What is a Piston Engine?

A piston engine is a heat engine that uses pistons to convert pressure into motion. This motion creates mechanical energy, which powers various machines or vehicles. Piston engines are also widely known as reciprocating engines.

Brief Overview of Piston Engines

Piston engines are one of the oldest and most common types of engines. They work by burning a fuel-air mixture inside cylinders. The combustion pushes pistons back and forth, creating energy. Piston engines are common in cars, planes, and power tools. They vary in design, size, and power output based on the application. Key features include compactness, reliability, and efficiency for their size.

The History and Evolution of Piston Engines

The history of piston engines dates back to the 17th century with early steam engines. The first internal combustion piston engine was built in the 1800s. Over time, engineers improved piston engines to make them more efficient and powerful. In the 20th century, they became the backbone of the automotive and aviation industries. Modern piston engines use advanced materials and technologies to increase durability and performance. Today, they remain critical in various applications despite emerging alternatives like electric motors.

Key Components of a Piston Engine

Understanding the key components of a piston engine is crucial. These elements work together to generate power and ensure smooth operation. Let’s explore what these parts do and why they matter.

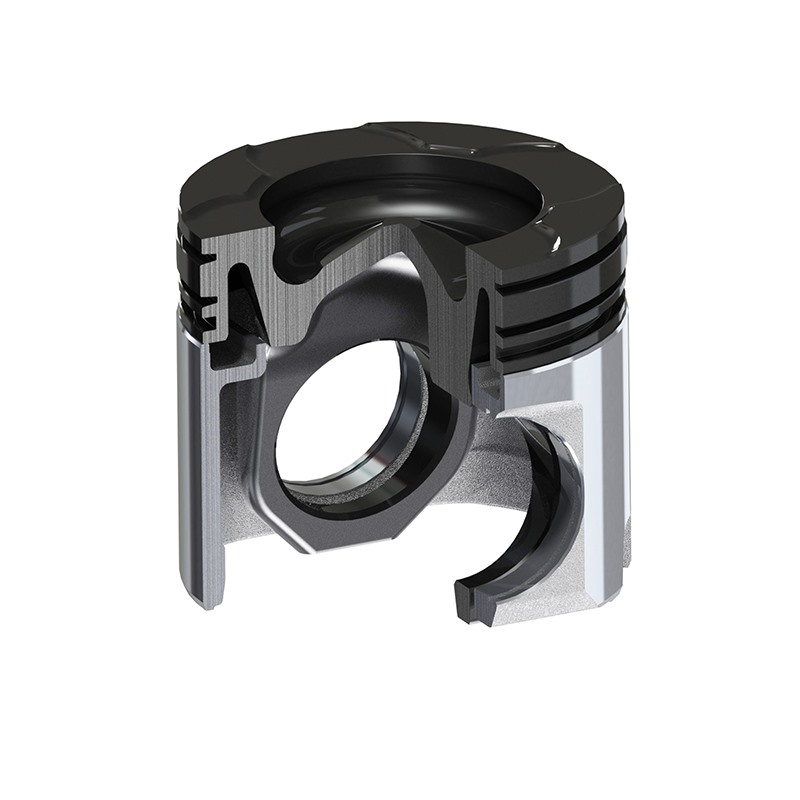

Pistons and Cylinders

Pistons move within cylinders to compress air-fuel mixtures. This compression leads to combustion, generating energy. Cylinders house pistons and guide their motion. They are durable to withstand high heat and pressure.

Crankshaft and Connecting Rods

The crankshaft converts the piston’s up-and-down motion into rotational force. Connecting rods link pistons to the crankshaft, allowing movement transfer. These parts are essential for creating usable mechanical energy.

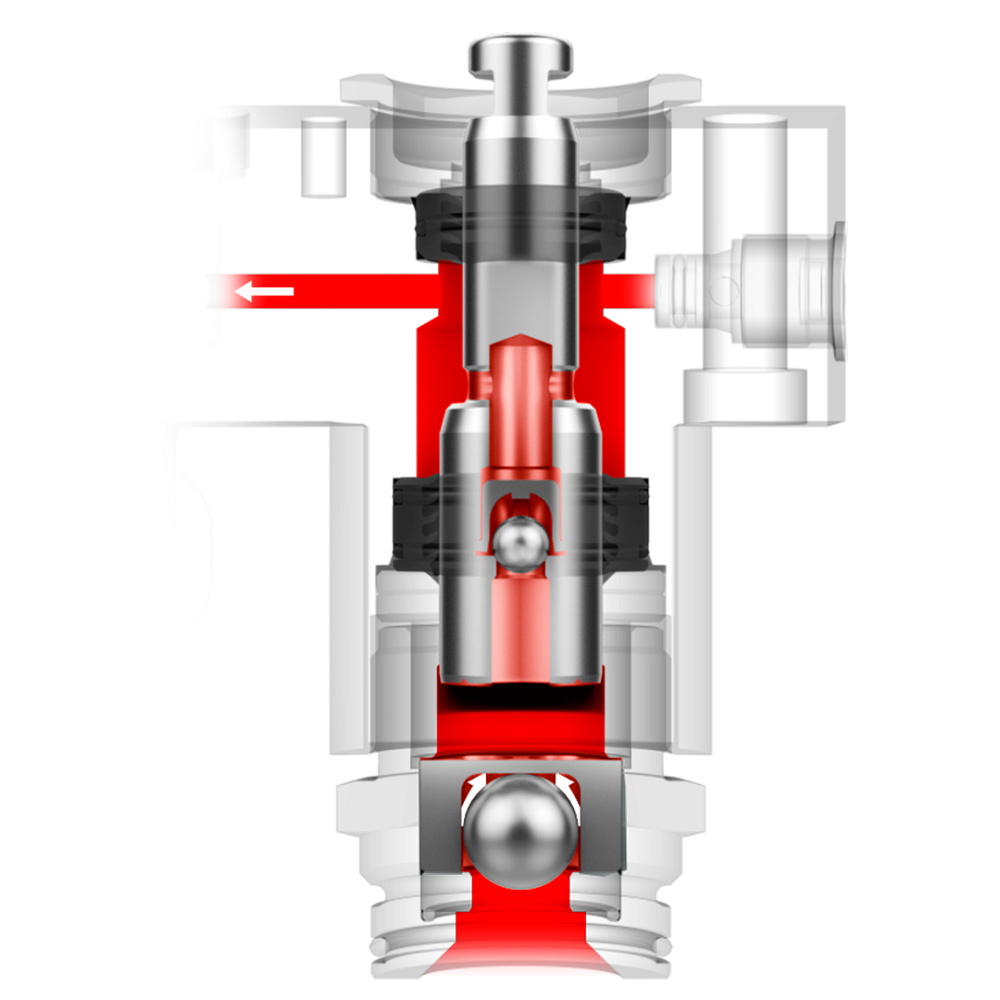

Valves and Camshafts

Valves control the flow of air and fuel into the cylinders. Exhaust valves remove burned gases. Camshafts regulate valve timing to optimize engine performance. Both ensure the engine runs efficiently.

Spark Plugs and Ignition System

Spark plugs create sparks to ignite the compressed air-fuel mixture. The ignition system powers the spark plugs and coordinates the timing. Without this, the engine wouldn’t start or run properly.

How Does a Piston Work?

Understanding how a piston engine works is vital for grasping its usefulness and operations. These engines follow specific cycles to convert chemical energy into mechanical force. Here, we explore the two primary methods: the four-stroke cycle and its key differences compared to the two-stroke cycle.

The Four-Stroke Cycle Explained

The four-stroke cycle is the most common operating process in piston engines. It consists of four distinct phases:

- Intake Stroke: The piston moves down, drawing in an air-fuel mixture through the intake valve.

- Compression Stroke: The piston moves up, compressing the mixture to prepare it for ignition.

- Power Stroke: A spark plug ignites the mixture, causing an explosion that forces the piston downward.

- Exhaust Stroke: The piston moves up again, expelling the burned gases through the exhaust valve.

This cycle repeats continuously, producing the rotational force needed to power devices. Four-stroke engines are known for their efficiency and durability. They are widely used in cars and machinery.

Differences Between Two-Stroke and Four-Stroke Engines

Two-stroke and four-stroke engines differ in how they complete combustion cycles.

- Faster Cycle in Two-Strokes: Two-stroke engines complete the intake, compression, power, and exhaust processes in two movements. This makes them faster but less efficient than four-stroke engines.

- Higher Fuel Efficiency in Four-Strokes: Four-stroke engines consume less fuel, making them suitable for long-term operations. Two-stroke engines burn oil with fuel, increasing emissions and fuel consumption.

- Usage: Two-stroke engines are lighter and more compact, making them ideal for smaller tools like chainsaws. Four-stroke engines are better for larger engines like those in cars and motorcycles.

Understanding these differences helps in choosing the right piston engine for specific applications.

Types of Piston

Piston engines come in various configurations to suit different applications and requirements. Their designs impact performance, efficiency, and usage. Let’s explore the most common types of piston engines.

Inline Engines

Inline engines have cylinders aligned in a straight row. This layout is simple and compact. They are commonly used in smaller vehicles, motorcycles, and compact cars. Inline engines offer easy maintenance and smooth operation. However, they may lack power in high-performance applications.

V-Type Engines

V-type engines have cylinders arranged in a “V” shape. They are favored for their balance and high power output. This design is common in sports cars, trucks, and luxury sedans. V-type engines are more compact than inline engines of similar power. However, they are more complex and costlier to maintain.

Flat or Boxer Engines

Flat or boxer engines have horizontally opposed cylinders. Pistons move side-by-side, producing excellent balance and reduced vibration. These engines are used in sports cars and some motorcycles. They offer a low center of gravity, improving stability and handling. However, their wider layout limits use in smaller vehicles.

Rotary Variants and Their Distinction

Rotary engines, though not traditional piston engines, are a variant worth mentioning. These engines use spinning rotors instead of pistons. They are compact, lightweight, and deliver high power for their size. Rotary engines are less common today due to lower efficiency and higher emissions. They are mainly found in specialized vehicles, such as Mazda’s RX series.

Understanding these types helps in selecting the right piston engine for specific needs and goals.

Advantages and Disadvantages of Piston

Piston engines play a vital role in many industries today. They offer several benefits but also come with limitations. Understanding these pros and cons can help in evaluating their effectiveness for specific uses.

Benefits in Modern Applications

- Wide Availability: Piston engines are widely used and easy to source globally. This makes them reliable options for industries requiring standardized components.

- Proven Performance: With over a century of optimization, piston engines are highly dependable and efficient for their size.

- Versatile Fuel Options: These engines can run on various fuels like gasoline, diesel, or alternative biofuels. This flexibility increases their usage in diverse sectors.

- Compact and Affordable: Piston engines are compact, making them ideal for vehicles and smaller machines. They are also relatively low-cost to manufacture and purchase.

- Repair and Maintenance: Their established presence means parts and services are readily available. Maintenance is straightforward compared to newer technologies.

Common Drawbacks and Limitations

- Fuel Dependency: Most piston engines rely on fossil fuels, which contribute to greenhouse gas emissions.

- Noise and Vibration: These engines can produce significant noise and vibrations, reducing comfort in vehicles and nearby areas.

- Energy Loss: Piston engines lose energy as heat during operation, making them less efficient than some alternatives.

- Environmental Impact: Emissions from piston engines harm air quality and accelerate climate change, especially in older models.

- Limited Innovation Potential: While advancements are ongoing, piston engines face growing competition from electric and hybrid systems.

Understanding these advantages and disadvantages helps in making better choices for specific applications. While piston engines remain reliable, modern challenges push towards cleaner and more efficient alternatives.

Piston Engines in Different Industries

Piston engines are widely used in various industries due to their reliability and efficiency. Each sector utilizes them based on specific needs, ranging from transportation to power generation. Below, we explore their applications in three major fields.

Automotive Applications

Piston engines are the backbone of the automotive industry. They are commonly found in cars, motorcycles, and trucks. These engines provide the power needed to drive vehicles smoothly and efficiently. Inline engines, V-type engines, and boxer engines are popular choices based on vehicle size and performance. Their ability to run on gasoline or diesel broadens their usability. Sports cars and luxury vehicles often rely on advanced piston engines for high-speed performance and power. For daily-use cars, smaller piston engines offer affordability and fuel efficiency.

Aerospace Uses

The aerospace industry also thrives on piston engines, especially for light aircraft and helicopters. These engines are favored for their simplicity, affordability, and ease of maintenance compared to alternatives. They work well for small planes used in private aviation and training. Aerospace piston engines often feature compact, lightweight designs tailored for flight requirements. However, they are less common in larger commercial aircraft, where turbine engines dominate. Rotary engines, a variant of piston engines, are occasionally seen in experimental planes and drones, valued for their lighter weight.

Impact on Power Generation and Smaller Machines

Piston engines play a vital role in generating electricity and powers industrial machines. Smaller piston engines are extensively used in generators for homes and businesses. These engines provide efficient and affordable energy solutions in areas without stable power grids. In industries, piston engines assist in running equipment such as pumps and compressors. Their compact sizes make them perfect for tools like chainsaws and lawnmowers. For larger power plants, piston engines can also run on biofuels, promoting greener energy options.

The versatility of piston engines ensures their relevance across these industries. This adaptability demonstrates why they remain integral even as new technologies emerge.

Maintenance and Care for Piston

Proper maintenance ensures the longevity and performance of piston engines. Regular care helps avoid costly repairs and downtime. Below, we discuss routine servicing tips and how to troubleshoot common problems in piston engines.

Routine Servicing Tips

- Change Oil Regularly: Replace engine oil as per the manufacturer’s schedule. Fresh oil ensures lubrication and reduces wear.

- Inspect Air Filters: Clean or change air filters to maintain airflow and fuel efficiency. Clogged filters can cause issues.

- Check Spark Plugs: Inspect and replace worn-out spark plugs. They are crucial for smooth ignition and engine operation.

- Monitor Coolant Levels: Ensure adequate coolant to prevent overheating. Low coolant can damage engine components.

- Evaluate Belts and Hoses: Inspect belts and hoses for cracks and leaks during routine checks. Replace damaged parts promptly.

- Keep Fuel Systems Clean: Use fuel additives when needed to clean injectors and lines. Dirty systems can reduce efficiency.

Routine servicing prevents minor issues. It also improves engine life and ensures safer operation.

Common Problems and Troubleshooting

- Engine Misfires: Misfires can occur due to bad spark plugs, dirty fuel, or ignition timing issues. Replace spark plugs or clean fuel systems as needed.

- Overheating Issues: Overheating may result from low coolant, a faulty thermostat, or a broken radiator. Check all cooling parts to find the source.

- Excessive Noise or Vibration: Noise is often caused by loose parts or worn components. Tighten bolts or replace damaged parts.

- Reduced Fuel Efficiency: Drop in efficiency might signal clogged air filters or injector troubles. Clean or replace them promptly.

- Hard Starting: If the engine struggles to start, inspect the ignition system and battery connections. Address faulty wires or replace weak batteries.

Understanding these problems simplifies troubleshooting. Regular checks minimize risks and extend performance.

Caring for a piston engine ensures reliability and reduces unexpected failures. Regular inspection and timely action are key to maintaining it.

The Future of Piston Engines

Piston engines have been around for a long time but continue to evolve. As technology advances, engineers focus on improving their efficiency and reducing their environmental impact. Additionally, comparisons with electric alternatives bring new perspectives on the relevance of piston engines in modern times.

Innovations in Efficiency and Performance

Advancements in fuel technology and materials are enhancing piston engine efficiency. Modern engines use lightweight, durable materials that reduce energy losses. Direct fuel injection and turbocharging improve power output while using less fuel. Engineers are also working on hybrid configurations. These combine piston engines with electric systems for better fuel economy and lower emissions. Furthermore, biofuels and synthetic fuels are being explored to reduce reliance on fossil fuels. Smart sensors and computerized management systems optimize engine performance in real-time. These innovations help piston engines meet stricter environmental standards and consumer expectations.

Comparing Piston Engines to Electric Alternatives

Electric motors are gaining popularity as an alternative to piston engine. They operate silently and produce zero emissions during use. However, piston engines offer some key advantages. They are more suitable for long-range applications due to widespread fuel availability. Piston engines also handle extreme environments, like high heat or cold, better than many battery systems. Initial costs for electric systems are higher compared to piston engines. In contrast, piston engines are well-established and cost-effective. However, electric technology is closing this gap with ongoing innovations. For now, piston engines remain essential in industries like aviation and heavy machinery. Balancing these factors helps decide between piston engines and electric power systems for specific needs.

The future of piston engines depends on balancing efficiency, cost, and environmental concerns. Innovations will improve their longevity, even as alternatives grow in popularity.

Leave a Reply