Piston pumps are crucial devices used across various industries for the transfer of fluids. They operate by utilizing the reciprocating motion of a piston within a cylinder to create pressure and facilitate fluid movement. Piston pumps are known for their versatility, efficiency, and ability to handle different types of fluids, from water to viscous liquids. This article will explore the advantages and disadvantages of piston pump in various industries, discussing their applications, functionality, and overall importance. By the end, you will have a comprehensive understanding of how piston pumps can impact different sectors.

Understanding Piston Pumps

What is a Piston Pump?

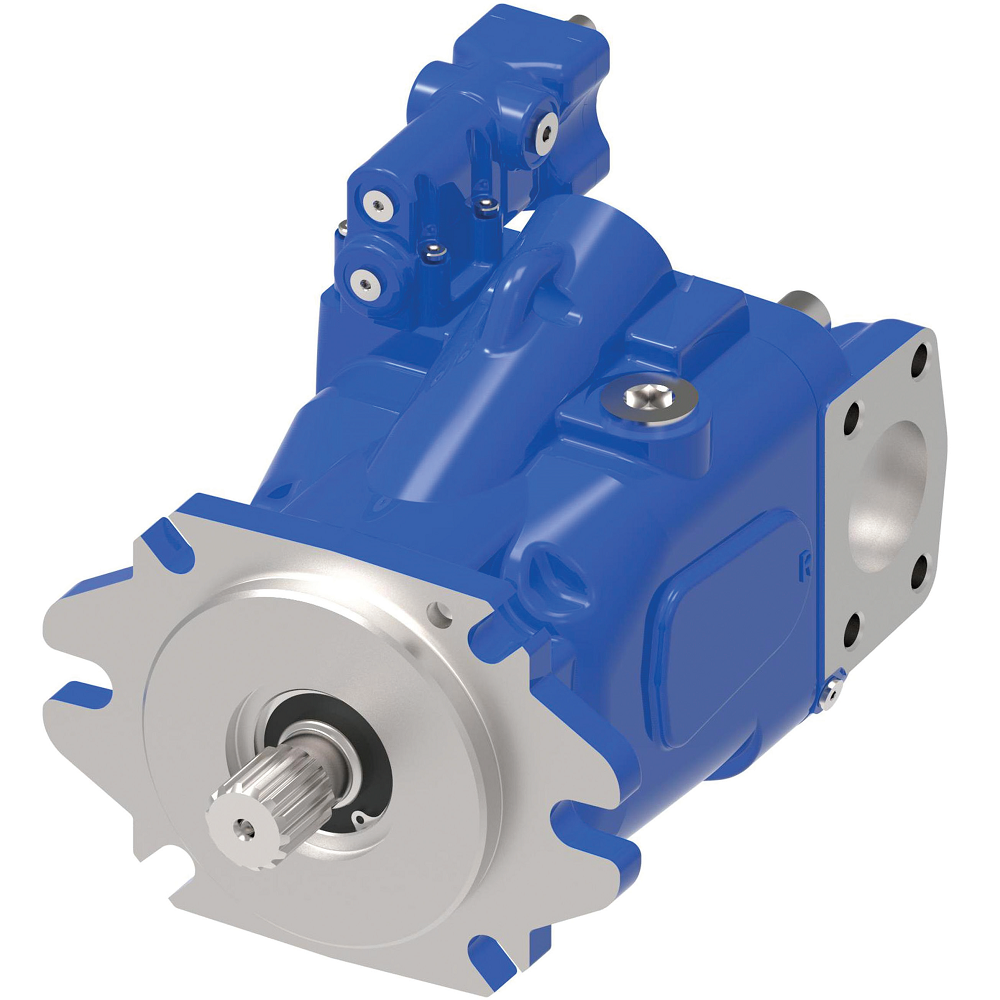

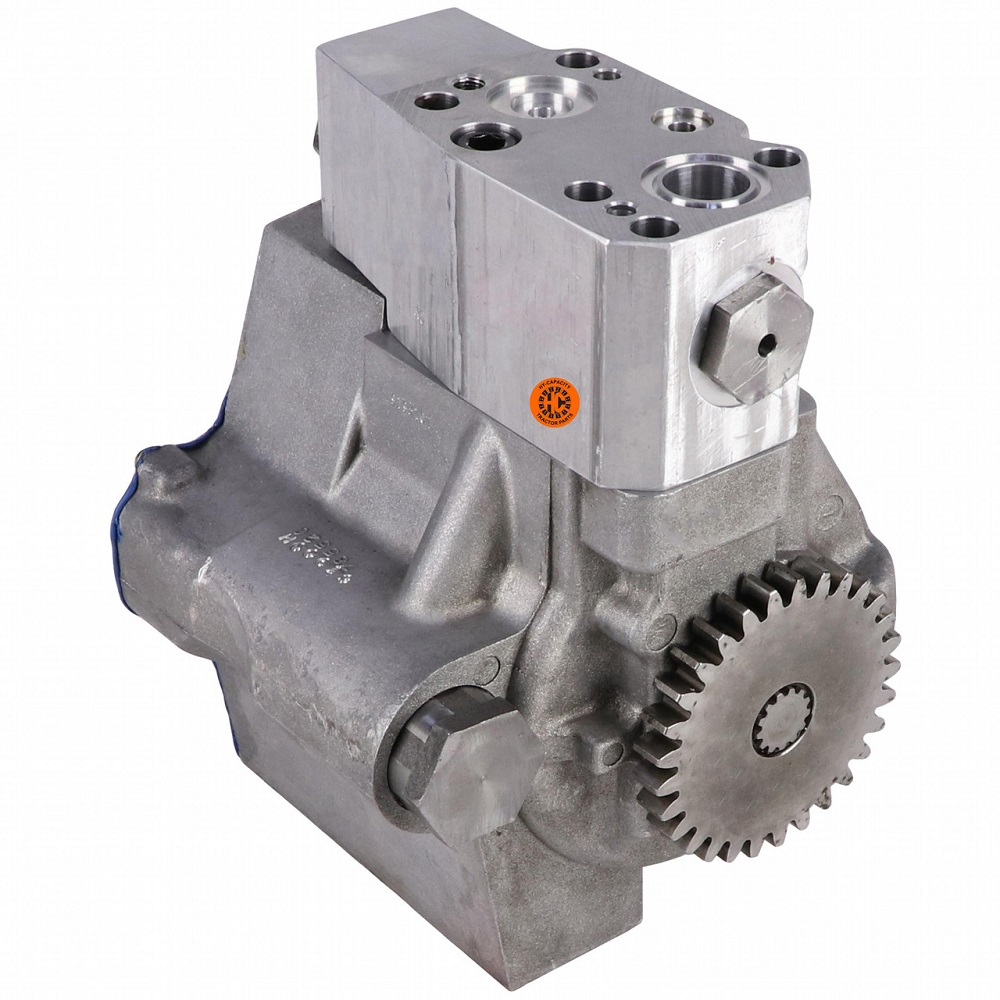

A piston pump is a positive displacement pump that uses a piston to move fluids. As the piston moves back and forth within a cylinder, it creates a vacuum that draws fluid into the pump on the intake stroke. When the piston moves forward, the fluid is expelled through an outlet. This mechanism enables piston pumps to provide consistent flow rates and high pressures, making them suitable for many applications.

Many industries, such as agriculture, manufacturing, automotive, and oil and gas, commonly use piston pumps. Their ability to handle a wide range of materials and conditions makes them a valuable tool in fluid management.

How Piston Pumps Work

The operation of a piston pump relies on several key components. These include the motor, piston, cylinder, inlet and outlet valves, and fluid reservoir. When the motor powers the pump, it connects to the piston, which begins to move.

During the intake stroke, the inlet valve opens, and fluid is drawn into the cylinder. As the piston moves back, it creates a low-pressure area that allows the fluid to enter. On the propulsion stroke, the piston moves forward, closing the inlet valve and opening the outlet valve, thereby forcing the fluid out of the pump.

This mechanism creates a reliable and strong flow of fluid, making piston pumps highly efficient in transporting various materials. Understanding how they work is essential before examining their advantages and disadvantages.

Advantages of Pumps

High Efficiency and Flow Control

One of the significant advantages of piston pumps is their high efficiency. They are capable of delivering a consistent flow rate, making them ideal for applications requiring precise fluid control. Because piston pumps can generate high pressures, they are capable of moving fluids over long distances or against significant resistance.

This efficiency is particularly beneficial in industries where accuracy and reliability are paramount, such as in chemical processing or hydraulic systems. The ability to regulate flow effectively allows operators to fine-tune operations and enhance overall productivity.

Versatility in Fluid Handling

Piston pumps are highly versatile and can handle a wide variety of fluids. This includes not only water but also more viscous and abrasive liquids. They are capable of pumping slurries, chemicals, and even pastes, making them suitable for industries such as mining, food and beverage processing, and petroleum.

This versatility allows piston pumps to function in different applications, making them indispensable in many sectors. Their ability to adapt to various fluids without compromising performance is a testament to their engineering design.

Durability and Reliability

Another advantage of piston pumps is their durability and reliability. The design of these pumps allows them to withstand high pressures and harsh operating conditions. Manufacturers construct most piston pumps from robust materials that can resist wear and corrosion, which is essential for handling abrasive materials or aggressive chemicals.

The long lifespan of piston pumps means less frequent replacements and lower maintenance costs for businesses. This durability provides peace of mind to operators who depend on their equipment to function correctly without encountering frequent failures.

Disadvantages of Pumps

Complexity of Design

Despite their many advantages, piston pumps can be more complex than other types of pumps. The many components involved in the operation, including seals, valves, and the piston itself, can lead to more parts that may need maintenance or repair.

This complexity can result in higher initial costs for purchasing and installation. Additionally, routine maintenance may require specialized knowledge, which could lead to increased labor costs. Companies need to ensure that their personnel are adequately trained to handle the specific requirements of piston pumps.

Pulsating Flow Characteristics

Piston pumps produce a pulsating flow due to the nature of their operation. Unlike centrifugal pumps that provide a smooth flow, the flow generated by piston pumps can exhibit fluctuations in pressure. This characteristic can create challenges in applications requiring a steady and uniform output.

To mitigate this pulsation, operators may need to use additional equipment, such as dampeners or reservoirs, leading to increased costs and complexity. Understanding the implications of this pulsating nature is critical for operators when integrating piston pumps with other equipment.

Limited Flow Rate Capabilities

Piston pumps are excellent for high-pressure applications, but they have limitations regarding flow rate. While they can produce high pressures, the flow rates are not as high as some other pump types, such as centrifugal pumps. This limitation can become a concern in applications with high-volume requirements.

As a result, it is crucial to assess the specific needs of your operation when considering piston pumps. In applications requiring a balanced combination of high pressure and high flow rates, alternative pump types might be more suitable.

Applications Across Various Industries

Agricultural Use

In agriculture, piston pumps are frequently used for irrigation and chemical application. These pumps enable farmers to move water from sources like rivers or lakes to fields efficiently. Their strength and durability make them ideal for handling various fertilizers and pesticides.

You can equip piston pumps with different nozzles to ensure that the right amount of fluid is applied to crops. This precision is essential for maximizing yield and minimizing waste. Many farmers rely on piston pumps for consistent and reliable performance, especially during critical growth periods.

Oil and Gas Industry

The oil and gas industry relies heavily on piston pumps for their efficiency in transferring viscous fluids. Operators utilize these pumps in drilling operations, where they move drilling mud to lubricate the drill bit and carry debris to the surface. The durability and high pressure of piston pumps make them ideal for such demanding applications.

Additionally, piston pumps are often employed in refining processes for the transfer of various oils and chemicals. Their ability to handle aggressive environments and high pressures ensures smooth and efficient operations throughout the extraction and processing stages.

Manufacturing and Industrial Applications

In manufacturing, piston pumps serve various functions, including powering hydraulic systems and transferring fluids in production lines. Their precision and ability to handle a range of materials make them valuable in production environments. From automotive shops to food processing plants, piston pumps are used extensively.

Furthermore, piston pumps are often incorporated into quality control systems. Their ability to maintain constant pressure and flow rates ensures that products meet standards and specifications. This reliability plays a critical role in maintaining quality across various manufacturing processes.

Maintenance of Piston Pumps

Regular Inspections

To keep piston pumps operating at peak efficiency, regular inspections are essential. Operators should schedule routine checks to monitor the condition of seals, valves, and the piston itself. These components are subject to wear and tear, and early detection can prevent more significant issues down the line.

During inspections, look for signs of leakage or abnormal noises, which may indicate potential problems. Taking proactive measures can significantly extend the pump’s lifespan and maintain its efficiency.

Lubrication and Cleaning

Proper lubrication is crucial for the smooth operation of piston pumps. Regularly lubricating moving parts reduces friction and wear, which can prolong the life of the pump. Manufacturers often provide specific instructions on the types of lubricants to use, so following these guidelines is essential.

Additionally, keeping piston pumps clean is vital for maintaining performance. Dust and debris can accumulate and interfere with moving parts, leading to malfunctions. Regularly cleaning the exterior and interior components can help prevent this buildup, ensuring the pump operates effectively.

Replacement of Worn Parts

Over time, certain components of piston pumps may wear out and require replacement. Seals and gaskets are particularly susceptible to degradation and may need to be changed more frequently. Staying vigilant about these components and replacing them as needed can prevent leaks and other performance issues.

Knowing the specific maintenance schedule for each type of piston pump can help operators manage the replacement of parts efficiently. Keeping a record of service and maintenance helps track when replacements are due, ensuring that the pump continues to operate smoothly.

FAQ:

1. What is a piston pump, and how does it work?

Answer: A piston pump is a type of positive displacement pump that uses a piston to create a vacuum that draws in fluid and then pushes it out with high pressure. The piston moves back and forth within a cylinder, and as it moves in one direction, it creates a negative pressure that draws fluid in through an inlet valve. When the piston moves in the opposite direction, it compresses the fluid and forces it out through an outlet valve. This action allows piston pumps to handle viscous fluids and generate high pressures, making them suitable for various applications.

2. What are the advantages of piston pumps?

Answer: The advantages of piston pumps include:

- High Pressure Capability: Piston pumps can generate very high pressures, making them suitable for applications requiring significant force.

- Versatility: They can handle a wide range of fluids, including viscous liquids, slurries, and even gases.

- Precise Flow Control: Piston pumps offer accurate flow rates and allow users to easily adjust them to meet specific application requirements.

- Durability: Constructed with robust materials, piston pumps tend to have longer service lives, especially when used in the right conditions.

- Self-Priming: Many piston pumps can start pumping without needing to be filled with liquid in advance, allowing them to self-prime.

3. What are the disadvantages of piston pumps?

Answer: The disadvantages of piston pumps include:

- Pulsation: Piston pumps may produce pulsating flow, which can necessitate additional components (like dampeners) to smooth out the output fluids and reduce pressure fluctuations.

- Maintenance Requirements: They often require more maintenance compared to centrifugal pumps due to the wear and tear on pistons, seals, and valves.

- Cost: Piston pumps can be more expensive to purchase and install than other pump types, such as centrifugal pumps.

- Limited Speed: They are typically slower than centrifugal pumps, which may not be ideal for applications requiring rapid fluid movement.

- Sensitive to Abrasives: When handling abrasive fluids, piston pumps may experience increased wear, leading to more frequent maintenance and replacement of parts.

4. In which industries are piston pumps commonly used?

Answer: Piston pumps are used in various industries, including:

- Oil and Gas: For transferring crude oil, high-pressure hydraulic fluids, and other viscous materials.

- Chemical Processing: Ideal for handling chemicals, acids, and solvents due to their ability to manage corrosive fluids.

- Food and Beverage: Commonly used in food processing and beverage production for transferring viscous liquids like syrups and pastes, with appropriate sanitary designs.

- Water Treatment: Employed in water purification and wastewater treatment processes to manage sludges and other thick materials.

- Construction and Mining: Used for applications requiring high pressure, such as hydraulic systems and transferring cement or slurries.

5. How do I choose the right piston pump for my application?

Answer: To choose the right piston pump for your application, consider the following factors:

- Fluid Characteristics: Evaluate the type of fluid you will be pumping, including viscosity, temperature, and whether it has abrasive or corrosive properties.

- Required Flow Rate: Determine the desired flow rate and pressure requirements for your application to ensure the pump meets those demands.

- Operating Environment: You should consider the environmental conditions where you will use the pump, such as temperature extremes, exposure to chemicals, and available power sources.

- Maintenance Needs: Assess your capability for maintenance and repairs, as some piston pumps may require more frequent servicing than others.

- Budget: Balance the upfront costs of the pump with its operational efficiency and maintenance costs over its expected service life.

Conclusion

Piston pumps are a vital component in various industries, providing a reliable method for transferring fluids. Their unique design and capabilities offer numerous advantages, including high efficiency, versatility, and durability. Understanding the essential role of piston pump and their impact on different applications can help industries optimize their operations.

While operators face challenges associated with piston pumps, such as maintenance complexities and pulsating flow characteristics, they can manage these issues with proper care and understanding. By regularly inspecting and maintaining piston pumps, businesses can ensure longevity and efficient performance.

Lastly, recognizing the specific needs of your industry and understanding the types of piston pumps and their uses will lead to better outcomes. From agriculture to manufacturing, piston pumps have proven to be indispensable tools for fluid management. With continued advancements in technology and materials, the future of piston pumps looks promising, offering even greater efficiency and reliability for a wide range of applications.

Leave a Reply