Introduction: Understanding Piston Pumps

What are Piston Pumps?

Piston pumps are a type of positive displacement pump that uses a piston to transfer fluids. They operate by moving a piston back and forth within a cylinder, creating a vacuum that draws fluid into the chamber and expelling it out on the return stroke. This mechanism allows piston pumps to generate a consistent flow of liquid, making them ideal for various industrial applications. Known for their efficiency and versatility, piston pumps can handle a wide range of fluids, including corrosive substances and high-viscosity liquids.

Importance in Various Industries

Piston pumps play a crucial role in many industries, including oil and gas, chemical processing, agriculture, and manufacturing. Their ability to handle high pressures and deliver precise flow rates makes them essential in applications that require reliability and accuracy. In agricultural sectors, for example, they are often used for irrigation and fertilizer application. In oil refineries, they facilitate the transfer of crude oil and other fluids. Understanding the applications of piston pumps helps businesses choose the right type of pump for their specific needs.

Overview of This Guide

This article provides an in-depth overview of piston pumps, detailing the different types available and their respective benefits. We will discuss factors to consider when choosing a piston pump, including system compatibility, fluid characteristics, and maintenance requirements. Additionally, we will explore various applications and technologies associated with piston pumps. By the end of this guide, you will be equipped with the knowledge necessary to select the right piston pump for your industry needs.

Types of Piston Pump

Single-Acting and Double-Acting Pumps

Piston pumps are categorized into two primary types: single-acting and double-acting. Single-acting pumps operate in such a way that the fluid is drawn in during one half of the stroke and expelled during the other half. This design is simpler and typically leads to lower manufacturing costs. In contrast, double-acting pumps enable fluid movement on both the forward and reverse strokes, resulting in a more continuous flow. Double-acting pumps are often preferred in high-demand applications because they generally offer higher efficiency and pressure capabilities.

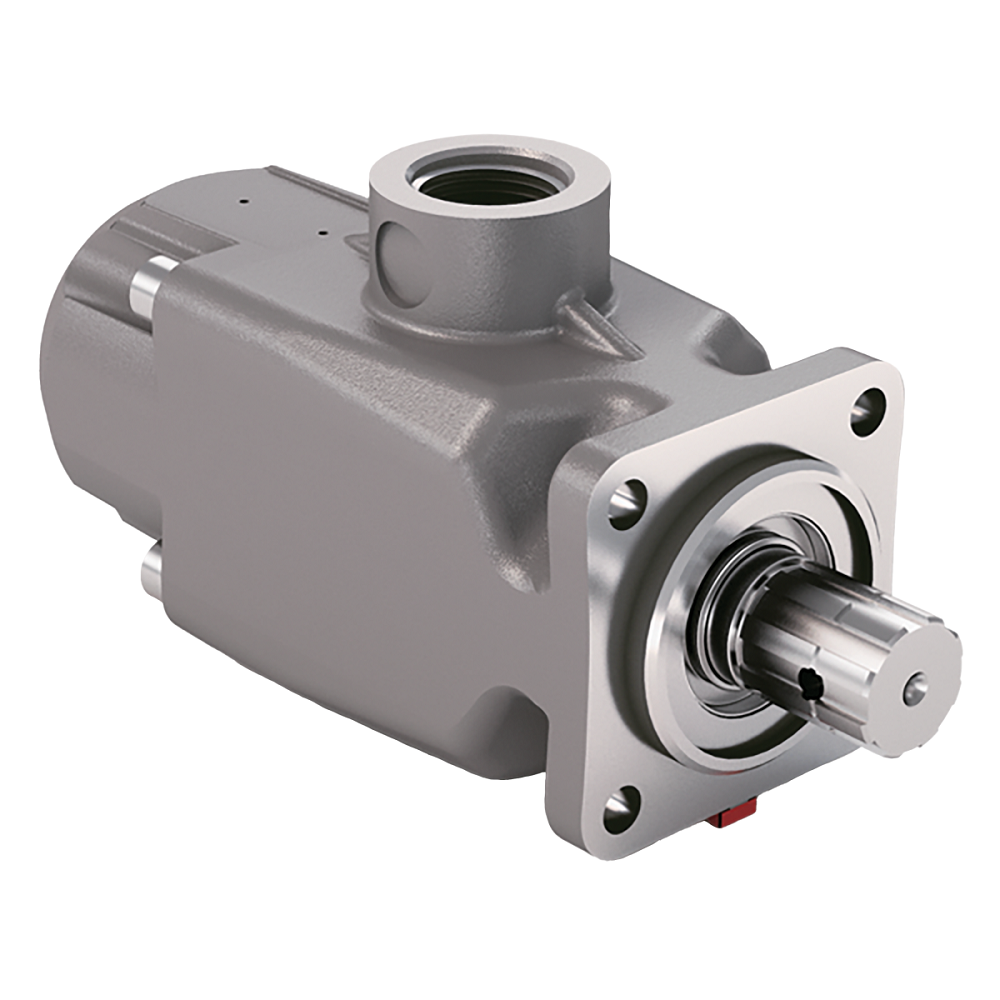

Hydraulic Piston Pumps

Hydraulic piston pumps utilize hydraulic fluid to create energy transfer. These pumps are often used in systems requiring significant force, such as hydraulic machinery and construction equipment. They can operate with a range of viscosities and deliver power in tight spaces. Hydraulic piston pumps are designed for specific pressure ratings, making them suitable for demanding applications where precision and reliability matter. Understanding their unique characteristics is vital for industries that rely on hydraulic systems for operation.

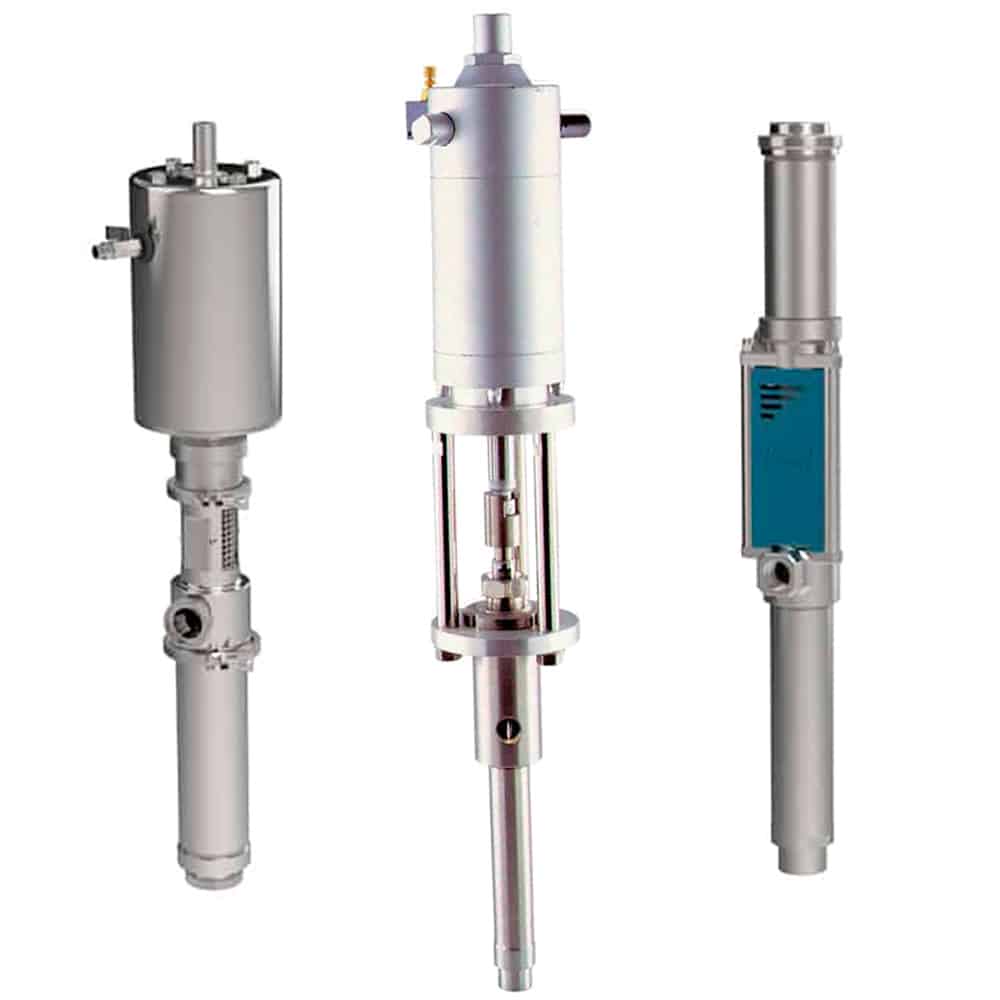

Pneumatic Piston Pumps

Pneumatic piston pumps use compressed air to drive the piston, creating fluid movement. Commonly employed in the food and beverage industry, these pumps are ideal for handling liquids sensitive to contamination. Pneumatic systems can be designed with features that maintain safe operating pressures, ensuring consistent performance without the need for complex electrical controls. The unique advantages of pneumatic piston pumps make them suitable for applications where cleanliness and efficiency are paramount.

Key Factors to Consider

Fluid Compatibility

Selecting the appropriate piston pump involves consideration of fluid compatibility. Different liquids can have varying chemical properties, affecting how they interact with the pump materials. If you’re dealing with corrosive substances, it is essential to choose a pump with materials such as stainless steel or specialized coatings. It is crucial to assess the fluid viscosity as well, ensuring that the chosen pump can handle the thickness of your liquid without compromising performance. Understanding these compatibility factors is vital for avoiding pump failure and ensuring longevity.

System Requirements

Before selecting a piston pump, it is necessary to assess your system requirements. This includes examining the desired flow rate, operating pressure, and power source availability. The flow rate determines how much fluid needs to be moved within a specific time frame. The pressure rating must correspond to your system’s demands to prevent damage or inefficiency. Additionally, consider the type of energy source available, whether it be pneumatic, hydraulic, or electric. Evaluating these system requirements will help narrow down appropriate pump options.

Maintenance Needs

Regular maintenance is crucial for the efficient operation of piston pumps. Different types of pumps may have varying maintenance needs, which should be considered during the selection process. Some pumps require regular inspections, lubrication, or part replacements, while others have more straightforward maintenance routines. Understanding the maintenance requirements of each type will help ensure that you select a pump that fits your operational capabilities. If a particular pump demands more time and resources than your team can provide, it may not be the right choice for your needs.

Applications of Piston Pump

Chemical Processing

Piston pumps are widely used in the chemical processing industry due to their ability to handle aggressive fluids. These pumps facilitate the transfer of acids, bases, and other chemicals in various manufacturing processes. Their precise flow control is essential for ensuring accurate dosing and formulation in chemical production. In chemical processing, safety and reliability are paramount, making piston pumps an ideal choice for these applications. They contribute to maintaining operational efficiencies while handling hazardous materials with care.

Oil and Gas Industry

In the oil and gas sector, piston pumps play a vital role in extracting, transporting, and processing crude oil and natural gas. These pumps enable the efficient transfer of viscous fluids through pipelines and storage systems. Hydraulic piston pumps are particularly favored for their ability to handle high pressures and substantial flow rates. The durability and reliability of piston pumps in this industry are critical, as they help maintain productivity and ensure the safety of operations in often challenging environments.

Agricultural Applications

Piston pumps are also extensively used in agriculture, particularly for irrigation and pesticide application. These pumps provide consistent pressure for effective fluid delivery across fields. Farmers appreciate the durability of piston pumps, as they can withstand various environmental conditions and heavy workloads. Additionally, the ability to adjust the flow rate enables precision in distributing fertilizers and pesticides, supporting crop health and yield. Utilizing piston pumps in agriculture enhances efficiency and contributes to sustainable farming practices.

Selecting the Right Manufacturer

Researching Reputable Brands

When purchasing a piston pump, choosing a reputable manufacturer is essential. Well-known brands like Graco, Parker Hannifin, and HydraForce have established their names by producing high-quality and reliable pumps. Researching these companies can provide insights into their product offerings, support services, and the technologies they employ. Engaging with manufacturers that have a strong reputation can lead to confidence in your purchase, ensuring that you receive a product designed to meet your specific needs.

Evaluating Customer Support

Customer support is a vital consideration when selecting a piston pump manufacturer. A brand that offers excellent customer service can make a significant difference in your experience, especially if you encounter issues or have questions about installation and operation. Look for companies that provide comprehensive resources, including manuals, troubleshooting guides, and access to technical support. Responsive customer service ensures that you receive assistance when you need it, facilitating smooth operations in your facility.

Reading Reviews and Testimonials

Reading reviews and testimonials from other users can provide additional insights into the effectiveness and reliability of different piston pumps. Often, past customers will share their experiences regarding performance, durability, and maintenance. Online forums, industry websites, and social media platforms can be rich sources for gathering feedback on specific products. Evaluating these insights will aid your decision-making process and ensure you select a piston pump that meets expectations.

Maintenance and Care

Regular Inspections

Performing regular inspections on your piston pump is a crucial aspect of maintenance. Regular checks can identify potential issues early, allowing for corrective actions before they escalate into more significant problems. Look for any signs of wear, leaks, or inconsistencies in performance. Monitoring these factors helps maintain reliability and extends the lifespan of your equipment. Keeping a maintenance log can assist in tracking inspections and upcoming maintenance tasks.

Lubrication and Cleaning

Proper lubrication is essential to ensure smooth operation and prevent wear on moving parts. Follow the manufacturer’s recommendations for lubrication frequency and type. Keeping the pump clean from dirt and debris also contributes to optimal performance. When cleaning, avoid using harsh chemicals that could damage components. A thorough cleaning routine ensures that your piston pump operates efficiently and minimizes the risk of breakdowns.

Replacement Parts

Keeping an eye on the condition of replacement parts is critical for maintaining the functionality of your piston pump. Components such as seals, hoses, and fittings may require replacement over time due to wear and tear. Familiarize yourself with the specific parts associated with your pump and their expected lifespans. Having a stock of essential replacement parts on hand can reduce downtime and ensure that your operations run smoothly.

FAQ:

- What is a piston pump?

A piston pump is a type of positive displacement pump that uses the mechanical action of pistons to move liquids or slurries. They operate by drawing fluid into a cylinder and then forcing it out, making them suitable for high-pressure applications. - What are the different types of piston pumps?

The main types of piston pumps include axial piston pumps, radial piston pumps, and diaphragm pumps. Each type has unique designs and specific applications. You commonly use axial and radial piston pumps for hydraulic systems, while you use diaphragm pumps for handling corrosive fluids. - How do I choose the right piston pump for my industry?

To choose the right piston pump, consider factors such as the type of fluid being pumped, required flow rate and pressure, the viscosity of the fluid, and the specific application. It’s also essential to evaluate compatibility with your existing systems and any regulatory requirements. - What industries commonly use piston pumps?

Industries such as oil and gas, agriculture, food and beverage, chemical processing, and construction widely use piston pumps. Many favor them for applications that require high pressure and precise fluid control. -

What are the maintenance requirements for piston pumps?

Maintenance for piston pumps typically involves regular inspection of seals and gaskets, checking for leaks, and monitoring performance to ensure efficient operation. Lubrication of moving parts and adherence to manufacturer guidelines for service intervals are also critical for longevity.

Conclusion: Maximizing Performance with Piston Pump

Emphasizing the Importance of the Right Choice

In conclusion, selecting the right piston pump for your industrial needs is vital for enhancing performance and efficiency. Understanding the different types of piston pumps and their applications will help you make an informed decision. Consider factors such as fluid compatibility, system requirements, and maintenance needs when choosing a pump. Taking the time to find the right solution can significantly impact your operations and boost productivity.

Commitment to Regular Maintenance

Regular maintenance and care are crucial for maximizing the lifespan and effectiveness of your piston pump. Prioritize regular inspections, proper lubrication, and cleaning to keep your pump in excellent condition. By being proactive about maintenance, you can avoid costly repairs and ensure that your piston pump operates efficiently. A well-maintained pump is integral to maintaining a productive work environment.

Invest in Quality and Innovation

As industries evolve, so too do the needs of their equipment. Investing in the best piston pumps for high-pressure operations and staying informed about technological advancements can position your business for long-term success. Choosing reputable manufacturers and embracing new technologies will ensure that you remain competitive within your industry. By harnessing the power and efficiency of high-quality piston pumps, you can achieve operational excellence and drive growth in your business for years to come.

Leave a Reply