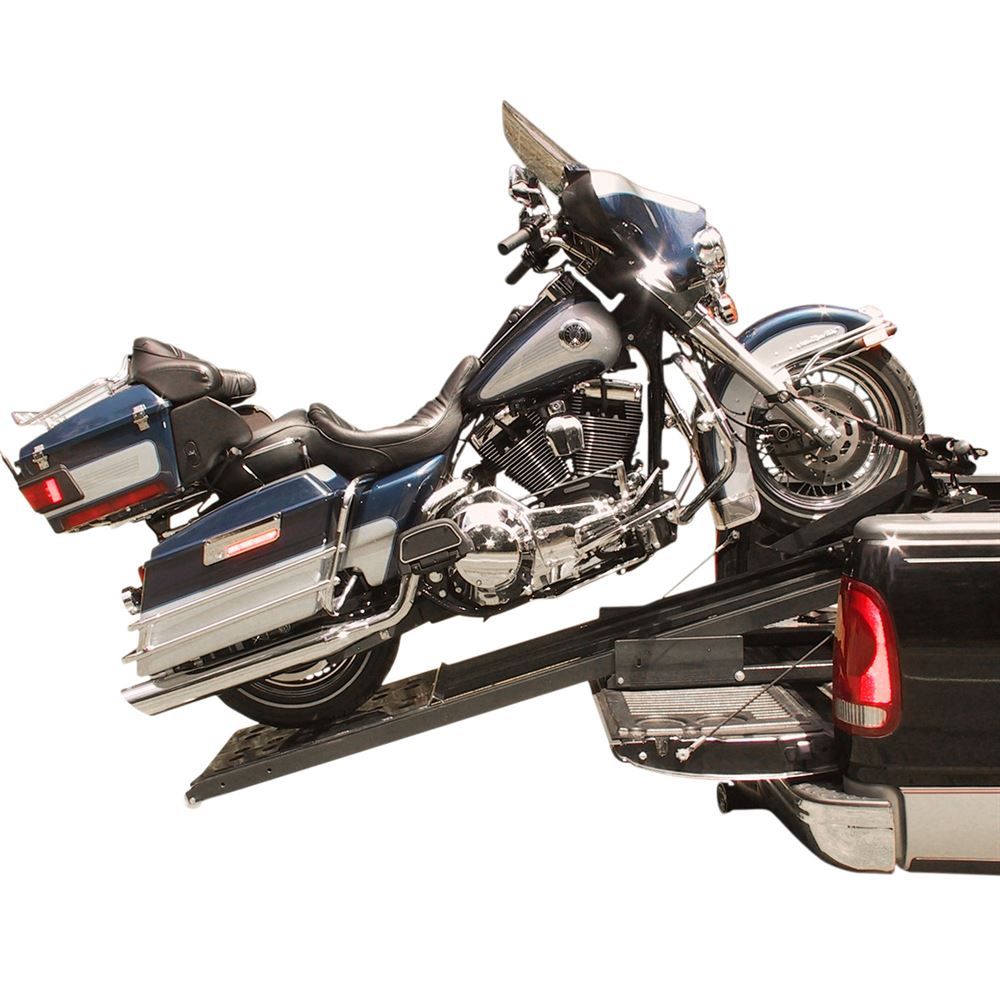

Types of Motorcycle Ramps for Trucks

Choosing the right motorcycle ramp for truck starts with understanding the types available. Each type offers distinct features designed to meet various loading needs.

Folding Ramps

Folding ramps are popular for their compact design and portability. They fold in half or multiple sections, making them easy to store in your truck. These ramps are often lightweight and built for easy handling. They’re suitable for occasional use and provide a convenient solution for those with limited storage space. Keep in mind, though, that folding ramps may have limited weight capacities compared to other options.

Arched Ramps

Arched ramps are designed to reduce the steepness of the loading incline. The arch ensures smoother transitions for your motorcycle, especially over uneven surfaces. These ramps are ideal for bikes with low ground clearance to prevent scraping. They offer excellent stability and are suitable for frequent use. The arch design also adds to their durability and strength, making them a preferred choice for heavier motorcycles.

Bi-Fold and Tri-Fold Ramps

Bi-fold ramps fold in two sections, while tri-fold ramps fold in three. This design allows for a broader loading surface, improving stability during use. Tri-fold ramps are particularly helpful for larger bikes or when loading onto taller trucks. Both ramps are compact when folded, making them easy to transport and store. They cater to users looking for versatility without compromising on strength.

Understanding these ramp types can help you make an informed decision. Each serves different needs and preferences, ensuring your motorcycle is loaded safely and efficiently.

Materials Used in Motorcycle Ramps

Understanding the materials used in motorcycle ramp for truck can help you choose the most suitable option. Each material type offers unique benefits, impacting durability, weight, and cost.

Aluminum

Aluminum is a preferred material for motorcycle ramps due to its lightweight nature. It allows for easy handling and portability, making it ideal for frequent use. Despite its light weight, aluminum ramps are strong and durable, capable of supporting significant weights. They are also resistant to rust and corrosion, ensuring long-term usability in various weather conditions. However, aluminum ramps may be more expensive compared to other materials.

Steel

Steel ramps are known for their superior strength and durability. They can handle heavier motorcycles and provide excellent stability during loading. Steel ramps are often more affordable than aluminum options, making them a popular choice for cost-conscious users. However, steel is significantly heavier, which can make handling and transport more challenging. Additionally, steel ramps are prone to rust if not properly maintained, so they require regular care.

Hybrid Materials

Hybrid ramps combine the best features of aluminum and steel. They often use steel for structural support and aluminum for other components. This blend balances strength and weight, offering a durable yet manageable solution. Hybrid ramps are efficient for those who want the benefits of both materials. They may come at a higher price point, but the combination of durability and portability justifies the cost.

Choosing the right material ensures that your motorcycle ramp performs well and lasts longer under different conditions.

Key Features to Consider When Choosing a Ramp

Selecting the best motorcycle ramp for truck requires focusing on key features. These features ensure safety, compatibility, and ease of use. Below are the most important ones to consider.

Ramp Load Capacity

A ramp’s weight capacity is crucial. It must support your motorcycle’s weight and your own. Check the manufacturer’s specifications before purchasing. Overloading a ramp can lead to damage or accidents. Always select a ramp with a higher capacity than your bike’s weight.

Ramp Length and Width

Ramp length affects the incline angle. Longer ramps offer a shallow, safer incline for loading. Width is also important for stability during loading. Wider ramps provide better support for wheels, especially for larger bikes. Consider the height of your truck when assessing ramp length.

Portability and Storage

If you plan to travel frequently, choose a ramp that’s easy to move and store. Foldable ramps, like bi-fold or tri-fold designs, are compact and portable. Lightweight ramps made of aluminum are easier to handle. Always ensure the ramp fits in your truck for easy transport.

Traction Surface and Grip

A ramp’s surface should provide excellent grip, preventing slips during loading. Look for ramps with anti-slip textures or rubberized finishes. These features enhance safety, especially in wet or muddy conditions. A secure loading experience is vital for both the rider and the motorcycle.

By focusing on these key features, you can find the perfect ramp. This ensures a smooth and safe loading process every time.

Benefits of Using a Motorcycle Ramp

Motorcycle ramps simplify truck loading and unloading tasks. They are designed for safety, convenience, and protection.

Ease of Loading and Unloading

Using a ramp makes loading and unloading motorcycles much easier. It eliminates the need to lift heavy bikes manually. With a proper ramp, you can smoothly roll your motorcycle onto your truck bed. This saves both time and energy. It’s especially helpful for larger or heavier motorcycles.

Improved Safety for Riders and Bikes

Motorcycle ramps reduce the risks associated with manual lifting. Riders can avoid injuries caused by heavy lifting or unstable loading. They also ensure that your motorcycle remains secure and balanced. Ramps with anti-slip surfaces improve stability, avoiding accidental slips during loading. Safety features like grip textures add confidence in various weather conditions.

Reduced Risk of Damage to Your Truck

Using a ramp prevents scratches or dents that can occur during motorcycle loading. Without a ramp, your truck bed may suffer damage from dragging or sudden drops. Protective ramp coatings further safeguard your truck from wear and tear. Choosing the right ramp minimizes such risks and keeps your truck in good condition.

Motorcycle ramps make loading efficient, safe, and worry-free for both riders and their trucks.

How to Calculate the Appropriate Ramp Size

Choosing the appropriate ramp size is essential for safe and efficient motorcycle loading. It ensures the incline is manageable for both the rider and the bike. Consider these factors carefully.

Factors Influencing Ramp Angle

The ramp’s angle directly impacts the ease of loading. Three key factors influence the ramp angle:

- Truck Bed Height: A taller truck bed creates a steeper incline. Measure the truck height accurately.

- Ramp Length: Longer ramps reduce the steepness of the incline. They are safer and easier to use.

- Motorcycle Type: Heavier or lower-clearance bikes require shallower inclines to prevent damage and ensure stability.

A steep ramp angle increases the risk of slips and difficulty maneuvering. Aim for a gentler angle by selecting an appropriately long ramp.

Determining the Right Length for Your Needs

To find the right ramp length, you need accurate calculations. Follow these steps:

- Measure Your Truck Bed Height: Record the height between the ground and the truck bed.

- Desired Ramp Angle: Choose an ideal ramp angle, typically between 15 to 20 degrees for safety.

- Apply a Formula: Use this formula: Ramp Length = Truck Bed Height / Tan(Ramp Angle). For example, if the truck bed height is 36 inches and the angle is 15 degrees, the ramp length would be approximately 138 inches.

By calculating the length carefully, you ensure safe loading angles tailored to your motorcycle and truck.

Understanding these factors helps you select the right ramp size. This improves loading safety and efficiency, preventing accidents or bike damage.

Maintenance Tips for Motorcycle Ramps

Proper maintenance is essential to keep your motorcycle ramp for truck in top condition. Regular care ensures safety, durability, and optimal performance.

Cleaning and Rust Prevention

- Clean After Each Use: Remove dirt, mud, and debris after every use. Use a damp cloth or mild soap for cleaning.

- Avoid Harsh Cleaners: Use non-corrosive cleaning products. Harsh chemicals can harm the ramp’s materials.

- Rustproof Steel Ramps: Apply anti-rust sprays to steel ramps for better protection. This prevents corrosion over time.

- Check for Stains or Residue: Persistent stains can weaken the ramp over time. Remove them promptly.

Regular cleaning maintains ramp appearance and functionality. Rust prevention extends its life significantly.

Inspecting for Wear and Tear

- Check Joints and Hinges: Inspect folding ramps’ hinges for wear. Tighten any loose bolts immediately.

- Examine the Surface: Look for damage to traction surfaces. Worn surfaces can reduce grip and safety.

- Inspect Weight-Bearing Sections: Over time, cracks or bends can appear. Replace the ramp if structural issues exist.

- Test Before Loading: Confirm the ramp’s stability before use. Perform regular load tests for safety.

Routine inspections prevent accidents by identifying problems early.

Proper Storage for Prolonged Durability

- Store Indoors When Possible: Keep ramps in a dry, covered area to protect from weather exposure.

- Fold Compactly: If using a folding ramp, fold it properly to save space and avoid damage.

- Use Protective Covers: Place ramps in protective bags or covers when not in use.

- Avoid Overstacking: Do not store heavy items on top of the ramp. This can cause warping.

Proper storage protects your ramp from wear and external damage. By following these maintenance tips, you can ensure the longevity and reliability of your motorcycle ramp.

Top Motorcycle Ramp Brands in the Market

When choosing a motorcycle ramp for truck, selecting from top brands ensures quality and reliability. Leading brands offer superior features, durable materials, and excellent customer support. Here’s a closer look at the highlights of top motorcycle ramp manufacturers.

Features and Services Offered by Top Brands

- High Weight Capacities: Trusted brands design ramps to handle heavy motorcycles safely and efficiently. Look for specific weight ratings.

- Premium Materials: Quality brands use materials like rust-resistant aluminum, heavy-duty steel, or hybrid combinations.

- Innovative Designs: Many top manufacturers offer folding designs, arched shapes, and tri-fold options for easy storage and use.

- Anti-Slip Surfaces: Leading brands focus on safety by adding textured or rubberized surfaces for better traction.

- Additional Accessories: Some ramps come with straps, loading mats, or carrying cases for added convenience.

- Comprehensive Warranties: Popular brands stand behind their products with warranties covering defects and performance issues.

- Customer Support: These brands often provide detailed instructions, setup videos, and helpful customer service.

User Reviews and Recommendations

- Positive Feedback on Durability: Users frequently praise ramps that endure heavy use and varied weather conditions.

- Safety and Stability Praise: Many buyers highlight how anti-slip designs and sturdy builds ensure secure loading.

- Ease of Use: Customers often favor ramps that fold easily and store compactly in their trucks.

- Value for Money: Brands offering a balance of quality and cost receive strong recommendations from users.

- Popular Choices by Motorcycle Type: Some reviews tailor ramp suggestions to specific bike models or truck heights.

By considering trusted brands and user experiences, you can ensure a smart ramp purchase. Invest in a ramp that prioritizes safety, quality, and convenience.

DIY vs. Pre-Made Ramps: Which Should You Choose?

When deciding between DIY and pre-made motorcycle ramp for truck, consider their unique benefits and drawbacks.

Pros and Cons of DIY Ramps

DIY ramps offer customization and cost savings but also come with limitations. Here’s what to consider:

Pros:

- Custom Design: Tailor the dimensions and features to fit your specific truck or motorcycle needs.

- Cost Efficiency: Building your own ramp is often cheaper than purchasing a pre-made one.

- Material Choice: Select quality materials that align with your budget and preferences.

- Learning Opportunity: Constructing a ramp helps you develop hands-on skills.

Cons:

- Safety Concerns: DIY ramps lack professional testing, increasing the risk of instability or damage.

- Material Durability: Inadequate materials may lead to quicker wear or failure under heavy use.

- Time-Consuming: Designing and building a ramp requires time and effort.

- Limited Features: DIY ramps may lack traction surfaces or folding designs found in pre-made options.

Pros and Cons of Pre-Made Ramps

Pre-made ramps are ready-to-use and professionally designed, offering convenience and reliability.

Pros:

- Safety Assurance: Professionally engineered ramps undergo testing for weight capacity and stability.

- Advanced Features: Often include grip surfaces, foldable designs, or arched shapes for easy use.

- Quick Accessibility: Purchasing a ramp saves time compared to constructing one yourself.

- Warranties and Support: Many ramps come with a warranty and customer assistance.

Cons:

- Higher Cost: Pre-made ramps can be more expensive, especially high-quality or branded models.

- Limited Customization: You may have fewer options to match specific truck or bike requirements.

- Storage Size: Some pre-made ramps might not be as compact or portable as desired.

Choosing between DIY and pre-made ramps depends on your loading needs, budget, and preferences. Evaluate these factors to make the best choice for your motorcycle ramp for trucks.

Leave a Reply