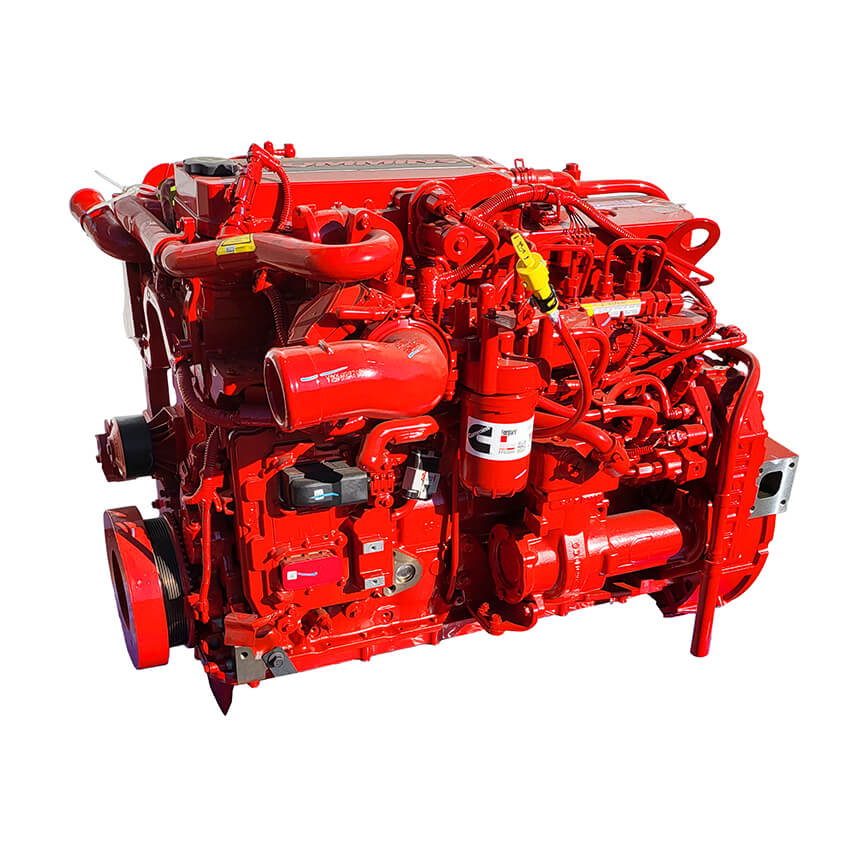

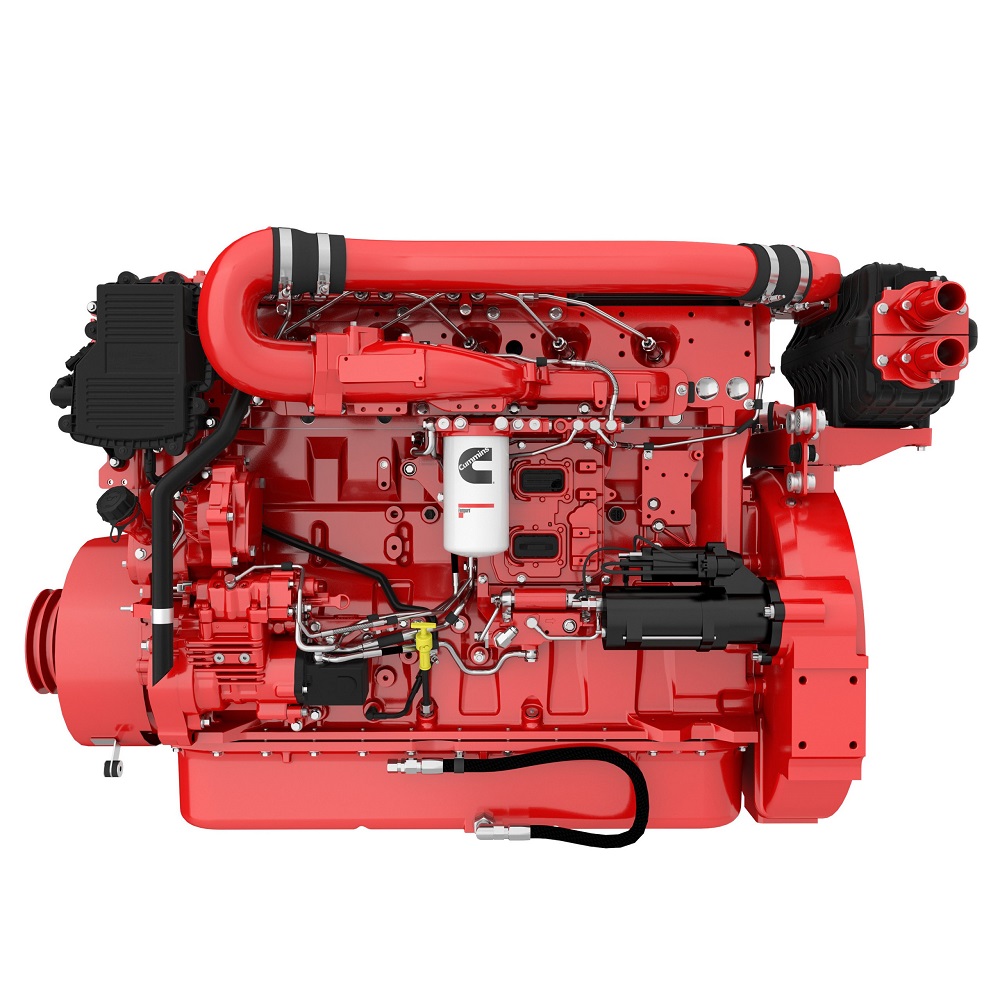

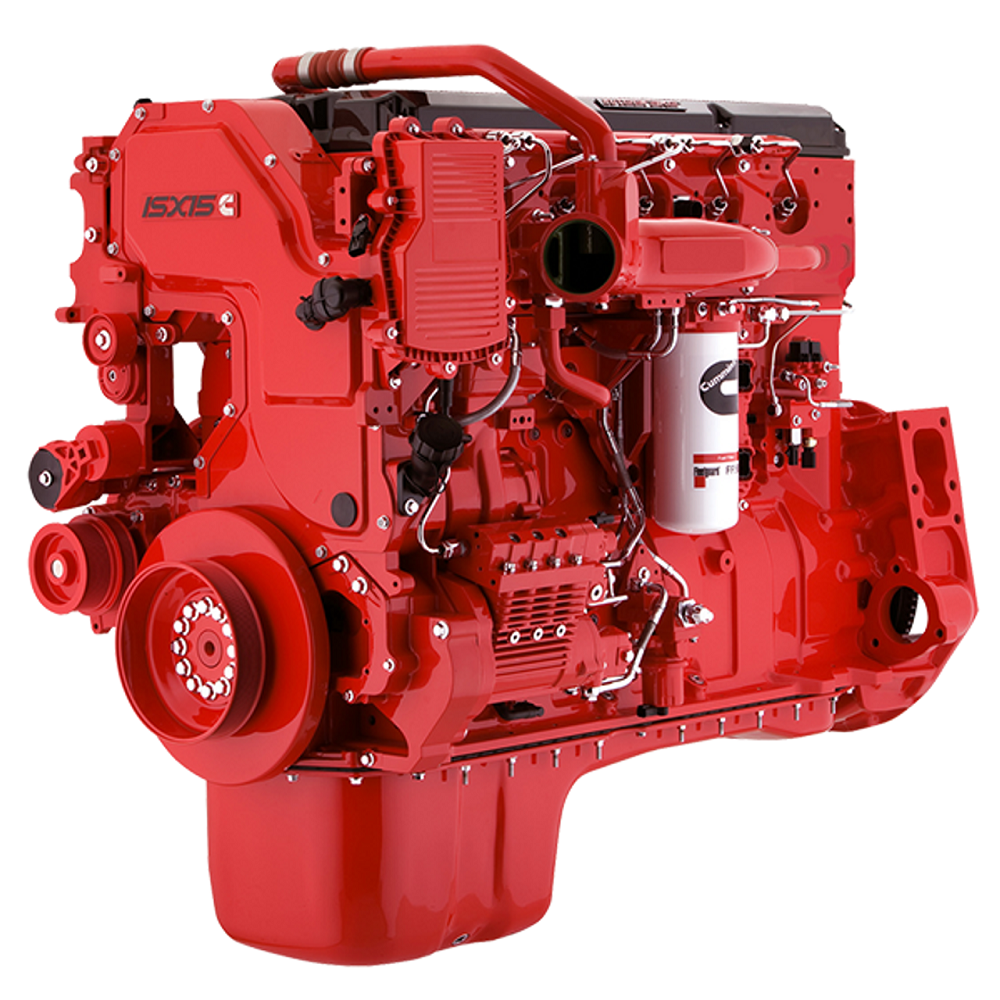

Introduction to Cummins Engine Components

Cummins engine parts are known for their durability and performance. To keep them running smoothly, understanding the various engine components is crucial. Here’s a quick overview of the main parts.

Cylinder Head: The powerhouse of the engine. It seals the top of cylinders and houses valves and injectors.

Camshaft: Controls the opening and closing of valves. It’s key in timing fuel injection and exhaust.

Crankshaft: Converts the up-and-down motion of pistons into rotational movement. Essential for engine power.

Turbocharger: Boosts engine efficiency and power by forcing more air into the combustion chamber.

Fuel Pump: Delivers diesel to the engine. Precision here ensures proper engine function.

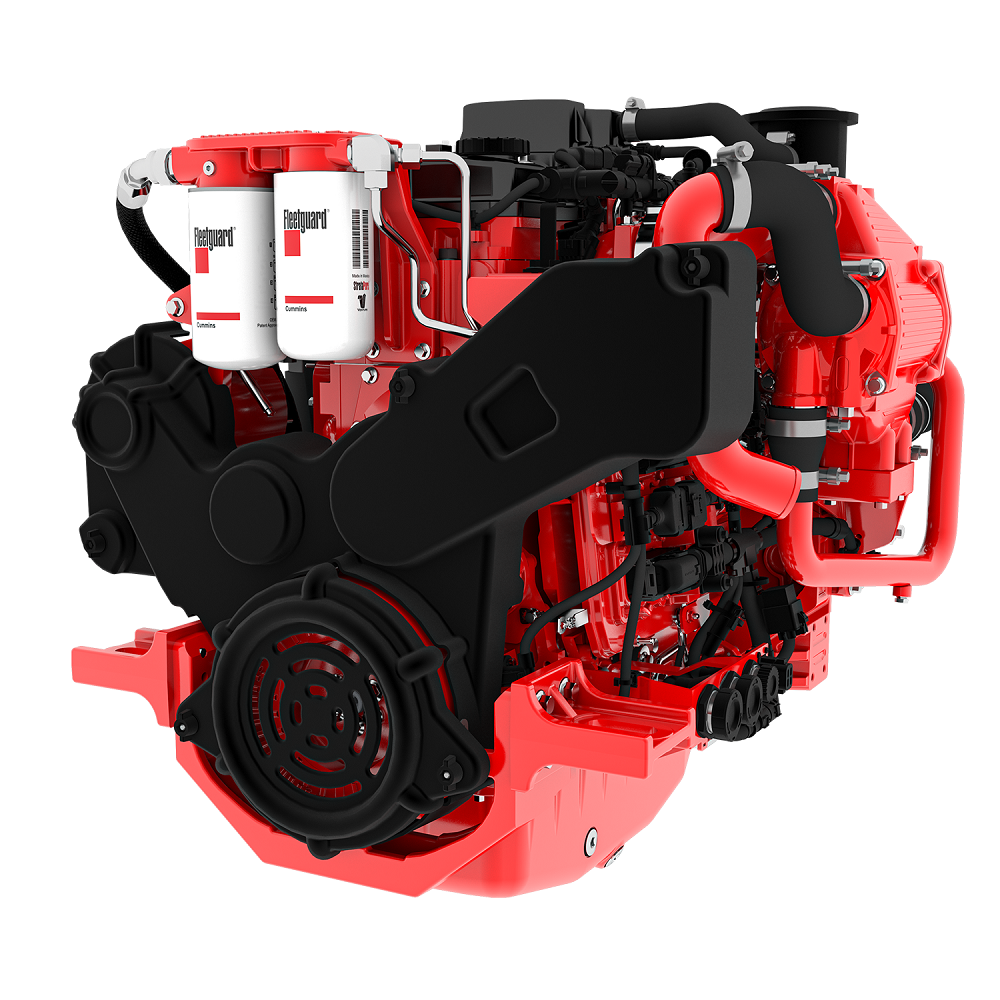

Filters: Clean oil and air are vital. Filters trap contaminants to protect engine parts.

Engine Control Module (ECM): The brain of the operation. It optimizes engine performance by managing various functions.

Knowing these components helps in diagnosing issues and performing accurate maintenance. Always use genuine Cummins engine parts for replacements to maintain the integrity and performance of your engine.

Regular Maintenance Schedules for Cummins Engines

To ensure your Cummins engine runs optimally, stick to a strict maintenance schedule. Regular checks keep the engine in prime condition and prevent breakdowns. Below is a guide to help you plan routine maintenance for your Cummins engine:

- Daily Inspections: Check oil levels, coolant levels, and look for any unusual signs of wear or leaks each day.

- Oil and Filter Changes: Change oil and oil filters at intervals recommended by the manufacturer. This is usually every 15,000 miles or 500 hours of operation.

- Fuel Filters Replacement: Replace fuel filters every other oil change to maintain clean fuel flow to the engine.

- Air Filter Service: Inspect and replace air filters as needed. A clogged air filter can lead to reduced engine performance.

- Coolant Checks: Monitor coolant condition and replace it according to the service intervals, typically around two years or 240,000 miles.

- Belt Inspections: Regularly inspect engine belts for cracks and wear. Replace as necessary to avoid unexpected failures.

Timing these maintenance activities correctly will help in extending the lifespan of your Cummins engine parts. Always record the dates and details of your maintenance tasks to keep track of the engine’s history. This record will also assist in diagnosing potential issues early. By adhering to a regular maintenance schedule, you minimize the risk of costly repairs and ensure your Cummins engine performs reliably in any situation.

Critical Cummins Parts to Monitor

Monitoring specific Cummins engine parts helps prevent major issues. Here are critical components to keep an eye on:

- Cylinder Head: Check for cracks. Look for coolant in the oil, which signals a leak.

- Camshaft: Inspect for wear. Ensure the timing of valves and fuel injection is precise.

- Crankshaft: Watch out for vibration. Check bearings for any signs of wear.

- Turbocharger: Listen for unusual noises. Observe performance for indications of issues.

- Fuel Pump: Monitor pressure. Check for fuel delivery consistency.

- Filters: Replace oil and air filters regularly. Dirty filters impact engine health.

- ECM: Look for error codes. Check software updates to ensure optimum performance.

Frequent checks of these Cummins engine parts help you catch problems early. This can save you from costly repairs in the future. Always prioritize maintenance to ensure long-lasting engine reliability.

Replacing Filters and Fluids in Cummins Engines

When caring for Cummins engine parts, replacing filters and fluids is key. This simple task can lead to better performance and a longer engine life. Here’s what to keep in mind:

- Oil Filters: Change them during oil changes. A clean oil filter means a cleaner engine.

- Fuel Filters: Every other oil change, put in a new fuel filter. This helps keep the fuel system clean.

- Air Filters: Check them often and replace when dirty. Clogged air filters can hurt engine power.

- Coolant: Replace it as the manual says, around every two years. Fresh coolant keeps the engine at the right temperature.

- Transmission Fluid: Not always noticed, but important. Change it according to your service schedule to prevent transmission issues.

- Power Steering Fluid: Check it often and top up as needed. It helps your steering stay smooth and responsive.

Always choose high-quality fluids and genuine Cummins engine parts for the best results. Using the right products protects your engine and keeps it running strong. Keep track of when you replace filters and fluids. This makes it easier to follow a maintenance schedule. This is one of the simplest ways to ensure your Cummins engine performs well over time.

Troubleshooting Common Issues with Cummins Parts

When you encounter problems with Cummins engine parts, knowing how to troubleshoot can save time and money. Here are common issues and how to fix them:

- Hard Starting or Failure to Start: Check battery voltage first. If the battery is fine, inspect the fuel system. This includes the fuel pump and injectors.

- Overheating Engine: Ensure that there’s enough coolant. Also, inspect the radiator, hoses, and thermostat. Cooling system blockages can cause overheating.

- Loss of Power: Look at air filters first. If they’re clean, consider the fuel filters and fuel quality. Poor fuel quality often results in power loss.

- Excessive Smoke: Identify the smoke’s color. Black smoke suggests too much fuel or not enough air. Blue smoke could mean oil is burning, while white smoke often comes from wrong fuel timing or low cylinder compression. Addressing these can reduce smoke output.

- Noise or Vibration: These usually come from the crankshaft or bearings. Inspect them for wear or damage. Make sure to fix any issues immediately.

- Oil Leaks: Identify the source of the leak. It might be as simple as tightening a bolt or as complex as replacing a seal. Keep oil levels in check.

- ECM Errors: If the ECM shows error codes, run diagnostics. Software updates or recalibration may be necessary.

Always refer to the Cummins manual for detailed troubleshooting steps. For persistent problems, consult a professional mechanic. Using genuine Cummins engine parts for repairs ensures compatibility and reliability.

The Importance of Using Genuine Cummins Parts for Repairs

When it comes to repairs, choosing genuine Cummins engine parts is essential. These parts ensure your engine runs as designed. They also uphold your vehicle’s warranty and maintain its value over time. Here’s why you should always opt for genuine parts:

- Guaranteed Compatibility: Genuine parts are made for your specific Cummins engine model. This means they fit and function perfectly. There’s no risk of parts not working right.

- Quality Assurance: Cummins parts undergo strict quality checks. This guarantees they meet high standards. You can trust these parts to last and perform well.

- Warranty Protection: Using genuine parts keeps your warranty valid. If you use non-Cummins parts, you might lose this protection.

- Better Resale Value: An engine maintained with genuine parts has higher value. If you decide to sell, you can ask for a better price.

- Support from Cummins: When you buy genuine, you get support from Cummins. They can help with fitting parts and solving problems.

- Reduced Risk of Failure: Non-genuine parts may not last as long. They can fail and damage your engine. Genuine parts reduce this risk.

In short, while non-genuine parts might be cheaper, they often come with risks. Investing in genuine Cummins engine parts is wiser for long-term engine health.

Upgrading Cummins Engine Parts for Better Performance

Optimizing the performance of your Cummins engine often involves upgrading specific parts. Here’s what you can consider for enhanced efficiency and power:

- Performance Tuners: Install a tuner to adjust engine settings. This improves horsepower and torque.

- High-Flow Air Intake System: A larger air intake allows more air into the engine. It boosts power and acceleration.

- Exhaust System Upgrades: Upgrade the exhaust for better airflow. This can increase fuel efficiency and performance.

- Upgraded Turbocharger: A more efficient turbocharger can provide more boost. This gives your engine extra power when needed.

- Bigger Injectors: Larger fuel injectors can improve fuel delivery. This upgrade offers better combustion and performance.

- Enhanced ECM Programming: Get the ECM reprogrammed for optimal engine output. This can sharpen throttle response and efficiency.

Choose upgrades that fit your needs and comply with regulations. Always use genuine Cummins engine parts for these upgrades to ensure compatibility. Seek expert advice if unsure about the best upgrades for your engine. Properly selected and installed upgrades can substantially improve your Cummins engine’s power and reliability over time.

Tips for Extending the Life of Your Cummins Engine

Regular maintenance ensures your Cummins engine parts work well for a long time. Here are additional tips to help you get the most out of your engine:

- Perform Regular Inspections: Check your engine often for signs of wear or damage. Catching issues early saves time and money.

- Use High-Quality Fuel: Clean, high-grade diesel fuel keeps the engine running smooth. It reduces wear on engine parts.

- Avoid Short Trips: Short trips can cause buildup in the engine. Try to use your vehicle for longer runs when possible.

- Warm Up the Engine: Before driving off, let the engine idle for a few minutes. This helps the oil circulate and protects engine parts.

- Drive Conservatively: Avoid rapid acceleration and hard braking. Smooth driving reduces stress on engine components.

- Use Correct Oil Grade: Always use the oil type recommended by Cummins. The right oil maintains engine lubrication and performance.

- Maintain Cooling System: Keep the coolant system clean. A well-maintained radiator and hoses keep engine temperature stable.

- Tackle Repairs Promptly: If you find an issue, fix it right away. Delaying repairs can lead to more damage.

- Keep Service Records: Document all maintenance and repairs. This helps with future troubleshooting and adds value to your vehicle.

Following these steps, along with using genuine Cummins engine parts, will help extend the engine’s life. A well-cared-for engine delivers reliable service and upholds its value over the years.

The Role of Technology in Maintenance

Utilizing Diagnostic Tools

Modern Cummins engines are equipped with advanced technology that makes maintenance more efficient. Diagnostic tools, such as onboard diagnostic systems, can provide real-time data about engine performance and identify potential issues before they become serious. These tools can quickly pinpoint problems such as fuel inefficiencies, overheating, or component malfunctions.

Benefits of Using Technology

Using diagnostic tools aids in preventive maintenance, allowing owners to address minor issues early. Instead of waiting for warning signs or breakdowns, these tools can alert you when something needs attention. Many motorcycle enthusiasts now incorporate technology into their maintenance routines, using apps and diagnostic devices to monitor engine health and performance on the go. This proactive approach contributes to better maintenance practices and enhances the overall riding experience.

Researching Latest Innovations

As engine technologies continue to evolve, it’s essential to keep up with the latest innovations in the field. Cummins frequently develops and introduces new technologies that improve performance, efficiency, and emissions control. For instance, advancements in fuel injection systems or turbocharging can significantly enhance engine output and reliability.

Staying Informed

Riders should take the time to research updates and innovations from Cummins. Engaging with forums, attending trade shows, and reading industry publications can help you gain insights into the latest trends. By staying informed about technological advancements, riders can make better decisions regarding their maintenance practices and equipment, ensuring the longevity and reliability of their engines.

Community Engagement in Maintenance Practices

Joining Local Riding Clubs

Being a part of a local riding club or organization can enhance your motorcycling experience. Many clubs focus on the shared commitment to safety and maintenance. These communities often provide valuable resources, including advice on maintenance and recommendations for trusted mechanics. Club members can share their distinct insights from personal experiences, leading to stronger riding skills and better engine care.

Collaborating with Other Riders

Attending events organized by these clubs presents additional opportunities for learning and growth. Workshops on engine maintenance, inspections, and repairs can be valuable avenues for enhancing your skills. This collaboration fosters a supportive environment where riders can exchange tips, tools, and resources that elevate maintenance practices.

Promoting Safe Riding Practices

Being involved in a motorcycle community facilitates a culture of safety, encouraging riders to prioritize preventative maintenance. By sharing knowledge about engine care and best practices, enthusiasts can collectively raise awareness about the importance of maintenance and safety. As members work together in promoting safe riding habits, they also enhance the overall riding experience for everyone involved.

Conclusion: Embracing Proactive Care for your Cummins Engine

A Final Reminder on Maintenance

In summary, proactively maintaining your Cummins engine is vital for ensuring its durability, performance, and longevity. Utilizing diagnostic tools, staying updated on innovations, and engaging with the community can significantly enhance your maintenance efforts. Each of these practices contributes to a well-functioning engine that serves you well on the open road.

The Rewards of Proper Maintenance

Ultimately, the effort you put into maintaining your Cummins engine parts will pay off in reliability and performance. With a commitment to regular inspections and proper care, you can enjoy countless adventures without worrying about unexpected breakages. The peace of mind that comes from knowing your engine is in top condition allows you to focus on what truly matters: the joy of riding.

Invest in Your Journey Ahead

As you look toward your next adventure, prioritize the health of your motorcycle. Taking the time to understand the components, utilize technology, and engage with fellow riders will make a significant difference. A well-maintained Cummins engine is not just a practical necessity; it represents freedom, exploration, and the thrill of the ride. Embrace each journey confidently, knowing you’ve invested in the mechanical heart of your motorcycle!

Leave a Reply