Introduction: Understanding the Hydraulic Piston

What is a Hydraulic Piston?

A hydraulic piston is a crucial component in hydraulic systems, which are designed to transmit power through fluid under pressure. The piston converts fluid pressure into linear motion, allowing the machinery to perform various tasks, such as lifting heavy loads or operating complicated machinery. You use hydraulic pistons in diverse applications, including construction equipment, automotive systems, and manufacturing machinery. Understanding how hydraulic pistons work and the importance of maintenance can help optimize performance and extend their lifespan.

The Role of Hydraulic Pistons in Various Industries

Hydraulic pistons play a vital role in numerous industries, facilitating work that requires considerable force. In the construction industry, they are used in excavators, dump trucks, and forklifts to move materials and lift heavy objects. In the automotive sector, hydraulic pistons control brake systems and power steering. Manufacturing facilities depend on hydraulic systems for precision machining and assembly lines. Given their widespread use, ensuring the reliable performance of hydraulic pistons is essential for overall operational efficiency and safety.

Overview of This Guide

This guide will discuss how to maintain the performance and longevity of hydraulic pistons. We will highlight common issues, maintenance practices, and best strategies for care. Understanding these factors can greatly enhance the functionality of hydraulic systems and prolong the life of their components. By the end of this guide, you will have valuable insights into maintaining the hydraulic pistons in your machinery.

Common Issues with Hydraulic Pistons

Wear and Tear

Wear and tear is one of the most common issues faced by hydraulic pistons. Over time, the constant movement of the piston within the cylinder can lead to surface degradation. Factors such as friction, temperature fluctuations, and fluid contamination contribute to wear. Symptoms of excessive wear may include reduced efficiency, abnormal noises, or visible damage to the piston surface. Regular inspections can detect early signs of wear, allowing for timely repairs or replacements that prevent further damage to the hydraulic system.

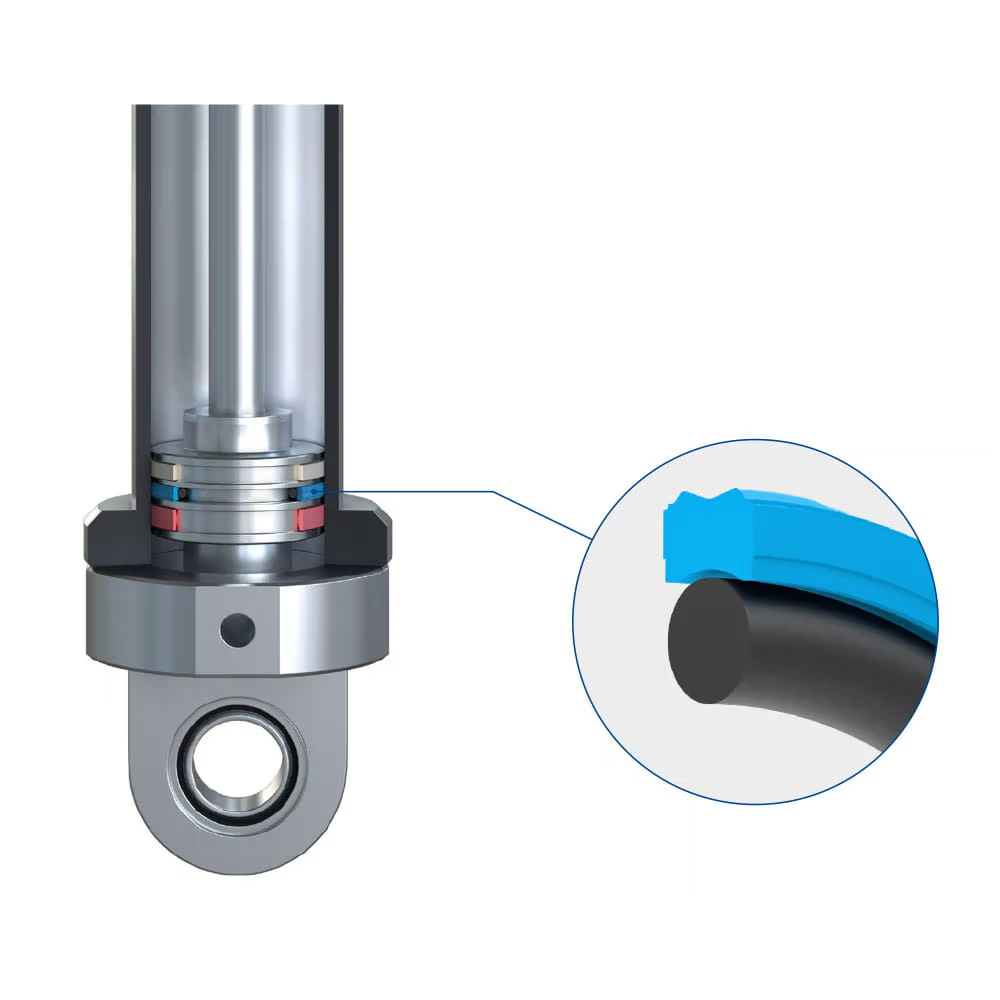

Seal Failure

Hydraulic pistons rely on seals to prevent fluid leaks and maintain pressure within the system. Seal failure can occur due to material degradation, chemical exposure, or improper installation. When seals fail, hydraulic fluid can leak out, leading to decreased performance and potential system failure. Monitoring seals for any signs of damage, such as cracking or discoloration, is critical for maintaining the integrity of the hydraulic system. Regularly replacing worn seals can prevent leaks and ensure that the system operates smoothly.

Contaminated Hydraulic Fluid

Contaminated hydraulic fluid is another issue that can severely impact hydraulic piston performance. Contaminants such as dirt, water, and metal particles can enter the hydraulic system, causing blockages and wear on the internal components. Contamination can result from poor maintenance practices, damaged seals, or inadequate filtration systems. Regular testing of hydraulic fluid quality and maintaining a clean environment can help prevent contamination. Ensuring that the fluid remains free of debris and moisture contributes to improved piston performance and a longer operational life.

Best Maintenance Practices

Routine Inspection

Routine inspection of hydraulic pistons is essential for maintaining optimal performance. Regular assessments allow you to identify any signs of wear or damage early. Check for leaks, unusual noises, or excessive movement in the piston. Inspect seals for signs of cracking or wear. Establish a maintenance schedule, ideally every few weeks or months, depending on usage. Documenting your findings during inspections helps track any changes over time, providing valuable information for future maintenance needs. A proactive approach significantly reduces the risk of serious system failures.

Lubrication

Proper lubrication is crucial for ensuring the longevity and performance of hydraulic pistons. Lubrication reduces friction between moving parts, minimizing wear and heating. The choice of lubricant is vital; always use the oil recommended by the manufacturer. Incorrect lubricants can lead to damage rather than protection. Regularly check lubricant levels, and apply lubrication as necessary to keep the moving parts operating smoothly. Regular lubrication can extend the life of hydraulic pistons and ensure they perform efficiently.

Cleaning

Keeping the hydraulic system clean contributes to the efficient operation of hydraulic pistons. Regularly clean external surfaces to remove dirt and debris, which can lead to contamination. If necessary, purge the hydraulic system to remove any accumulated contaminants, especially when changing hydraulic fluid. Cleaning filters and screens within the hydraulic system is also critical to prevent blockages. A clean system ensures smooth operation and minimizes wear on the pistons.

Understanding the Importance of Proper Fluid

Choosing the Right Hydraulic Fluid

The hydraulic fluid you choose significantly impacts the performance and longevity of the system. Selecting the right fluid involves considering factors such as viscosity, temperature range, and the specific requirements of the hydraulic system. For example, some systems may require fluids with specific additives to enhance lubrication or prevent corrosion. Using the wrong fluid can lead to failures, increased wear, and potential damage. It’s crucial to follow manufacturer recommendations to ensure that the right fluid is used for optimal performance.

Regular Fluid Checks

Maintaining appropriate hydraulic fluid levels is essential for the proper functioning of hydraulic pistons. Inspect the fluid level regularly and top off as needed. Low fluid levels can lead to increased friction and overheating, resulting in damage. Additionally, check the fluid for clarity and color. If the fluid appears cloudy, contains foreign particles, or is discolored, it may need to be replaced. Regular fluid checks help sustain system performance and extend the life of hydraulic pistons.

Fluid Replacement Schedule

Establishing a fluid replacement schedule is key to ensuring the longevity of hydraulic systems. Most hydraulic fluids should be replaced every 1,000 to 5,000 hours of operation, depending on system usage and the type of fluid. Regular replacement prevents contamination and maintains the hydraulic efficiency of the system. Keeping a log of fluid changes helps track maintenance needs and allows for better planning for future changes and assessments.

Understanding Design and Engineering Considerations

Material Selection

The materials used in hydraulic piston construction play a significant role in their performance and durability. High-quality materials such as forged steel or aluminum are preferred for piston design, ensuring they withstand high pressures and temperatures. Selecting the right materials is crucial for the intended application, as subpar materials can lead to premature wear or failure. Manufacturers should provide detailed specifications regarding material options, so it is important to take these into account when selecting hydraulic pistons.

Designing for Performance

When engineers design hydraulic systems, they must consider factors that impact the hydraulic piston’s performance. Common design features include ensuring the correct dimensional tolerances for the piston and cylinder. Attention to detail in design helps prevent issues, such as excessive clearance or tight fit that could lead to binding. Proper design ensures smooth movement and helps maintain efficiency in the hydraulic system. Collaborating with experienced engineers can significantly improve hydraulic piston performance and reliability.

Compatibility Considerations

Compatibility between hydraulic components, including pistons, fluids, and seals, is vital for optimal system operation. Using parts that are designed to work together will minimize the risks of failure and enhance efficiency. Manufacturers often provide compatibility charts or specifications to help customers make informed choices. Consulting these resources can lead to better performance and longevity for hydraulic systems.

Detecting and Addressing Performance Issues

Listening for Unusual Noises

Unusual noises during operation can indicate potential issues with hydraulic pistons. Common sounds include grinding, whirring, or rattling, which may be signs of wear, lack of lubrication, or misalignment. Operators should listen carefully for any changes in sound and take immediate action if problems are detected. Addressing performance issues early can prevent more severe damage and costly repairs down the line. Regularly communicating with operators about noise observations can help maintain equipment integrity.

Monitoring System Pressure

Monitoring hydraulic system pressure is crucial for ensuring healthy piston performance. Fluctuations or drops in pressure can indicate complications, such as leaks or blockages within the system. Using pressure gauges can provide real-time feedback about hydraulic functionality. If significant changes in pressure are observed, it is essential to conduct further investigation to identify the root cause. Ensuring the pressure remains within the recommended range will improve efficiency and extend the lifespan of hydraulic components.

Evaluating System Performance

Regular evaluations of system performance should be part of hydraulic piston maintenance. This involves assessing the overall effectiveness, the ability to handle load requirements, and checking for any sudden changes in behavior. Operators should conduct visual inspections to support performance evaluations. You can keep detailed records of evaluations to help track trends over time and create a baseline against which you can measure future performance.

FAQ:

- What is a hydraulic piston?

A hydraulic piston is a cylindrical component used in hydraulic systems to convert hydraulic pressure into linear motion. It moves up and down in a cylinder, enabling various machinery and equipment to perform tasks like lifting, pushing, or pulling. - How often should hydraulic pistons be inspected?

Hydraulic pistons should be inspected regularly, typically as part of routine maintenance schedules. Inspect for signs of wear, leaks, or damage at least quarterly or more frequently if the machinery operates in harsh conditions. - What maintenance practices can enhance the longevity of hydraulic pistons?

Key practices include regular cleaning of the piston and cylinder, ensuring proper lubrication, checking hydraulic fluid levels, monitoring for leaks, and replacing seals and gaskets as needed. Adhering to the manufacturer’s maintenance guidelines is crucial. - What are the common signs of hydraulic piston failure?

Common signs of hydraulic piston failure include decreased performance or efficiency, unusual noises (such as grinding or knocking), fluid leaks around the piston area, erratic movement, and excessive wear or scoring on the piston surface. -

How do I choose the right hydraulic fluid for my piston system?

Select hydraulic fluid based on the manufacturer’s specifications, considering factors like viscosity, temperature range, and fluid compatibility with the materials used in your piston system. Using the right fluid helps maintain performance and prevents damage.

Conclusion: Prolonging the Life of Hydraulic Pistons

Prioritizing Maintenance

In conclusion, maintaining hydraulic pistons is essential for ensuring performance and longevity. Regular inspections, proper lubrication, and careful monitoring of hydraulic fluids will greatly enhance their effectiveness. Addressing common issues quickly can prevent more significant problems that lead to costly repairs.

Invest in Quality

Investing in high-quality hydraulic pistons and components is vital for ensuring optimal performance. The right materials and designs significantly improve durability and reliability in various applications. Decisions made regarding hydraulic pistons should consider both the immediate needs and long-term implications, as poorly chosen components can lead to ongoing maintenance challenges.

Stay Informed and Proactive

Ultimately, being informed about the technology and best practices for hydraulic piston maintenance can lead to better decision-making and more effective maintenance routines. Staying proactive in addressing challenges and understanding system requirements helps create a culture of equipment care. By prioritizing these strategies, you can extend the life of your hydraulic pistons and ensure they perform reliably for years to come. Embracing responsible maintenance practices, using high-quality components, and implementing informed strategies will result in enhanced efficiency and long-term success for your hydraulic systems.

Leave a Reply