In the world of internal combustion engines, the opposed piston engine represents a unique and innovative design. Unlike conventional engines that use a single piston per cylinder, this engine uses two pistons operating in opposite directions within the same cylinder. This design fosters improved efficiency, compactness, and performance. Understanding the mechanics of the opposed piston engine reveals its potential benefits for various applications, from automotive to aerospace. In this article, we will explore the workings of the opposed piston engine, its advantages and challenges, while providing insights into its applications in modern technology.

What is an Opposed Piston Engine?

Basic Design Overview

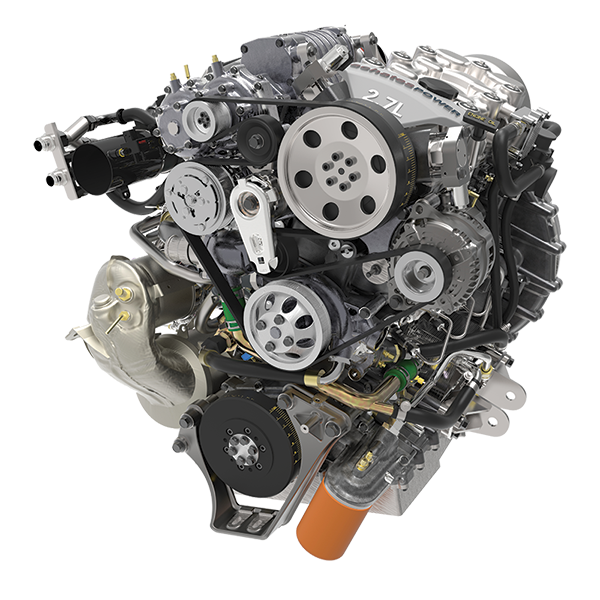

The opposed piston engine consists of two pistons located within a single cylinder, each piston moving toward the center during its respective stroke. This design does away with the need for a cylinder head, typically found in conventional engines. Instead of a head, the fuel-air mixture is introduced from the sides of the cylinder as the pistons draw inward. Each piston plays a crucial role, compressing the combustion mixture at one end while the other piston exhausts gases at the opposite end.

The concept dates back to the early 19th century, but it has become more prevalent as engine technology has advanced. The fundamental simplicity of the opposed piston design makes it a fascinating topic in the field of engineering. Manufacturers have explored the potential of this configuration for various applications over the years.

Historical Context

The origins of the opposed piston engine can be traced back to the 1880s when innovations in engine design were rapidly evolving. One of the earliest inventors to explore this configuration was German engineer Karl Benz, known for his pioneering work in the automotive industry. He recognized the advantages of using opposing pistons in reducing engine size and improving power output.

Over time, various manufacturers have attempted to refine and commercialize this engine design. Companies like Junkers and Deltic Engines became known for their successful opposed piston engines, which were used in airplanes and locomotives. This historical context illustrates how the technology has developed over time and paved the way for modern applications.

The Mechanics of Opposed Piston

The Functioning Cycle

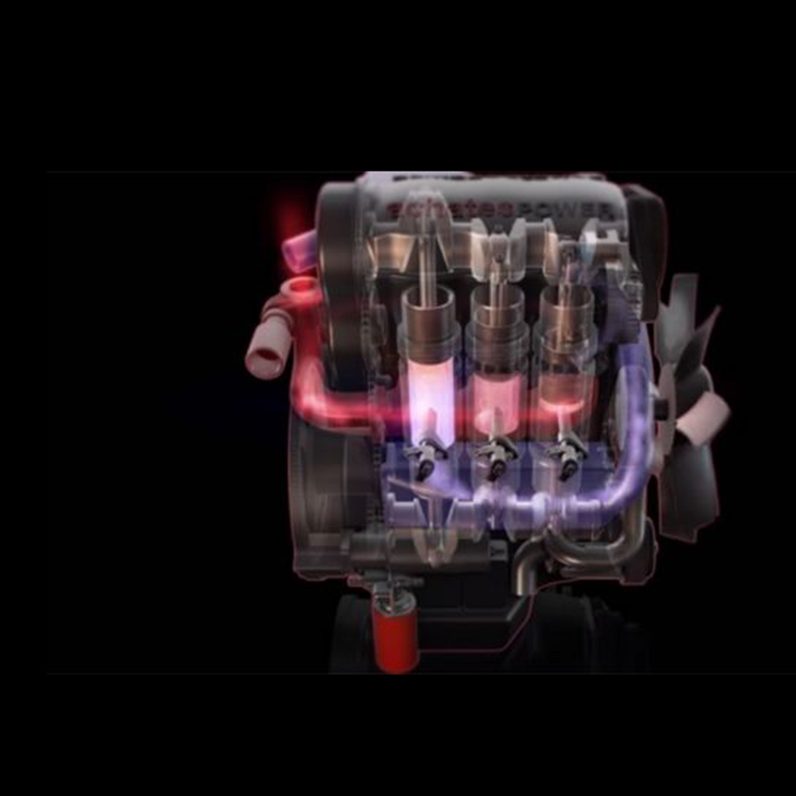

An opposed piston engine operates on a two-stroke cycle that includes intake, compression, combustion, and exhaust. The intake process begins when one piston moves down, creating a vacuum that draws a fuel-air mixture into the combustion chamber. Once the cylinder fills, both pistons begin to move upward in a synchronized manner.

As they compress the mixture, the spark plug ignites it, creating a combustion event. The force generated by the explosion drives the pistons downward. One piston experiences power while the other moves to begin the exhaust process, pushing spent gases out of the cylinder. This efficient cycle allows the engine to produce power continuously without the need for complicated valve systems found in traditional four-stroke engines.

Design Advantages

The opposed piston engine design offers several mechanical advantages. First, it eliminates the need for a cylinder head, simplifying the overall construction. This reduction in complexity can lead to lighter engine designs and fewer components that could otherwise fail. With the pistons operating in tandem, engine vibrations can be minimized, resulting in a smoother operation.

Additionally, opposed piston engines can have a higher power-to-weight ratio. Given their compact structure and efficient operation, they can produce significant power relative to their size. This characteristic is particularly desirable in applications where weight and space constraints are important, such as in aviation and automotive design.

Cooling Efficiency

Cooling is another critical factor in engine performance. Unlike conventional engines that often rely on water cooling, opposed piston engines can facilitate better thermal management. The opposing movement of the pistons creates an in-cylinder cooling effect, as the intake process introduces cooler air into the combustion chamber.

Moreover, the design allows for more effective heat dissipation due to the absence of a cylinder head that can retain heat. This enhanced cooling capability helps reduce the risk of overheating and can prolong engine life, ensuring reliable performance across various operating conditions.

Benefits of Opposed Piston

Increased Efficiency

One of the most notable benefits of opposed piston engines is their improved thermal efficiency. The two-stroke cycle can be more efficient than traditional four-stroke designs because it enables power strokes with fewer moving parts. The absence of a valvetrain system means that less energy is wasted opening and closing valves, allowing for more direct energy transfer during combustion.

Additionally, a tighter cylinder design reduces the space where combustion gases can escape, minimizing the risk of incomplete combustion. This efficiency translates directly into better fuel economy, making opposed piston engines attractive for a range of applications, particularly in areas where fuel consumption is critical.

Compact Size and Weight

The unique design of opposed piston engines leads to a more compact size compared to traditional engines with a similar power output. With fewer components, such as no intake or exhaust valves, the overall weight can be reduced significantly. This characteristic makes opposed piston engines particularly appealing for applications in aviation, where weight savings are paramount.

A lightweight yet powerful engine can offer better performance and handling, making it a desirable choice for aircraft and high-performance vehicles. The compact nature of opposed piston engines also allows for more efficient space utilization in machinery and vehicles.

Environmental Benefits

In today’s world, environmental concerns are driving the automotive and aviation sectors toward cleaner technologies. Opposed piston engines contribute to this goal through their efficient combustion processes. With higher thermal efficiency, opposed piston engines tend to produce fewer emissions compared to their traditional counterparts.

The potential for using alternative fuels, such as biofuels and hydrogen, can be integrated into the opposed piston design. Their versatility allows for adaptations that meet stricter environmental regulations, making them a viable option for future sustainable transportation solutions.

Applications of Opposed Piston

Aviation

The aviation industry has long been a key beneficiary of opposed piston engine technology. Early models found success in military and civilian aircraft due to their power-to-weight ratio. Modern advancements have led to the development of lightweight, efficient engines that meet the rigorous demands of flying. Companies like Rolls-Royce and Lycoming have explored or produced opposed piston engines for aircraft applications.

The growing demand for fuel-efficient and low-emission air travel only amplifies the interest in this engine design. With ongoing research and development, opposed piston engines are being adapted to meet the specific needs of academic and experimental aircraft, showcasing their potential in this field.

Automotive Use

While opposed piston engines are not as prevalent in the automotive market, that is changing. Several manufacturers are exploring this technology for performance and efficiency gains. Companies like Achates Power and the now-defunct Deltic have designed opposed piston engines tailored for passenger vehicles and commercial transport.

The potential for reduced emissions and fuel consumption makes opposed piston engines an attractive alternative to traditional designs. As the automotive industry continues to evolve with electric and hybrid technologies, the opportunity for innovation in traditional engine designs, including opposed piston concepts, remains open.

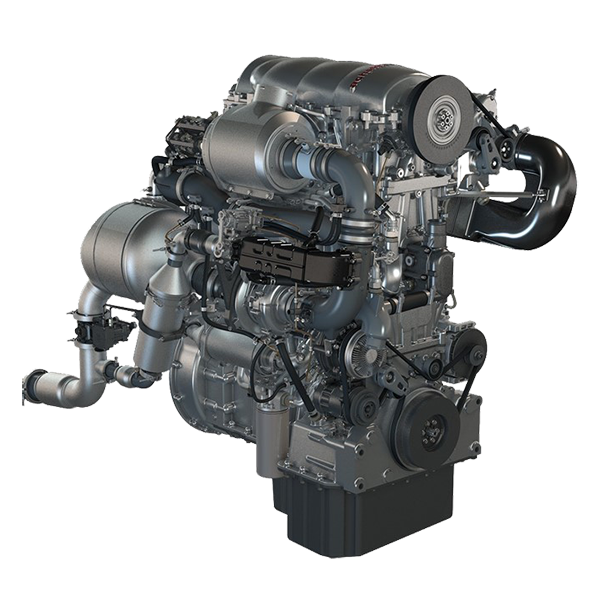

Marine Applications

Opposed piston engines are also being considered for use in marine applications. Ships and boats require efficient and reliable engines, especially for long-distance travel. The compactness and durability of opposed piston designs can translate well into marine engine systems. Their fuel efficiency can minimize operational costs and emissions, making them ideal for the eco-conscious maritime industry.

Research into integrating opposed piston engines in hybrid or electric marine systems is ongoing. By combining the efficiency of this engine design with sustainable technologies, marine transport can transition into a more environmentally friendly future.

Challenges and Considerations

Manufacturing Complexity

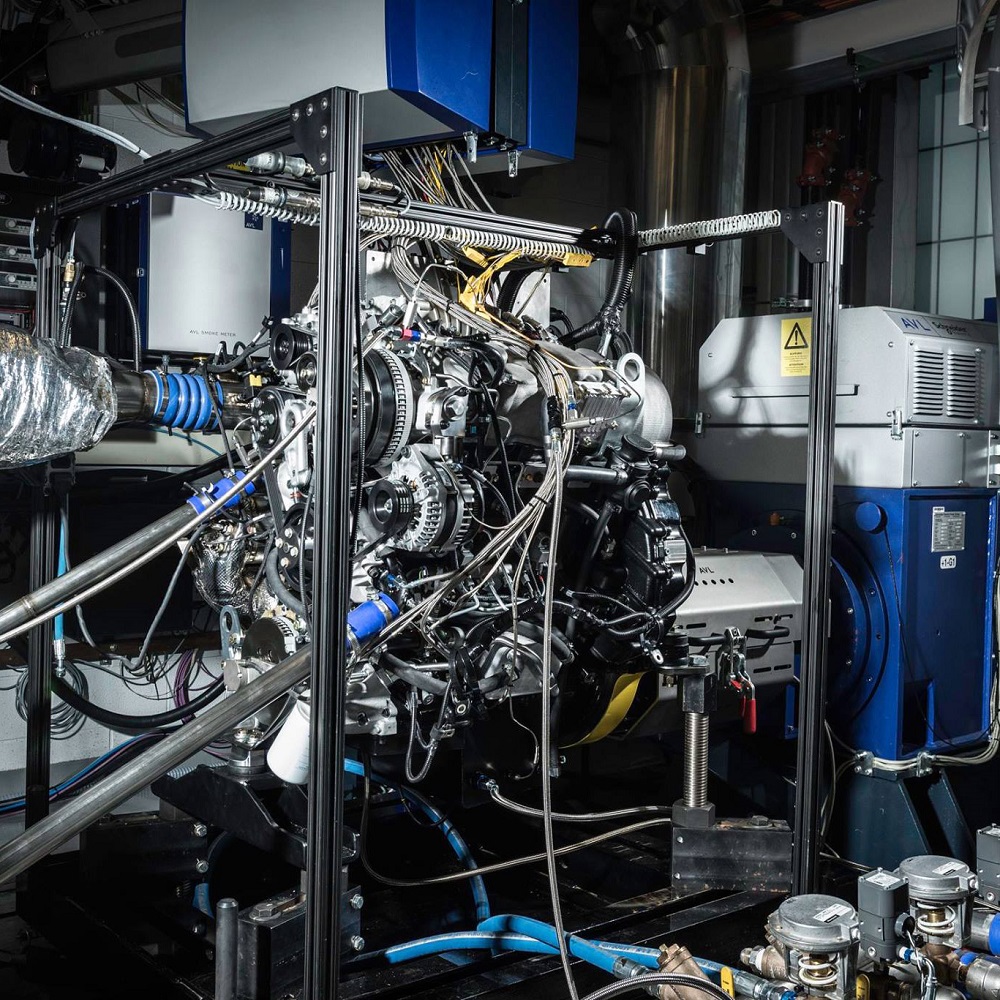

Despite their benefits, opposed piston engines face manufacturing challenges. The unique design requires precision engineering to ensure the alignment and movement of two pistons within a single cylinder. This complexity can lead to increased manufacturing costs compared to traditional engine designs. Manufacturers must invest in specialized machinery and processes that can produce these intricate components efficiently.

Maintenance Requirements

Maintenance can also be more complicated for opposed piston engines. The moving parts and unique configuration can require specialized knowledge for proper upkeep. Without the proper maintenance, the performance benefits may diminish over time. This factor could deter some consumers and manufacturers from adopting this engine design for broader use.

Market Acceptance

Market acceptance is another hurdle for opposed piston engines. Traditional engines have a long-standing history and an established presence in the automotive and aviation industries. Convincing manufacturers and consumers to transition to an alternative design requires the demonstration of clear advantages in performance, efficiency, and cost.

Engaging in successful pilot programs and public education about the benefits of opposed piston engines is crucial to increasing market acceptance. Ongoing research and case studies showcasing success in various applications can help facilitate the transition toward these innovative engines.

The Future of Opposed Piston Engines

Technological Advancements

As technology continues to advance, we can expect further refinements to opposed piston engines. Innovations in materials, such as lightweight composites and advanced alloys, can yield more efficient designs. Improved manufacturing techniques, including 3D printing, can reduce costs and enhance precision in production.

Additionally, integrating digital technologies and machine learning can optimize engine performance through real-time monitoring and adjustments. The future may hold new configurations that leverage opposed piston designs to achieve even higher efficiency and performance metrics.

Exploring Alternative Fuels

With the global push for sustainability, exploring alternative fuels is pivotal for the next generation of opposed piston engines. Hydrogen fuel cells, biofuels, and synthetic fuels can be considered for integration within this engine type. These cleaner fuel options could significantly reduce emissions while maintaining engine performance.

Research into alternative fuels must continue to ensure compatibility with current opposed piston designs. Flexible fuel systems will expand the potential applications and enhance the environmental benefits associated with opposed piston technology.

The Role in Sustainable Transportation

Opposed piston engines have the potential to play a significant role in sustainable transportation. Their adaptability to various applications and interest in alternative fuels make them a strong candidate in the quest for reduced environmental impact. As industries seek to transition toward cleaner technologies, opposed piston engines represent an innovative pathway forward.

Investing in the development of this technology supports a more sustainable future in multiple sectors, including automotive, aviation, and marine transport. Collaboration between engineers, manufacturers, and researchers will be crucial in realizing the full potential of opposed piston engines in modern society.

FAQ:

- What is an opposed piston engine?

An opposed piston engine is a type of internal combustion engine that uses two pistons per cylinder, which move in opposite directions. This design allows for efficient power generation, as it eliminates the need for conventional valves, and offers a more compact layout. - What are the main benefits of opposed piston engines?

Opposed piston engines offer several benefits, including higher thermal efficiency, reduced weight and complexity, improved fuel efficiency, and lower emissions. Their design can also lead to smoother operation due to balanced forces, resulting in less vibration. - What applications commonly use opposed piston engines?

Opposed piston engines are often used in marine applications, heavy machinery, and some military vehicles. They have also been explored for use in advanced automotive applications and in smaller, high-performance engines due to their efficiency and compactness. - How do opposed piston engines compare to traditional piston engines?

Opposed piston engines generally provide better fuel efficiency and power-to-weight ratios compared to traditional inline or V-type engines. While they are less common, their unique design allows for innovative solutions in specific applications, especially where space and weight are critical. -

What are some challenges faced by opposed piston engines?

Some challenges include the complexity of the design, the need for precise manufacturing to ensure correct alignment of the pistons, and potential wear issues due to the piston motion. Additionally, they may require more sophisticated lubrication and cooling systems to manage the unique mechanics.

Conclusion: Understanding and Embracing Innovation

In conclusion, the opposed piston engine is an innovative design that offers numerous mechanical advantages and benefits. Its unique configuration provides improvements in efficiency, compactness, and performance, making it a captivating area of study for engineers and automotive enthusiasts alike.

Understanding the mechanics, applications, and challenges associated with opposed piston engines is essential for recognizing their potential future impact. As technology continues to evolve, the opportunity to explore new configurations with sustainability in mind makes this engine design highly relevant.

With ongoing research, development, and acceptance in various industries, opposed piston engines are poised to play a crucial role in the future of transportation technology. Their fuel efficiency advantages of opposed piston engines make them an attractive solution for achieving more sustainable energy use in the automotive, aviation, and marine sectors. Embracing innovation in engine design not only drives efficiency but also paves the way for greener and more cost-effective solutions. The journey of the opposed piston engine has only just begun, promising exciting advancements and possibilities in the years to come.

Leave a Reply