What is Crankshaft Grinding?

Crankshaft grinding is critical for engine health and performance. It restores crankshafts to optimal functionality.

Definition and Purpose

Crankshaft grinding involves machining the crankshaft’s surfaces. It eliminates imperfections and wear from use. This process ensures smooth operation and proper rotation. Grinding improves engine performance and prevents costly failures.

Components of a Crankshaft

A crankshaft consists of key parts essential for its role in engines:

- Main Journals: Connect to the engine block and support rotation.

- Rod Journals: Attach to connecting rods and convert motion into power.

- Counterweights: Balance the crankshaft and reduce vibrations.

- Oil Holes: Ensure lubrication flows to prevent friction damage.

- Flywheel Mount: Links to the flywheel for energy storage.

Understanding these components helps identify areas needing repair during grinding.

Why is Crankshaft Grinding Necessary?

Crankshaft grinding is essential for maintaining engine efficiency and preventing costly breakdowns. It addresses wear and tear issues caused by regular engine use and provides necessary repairs.

Common Issues with Crankshafts

Crankshafts face numerous challenges during their lifespan, including:

- Surface Wear: Friction and heat cause uneven surfaces, leading to engine problems.

- Cracks: Stress and improper lubrication result in dangerous fractures.

- Distortion: Overheating or excessive force can warp crankshafts, reducing performance.

- Corrosion: Exposure to moisture or chemicals leads to rust and weakens the crankshaft.

- Misalignment: Accidents or improper installation can result in unbalanced operation.

These issues disrupt smooth rotation and cause engine instability, making grinding vital.

Symptoms of a Damaged Crankshaft

Recognizing crankshaft problems early can prevent costly repairs. Look out for these symptoms:

- Strange Engine Noises: Knocking sounds or repetitive ticking indicate crankshaft troubles.

- Reduced Engine Power: Damaged crankshafts fail to efficiently convert motion into power.

- Excessive Vibrations: Imbalanced crankshafts lead to noticeable vibrations during operation.

- Oil Leakage: Worn oil seals around the crankshaft result in unexpected oil leaks.

- Difficulty Starting Engine: Faulty crankshafts cause trouble with ignition.

Identifying these symptoms ensures timely crankshaft grinding to restore proper functionality.

Tools and Equipment Used for Crankshaft

Crankshaft grinding requires specialized tools for precision and efficiency. Proper machinery ensures accurate results and engine safety.

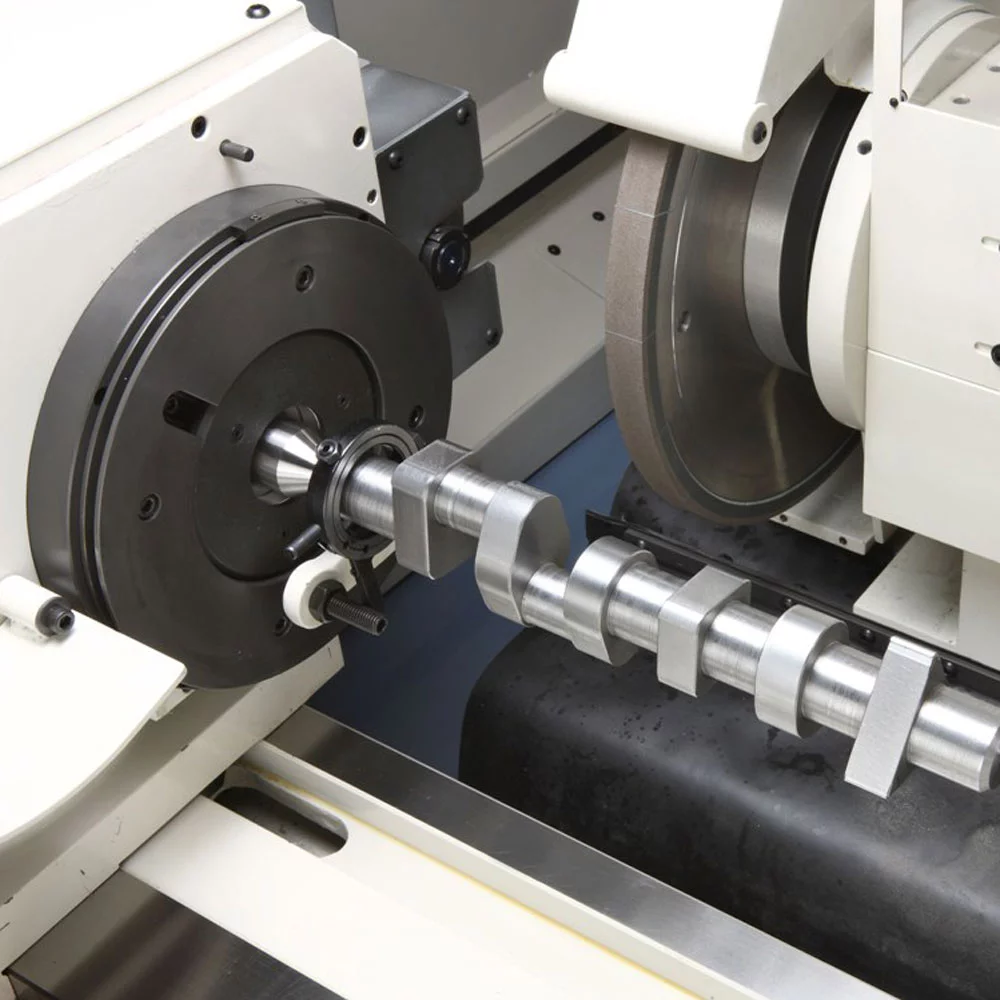

Overview of Necessary Machinery

- Crankshaft Grinder: This machine grinds the crankshaft to correct dimensions. It removes imperfections and smoothens surfaces.

- Steady Rest and Chuck: These ensure the crankshaft stays stable during grinding.

- Measuring Tools: Dial indicators and micrometers check dimensional accuracy throughout the process.

- Grinding Wheels: Abrasive wheels are essential for shaping and polishing crankshaft surfaces.

- Balancing Machine: Used to ensure the crankshaft runs smoothly without vibrations.

Investing in quality equipment helps achieve precise and long-lasting repairs.

Safety Measures in Grinding Operations

Crankshaft grinding involves risks if safety rules are ignored. Follow these guidelines for safe operations:

- Eye and Ear Protection: Wear safety goggles and earplugs to prevent injury.

- Proper Training: Only trained professionals should perform grinding tasks.

- Secure Work Area: Keep the workspace clean and free from obstructions.

- Regular Maintenance: Inspect machinery before use to prevent accidents.

- Dust Extraction System: Reduces harmful dust exposure during grinding.

- Appropriate Attire: Avoid loose clothing to prevent entanglement in machinery.

Adhering to these measures ensures a safe and efficient grinding process.

Step-by-Step Process of Crankshaft

Understanding the crankshaft grinding process helps you grasp its precision and importance. It’s a series of deliberate steps to restore the crankshaft’s surface and functionality.

Inspection and Preparation

Proper inspection and preparation ensure a successful grinding process. Here’s how it begins:

- Thorough Inspection: Examine the crankshaft for damage, cracks, or wear. Use tools like magnaflux machines to detect invisible flaws.

- Measurement: Measure journals and surfaces for roundness and alignment using micrometers.

- Cleaning: Clean the crankshaft to remove grease, grime, and oil. This ensures precise grinding operations.

- Setup: Mount the crankshaft securely on the grinding machine using steady rests and chucks.

- Planning: Decide how much material to remove for proper crankshaft dimension without overgrinding.

Grinding Techniques and Methods

Precision and accuracy are key when grinding crankshafts. Follow these techniques:

- Choosing Grinding Wheels: Select the appropriate wheel type and grit size for the crankshaft material.

- Positioning the Crankshaft: Align the crankshaft carefully to prevent wobbling during grinding.

- Consistent Speed: Maintain consistent grinding wheel speed to avoid uneven surfaces.

- Light Passes: Remove material in small, even increments to avoid overheating or damage.

- Cooling System: Use a cooling system to reduce heat and protect the crankshaft.

- Polishing: Finish with polishing to achieve smooth and exact dimensions.

Final Balancing and Testing

After grinding, balance and test the crankshaft for optimal performance:

- Balancing: Use a balancing machine to correct any imbalances. This reduces vibrations during engine operation.

- Dimensional Testing: Check dimensions with micrometers to confirm adherence to specifications.

- Surface Inspection: Inspect surfaces to ensure no scratches or imperfections remain.

- Operational Testing: Install the crankshaft in a test setup to monitor its functionality.

- Final Cleaning: Give the crankshaft a final thorough cleaning before returning it for assembly.

By adhering to these steps, crankshaft grinding ensures accurate repairs and long-term engine efficiency.

Benefits of Crankshaft

Crankshaft grinding provides numerous advantages that contribute to better engine performance and cost savings. By addressing surface issues and restoring optimal dimensions, this process is key to enhancing engine reliability and longevity.

Improved Engine Performance

Crankshaft grinding improves the smoothness and precision of engine operations. Restoring the crankshaft ensures proper rotation and reduces vibrations. Enhanced surfaces allow efficient motion conversion, boosting power output. Proper grinding eliminates inefficiencies, ensuring a stable and quiet driving experience. The process also minimizes engine stress, increasing its overall reliability.

Prolonging Engine Lifespan

Regular crankshaft grinding prevents long-term engine damage. It corrects wear, cracks, and distortions before they become critical issues. Smooth surfaces reduce friction, preventing excessive heat generation. Proper lubrication flow is ensured, reducing component wear. Grinding prevents failure that could lead to engine breakdown, extending its service life significantly.

Cost-Effective Maintenance

Grinding is a budget-friendly alternative to crankshaft replacement. It repairs damage at a fraction of the cost. Timely grinding prevents extensive engine repairs, saving money in the long run. Restored crankshafts reduce fuel consumption, lowering operating costs. Regular maintenance ensures optimal performance, avoiding expensive emergency fixes.

Common Mistakes to Avoid During Crankshaft

Crankshaft grinding requires precision and attention to detail. Mistakes can compromise engine performance and safety. Below are common errors to prevent during crankshaft grinding.

Overgrinding and its Consequences

Overgrinding is a frequent mistake in crankshaft grinding. Removing too much material leads to serious issues:

- Reduced Structural Integrity: Excessive grinding weakens the crankshaft and risks catastrophic failure.

- Dimension Issues: Improper grinding alters dimensions, causing improper fits and misalignment.

- Heat Damage: Excessive grinding generates heat, causing surface hardening or cracks.

- Costlier Repairs: A damaged crankshaft often requires replacement, increasing maintenance costs.

Avoid overgrinding by removing material in small increments and monitoring progress carefully.

Ensuring Proper Measurements

Incorrect measurements are a common grinding error. This can result in poor engine performance. Here’s how to ensure accurate dimensions:

- Use Precision Tools: Always use reliable micrometers and dial indicators for measurement.

- Double-Check Measurements: Regularly confirm dimensions during the grinding process.

- Surface Alignment: Check for roundness and proper alignment of journals.

- Follow Specifications: Grind according to manufacturer guidelines to maintain required tolerances.

Proper measurements protect the crankshaft and improve engine reliability.

Crankshaft Grinding vs. Replacement: Which is Better?

Crankshaft grinding and replacement play distinct roles when addressing crankshaft issues. Choosing between them depends on the crankshaft’s condition, cost, and engine needs.

Factors to Consider

To decide whether grinding or replacement is better, consider these key factors:

- Extent of Damage: Light surface wear or minor imperfections can usually be resolved with grinding. Severe cracks, corrosion, or extensive distortion may require replacement to ensure safety and reliability.

- Engine Type and Usage: High-performance engines demand precise crankshaft conditions, making replacement more suitable for extreme damage. Standard vehicles often benefit from grinding for cost-effectiveness.

- Time Constraints: Grinding is generally quicker than acquiring and installing a replacement crankshaft.

- Material Integrity: If grinding compromises the crankshaft’s strength, replacement is a safer option.

- Manufacturer Recommendations: Always adhere to manufacturer guidelines for proper crankshaft care.

Cost Analysis of Both Options

Both crankshaft grinding and replacement come with distinct costs. Evaluate these aspects:

- Grinding Costs: Grinding is often more affordable than full replacement. It involves restoring the crankshaft without purchasing a new one. It minimizes downtime and material expenses.

- Replacement Costs: Replacement is costlier due to the purchase of a new crankshaft. It includes installation fees and is more labor-intensive, especially for complex engine systems.

- Long-Term Implications: Grinding provides temporary cost-effectiveness but may need repeated repairs if damage reoccurs. Replacement ensures long-term reliability and reduces the risk of sudden failure.

- Fuel Efficiency Benefits: Properly ground crankshafts improve engine function and save on fuel costs. Replacements may require a larger upfront investment but could yield significant efficiency benefits.

In conclusion, whether grinding or replacement is better depends on damage severity, usage, and budget. Evaluate these factors carefully to make the right choice for your engine.

Tips for Choosing a Professional Crankshaft Grinding Service

Selecting the right crankshaft grinding service is crucial for engine maintenance and performance. An expert, reliable service ensures precise repairs and long-lasting results. Below are key considerations to guide your choice.

Key Qualities to Look For

- Experience and Expertise: Ensure the service has skilled professionals with significant experience in crankshaft grinding.

- Use of Advanced Equipment: Choose a service that employs modern tools for accuracy and efficiency.

- Attention to Detail: Look for services known for precision and meticulous attention to specifications.

- Positive Reputation: Check customer reviews and testimonials for insights about their reliability and quality.

- Fair Pricing: Ensure competitive pricing without compromising the quality of service.

- Warranty or Guarantee: Opt for services offering guarantees to ensure accountability and customer satisfaction.

- Customized Service Options: Choose a service provider adaptable to specific engine or crankshaft needs.

Questions to Ask Before Hiring

- What is Your Experience in Crankshaft Grinding? Inquire about their track record and expertise in handling similar tasks.

- What Equipment Do You Use? Confirm they use modern machinery and tools for precise results.

- Do You Provide References? Request references from past customers for a better understanding of their work.

- What Safety Measures Do You Follow? Ask about safety protocols during grinding operations.

- How Do You Ensure Accuracy? Learn about their process for checking dimensions and ensuring proper alignment.

- Do You Offer a Warranty? Verify if they stand by their work with warranties or performance guarantees.

- What is the Turnaround Time? Get an estimated timeframe for completing the grinding process.

By considering these qualities and asking vital questions, you can ensure a reliable crankshaft grinding service. This choice directly impacts engine longevity and performance.

Best Practices for Maintaining Crankshafts

Regular Inspection

Regular inspection of the crankshaft is crucial for maintaining engine health. Mechanics should check for signs of wear, damage, and proper lubrication during routine maintenance. Catching issues early can prevent more extensive repairs.

During inspections, measuring journal sizes and surface imperfections provides vital information. Keeping a detailed maintenance log helps track the condition of the crankshaft over time. This practice allows vehicle owners to make informed decisions regarding repairs and replacements.

Lubrication Management

Proper lubrication is essential for ensuring the longevity of the crankshaft. Always use the manufacturer-recommended oil type and viscosity for your engine. Frequent oil changes are vital for maintaining clean lubrication and reducing wear on crankshaft components.

Monitoring oil levels helps prevent insufficient lubrication. If you notice the oil becoming dirty or contaminated, change it immediately to preserve engine integrity. Consistent lubrication management significantly extends the life of the crankshaft.

Engine Overhaul Considerations

If significant wear on the crankshaft is detected, consider undertaking an engine overhaul. This comprehensive approach addresses not only the crankshaft but other components that may contribute to wear. An overhaul can include replacing bearings, seals, and engaging in crankshaft grinding.

Scheduling periodic overhauls is wise for maintaining older engines or vehicles subjected to demanding conditions. Prioritizing engine health will prevent minor issues from escalating into major repairs down the line. Investing in regular maintenance can lead to enhanced performance and longevity for your vehicle.

Conclusion

Crankshaft grinding is an essential process that ensures the efficiency and longevity of internal combustion engines. By understanding the techniques involved and the advantages of this vital process, vehicle owners can make informed decisions regarding maintenance and repairs.

Regular inspection and maintenance of the crankshaft will prevent significant wear and ensure continued engine performance. Crankshaft grinding serves as a cost-effective and eco-friendly solution for maintaining engine health, prolonging the life of components while delivering reliable performance.

Taking the time to understand the critical role of the crankshaft and the importance of its maintenance will lead to better automotive practices. Investing in quality parts and engaging skilled technicians for repairs will yield the best results, allowing you to enjoy reliable and smooth engine operation for years to come. Your vehicle’s performance ultimately depends on how you care for its critical components, particularly the crankshaft.

Leave a Reply