Overview of Jet Engine Functionality

Jet engine parts power modern airplanes, enabling them to travel long distances quickly. Their efficiency depends on many interconnected parts working in harmony. Each component plays a critical role in producing thrust and maintaining performance.

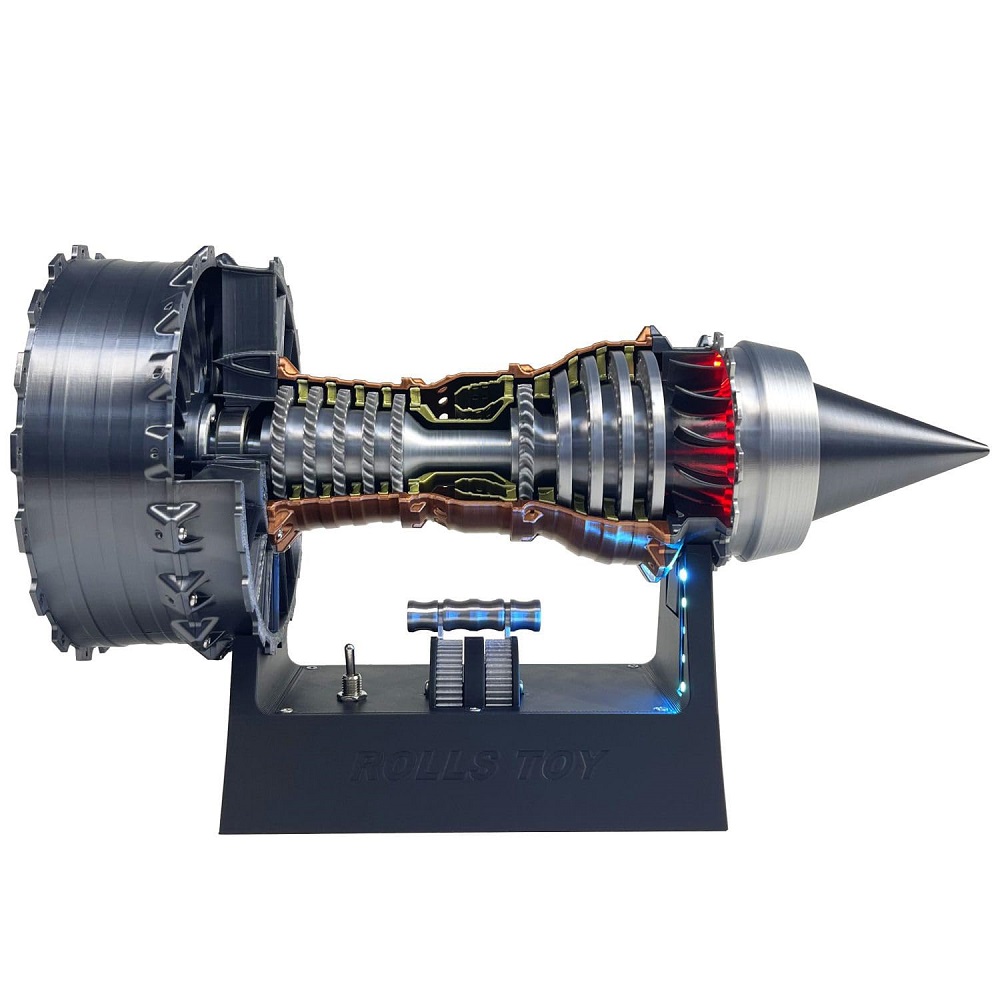

How Jet Engines Work

Jet engines function by drawing in air, compressing it, and mixing it with fuel. This mixture ignites in the combustion chamber, producing high-pressure gases. These gases exit the engine at high speed through the nozzle. This action generates thrust, propelling the aircraft forward.

The process relies on four main stages: air intake, compression, combustion, and exhaust. The compressor increases air pressure, making combustion more efficient. The turbine extracts energy from hot gases to drive the compressor. Together, these parts create a continuous cycle of energy production.

The Importance of Key Components

Every jet engine component is vital for safe and efficient operation. For example, the fan influences thrust by moving large amounts of air. The nozzle ensures the exhaust flows in the right direction for maximum propulsion. High-performance materials are used to withstand extreme heat and pressure.

Failures in parts like the turbine or compressor can disrupt engine functionality. Regular maintenance ensures that critical components remain reliable. By understanding these parts, engineers improve efficiency and safety in aviation systems.

Major Components of a Jet Engine

Jet engines are complex machines with several essential components. Each part contributes to efficiency and thrust production. Understanding these major components helps in maintaining engine performance and improving aviation technology.

Compressor: Role in Air Pressure Increase

The compressor pulls in air and increases its pressure. This process prepares air for combustion. It consists of multiple blades arranged in stages to compress air efficiently. The compressor’s role is critical to engine functionality and power generation.

Turbine: Energy Extraction and Conversion

The turbine extracts energy from high-pressure gases exiting the combustion chamber. This energy powers the compressor and other systems. Turbines must endure extreme heat and mechanical stress. They play a key role in ensuring the engine’s continuous operation.

Combustion Chamber: Fuel Ignition and Power Generation

The combustion chamber mixes compressed air with fuel, igniting the mixture to produce hot gases. These gases create pressure that drives the turbine. The combustion chamber is designed to handle intense heat and pressure safely. Its efficiency directly impacts engine thrust.

Fan: Impact on Thrust Production

The fan moves huge amounts of air to generate thrust. It also supports engine cooling. Located at the front of the engine, the fan affects fuel efficiency and overall performance. Larger fans can enhance thrust while maintaining smooth operation.

Nozzle: Directing Exhaust Flow

The nozzle controls the direction and speed of exhaust gases leaving the engine. It ensures that gases exit the engine to maximize propulsion. Nozzle design influences thrust and aircraft maneuverability. Proper nozzle calibration is essential for efficient flight.

Materials Used in Jet Engine Parts

The materials used in jet engines are critical for their efficiency and durability. Jet engines operate under extreme conditions, including high temperatures and pressures. These conditions demand specialized materials to ensure performance and safety. Engineers rely on materials that can withstand stress while maintaining lightweight properties.

High-Temperature Alloys and Their Benefits

High-temperature alloys play a vital role in jet engines. Turbines and combustion chambers face intense heat during operation. These high-temperature alloys, often called superalloys, resist deformation at elevated temperatures. Materials like nickel-based superalloys are commonly used. They offer strength and stability under extreme heat and pressure.

Superalloys also provide excellent resistance to oxidation and corrosion. This increases the lifespan of jet engine components. These materials allow turbines to function efficiently without frequent replacements. Thus, they enhance overall engine performance and reduce maintenance needs.

Lightweight Composites for Efficiency

Lightweight composites improve fuel efficiency and aircraft performance. Components like fans and airframes often use these materials. Composites like carbon-fiber-reinforced polymers combine strength with reduced weight. This helps in lowering fuel consumption while maintaining structural integrity.

Lightweight materials also reduce stress on other engine parts. This results in longer service life and better reliability. Their use supports the aerospace industry’s goal of creating eco-friendly and cost-effective engines. By balancing durability and weight, composites make modern jet engines more efficient and sustainable.

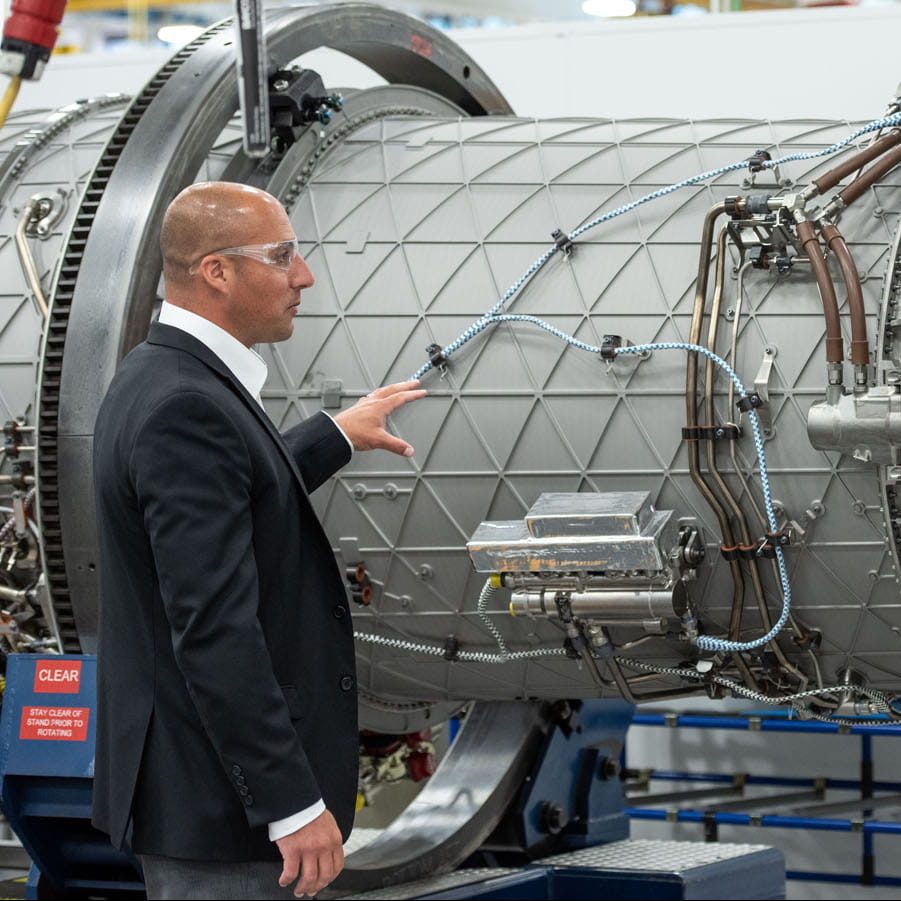

Maintenance and Durability of Jet Engine Components

Maintaining jet engine components is essential for safety, performance, and longevity. Routine care prevents unexpected failures and ensures engines perform at their best. Jet engines operate under intense conditions, so a systematic approach to maintenance is crucial.

Routine Inspection and Servicing

Routine inspections detect wear and tear early, avoiding costly repairs. Engineers check critical parts like turbines, compressors, and fans. Cleaning and lubrication are part of regular servicing to reduce friction and stress. Sensors and diagnostic tools monitor engine health for precise servicing schedules.

Temperature and pressure checks ensure materials withstand operational demands. Technicians also examine seals, bolts, and connectors. Small faults, if ignored, can lead to significant failures. Scheduled inspections increase safety and enhance engine reliability.

Life Cycle and Replacement Strategies

Every engine part has a defined life cycle. Manufacturers provide guidelines to replace components before failure. High-stress parts like turbines and combustion chambers need timely replacement due to heat exposure. Materials’ fatigue limits are critical markers for replacement.

Planned part replacements reduce downtime and prevent in-flight issues. Engineers analyze performance data to predict component wear. Investing in quality spare parts ensures durability and efficiency. Adhering to replacement schedules supports long-term engine functionality and reduces repair costs.

Innovations in Jet Engine Design and Components

Advances in jet engine technology continually enhance efficiency, safety, and performance. Engineers innovate with materials, designs, and systems to meet demanding industry needs. These innovations drive progress in aviation and support sustainable energy solutions.

Advances in Materials Technology

Modern materials are redefining jet engine capabilities. Superalloys withstand extreme temperatures and provide lasting durability. Nickel-based superalloys are used in turbines and combustion chambers for reliable high-temperature operation.

Lightweight composites improve fuel efficiency by reducing engine weight. Carbon-fiber-reinforced polymers combine strength and lightness for better performance. These materials also reduce stress on engine components, extending their life span.

Advanced coatings protect parts from oxidation, corrosion, and wear. Ceramic coatings are applied to turbine blades to enhance heat resistance. These materials ensure engines remain efficient even under harsh conditions.

Future Trends in Jet Propulsion Systems

Future jet propulsion systems aim for better efficiency and sustainability. Hybrid-electric engines combine fuel and electricity to reduce environmental impacts. These systems enhance thrust while lowering emissions.

Additive manufacturing, like 3D printing, enables complex part designs with reduced weight. This improves engine assembly and maintenance while cutting production costs.

Variable cycle engines adjust operation mode based on flight conditions. They optimize fuel use and performance at different speeds. Such systems ensure engines remain efficient during diverse operations.

Engineers are also exploring alternative fuels, such as biofuels and hydrogen. These fuels reduce carbon emissions without compromising power. The move towards green energy aligns with industry goals for eco-friendly aviation systems.

Importance of Jet Engine Components in Aviation Safety

Jet engine components are critical for ensuring the safety and reliability of aircraft. Proper functioning of these parts impacts overall engine performance and supports secure operations. Understanding their role helps prevent failures and maintain confidence in aviation systems.

Ensuring Performance and Reliability

Every component in a jet engine contributes directly to safe flight operations. Efficient compressors provide the right air pressure for combustion. Turbine blades ensure smooth conversion of gas energy into power. Reliable fans generate consistent thrust needed for aircraft movement.

Regular maintenance plays a vital role in sustaining performance. Cleaning prevents blockages, while inspections detect wear early. Servicing helps avoid malfunctions that could compromise safety. Engineers use advanced diagnostics to pinpoint potential issues and schedule timely repairs.

High-quality materials also enhance reliability. Superalloys resist heat damage, ensuring durability. Lightweight composites reduce engine stress, extending component life. These materials improve safety by minimizing risks of operational failure.

Impact of Component Failures

Component failures can have severe consequences in aviation. A damaged turbine may lead to reduced thrust and engine shutdown. Compressor issues can disrupt air pressure and combustion processes. Faulty nozzles may affect exhaust flow, impairing aircraft maneuverability.

Failures in critical parts can result in emergency situations. Pilot performance depends on engines working seamlessly during flight. Technicians address these risks through routine checks and replacement strategies. Early detection reduces downtime and prevents flight disruptions.

By maintaining jet engine parts and using advanced technologies, aviation safety is greatly improved. Every component plays a vital role in achieving reliable and secure operations.

Innovations in Jet Engine Design

1. Lightweight Materials

One of the most significant advancements in jet engine design has been the use of lightweight materials. Historically, jet engine components were constructed primarily from heavier metals like steel and aluminum. However, recent innovations have introduced high-strength composites and titanium alloys. These materials offer the same durability and performance characteristics as traditional metals, but at a considerably reduced weight.

Benefits of Weight Reduction

The reduction of weight in jet engine components leads to enhanced fuel efficiency. Lighter engines require less fuel to operate, which translates to cost savings for airlines and reduced emissions. Additionally, weight savings contribute to improved overall aircraft performance, including faster takeoff speeds and increased payload capacity. By integrating lightweight materials, manufacturers can enhance both the efficiency and effectiveness of modern jet engines.

2. Advanced Turbomachinery

Recent technology developments have also focused on advancing the turbomachinery in jet engines. The efficiency of compressors and turbines is vital to overall engine performance. With the introduction of computational fluid dynamics (CFD) simulations, engineers can optimize the shapes and configurations of blades in compressors and turbines.

Enhancing Efficiency

These advancements allow for a higher compression ratio and better airflow management, resulting in increased engine power and improved fuel efficiency. As turbomachinery becomes more efficient, jet engines can produce more thrust with less fuel consumption. This trend toward efficiency is essential in meeting both economic and environmental goals within the aviation industry.

3. Quiet Technologies

Another important area of innovation involves the development of quieter jet engines. Noise pollution around airports is a growing concern, and manufacturers are investing in technologies that minimize sound output. Noise reduction measures may include designing quieter fan blades, using advanced materials that absorb sound, and incorporating sound-attenuating designs in engine casings.

Addressing Community Concerns

The introduction of quieter engines helps alleviate community concerns surrounding noise pollution while maintaining the performance standards that airlines require. As regulations tighten surrounding noise levels, manufacturers must adapt their designs accordingly. By focusing on quiet technologies, the airline industry can enhance its relationship with surrounding communities while ensuring efficient operations.

4. Environmental Considerations

As sustainability becomes a priority for industries worldwide, the aviation sector is no exception. Jet engine manufacturers are actively working to develop engines that operate using alternative fuels and produce lower emissions. This goal includes ongoing research into sustainable aviation fuels (SAFs) derived from renewable resources.

The Path Forward

Adopting SAFs can significantly reduce the carbon footprint associated with air travel, contributing to global efforts to combat climate change. Additionally, innovations in engine design that focus on minimizing waste and improving overall efficiency can play a crucial role in creating a more sustainable aviation ecosystem. By prioritizing environmental considerations, the aviation industry aims to ensure its future while respecting the planet’s health.

Conclusion: The Future of Jet Engine Components

Adapting to Technological Advances

In conclusion, understanding the components of jet engines is essential for those involved in aviation maintenance, engineering, and enthusiasts alike. The evolution of jet engine parts has led to significant improvements in efficiency, performance, safety, and sustainability. By staying informed about ongoing innovations, we can appreciate the remarkable capabilities and advancements within the industry.

A Commitment to Safety and Performance

Safety and performance are paramount in the aviation sector, and the ongoing development of jet engine technology is vital to achieving these goals. Each component, from the fan to the exhaust nozzle, works collectively to ensure reliability and efficiency in air travel. By investing in high-quality parts and prioritizing maintenance, aviation professionals can uphold safety standards and foster exceptional performance.

Embracing Future Innovations

Looking ahead, the aviation industry will undoubtedly continue to explore advancements in jet engine technology. Emerging materials, sophisticated design methodologies, and a focus on sustainability will shape the future landscape of air travel. As engineers and manufacturers develop innovative solutions to meet the demands of an evolving world, the importance of understanding jet engine components will persist.

Inspiring Future Generations

Ultimately, educating the next generation about jet engine technology and its components can inspire future engineers and aviation professionals. With a commitment to innovation and sustainability, the future of air travel looks promising. By fostering curiosity and knowledge about jet engine parts, we can cultivate a passion for aviation and ensure a bright future for the industry. Embracing the complexities of jet engines not only enhances our understanding but also prepares us for the advancements that lie ahead.

Leave a Reply