Introduction: Understanding the Piston Cylinder

What is a Piston Cylinder?

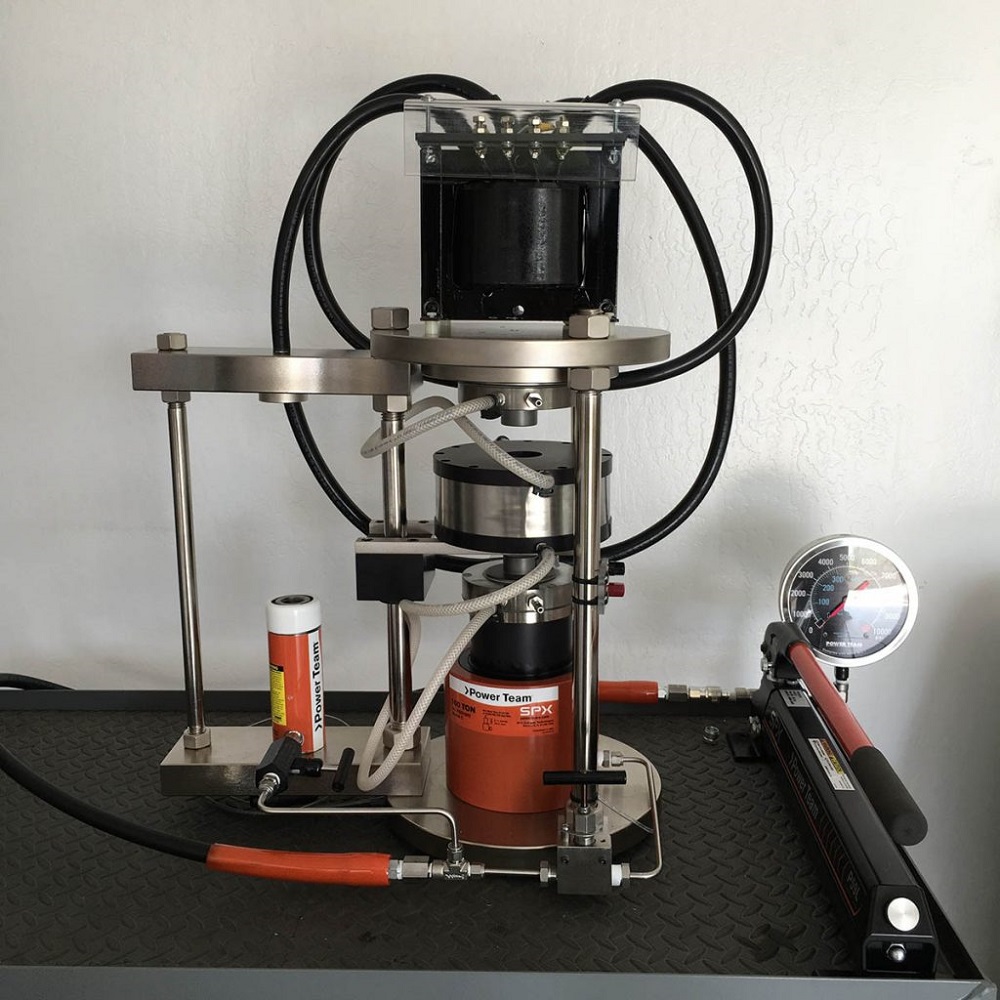

The piston cylinder is a fundamental component in various machines, particularly in internal combustion engines and hydraulic systems. It consists of a cylindrical chamber in which a piston moves up and down or back and forth, facilitating the conversion of pressure energy into mechanical energy. The efficiency and performance of engines and hydraulic systems largely depend on the design and functionality of the piston cylinder. With advancements in technology, the design of piston cylinders has evolved, leading to numerous innovations that enhance their performance and durability.

Importance of Design in Piston Cylinders

The design of the piston cylinder is critical for ensuring the efficient operation of engines and hydraulic systems. The shape, material, and sizing of the cylinder directly influence the system’s overall performance. A well-designed piston cylinder can minimize friction, reduce wear, and enhance the efficiency of power transmission. Innovations in materials and manufacturing processes have paved the way for more resilient and lightweight designs, resulting in better fuel efficiency and improved functionality. Understanding these design principles is essential for engineers and manufacturers alike.

Overview of This Guide

This article will discuss recent innovations and advances in piston cylinder design technology. We will explore various aspects, including materials, manufacturing techniques, and performance improvements. By the end of this guide, readers will gain insights into the latest trends that are shaping the future of piston cylinder technology and the impact these changes have on different industries.

Materials Used in Piston Cylinder Design

Traditional Materials

Historically, piston cylinders were predominantly made from cast iron and aluminum alloys due to their strength, durability, and relatively low cost. Cast iron offers excellent wear resistance and the ability to absorb vibrations, making it suitable for heavy-duty applications. Conversely, aluminum alloys provide lighter options that enhance fuel efficiency and reduce overall weight in automotive applications. However, as technology progresses, the focus has shifted toward more advanced materials that can offer superior performance.

Advanced Composites

Recent advancements in materials science have led to the development of composite materials for piston cylinder construction. Composites combine different materials to optimize their properties, resulting in lightweight solutions with improved strength and resistance to wear. For instance, carbon fiber-reinforced polymers (CFRP) have gained attention for their high strength-to-weight ratio and durability. These materials are particularly advantageous in racing and high-performance applications, where every ounce of weight matters.

Coatings and Surface Treatments

Innovative surface treatments and coatings have also revolutionized piston cylinder design. Hard coatings like nitriding or thermal barrier coatings can dramatically enhance wear resistance and thermal stability. These treatments minimize friction between the piston and cylinder wall, improving overall efficiency. Additionally, low-friction coatings reduce the energy lost during operation, leading to better fuel economy in engines. Understanding the benefits of these coatings can help manufacturers choose the right treatments for their specific applications.

Manufacturing Techniques

Precision Machining

Precision machining is a crucial step in manufacturing high-quality piston cylinders. This process involves cutting, drilling, and shaping materials to achieve tight tolerances and smooth finishes. Advanced CNC (Computer Numerical Control) machines allow manufacturers to produce complex designs with a high degree of accuracy. This consistency is vital in ensuring that pistons fit seamlessly within their respective cylinders, reducing wear and extending the overall lifespan of the components.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has emerged as a groundbreaking technology in piston cylinder design. This method enables the creation of complex geometries that would be challenging or impossible to achieve with traditional manufacturing techniques. By layering materials, manufacturers can produce customized components with enhanced performance characteristics. The ability to rapidly prototype and test designs using additive manufacturing is transforming the development process, allowing for more innovative piston cylinder solutions.

Automation in Production

The integration of automation into piston cylinder production has also revolutionized the industry. Automated systems streamline the manufacturing process, improving efficiency and reducing labor costs. Robotics can handle repetitive tasks with precision, freeing up skilled workers to focus on more complex duties. The use of automation not only speeds up production but also enhances quality control, ensuring that each piston cylinder meets strict standards without significant variability.

Performance Innovations

Enhanced Sealing Technologies

Sealing is crucial in piston cylinder performance, as leaks can severely affect efficiency and functionality. Recent innovations in sealing technologies have produced advanced seal designs that offer better resistance to wear and pressure. These seals can handle high temperatures and corrosive environments, ensuring long-term durability. New materials like fluorocarbon and specialty elastomers are becoming common in seal production, improving the overall performance of hydraulic and engine systems. Understanding these advancements can help manufacturers select the appropriate sealing solutions for their applications.

Improved Lubrication Systems

The lubrication of piston cylinders is essential for reducing friction and preventing wear during operation. Recent innovations have introduced advanced lubrication systems that enhance performance. These systems can include specialized oil formulations that provide better heat resistance and reduce viscosity under different operating conditions. Some designs now incorporate automatic lubrication systems that deliver precise amounts of lubricant as needed, further improving efficiency and reducing maintenance needs. This improved approach to lubrication prolongs the life of piston cylinders and enhances overall system performance.

Adaptable Performance Features

Modern piston cylinder designs often include adaptable features to meet changing operational demands. For example, variable displacement designs allow the system to adjust the volume of fluid moved by the piston based on load requirements. This adaptability improves energy efficiency and performance during varying operational conditions. The development of smart hydraulic systems incorporates sensors and control technologies that allow for real-time adjustments, optimizing performance without manual intervention. These innovations significantly enhance the versatility and efficiency of hydraulic systems across various applications.

Maintenance Considerations

Regular Inspection Routines

Conducting regular inspections is essential for maintaining the performance and longevity of piston cylinders. Operators should develop a routine inspection schedule that focuses on critical components, including seals, lubrication levels, and potential wear indicators. Visual inspections should identify any signs of leaks or damage promptly. Establishing a consistent maintenance program can catch potential issues before they escalate, saving both time and money in repairs.

Lubrication Protocols

Proper lubrication is a cornerstone of effective piston cylinder maintenance. It is vital that the correct lubricant is chosen based on the specific application and operating conditions of the piston cylinder. Regularly checking and replenishing lubricant levels ensures that friction is minimized, and the components operate smoothly. Additionally, maintaining clean lubrication by filtering out contaminants is crucial in preserving the functionality and longevity of the piston cylinder.

Repair and Replacement Practices

When issues arise, timely repair or replacement of damaged components is crucial for maintaining system integrity. Operators should be familiar with the signs of wear and know when to call for repairs. Having a reliable strategy for sourcing replacement parts is equally important. Familiarity with the manufacturer’s specifications and recommendations helps ensure compatibility and performance. Educating staff on proper handling and installation techniques can prevent further damage during repairs.

Understanding the Engineering Behind Piston

Considerations for System Design

Engineering a hydraulic or pneumatic system with piston cylinders requires careful planning and design. Factors such as load requirements and operational environments must be taken into account. Proper sizing of the piston cylinder is crucial, as under- or over-sizing can lead to inefficient operation. Collaborating with experienced engineers ensures that the system design effectively meets all operational demands while maximizing performance.

Calculating Performance Requirements

To optimize the performance of piston cylinders, engineers must accurately calculate performance requirements, including pressure ratings and fluid dynamics. This involves understanding how the piston interacts with surrounding components and the impact of heat and pressure on material performance. Using simulation tools can aid engineers in predicting behavior under various conditions, leading to better designs that meet specific requirements. Ensuring these calculations are precise helps to create reliable and effective hydraulic or pneumatic systems.

Keeping Up with Industry Standards

Compliance with industry standards is essential for the design and maintenance of piston cylinders. Various organizations set guidelines to ensure safety and efficacy in hydraulic and pneumatic applications. Familiarize yourself with relevant standards, such as those from the International Organization for Standardization (ISO) and American National Standards Institute (ANSI). Adhering to these regulations not only promotes safe practices but also enhances product quality and reliability in the marketplace.

Future Trends in Piston Cylinder Technology

Integration of Smart Technologies

The integration of smart technologies is transforming industries that utilize piston cylinders. Modern hydraulic systems often come equipped with sensors that monitor pressure, temperature, and fluid levels. This data is invaluable for optimizing performance and discovering potential issues before they lead to failures. Smart piston systems can communicate with control units to make real-time adjustments, improving operational efficiency. The future will likely see wider adoption of these technologies, leading to more responsive and efficient systems.

Sustainability Focus

As environmental concerns rise, there is a growing demand for sustainable solutions in manufacturing and engineering. Innovations in piston cylinder designs focus on reducing waste and improving energy efficiency. This includes using processes that minimize resource consumption and bio-based materials in production. Manufacturers that prioritize sustainable practices will benefit from increased consumer trust and compliance with regulatory requirements. Investing in eco-friendly materials can also eventually lead to cost savings in production.

Customization and Flexibility

The future of piston cylinder technology is leaning towards customization and flexibility. Custom designs tailored for specific applications will become increasingly common. This not only enhances performance but also allows for better integration into complex systems. Tailoring designs to fit unique operational requirements ensures that each system operates at its peak efficiency. As various industries continue to evolve, the demand for adaptable and innovative solutions will rise, reshaping how piston cylinders are utilized.

FAQ:

- What is a piston cylinder?

A piston cylinder is a mechanical component where a piston moves within a cylindrical chamber, converting pressure into linear motion. It is commonly used in engines, hydraulic systems, and pneumatic devices to facilitate the movement of fluids or gases. - What are the latest innovations in piston cylinder design?

Recent innovations include advanced materials (such as composites and coatings for durability), improved sealing technologies to reduce leakage, lightweight designs for better efficiency, and smart sensors integrated for real-time monitoring of performance and wear. - How do advancements in design technology improve piston cylinder performance?

Advancements such as computational fluid dynamics (CFD) allow for optimized shapes and flow characteristics, leading to reduced friction and wear, enhanced thermal efficiency, and improved overall performance in various applications, from automotive to industrial machinery. - What role do piston cylinders play in modern machinery?

Piston cylinders are crucial in mechanical systems, enabling efficient power generation, precise movement control, and effective fluid handling. They are used in applications ranging from engines and hydraulic pumps to industrial automation and robotics. -

How do I select the right piston cylinder for my application?

When selecting a piston cylinder, consider factors such as the required pressure and stroke length, material compatibility, environmental conditions, and specific industry standards. Consulting with manufacturers or technical experts can also provide valuable insights tailored to your needs.

Conclusion: Elevating Performance with Proper Care

Emphasizing Effective Maintenance

In conclusion, the performance and longevity of hydraulic pistons are directly influenced by effective maintenance practices. Regular inspections, proper lubrication, and timely repairs are essential for ensuring optimal functionality. Being proactive in maintenance helps avoid costly downtimes and ensures that piston cylinder operate efficiently under load.

Invest in Quality Components

Investing in high-quality piston cylinder and materials is crucial in ensuring long-term reliability and performance. The right components will significantly enhance the overall effectiveness of hydraulic and pneumatic systems. Selecting parts that are compatible with existing systems will further prevent issues down the line, optimizing performance.

Stay Informed and Adaptable

Finally, staying informed about the latest innovations in piston cylinder design for efficiency and the newest industry standards is essential for achieving success. Embracing these advancements and adapting maintenance strategies to incorporate new technologies can result in significant improvements in both performance and operational efficiency. As technologies continue to evolve and industries advance, ensuring the adaptability of your systems will keep you at the forefront of hydraulic and pneumatic engineering. By prioritizing proper care and a deep understanding of these innovations, you can maximize the benefits of well-maintained piston cylinders for years to come.

Leave a Reply