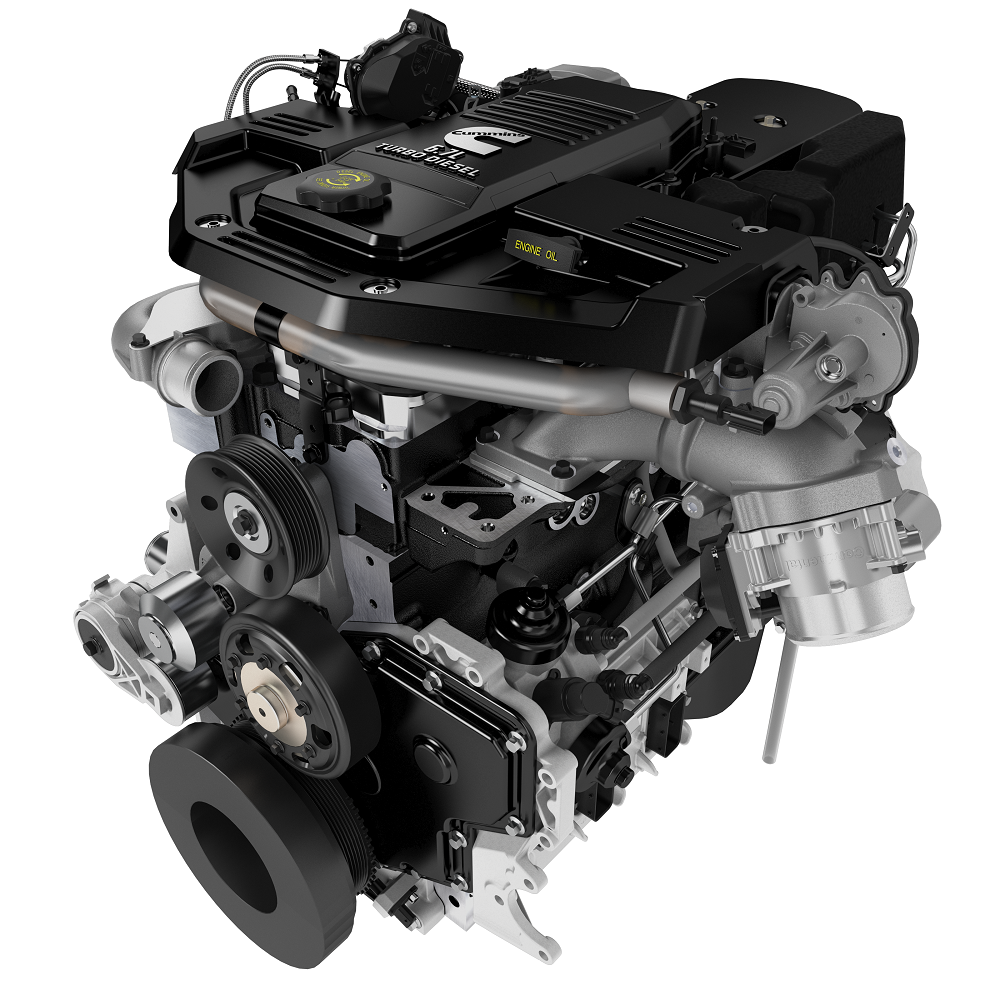

Overview of the 24 Valve Cummins Engine

The 24 Valve Cummins engine is known for its power, efficiency, and durability. It is highly valued across industries and automotive applications, thanks to its advanced design. Cummins introduced this engine to improve performance and meet changing market needs.

History and Development

The 24 Valve Cummins engine was launched in the late 1990s. It replaced the 12 Valve Cummins, offering better technology and features. The engine leveraged electronic fuel injection systems for optimized performance. This upgrade marked a shift from mechanical systems used in previous models. Cummins aimed to meet stricter emission regulations while enhancing reliability.

Applications in Automobiles and Industries

The 24 Valve Cummins engine is widely used in heavy-duty trucks and pickups. It is a favorite among automobile manufacturers for its towing capability. Many industries use this engine in machinery and equipment for its consistent performance. It is also preferred for agriculture, construction, and marine applications due to its versatility.

Specifications of the 24 Valve Cummins Engine

The 24 valve Cummins engine offers advanced specifications designed for superior performance and reliability. Below, we delve into its engine size, horsepower and torque ratings, and fuel system technology.

Engine Size and Configuration

The 24 valve Cummins engine features a 5.9-liter inline-six configuration. This layout ensures balanced performance and reduced vibration. The six-cylinder design contributes to its smooth operation and high efficiency. Its compact size allows for easy installation in various vehicles and machinery. The engine is also known for its cast-iron construction, enhancing strength and durability.

Horsepower and Torque Ratings

This engine stands out for its impressive output. Early models produced around 215-235 horsepower and 420-460 lb-ft of torque. Over time, upgrades boosted these numbers. Newer versions provide up to 350 horsepower and 600 lb-ft of torque. This makes it ideal for towing, heavy-duty tasks, and high-performance applications. The balance of power and torque ensures exceptional handling under load.

Fuel System and Injection Technology

The 24 valve Cummins engine introduced electronic fuel injection (EFI) technology. This system replaced the mechanical pumps of earlier versions. EFI optimizes fuel delivery for greater efficiency and reduced emissions. The engine relies on Bosch VP44 injection pumps to ensure precision. This setup provides consistent performance and minimizes fuel waste. Additionally, the improved injection system contributes to better cold-start capabilities and smoother operation.

These specifications highlight why the 24 valve Cummins engine remains popular. Its robust design, power output, and advanced fuel system set industry standards.

Performance Features of the 24 Valve Cummins Engine

The 24 Valve Cummins engine offers standout performance features. These features ensure its excellence in demanding tasks.

Durability and Reliability

The 24 Valve Cummins engine is built to last. Its cast-iron construction ensures strong durability. The inline-six design reduces wear and enhances reliability. Advanced electronic systems minimize operational issues over time. With regular maintenance, it delivers consistent performance for years.

Towing Capacity and Load Handling

The engine excels in towing and load-handling tasks. It delivers powerful torque under heavy loads. Early models provided up to 460 lb-ft, while newer ones manage 600 lb-ft. Precision engineering ensures smooth handling even with substantial towing weights. These features make it a favorite for commercial and personal use.

Efficiency and Fuel Economy

Efficiency is a focal point of the 24 Valve Cummins engine. The electronic fuel injection system ensures optimal fuel delivery. This translates to reduced waste and better fuel economy. Advanced injection technology lowers emissions and enhances mileage. It’s a smart choice for those seeking both power and efficiency.

Common Upgrades and Modifications

The 24 valve Cummins engine is highly popular among enthusiasts for its upgrade potential. Modifications can enhance performance, efficiency, and reliability, making it even more versatile.

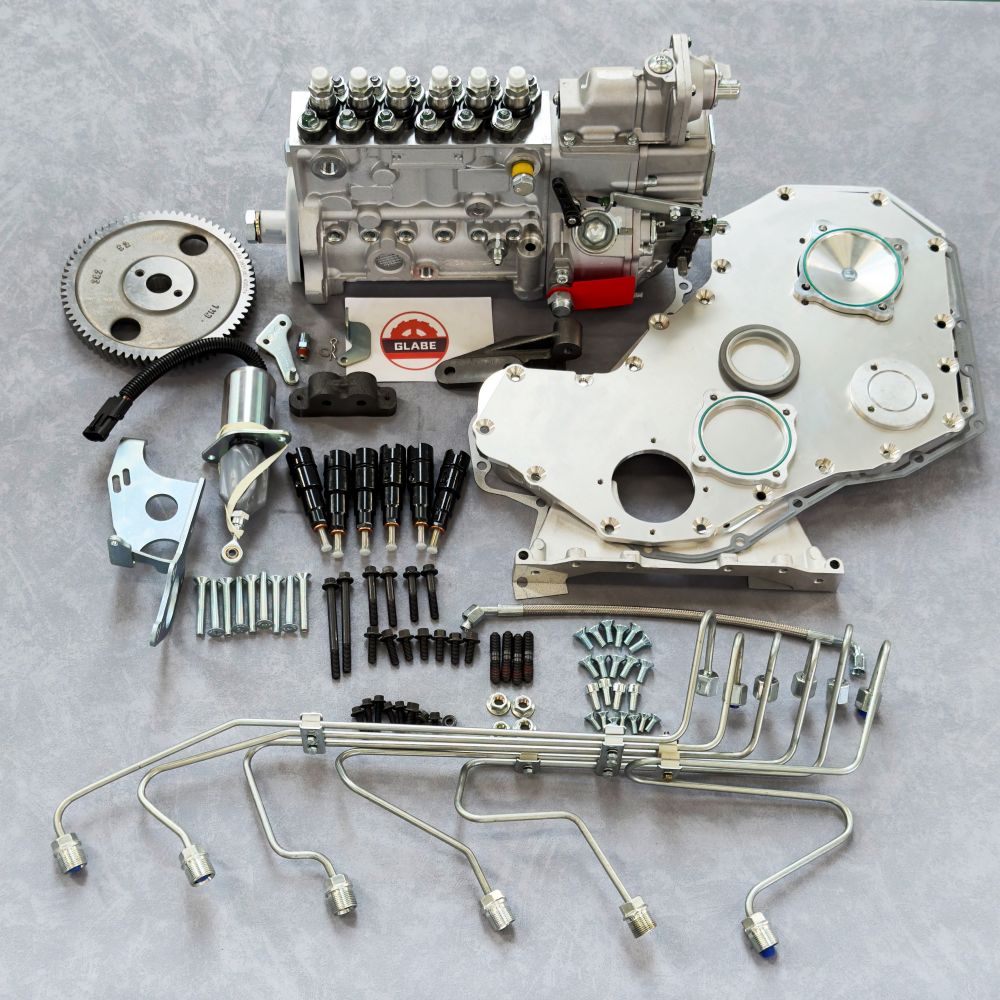

Popular Aftermarket Parts

Aftermarket parts allow users to tailor their 24 valve Cummins engine for specific needs. Below are some popular options:

- Cold Air Intakes – These improve airflow, boosting horsepower and torque. They also increase fuel efficiency.

- High-Performance Turbos – Upgraded turbos enhance power delivery and support higher boost levels.

- Exhaust Systems – Aftermarket exhaust systems reduce backpressure, improving performance and engine sound.

- Fuel Injectors – High-performance injectors optimize fuel delivery for better efficiency and output.

- Intercoolers – Upgraded intercoolers lower intake air temperature, improving overall engine performance.

These parts are widely available and relatively easy to install, making them ideal for owners looking to enhance their engine.

Performance Tuning Options

Tuning the 24 valve Cummins engine allows for customized performance. Here are some common tuning methods:

- ECU Programming – Adjustments to the engine control unit optimize power and fuel economy.

- Plug-and-Play Chips – These chips offer quick performance upgrades without major modifications.

- Custom Dyno Tuning – Professional tuning ensures precise adjustments for maximum performance gains.

- Boost Controllers – These allow you to fine-tune turbo boost pressure for different driving needs.

- Transmission Tuning – Upgrades to work alongside engine improvements ensure smoother power delivery.

Both aftermarket parts and tuning provide significant improvements. Combining them amplifies the engine’s potential, making it suitable for various applications like towing, racing, or daily driving.

Maintenance and Troubleshooting Tips

Proper care helps the 24 valve Cummins engine perform efficiently and last longer. Regular maintenance and proactive troubleshooting ensure its reliability.

Scheduled Maintenance Checklist

Routine maintenance keeps the 24 valve Cummins engine in optimal condition. Here’s a checklist to follow:

- Oil Changes – Change engine oil every 5,000-7,000 miles. Use high-quality oil for durability.

- Air Filter Replacement – Replace the air filter every 15,000-30,000 miles. A clean filter ensures proper airflow.

- Fuel Filter Maintenance – Replace the fuel filter every 15,000 miles. This prevents clogging and improves fuel efficiency.

- Cooling System Inspection – Check coolant levels regularly. Flush and replace coolant every 50,000 miles.

- Belt and Hose Checks – Inspect belts and hoses for wear. Replace them to avoid failures.

- Valve Adjustment – Schedule rocker arm and valve lash adjustments to ensure proper engine operation.

- Battery Maintenance – Clean terminals and check battery voltage. Replace old batteries promptly.

- Injector Cleaning – Clean fuel injectors as needed. This maintains smooth fuel delivery.

Adhering to these points reduces wear and avoids costly engine repairs.

Diagnosing Common Engine Issues

Sometimes problems arise that need troubleshooting. Here are some common issues and how to diagnose them:

- Hard Starting – Check the battery and fuel injection system for any faults.

- Overheating – Inspect the cooling system for leaks, blockages, or low coolant levels.

- Decreased Power – Examine the turbocharger and the air intake system for damage.

- Excessive Smoke – Look at injectors for malfunction, and verify proper air-fuel mixture.

- Knocking Sounds – Investigate internal components like valves and timing for wear or improper adjustment.

- Oil Leaks – Inspect engine gaskets and seals for any damage or improper fitting.

Quick diagnosis and professional help prevent minor problems from turning into major ones. Whether it’s routine maintenance or specific troubleshooting, every 24 valve Cummins engine owner should prioritize care to ensure optimal performance.

Comparison with Other Cummins Engines

Understanding how the 24 Valve Cummins engine compares can help you appreciate its unique features. Two key comparisons include differences with the 12 Valve Cummins and upgrades from earlier models.

Difference Between 12 Valve and 24 Valve Cummins

The shift from the 12 Valve Cummins to the 24 Valve Cummins brought considerable changes.

- Fuel System Technology: The 12 Valve Cummins uses mechanical fuel injection, while the 24 Valve features electronic fuel injection (EFI). EFI improves fuel delivery, efficiency, and lowers emissions.

- Performance Enhancements: The 24 Valve Cummins offers higher horsepower and torque. Early 12 Valve models typically produced 160-215 horsepower and 400-440 lb-ft of torque, whereas 24 Valve versions deliver up to 350 horsepower and 600 lb-ft.

- Cylinder Head Design: The 24 Valve comes with a redesigned cylinder head for better airflow, enhancing efficiency and power.

- Emissions Compliance: The 24 Valve engine was developed to meet stricter emissions regulations compared to the 12 Valve.

- Reliability and Maintenance: The 12 Valve is known for simplicity and reliability due to fewer electronic components. The 24 Valve, while advanced, requires careful maintenance due to its electronic systems.

Key Upgrades From Previous Models

Cummins introduced crucial upgrades to improve the performance and functionality of the 24 Valve engine.

- Advanced Injection Pumps: The 24 Valve uses Bosch VP44 injection pumps. These pumps ensure precise fuel delivery and better efficiency.

- Improved Towing and Handling: Enhanced torque values make the 24 Valve Cummins excel in towing and load-handling tasks.

- Cold-Start Capability: The electronic injection system improved cold-starting, making it reliable in extreme conditions.

- Emission Control: Enhanced fuel systems contribute to reduced emissions while maintaining performance.

- Injector Design: The newly designed injectors in the 24 Valve ensure consistent and smooth fuel delivery.

These upgrades and changes highlight why the 24 Valve Cummins is often preferred. Its balance between technological improvements and robust performance ensures reliability and versatility across applications.

FAQ About the 24 Valve Engine

Common Buyer Queries

Buyers often ask key questions about the 24 valve Cummins engine. Here are some common queries:

- Is the 24 Valve Cummins engine reliable?

- Yes, its cast-iron design ensures strength and durability. Regular maintenance boosts its reliability.

- What is the towing capacity of this engine?

- Early models manage up to 460 lb-ft of torque. Newer versions go up to 600 lb-ft.

- Does this engine have good fuel efficiency?

- Yes, electronic fuel injection improves efficiency and lowers emissions.

- Can I install aftermarket upgrades?

- Absolutely. Popular options include cold air intakes, high-performance turbos, and custom tuning.

- How often should maintenance be done?

- Follow a checklist. Oil changes every 7,000 miles and air filter replacements every 30,000 miles.

- How does it compare to other Cummins engines?

- It has better emission compliance and higher power output than older models.

Expert Recommendations and Advice

Experts agree on several tips for maximizing the performance of your 24 valve Cummins engine:

- Stick to scheduled maintenance:

- Regular oil changes, fuel filter replacements, and coolant checks are essential.

- Consider aftermarket upgrades:

- Upgrade turbos, intercoolers, or fuel injectors for improved performance and efficiency.

- Tune your engine professionally:

- Dyno tuning and ECU programming deliver precise adjustments for better gains.

- Protect the fuel system:

- Use clean fuel and keep injectors cleaned regularly to avoid clogging.

- Inspect belts and hoses:

- Replace worn-out belts or hoses to prevent sudden failures.

Following these recommendations ensures your engine remains powerful, efficient, and reliable over time.

The Global Impact of Cummins Technology

1. Contributions to Different Markets

Cummins has a substantial global presence, influencing various markets beyond traditional automotive applications. Their innovative engines are featured in construction machinery, agricultural equipment, and power generation systems. The versatility of the 24-valve Cummins engine enables it to seamlessly integrate into multiple industries, providing efficient power solutions. As industries seek reliable and powerful engines to enhance productivity, Cummins remains a leader in meeting these diverse needs.

2. Commitment to Sustainability and Innovation

As environmental regulations become increasingly stringent worldwide, Cummins has dedicated resources to developing sustainable engine technologies. Their commitment to reducing emissions and improving fuel efficiency demonstrates their proactive approach in adapting to evolving market demands. Collaboration with governments and organizations further enables Cummins to lead initiatives focused on creating greener energy solutions. This commitment will ensure the 24-valve Cummins engine continues to play a significant role in sustainable transportation and heavy-duty applications.

3. Future Developments and Trends

Looking ahead, Cummins aims to keep pushing the boundaries of diesel technology, including the evolution of the 24-valve engine. With ongoing innovations in hybrid and electric technology, Cummins is positioning itself to meet changing consumer preferences. Future models may incorporate advanced features such as smart connectivity, enhancing performance with real-time data and diagnostics. As the company continues to adapt, the legacy of the 24-valve engine will undoubtedly evolve to embrace the challenges of tomorrow’s power needs.

Conclusion

In summary, the 24 valve Cummins engine stands as a formidable force in the realm of diesel engines, offering unparalleled power, durability, and efficiency. Its application across various industries illustrates the engine’s versatility, while user satisfaction and community support reinforce its positive reputation. By understanding its specifications, benefits, and future potential, individuals can appreciate the substantial role this engine plays in modern transportation and industrial practices.

As technology continues to advance, the 24 valve Cummins engine will remain at the forefront of innovation. With a commitment to sustainability and responsiveness to market demands, the engine’s evolution will ensure its relevance for years to come. For those seeking reliability, performance, and efficiency, investing in a vehicle equipped with a 24-valve Cummins engine is a decision that embodies both quality and confidence.

By embracing this powerful engine, riders and operators can enjoy the joy of seamless performance, whether on the road, in the field, or at sea. The 24 valve Cummins engine serves as a reminder that enhancing power and efficiency can go hand in hand with environmental responsibility, making it a true leader in the world of diesel technology.

Leave a Reply