What Are Engine Cylinders?

Engine cylinder is essential components of any internal combustion engine. They provide the chamber where the fuel burns and energy is generated. Cylinders directly affect an engine’s performance, fuel efficiency, and power output. Understanding their design and function is crucial for anyone interested in vehicles or mechanical systems.

Definition and Purpose of Engine Cylinders

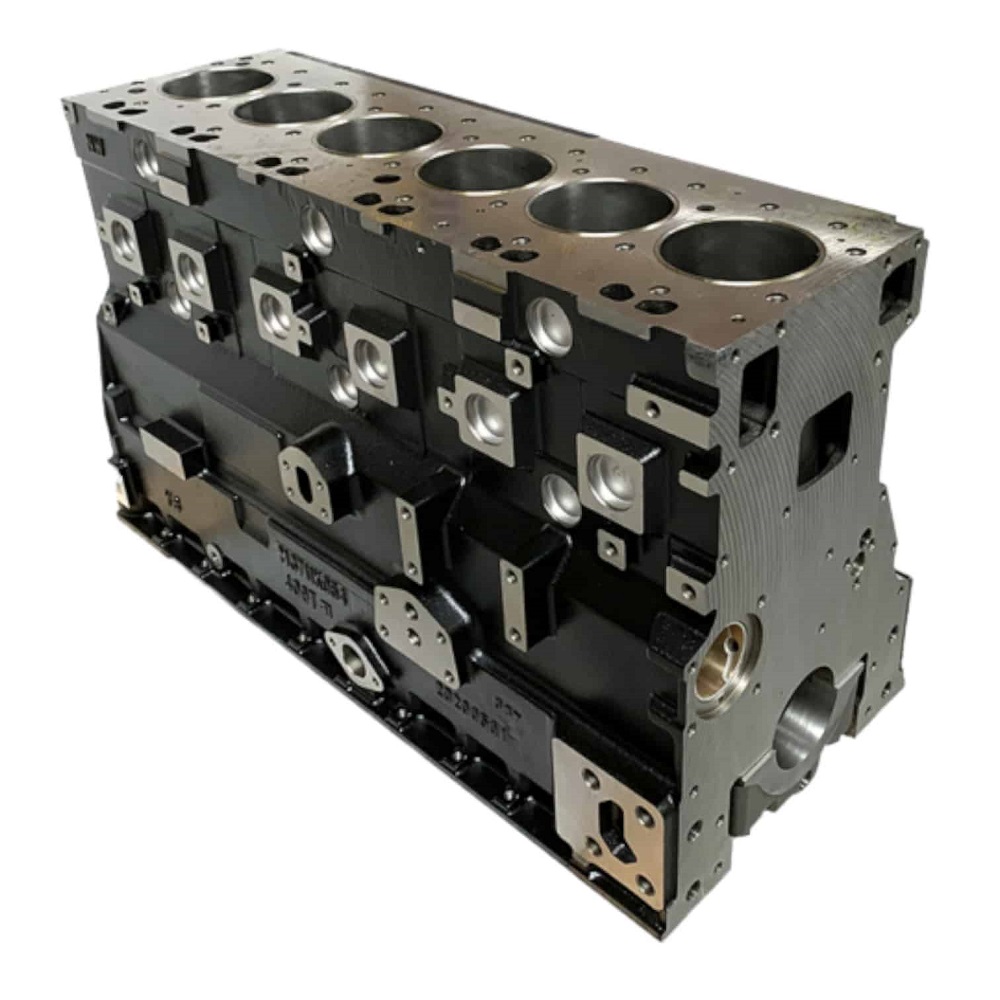

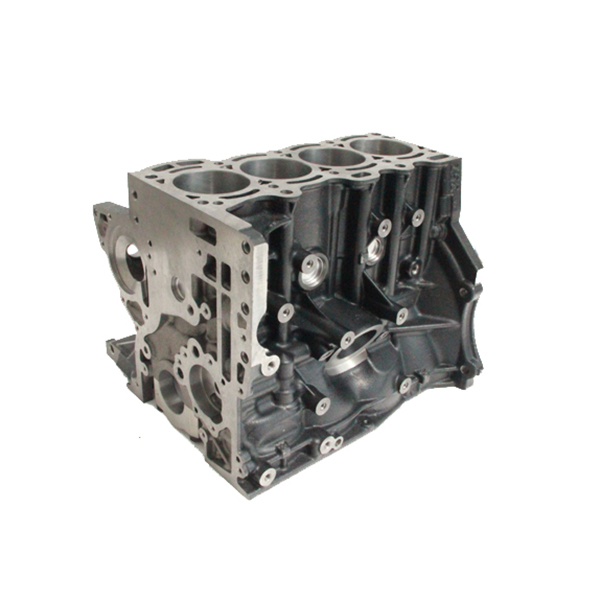

Engine cylinders are hollow spaces within the engine block that house pistons. They guide piston movement and facilitate combustion. The primary purpose of a cylinder is to convert chemical energy from fuel into mechanical energy. This mechanical energy powers the vehicle’s movement. Without cylinders, the combustion process cannot take place efficiently.

Key Components of an Engine Cylinder

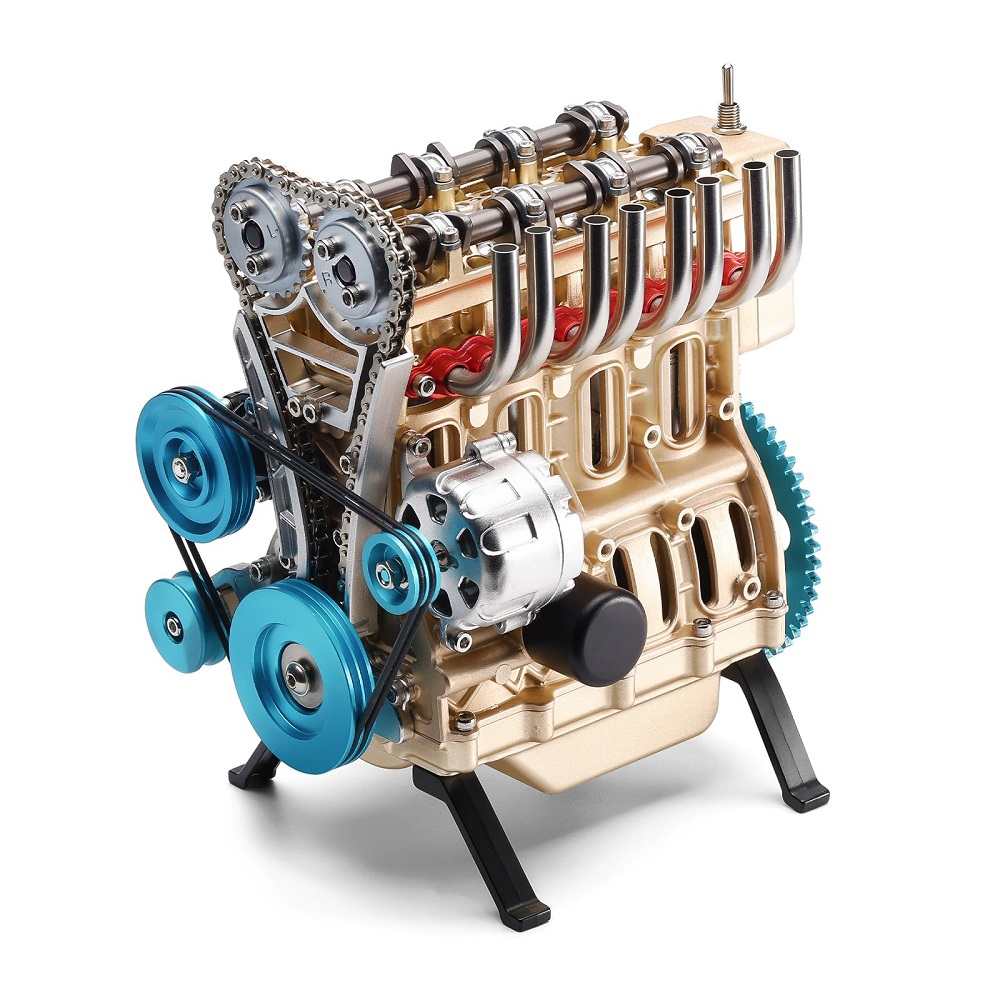

Engine cylinders consist of several critical parts that work in harmony:

- Cylinder Wall: Forms the chamber’s structure and withstands high pressure and temperature during operation.

- Piston: Moves up and down within the cylinder to compress fuel and release energy.

- Piston Rings: Help seal the gap between the piston and cylinder wall, preventing leaks.

- Cylinder Head: Seals the top of the cylinder and houses valves for air and fuel flow.

- Spark Plug or Injector: Ignites the air-fuel mixture or injects fuel in diesel engines.

Each part ensures the cylinder operates efficiently, safely, and reliably. Proper care and maintenance are necessary to keep these components in good condition.

Types of Engine Cylinders

Engine cylinders come in various configurations to suit different engine designs and requirements. Each type has its unique characteristics and benefits, influencing engine performance, efficiency, and application. Understanding these designs can help in selecting or maintaining engines better.

Inline Cylinders

Inline cylinders are arranged in a straight line within the engine block. They are compact and widely used in small to medium-sized cars. This design facilitates simpler manufacturing and maintenance. Inline cylinders typically offer smooth operation, which makes them popular for everyday driving. However, their size may limit power output in larger engines.

V-Shaped Cylinders

In V-shaped configurations, cylinders are aligned in two angled rows forming a ‘V’ shape. This arrangement optimizes space and improves power output. V-shaped engines are ideal for high-performance cars, trucks, and sports vehicles. Their compact design allows for more cylinders without increasing engine size significantly. However, these engines can be more expensive and complex to maintain.

Opposed or Boxer Cylinders

Opposed cylinder engines, often known as boxer engines, have cylinders lying flat and opposing each other. This creates a low, wide engine profile, lowering the vehicle’s center of gravity. Boxer engines are known for smooth and balanced performance. They are commonly used in sports cars and certain motorcycles. However, their design may complicate repairs and increase manufacturing costs.

Rotary Cylinder Arrangements

Rotary engines utilize a completely different approach, where cylinders in the traditional sense are replaced by rotor chambers. These are compact and lighter, offering high power-to-weight ratios. Rotary engines are great for smaller vehicles and motorcycles with unique performance needs. However, they may consume more fuel and require meticulous maintenance.

Each cylinder design type plays a vital role in meeting specific automotive and performance goals. Choosing the right configuration depends on vehicle use and desired engine characteristics.

How Cylinders Function

Engine cylinders are vital for the functioning of an internal combustion engine. They play a key role in the combustion process and directly impact vehicle performance.

The Four-Stroke Process Explained

The four-stroke process includes four key stages: intake, compression, power, and exhaust.

- Intake: The intake valve opens, letting a mix of fuel and air enter the cylinder.

- Compression: The piston compresses the air-fuel mixture, improving energy generation during combustion.

- Power: A spark plug ignites the mixture, causing an explosion that pushes the piston down.

- Exhaust: The exhaust valve opens, expelling burned gases out of the cylinder.

This process continuously generates enough power to move the vehicle efficiently.

The Role of Pistons and Combustion

Pistons are critical components in the cylinder’s operation. They move up and down as fuel burns.

- Compression Role: Pistons compress the air-fuel mix to prepare for combustion.

- Energy Conversion: The explosion drives the pistons, converting energy into useful mechanical power.

- Controlled Movement: Pistons’ precise movement ensures the engine runs smoothly and efficiently.

Without pistons, the combustion process would fail, impacting overall engine performance.

Relationship Between Cylinders and Engine Power

The number and design of cylinders directly influence engine power and efficiency.

- More Cylinders: Engines with more cylinders produce higher power at the cost of reduced efficiency.

- Fewer Cylinders: Fewer cylinders enhance efficiency but may reduce overall power output.

- Cylinder Design: Inline, V-shaped, and boxer cylinders cater to specific power and efficiency needs.

The balance between cylinder design and quantity is essential for achieving desired performance levels.

Materials Used in Cylinders

Engine cylinders must endure extreme pressure, temperature, and wear. Choosing the right materials is critical.

Common Cylinder Materials

Several materials are commonly used for engine cylinders. They balance durability and performance efficiently:

- Cast Iron: Cast iron is durable and wear-resistant. It is suitable for heavy-duty engines.

- Aluminum: Aluminum is lightweight and dissipates heat quickly, improving fuel efficiency and power.

- Steel: Steel is strong and ideal for high-performance engines needing extra durability.

- Nickel Alloys: Nickel alloys withstand high temperatures, making them ideal for specialized applications.

These materials are carefully chosen based on the engine type and its use.

Importance of Material Choice for Durability

The material impacts cylinder durability and engine efficiency. Key factors include:

- Heat Resistance: High-temperature materials prevent warping during combustion.

- Strength: Strong materials tolerate the pressure created during combustion cycles.

- Wear Resistance: Wear-resistant materials ensure long-lasting performance with minimal maintenance.

- Weight: Lightweight materials improve fuel efficiency and reduce vehicle weight.

Proper material selection enhances engine reliability and reduces repair costs over time.

Cylinder Configurations and Their Impact

Understanding cylinder configurations is crucial for evaluating engine performance, efficiency, and application. The arrangement and quantity of cylinders directly influence how an engine operates. Different configurations cater to unique vehicle requirements, offering varying levels of power, balance, and fuel economy.

How Cylinder Quantity Affects Engine Performance

The number of cylinders in an engine is a significant factor in determining its capabilities.

- More Cylinders: Engines with more cylinders generate greater power. They run smoother since power delivery is more consistent. However, they typically consume more fuel, reducing overall efficiency.

- Fewer Cylinders: Engines with fewer cylinders offer higher fuel efficiency. They are lighter and cost less to produce. However, they may lack the power needed for heavier or high-performance vehicles.

- Optimal Balance: Designers optimize cylinder quantity based on the vehicle’s purpose, balancing power, and efficiency.

For instance, four-cylinder engines are common in compact cars for daily use. In contrast, eight-cylinder engines are preferred in trucks and sports cars for their superior power.

Cylinder Arrangements in Different Vehicles

The arrangement of cylinders directly affects how an engine functions. Each design fits specific vehicle needs:

- Inline Arrangement: Most common for cars, offering a compact design for space-saving.

- V-Shaped Arrangement: Ideal for performance vehicles, as it enables higher cylinder counts in smaller spaces.

- Boxer Arrangement: Frequently used in sports cars, known for stability due to its low center of gravity.

- Rotary Engines: Found in specialized vehicles, offering a unique power-to-weight advantage.

The arrangement impacts torque, balance, and the overall profile of the engine, shaping how it performs.

Benefits and Drawbacks of Multi-Cylinder Engines

Multi-cylinder engines have distinct benefits and limitations based on their design and quantity.

Benefits:

- Smoother Operation: More cylinders mean smoother engine performance.

- High Power: Multi-cylinder setups generate greater power due to the increased combustion cycles.

- Durability: Power distribution over more cylinders reduces wear and tear.

Drawbacks:

- Higher Fuel Consumption: More cylinders consume more fuel, reducing efficiency.

- Increased Complexity: Maintenance and repairs become more challenging.

- Costlier: Producing and maintaining these engines is often more expensive.

Overall, the choice of configuration and cylinder quantity depends on the intended use of the vehicle. Balancing power, efficiency, and cost is critical for designing engines tailored to specific needs.

Maintenance and Care for Cylinders

Proper maintenance of engine cylinders is vital for vehicle performance and longevity. Routine checks and timely repairs ensure smooth functioning, enhanced efficiency, and reduced repair costs.

Signs of Cylinder Damage or Wear

Identifying cylinder issues early can prevent severe engine problems. Common signs include:

- Reduced Engine Performance: A noticeable drop in power output and acceleration.

- Increased Fuel Consumption: Damaged cylinders cause inefficient combustion, leading to higher fuel usage.

- Excessive Smoke: Blue or white smoke from the exhaust may indicate cylinder wear.

- Unusual Noises: Knocking or tapping sounds suggest internal cylinder or piston damage.

- Compression Loss: Low compression results in rough idling or difficulty starting the engine.

- Oil Leakage: Oil near the cylinder head indicates a potential seal or gasket issue.

Paying attention to these warning signs can save you from costly engine overhauls.

Regular Maintenance Tips

Consistent maintenance extends cylinder life and avoids unnecessary damage. Key tips include:

- Change Engine Oil: Use high-quality oil and replace it as per the manufacturer’s recommendations.

- Check Coolant Levels: Maintain adequate coolant to prevent overheating and cylinder warping.

- Inspect Air and Fuel Filters: Clean or replace filters to avoid debris entering the cylinders.

- Monitor Spark Plugs: Faulty spark plugs can disrupt combustion and harm cylinder walls.

- Clean Carbon Deposits: Regularly remove carbon build-up to avoid performance issues.

- Schedule Professional Inspections: Experts can spot internal wear you might miss.

These practices ensure optimal cylinder operation and reduce long-term expenses.

When to Replace or Repair Cylinders

Deciding between repairs and replacement depends on the extent of the damage. Key considerations include:

- Minor Wear: Address this with re-machining or honing to restore cylinder surface.

- Cracks or Severe Damage: Replace the cylinder entirely to avoid risking engine failure.

- Repeated Issues: Frequent cylinder problems may necessitate full engine overhaul.

- Manufacturer Guidelines: Always adhere to the manufacturer’s repair or replacement standards.

Timely action helps ensure vehicle reliability and avoids sudden breakdowns. Regular care is essential for a long-lasting engine.

Innovations in Engine Cylinder Design

Engine cylinder technology continues to evolve, aiming to improve efficiency, durability, and environmental sustainability. Modern innovations address engine performance challenges while meeting stricter emissions standards.

Advancements in Cylinder Efficiency

Several advancements have significantly enhanced the efficiency of engine cylinders:

- Direct Fuel Injection: Modern cylinders use direct injection for precise fuel delivery. This maximizes combustion and reduces wasted fuel.

- Turbocharging: Turbochargers increase air intake in cylinders, boosting power without increasing size or weight.

- Variable Valve Timing: This technology adjusts valve operation for optimal combustion, improving power and fuel economy.

- Lightweight Materials: Advanced aluminum and composite materials reduce weight, enhancing acceleration and fuel efficiency.

- Reduced Friction Coatings: Coatings like diamond-like carbon (DLC) minimize internal friction, improving overall engine performance.

These innovations deliver more power while maintaining better fuel efficiency and lower emissions.

Trends in Material and Design Technologies

Material and design innovations play a crucial role in improving engine cylinder performance:

- High-Strength Alloys: Materials like titanium and nickel alloys enhance heat resistance and wear durability.

- 3D Printing: Additive manufacturing allows precise, customized cylinder designs for optimal performance.

- Nanotechnology: Nano-coatings provide excellent heat resistance and lubrication, extending cylinder lifespan.

- Integrated Sensors: Smart cylinders feature embedded sensors to monitor pressure, temperature, and performance in real time.

- Modular Designs: Modular cylinders simplify replacement and repair, reducing downtime for vehicle owners.

These developments not only improve engine performance but also contribute to sustainable manufacturing practices. Engineers continually explore new ways to improve cylinders, ensuring engines meet modern demands for power and efficiency.

FAQs About Engine Cylinders

Common Questions and Answers

What is an engine cylinder’s primary role?

An engine cylinder provides the chamber where combustion occurs, generating power for the vehicle.

How many cylinders are ideal for a car?

It depends on the car’s purpose. Compact cars typically have 4 cylinders, while sports cars may have 6 or 8.

Are more cylinders always better?

Not necessarily. More cylinders offer more power but reduce fuel efficiency and increase costs.

Why are some engines inline and others V-shaped?

Each arrangement optimizes space, power, and engine balance based on vehicle design and application.

What materials are commonly used in engine cylinders?

Common materials include cast iron, aluminum, steel, and nickel alloys for durability and performance.

How can I tell if my engine cylinders have issues?

Look out for reduced power, increased fuel use, unusual noises, excessive smoke, or oil leaks.

Can damaged cylinders be repaired?

Minor damage can be repaired by honing or reshaping. Severe damage may require replacement.

Misconceptions About Engine Cylinders

Myth 1: Multi-cylinder engines are always more efficient.

Truth: While multi-cylinder engines offer more power, they often consume more fuel.

Myth 2: All cylinders are the same across cars.

Truth: Cylinders differ in material, design, and arrangement based on engine type and application.

Myth 3: Cylinder problems always require full engine replacement.

Truth: Many cylinder issues can be fixed without replacing the entire engine.

Myth 4: Inline engines are outdated.

Truth: Inline engines are still widely used, especially in compact and efficient cars.

Myth 5: Cylinder maintenance is optional.

Truth: Regular maintenance is essential for efficiency, longevity, and preventing costly repairs.

Leave a Reply