Piston pump hydraulic play a crucial role in various industrial applications and machinery. These devices are designed to convert mechanical energy into hydraulic energy, effectively powering hydraulic systems. Their efficiency and reliability make piston pumps a fundamental component in numerous machines, from construction equipment to manufacturing processes. In this comprehensive guide, we will explore the principles behind piston pump hydraulic, their types and advantages, key components, maintenance practices, and applications in different industries. By the end of this article, you will have a thorough understanding of why piston pump hydraulic are essential to many mechanical systems.

What is a Piston Pump?

A piston pump is a type of positive displacement pump. It moves fluid by enclosing it in a chamber and forcing it through the system. Piston pumps are widely used in hydraulic systems due to their efficiency and reliability.

Overview of Piston Pumps

Piston pumps operate by using a reciprocating piston mechanism. The movement of the piston creates pressurized fluid flow. They generate high pressure and are suitable for various industrial applications. These pumps can handle a variety of fluids, including hydraulic oil, water, and chemicals. The ability to work under high pressure makes piston pumps essential in hydraulic systems.

Types of Piston Pumps (Axial, Radial)

Axial Piston Pumps:

- These pumps have pistons arranged parallel to the drive shaft.

- They are commonly used in high-pressure hydraulic systems.

- Axial models offer a compact design, making them ideal for tight spaces.

Radial Piston Pumps:

- In these pumps, pistons are positioned radially around the drive shaft.

- They generate very high pressure and are highly durable.

- Radial pumps are often used in heavy-duty applications, such as industrial machinery.

Both types are vital for specific applications, determined by the system’s pressure and flow requirements.

How Do Piston Pumps Work in Hydraulic Systems?

Piston pumps serve as the backbone of many hydraulic systems. They transform mechanical energy into hydraulic energy, enabling efficient fluid movement. By generating high pressure, they ensure consistent and precise operation in industrial applications. Let’s delve into how these pumps operate and the essential components that enable their functionality.

Operating Principles of Piston Pumps

- Reciprocating Motion: Piston pumps rely on a reciprocating piston mechanism to displace fluid. The piston moves inside a cylinder, creating alternating pressure and suction.

- Fluid Movement: During suction strokes, the piston pulls fluid into the pump chamber. During pressure strokes, it forces the fluid out.

- Positive Displacement: The pump ensures consistent fluid flow regardless of system pressure changes. This characteristic is vital for maintaining hydraulic system stability.

- Check Valves: Check valves regulate fluid direction, ensuring no backflow occurs during operation.

The operating principle helps piston pumps achieve high-pressure and controlled flow in critical applications.

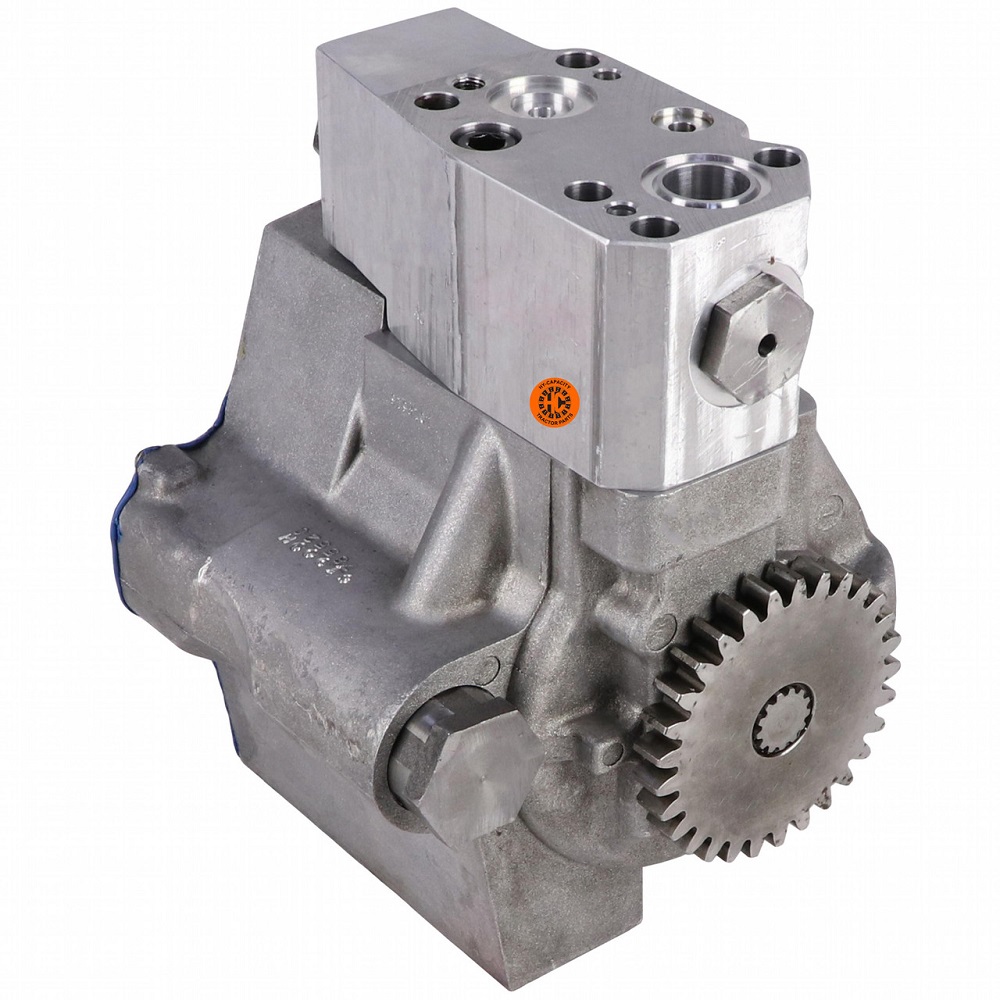

Key Components of a Piston Pump

- Cylinder Block: Houses the pistons and creates a sealed chamber for fluid displacement.

- Pistons: These are the prime moving parts, responsible for pumping fluid through the system.

- Drive Shaft: Connects to the motor, transferring rotational energy to the pump mechanism.

- Swash Plate or Cam: Converts rotational energy into reciprocating motion for the pistons.

- Check Valves: Allow fluid flow in one direction and prevent backflow during operation.

- Seal Assemblies: Prevent fluid leakage and protect internal components from wear.

Together, these components ensure the efficient operation of piston pumps. Their design supports high pressure, reliability, and adaptability across diverse hydraulic systems.

Advantages of Piston Pumps in Hydraulic Applications

Piston pumps offer numerous benefits that make them indispensable in hydraulic systems. Their design and functionality ensure high performance and reliability across various industries. Below are the key advantages.

Efficiency and Power Output

- High Power-to-Weight Ratio: Piston pumps deliver unmatched power while maintaining a compact size.

- Precise Fluid Control: They ensure accurate flow regulation, vital for demanding hydraulic applications.

- Energy Efficiency: These pumps operate with reduced energy consumption, improving system performance.

- Pressure Handling Capability: Piston pumps handle high pressures, ensuring stability in critical operations.

Efficient operation and superior power output make piston pumps ideal for performance-critical equipment.

Versatility and Durability

- Wide Application Range: Piston pumps work with diverse fluids, including oils and chemicals.

- Durability in Tough Environments: Their robust construction withstands wear and tear in harsh conditions.

- Adjustable Flow Rates: These pumps adapt to varying hydraulic system demands effortlessly.

- Minimal Downtime: Reliable components reduce maintenance frequency and ensure prolonged usage.

The combination of versatility and durability enhances their longevity and adaptability in different industries.

Piston pumps combine efficiency, power, and adaptability, making them essential for modern hydraulic systems.

Common Applications of Piston Pumps in Industry

Piston pumps are widely used across various industries due to their efficiency and adaptability. Their ability to generate high pressure and handle diverse fluids makes them indispensable. Below are some of the most common applications in industrial settings.

Construction and Heavy Machinery

Piston pumps play a critical role in construction equipment and heavy machinery.

- Hydraulic Excavators: Piston pumps power excavators’ hydraulic systems for smooth arm and bucket movements.

- Cranes and Loaders: They provide precise control for lifting and moving heavy loads.

- Concrete Pumps: Piston pumps enable efficient concrete placement in building projects.

- Trenchers and Bulldozers: These pumps ensure stable hydraulic operation in demanding terrain and conditions.

Their durability and power output support heavy-duty tasks in construction sites.

Manufacturing and Automation Systems

In manufacturing, piston pumps ensure precise and consistent operation of automated systems.

- Injection Molding Machines: Piston pumps regulate hydraulic pressure for material shaping processes.

- Press Machines: They maintain high pressure for forming and stamping industrial components.

- Robotics Systems: Piston pumps enable controlled movements in factory robotics.

- Assembly Lines: These pumps help in fluid handling for consistent production output.

Their reliability and accuracy are essential for high-speed operations in industrial automation.

Aerospace and Marine Systems

Piston pumps serve specialized fluid management needs in aerospace and marine sectors.

- Aircraft Hydraulic Systems: Piston pumps manage critical flight controls and landing gear movements.

- Marine Steering Systems: These pumps provide precise movement for ship rudders and steering systems.

- Fuel Injection Systems: Piston pumps ensure efficient and controlled fuel delivery.

- Navigational Equipment: They supply hydraulic power for stabilizers and automated controls.

Their ability to operate under extreme conditions ensures reliability in high-stakes applications.

Piston pumps are essential for varied industries, addressing specific operational demands effectively.

Maintenance and Troubleshooting of Piston Pumps

Maintaining piston pumps is critical for ensuring consistent performance and a long lifespan. Regular inspection and proactive troubleshooting can help avoid failures, minimize downtime, and improve efficiency. Below, we’ll discuss essential maintenance practices, common issues, and tips for extending pump lifespan.

Routine Maintenance Practices

- Inspect Seals and Valves Regularly: Check for wear, cracks, or leaks in seals and check valves.

- Monitor Fluid Levels and Condition: Always use clean and recommended fluids to ensure smooth operation.

- Lubricate Moving Parts: Regularly lubricate pistons, shafts, and other mobile components to reduce wear.

- Check for Vibrations: Excess vibrations can indicate misalignment or component wear.

- Clean the Pump Exterior: Keep the pump free of dirt and debris that can affect operation.

- Follow Manufacturer Guidelines: Adhere to the maintenance schedule and instructions provided by the manufacturer.

With these steps, you can prevent many common issues and ensure smooth pump performance.

Diagnosing Common Issues

Even with routine maintenance, piston pumps can encounter problems. Below are common issues and their possible solutions:

- Pressure Loss:

- Possible Cause: Worn seals or valves.

- Solution: Inspect and replace faulty components.

- Noisy Operation:

- Possible Cause: Air trapped in the fluid or loose components.

- Solution: Bleed the system to release air and tighten any loose parts.

- Overheating:

- Possible Cause: Inadequate lubrication or overworked pump.

- Solution: Check lubrication levels and ensure the pump isn’t exceeding its capacity.

- Fluid Leaks:

- Possible Cause: Damaged seals or improper fitting.

- Solution: Replace damaged seals and ensure all parts are properly installed.

Addressing these issues promptly can prevent system failures and reduce repair costs.

Tips for Extending Pump Lifespan

- Use Quality Materials: Always use OEM parts and recommended fluids.

- Avoid Overloading the Pump: Stay within the pump’s pressure and flow rate specifications.

- Store Properly: Protect idle pumps from dust, moisture, and extreme temperatures.

- Train Operators: Ensure personnel are trained to handle the pump and troubleshoot minor concerns.

- Conduct Periodic Overhauls: Schedule detailed inspections and part replacements annually.

- Monitor Operating Conditions: Detect and rectify abnormal pressure, temperature, or noise quickly.

Proper care, consistent upkeep, and timely actions can significantly enhance the performance and life of piston pumps.

Comparing Piston Pumps with Other Hydraulic Pumps

Hydraulic systems rely on different types of pumps to convert mechanical energy into fluid power. Piston pumps are often compared to other hydraulic pumps, like gear pumps and vane pumps. Understanding these differences helps in choosing the right pump for specific applications.

Piston Pumps vs Gear Pumps

- Pressure Capacity: Piston pumps handle higher pressures than gear pumps, making them ideal for demanding tasks.

- Efficiency: Piston pumps are more energy-efficient due to their precise fluid control.

- Design: Gear pumps have a simpler design, which makes them more affordable but less refined.

- Durability: Gear pumps have fewer moving parts, which can lead to longer service life under less stress.

- Applications: Piston pumps work well in high-pressure environments. Gear pumps suit low-pressure and consistent flow systems.

- Fluid Compatibility: Piston pumps manage a wider range of fluids. Gear pumps are more limited in fluid type.

In applications needing high pressure and precision, piston pumps outperform gear pumps. Gear pumps are better for simpler, low-pressure systems.

Piston Pumps vs Vane Pumps

- Pressure Handling: Piston pumps offer superior pressure capacity compared to vane pumps.

- Flow Control: Vane pumps provide smoother and quieter operation but lack the precise control of piston pumps.

- Maintenance: Vane pumps are easier to maintain due to fewer complex components.

- Efficiency: Piston pumps are generally more efficient under varying system demands.

- Adaptability: Vane pumps are suited for medium-pressure applications and handle consistent flow well.

- Cost: Vane pumps are typically less expensive than piston pumps.

If your system requires high pressure and fluid versatility, piston pumps are ideal. For quieter operation and medium-pressure tasks, vane pumps are a suitable choice.

Comparing these pumps highlights their strengths and helps in selecting the best fit for specific hydraulic needs.

How to Choose the Right Piston Pump for Your Needs

Choosing the right piston pump can maximize hydraulic system performance and efficiency. Consider several factors to ensure the pump suits your specific needs.

Factors to Consider (Pressure, Flow Rate, Application)

- Pressure Requirements: Identify the system’s maximum operating pressure. Piston pumps excel in high-pressure environments.

- Flow Rate Needs: Determine the required fluid flow rate. Match the pump’s output to your application.

- Type of Fluid: Ensure compatibility with the fluid used, like hydraulic oil or chemicals.

- Application Specifics: Examine the industry needs, such as construction, manufacturing, or aerospace.

- Space Constraints: Evaluate the available space and opt for compact designs if necessary.

- Durability: For harsh conditions, select a pump known for robust construction and long wear life.

Careful assessment of these factors ensures a well-fitted piston pump for optimal system performance.

Selecting Pumps for Specialized Hydraulic Systems

- High-Pressure Systems: Choose axial piston pumps for reliable high-pressure operation in tight spaces.

- Heavy-Duty Applications: Opt for radial piston pumps due to their durability and pressure handling.

- Variable Flow Systems: Consider pumps with adjustable flow rates to maximize system adaptability.

- Compact Applications: Select smaller models for systems with limited space.

- Fluid-Sensitive Environments: Verify compatibility for specific fluids like chemicals or seawater in marine and industrial settings.

- Automated Systems: Look for piston pumps that support precise and consistent motion in robotics or manufacturing.

Selecting the right pump depends on understanding the unique demands of your hydraulic system. Prioritize performance, reliability, and adaptability to achieve ideal results.

Conclusion

Piston pump hydraulics are critical to powering a wide array of machinery and systems across many industries. Their ability to convert mechanical energy into hydraulic power makes them indispensable in manufacturing, construction, automotive applications, and beyond. The understanding of how these pumps work, their advantages, and the innovations ahead provides insight into their importance in day-to-day operations.

As technology progresses, piston pump designs will continue to advance, leading to improved efficiency, safety, and versatility. The right maintenance practices ensure that piston pump hydraulic remain reliable and effective components of hydraulic systems.

Whether in heavy equipment, industrial production, or automotive applications, piston pump hydraulic will remain central to the function of modern machines. By recognizing the significance and potential of these pumps, industries can harness the full power of hydraulic systems and drive continued innovation in their fields. Embracing advancements in piston pump technology contributes to sustainable practices and enhances the efficiency of operations across sectors. This journey into understanding piston pump hydraulic showcases how these components truly are the key to powering various systems effectively and sustainably.

Leave a Reply