In the world of manufacturing and food production, efficiency and precision are essential components of success. One product that has become increasingly popular in these industries is the piston filler. Piston fillers are versatile machines designed to dispense liquids, creams, and pastes with a high level of accuracy. Whether you’re filling jars with sauces, bottles with oils, or tubes with cosmetics, the right piston filler can streamline production and enhance product consistency. This article will explore what piston fillers are, the various types available, how to choose the right model for your business needs, and the benefits of integrating this technology into your production process.

What is a Piston Filler?

Overview of Piston Fillers

A piston filler is a filling machine that uses a piston mechanism to dispense a specific volume of product into containers. This machine operates by drawing a liquid into a cylinder through a suction stroke and then expelling it into the container during a dispensing stroke. Piston fillers are known for their precision and efficiency, which make them ideal for various industries, including food and beverage, pharmaceuticals, and cosmetics.

These machines come in different configurations, including semi-automatic and fully automatic models. While semi-automatic fillers require some level of operator intervention, fully automatic models can function independently with minimal human oversight. The choice between these types often depends on the scale of production and budget considerations.

How Piston Fillers Operate

Piston fillers operate using a simple principle: the displacement of liquid through a piston mechanism. When the piston moves back, it creates a vacuum that draws liquid from a feeding tank into the cylinder. Upon moving forward, the piston forces the liquid out through a nozzle into the chosen container.

The machine is equipped with settings to adjust the volume of liquid dispensed per cycle. This versatility allows for the filling of various container sizes and types without needing separate machines. The ability to quickly change settings is beneficial for production lines that require flexibility and adaptability.

Applications of Piston Fillers

Various sectors commonly use piston fillers due to their adaptability to different substances. Manufacturers particularly favor them for filling thicker or more viscous materials like sauces, creams, lotions, and even some solid products like pastes. The precision offered by piston fillers mitigates the risk of overfilling or underfilling and significantly improves product consistency.

In the food industry, piston fillers are used to package everything from jams and jellies to dressings and marinades. In cosmetics, they help fill tubes with creams and serums while ensuring accuracy and limiting waste. These applications demonstrate the versatility of piston fillers across multiple products and industries.

Types of Piston Fillers

Standard Piston Fillers

Standard piston fillers are the most common type found in production lines. They are straightforward in design and often made from stainless steel, making them easy to clean and maintain. These fillers can be operated manually or automatically, depending on the model.

Standard piston fillers come in various sizes to accommodate different production volumes. They can dispense a wide range of liquid viscosities, making them suitable for various products. These machines are often ideal for small to medium-sized operations that require reliability at an affordable price point.

Sanitary Piston Fillers

Sanitary piston fillers are designed specifically for use in industries that require strict hygiene standards, such as food and pharmaceuticals. These machines feature smooth surfaces, easily removable components, and specialized designs that minimize contamination risks.

Sanitary piston fillers often come equipped with features such as sterile filling nozzles and automated cleaning systems. These enhancements make them suitable for continuous use in environments where cleanliness is paramount. The initial investment may be higher, but the long-term benefits of such equipment can outweigh the costs, especially for businesses sensitive to contamination issues.

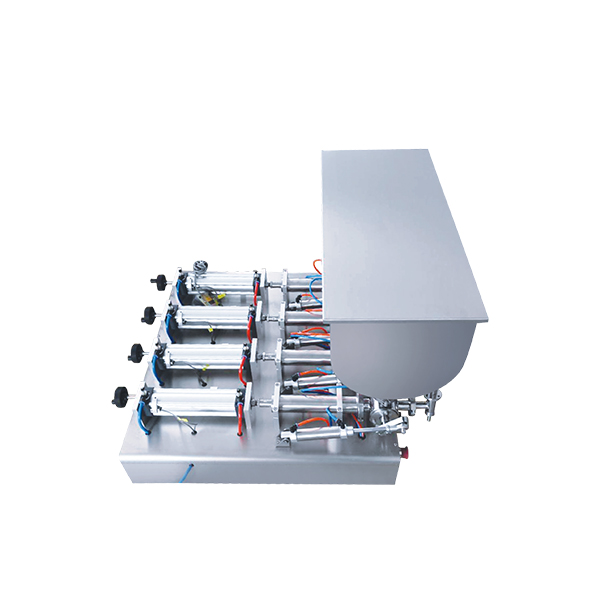

Multi-Head Piston Fillers

For large production facilities needing high-output solutions, multi-head piston fillers are the ideal choice. These machines feature multiple filling heads working in unison to fill several containers simultaneously, greatly increasing production speed and efficiency. Multi-head fillers can drastically reduce production time while maintaining the accuracy of liquid dispensation.

These machines can be customized according to the specific needs of a facility. They can handle a vast range of containers simultaneously, from small tubes to large jars. Though they come with a higher price tag, their ability to scale production makes them an excellent choice for businesses focusing on growth and efficiency.

Choosing the Right Piston

Assessing Production Needs

When selecting a piston filler, the first step is to assess your production needs. Consider the types of products you will be filling and their viscosity. For thinner liquids, a standard piston filler may suffice; however, for thicker substances, you should choose a model specifically designed to handle heavier viscosities.

Furthermore, consider your production volume. If you operate a smaller facility, a standard or semi-automatic filler might meet your needs. In contrast, larger businesses requiring extensive output may benefit from a multi-head filler. Understanding how your production needs will evolve over time is vital when making your decision.

Budget Considerations

Budget is another critical factor to consider when choosing a piston filler. While there are various options on the market, they can vary greatly in price. Set a budget that encompasses not only the initial purchase but also the long-term operational costs.

It’s essential to factor in maintenance, cleaning, and potential upgrades when setting your budget. Investing in a higher-quality machine can result in lower operational costs over time, as well as less downtime for repairs and maintenance. Don’t forget to explore financing options if needed; many manufacturers offer plans that can make purchasing ambitious models more manageable.

Space and Layout

You should also consider the space available for your piston filler. Measure the area where you plan to install the machine and ensure that you can integrate any additional equipment or conveyors seamlessly. Multi-head fillers and larger models may require more substantial real estate than smaller, manual options.

Consulting with equipment suppliers can help you maximize your layout. They can provide recommendations for configuring your production line, enhancing workflow, and ensuring that all machines work together efficiently. Making the most of your available space will positively impact your workflow, productivity, and overall efficiency.

Key Features to Simplify Operations

User-Friendly Controls

In a working environment, user-friendly controls can dramatically enhance operational efficiency. Look for piston fillers that come with intuitive control panels. Touchscreen interfaces can offer advanced programmable settings, allowing operators to adjust filling volumes and speeds easily.

Simplicity in design and operation minimizes training time for new staff and increases overall productivity. Operators who find the machine easy to use will perform their tasks more confidently and efficiently. This consideration can lead to a significant improvement in your production process.

Maintenance and Cleaning Features

Maintenance and cleaning are critical aspects of piston filler operations. The best models are designed for easy disassembly, allowing for efficient cleaning and maintenance. Look for features that enable quick access to components, minimizing downtime during routine cleaning.

Models with self-cleaning options or those that require minimal manual cleaning can significantly reduce labor costs. Ensuring that you can maintain your piston filler effortlessly will help enhance its longevity and performance, keeping your production line running smoothly.

Compatibility with Containers

Every production facility may work with various container types, so selecting a piston filler that is compatible with your packaging needs is crucial. Look for machines that offer quick-change capabilities for different container sizes and shapes. This flexibility allows you to adapt to changing production requirements without investing in additional equipment.

Many advanced models include interchangeable nozzles to accommodate numerous container types. Having this compatibility can ensure that your piston filler is a versatile piece of machinery that you can utilize across various product lines while enhancing efficiency.

Integrating Piston Fillers into Your Production Line

Assessing Existing Equipment

Before integrating a new piston filler into your production line, assess your existing equipment. Understanding how the new machine fits into your current setup will help ensure a smooth transition. Identify any necessary adjustments to ensure compatibility, including conveyor systems and other filling equipment.

Consultation with industry experts can provide insights on how to optimize your production line effectively. They can recommend changes that enhance workflow and improve efficiency when adding a new piston filler.

Training Employees

Once the piston filler is installed, training your employees to use it effectively is vital. Proper training minimizes errors, maximizes production efficiency, and helps establish safety protocols. Ensure that operators understand how to operate the machine, perform regular maintenance, and troubleshoot common issues.

Additionally, ongoing training can be beneficial, especially when introducing new employees or upgrading equipment. Keeping staff informed about the latest advancements can help streamline operations and improve productivity across your production line.

Monitoring Performance

After the pistons filler is in operation, continuous monitoring of its performance is crucial. Track metrics such as filling accuracy, speed, and downtime. Regularly reviewing this data helps identify areas for improvement, ensuring that your production line operates at peak efficiency.

Establishing performance benchmarks allows you to measure the effectiveness of your new piston filler. By maintaining open communication with operators, you can gather valuable feedback that informs future equipment decisions or adjustments to processes.

FAQ:

- What is a piston filler?

A piston filler is a type of liquid filling machine that uses a piston mechanism to dispense precise amounts of liquid or viscous materials into containers. It’s commonly used in industries such as food and beverage, cosmetics, pharmaceuticals, and chemicals for its accuracy and efficiency. - What are the key features to look for in a piston filler?

Key features to consider include fill volume accuracy, adjustable speed settings, ease of cleaning, compatibility with different container sizes, and the ability to handle various viscosities. Additionally, features such as data logging and automation capabilities can enhance efficiency. - How do I determine the right size piston filler for my needs?

To determine the right size, consider factors such as the volume of liquid to be filled per cycle, the viscosity of the product, container sizes, and the production speed required. Consulting with manufacturers or experts can help you find a model that meets those specifications. - What industries commonly use piston fillers?

Several industries widely use piston fillers, including food and beverage (sauces, dressings), cosmetics (creams, lotions), pharmaceuticals (liquids, syrups), and industrial applications (adhesives, chemicals). Their versatility allows them to handle a range of products. -

How do I maintain my piston filler?

Regular maintenance is essential for optimal performance. This includes routine cleaning of parts in contact with the product, inspecting seals and gaskets for wear, checking for clogs or blockages in pipes, and ensuring that the piston moves smoothly. Consulting the manufacturer’s maintenance guidelines is important as well.

Conclusion: Optimize Your Production with the Right Filler

In conclusion, choosing the right piston filler is a critical step toward optimizing your business’s production process. By understanding the different types of piston fillers available, their key features, and considerations for your specific needs, you can make an informed choice that aligns with your operational goals.

Integrating a piston filler into your production line can greatly enhance efficiency and product consistency. As you consider factors such as fit, compatibility, and employee training, remember that investing in high-quality equipment will pay off in the long run. Regular monitoring and maintenance will ensure that your piston filler continues to perform effectively over time.

Ultimately, choosing the right piston filler—such as affordable piston fillers for liquid and paste products—can lead to improved productivity, reduced downtime, and enhanced product quality. As you embark on this journey, embrace the advantages that modern piston filler offer and watch your production capabilities expand. Regardless of your industry, investing in an appropriate piston filler will elevate your operational success, ensuring you meet the demands of your business and customers with efficiency and precision.

Leave a Reply