines:

- Compact and lightweight.

- Cost-effective production.

- Smooth operation due to fewer moving parts.

V-Engines

V-engines have cylinders arranged in a “V” shape. This configuration helps save space. V-engines are commonly found in high-performance cars and trucks. They offer more power and smoother operation compared to inline engines. Despite their power, they can be more complex to maintain.

Key benefits of V-engines:

- Compact design for high power output.

- Improved balance and reduced vibrations.

- Ideal for powerful vehicles.

Boxer Engines

Boxer engines feature horizontally opposed cylinders. They lie flat and mirror each other. This design allows for a lower center of gravity, enhancing vehicle stability. Boxer engines are known for their smooth performance and are widely used in sports cars and airplanes.

Why choose boxer engines:

- Lower center of gravity improves handling.

- Enhanced engine balance and reduced vibrations.

- Unique design optimizes stability for specialized applications.

Each engine type offers benefits for specific applications. Choosing the right engine depends on space, power, and performance needs.

Components of a Crankshaft Engine

Crankshaft engines rely on key components working together for efficient performance. Each part has a specific role.

Pistons and Connecting Rods

Pistons move up and down due to fuel combustion. This movement generates linear energy. Connecting rods link the pistons to the crankshaft. They transfer the pistons’ energy to the crankshaft for rotation. Without these parts, energy conversion within the engine would fail.

Key roles:

- Pistons create linear energy inside the engine.

- Connecting rods transfer this energy to the crankshaft.

Bearings and Journals

Bearings allow the crankshaft to spin freely. They minimize wear and tear caused by continuous movement. Journals are the parts of the crankshaft that rest on the bearings. They ensure a stable connection and precise alignment.

Functions:

- Bearings reduce friction during crankshaft motion.

- Journals provide structural support for smooth operation.

Counterweights and Balancing Mechanisms

Counterweights are attached to the crankshaft. They offset the forces created by pistons and rods. This prevents excessive vibrations and unbalanced motion. Proper balancing reduces wear on engine components. It also ensures steady and efficient performance.

Importance:

- Counterweights reduce engine vibration.

- Balancing mechanisms improve durability and reliability.

These components work together to ensure the crankshaft engine operates smoothly and efficiently.

How Crankshaft Generate Power

Crankshaft engines generate power by converting energy from fuel combustion into mechanical motion. This process involves intricate cycles and precise timing mechanisms, ensuring efficient performance. Understanding this operation highlights the remarkable design of crankshaft engines.

The Four-Stroke Cycle and Crankshaft Functionality

The four-stroke cycle is essential to internal combustion engines. It uses the crankshaft to produce motion. The cycle involves four key stages:

- Intake Stroke: The piston moves downward, drawing air and fuel into the cylinder.

- Compression Stroke: The piston moves upward, compressing the air-fuel mixture.

- Power Stroke: Combustion occurs, forcing the piston downward and generating power.

- Exhaust Stroke: The piston moves upward again, expelling waste gases.

During these stages, connecting rods transfer the pistons’ energy to the crankshaft. The crankshaft rotates continuously, driving the vehicle or machine. This efficient system ensures constant energy production during operation.

Timing in Crankshaft Operation

Timing is critical in crankshaft engine functionality. It ensures that every component works in harmony. Proper timing guarantees smooth power delivery and efficient combustion.

- Camshaft Coordination: The crankshaft and camshaft must stay perfectly synchronized. This alignment controls the opening and closing of engine valves.

- Ignition Timing: Spark plugs ignite the air-fuel mixture at the right moment. This precision maximizes power output while minimizing waste.

- Balancing Forces: Counterweights on the crankshaft reduce vibrations, ensuring stable operation.

Without accurate timing, engine efficiency drops, and wear increases. Modern crankshaft engines use sophisticated systems to maintain precise timing. This enhances reliability, performance, and longevity in various applications.

Common Issues with Crankshaft

Crankshaft engines are vital but can face mechanical problems over time. Understanding these problems helps maintain engine efficiency and longevity. Two common issues are crankshaft misalignment and general wear, along with symptoms signaling a failing crankshaft.

Crankshaft Misalignment and Wear

Crankshaft misalignment occurs when the shaft shifts from its proper position. It can lead to uneven engine performance and excessive wear on connecting parts.

Causes of Crankshaft Misalignment:

- Manufacturing errors or incorrect assembly.

- Improper installation of bearings or related components.

- Excessive stress from prolonged high-torque operations.

Symptoms of Misalignment:

- Unusual engine vibration during operation.

- Reduced power output and inconsistent performance.

- Early wear and tear on pistons, rods, or bearings.

Wear is another critical issue. The crankshaft endures friction, heat, and mechanical stress repeatedly. Over time, this degrades the surface, reducing overall efficiency.

Causes of Wear:

- Poor lubrication from insufficient engine oils.

- Dirt and debris caught in the lubrication system.

- Prolonged use or lack of timely maintenance.

Symptoms of a Failing Crankshaft

A failing crankshaft shows distinct warning signs. Recognizing these symptoms early can prevent severe engine damage.

Key Indicators:

- Knocking sounds: Loose or damaged parts can produce knocking noises.

- Engine stalling: The vehicle may stop unexpectedly due to irregular power output.

- Oil leaks: Damage to crankshafts or seals can result in noticeable oil leakage.

- Visible wear on the shaft: Cracks or grooves are visible during inspections.

Addressing these issues immediately ensures the durability of the crankshaft engine. Regular maintenance can prevent failures and keep the engine performing effectively.

Maintenance and Care for Crankshaft

Proper maintenance extends a crankshaft engine’s life and ensures optimal performance. Routine care prevents wear and malfunctions.

Regular Inspection Procedures

Regular inspections help identify issues before they become critical. Follow these steps for effective examination:

- Check for Misalignments: Look for unusual vibrations or irregular rotations. Misaligned crankshafts reduce efficiency.

- Inspect Bearings and Journals: Examine for excessive wear or damage. Replace worn parts immediately.

- Monitor Oil Levels: Ensure proper lubrication to reduce friction and overheating in engine components.

- Search for Cracks or Grooves: Inspect the crankshaft surface visually. Damage impacts reliability and performance.

- Verify Timing Systems: Ensure synchronization between the crankshaft and other parts, like the camshaft.

Conducting frequent inspections prevents unexpected failures and costly repairs.

Tips to Extend Crankshaft Longevity

Implement these practices to enhance crankshaft durability and engine efficiency:

- Use High-Quality Lubricants: Premium oils reduce friction and wear.

- Clean the Lubrication System: Remove dirt and debris to maintain smooth oil circulation.

- Avoid High-Torque Stress: Operate machinery within recommended limits to avoid excessive strain.

- Perform Timely Maintenance: Replace worn or damaged parts promptly to prevent further issues.

- Balance Engine Components: Ensure counterweights and balancing mechanisms work properly.

By following these steps, engines will run longer with fewer disruptions.

Applications of Crankshaft Engines

Crankshaft engines power a wide range of industries. Their versatility makes them essential in many applications. Two major sectors that rely heavily on crankshaft engines are the automotive and aviation/marine industries.

Automotive Industry

Crankshaft engines are the core of vehicles. They power cars, trucks, and motorcycles. These engines convert fuel energy to motion, making transportation possible. In cars, they ensure smooth operation and efficient power delivery. Truck engines use crankshafts to generate high torque needed for heavy loads. Motorcycles benefit from compact, high-performance crankshaft designs.

In electric or hybrid vehicles, crankshaft engines play a supporting role. They work in combination with electric motors to enhance efficiency. This mix improves fuel consumption and reduces emissions. The automotive industry continually improves crankshaft engines for better performance and environmental impact.

Aviation and Marine Use

Crankshaft engine play a vital role in aviation and marine industries. In airplanes, they power propellers by converting energy to motion. These engines ensure reliability and safety during flights. Light aircraft often use boxer engines for stability and balance.

In marine applications, crankshaft engins drive boats and ships. They deliver the power needed for different watercraft, from small boats to large ships. Marine engines are designed for durability to withstand harsh ocean environments. Their efficient design ensures smooth operation over long distances.

Both industries require precision and high performance. Crankshaft engine meet these demands with reliable and efficient operation. Their continual innovation keeps them relevant in these critical sectors.

Understanding the Crankshaft’s Role

Crucial Component in Internal Combustion Engines

In conclusion, the crankshaft is an essential component of internal combustion engines that plays a fundamental role in their functionality. Understanding how it works and its significance can help vehicle owners appreciate the complex processes that allow their cars to perform. The crankshaft’s ability to convert linear motion into rotational power makes it a key player in the engine’s operation.

Maintenance and Care for Longevity

Proper maintenance of the crankshaft engine ensures its longevity and contributes to the overall health of the engine. Recognizing the signs of wear, adhering to maintenance schedules, and understanding how the crankshaft fits into the wider system of the engine are all vital steps for vehicle owners. By taking care of this crucial component, drivers can prolong the life of their engines and enhance their performance.

Future Implications for Automotive Engineering

As automotive engineering advances, the crankshaft engine will continue to evolve alongside it. Improvements in materials, design, and technology will shape the future of crankshaft development. The attention given to this essential component will not only improve performance but also enhance fuel efficiency and reliability. For automotive enthusiasts and professionals alike, understanding the intricacies of the crankshaft will be important as the automotive landscape continues to change.

Leave a Reply