Overview of Engine Valves

Engine valve stem is essential components of internal combustion engines. They control the flow of air and fuel into the engine and allow exhaust gases to exit. Valves work in a timed sequence to ensure the engine runs smoothly and efficiently. Here, we will discuss what engine valves are and their various types.

What are Engine Valves?

Engine valves regulate the intake and exhaust processes in an engine. They open and close at precise times to allow air-fuel mixture entry and expel exhaust gases. There are two main types: intake valves and exhaust valves. Intake valves enable air and fuel to enter the combustion chamber, while exhaust valves release burnt gases. The coordinated movement of these valves ensures seamless engine operation.

Types of Engine Valves and Their Roles

- Intake Valves: These valves allow the air-fuel mixture to enter the combustion chamber. Proper sealing is crucial to prevent pressure loss.

- Exhaust Valves: They expel combustion gases after combustion. Their durability ensures long-term performance under high temperatures.

- Poppet Valves: These are the most common valves. Their disc shape ensures a tight seal when closed.

- Rotary Valves: Found in specialized engines, they rotate to control valve timing and airflow.

- Reed Valves: Typically used in two-stroke engines, these function as one-way check valves.

Each type of valve is designed for a specific function, contributing to optimal engine efficiency.

Anatomy of an Engine Valve Stem

The engine valve stem plays a crucial role in the function of engine valves. It connects the valve head to the valve mechanism, allowing precise movement. Understanding the anatomy of the valve stem is vital to grasp its overall functionality.

Key Components of a Valve Stem

- Stem Shaft: The long, cylindrical part of the valve stem. It ensures smooth motion within the valve guide.

- Tip: Located at the top, it interacts with the valve lifter or rocker arm. It undergoes wear and needs a hard surface to endure stress.

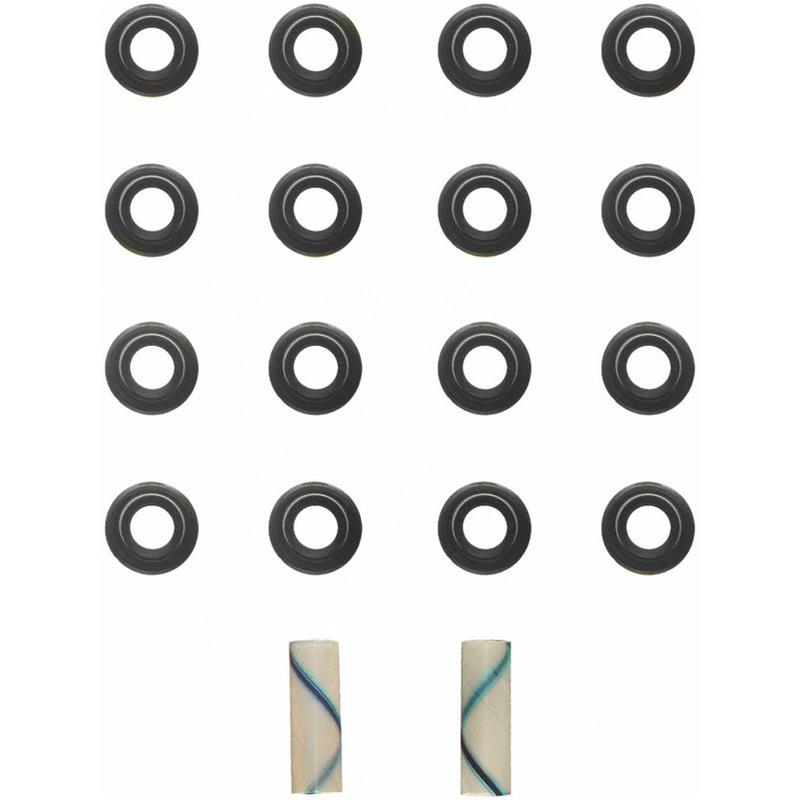

- Stem Seal: Positioned on the stem to block oil leakage into the combustion chamber. It prevents oil contamination in the air-fuel mixture.

- Valve Groove: Found at the upper end, it secures the valve to the valve springs. It ensures precise positioning during operation.

- Stem Seats: Located near the lower part, these make contact with the valve guide. They help maintain alignment and reduce wear.

Each component serves a specific purpose, ensuring optimal engine valve operation.

Materials Used in Valve Stem Construction

- Steel Alloys: Commonly used for durability and heat resistance. Chromium or nickel can enhance strength.

- Titanium: Offers high strength-to-weight ratios. It is used in high-performance engines.

- Sodium-Filled Valves: These are used for efficient heat dissipation. They are ideal for exhaust valve stems.

- Ceramics: Found in advanced engines, ceramics provide exceptional heat resistance but are less common.

Using the right materials ensures valve stems can withstand heat, pressure, and wear. This enhances the engine’s performance and reliability.

Function of the Engine Valve Stem

The engine valve stem is essential to the efficient operation of engine valves. It ensures precise movement and control during the intake and exhaust cycles. In this section, we’ll explore how the valve stem functions within the engine.

How the Valve Stem Contributes to Valve Operation

- Smooth Movement: The valve stem ensures the valve moves smoothly within the valve guide.

- Alignment: It maintains the valve’s alignment for effective sealing and combustion.

- Force Transmission: The stem transmits forces from the valve springs to open or close the valves.

- Oil Control: With the help of oil seals, it prevents oil leakage into the combustion chamber.

Every aspect of the valve stem’s operation supports the performance of the intake and exhaust valves.

Role in the Internal Combustion Process

- Opening Intake Valves: The valve stem assists intake valves in introducing air and fuel into the combustion chamber.

- Closing Exhaust Valves: It supports exhaust valves in removing burnt gases from the engine.

- Precise Timing: It synchronizes valve movements with the piston’s motion for efficient combustion.

- Withstanding Pressure: The stem endures high pressure and heat during combustion cycles.

The valve stem is fundamental to delivering power and maintaining engine efficiency over time.

Common Issues with Valve Stems

Engine valve stems are sturdy but can face damage over time. Identifying issues early can save repair costs and maintain performance. Below, we’ll explore signs of faulty valve stems and how to prevent wear.

Signs of a Damaged or Faulty Valve Stem

- Oil Leaks in Combustion Chamber: Faulty stem seals allow oil to leak, causing smoke and reduced performance.

- Poor Engine Compression: Worn stems may not seal properly, leading to power loss and inefficiency.

- Unusual Noises: Knocking or ticking sounds often signal stem or valve issues.

- Increased Emissions: Faulty stems disrupt combustion, causing higher exhaust emissions.

Recognizing these signs can help prevent expensive engine repairs.

Causes and Prevention of Valve Stem Wear

- High Heat and Pressure: Constant exposure leads to material degradation. Use heat-resistant materials for better longevity.

- Oil Contamination: Dirty oil causes abrasions within the valve guide. Regular oil changes prevent contamination.

- Poor Lubrication: Lack of proper oiling increases friction and accelerates wear. Maintain oil levels to ensure lubrication.

- Misalignment: Manufacturing defects or excessive wear can misalign stems. Professional inspections reduce such risks.

To prevent wear, follow maintenance schedules and choose high-quality parts for replacements. Proper care enhances engine life and reliability.

Valve Stem Maintenance and Replacement

Maintaining and replacing the engine valve stem is crucial for optimal engine performance and durability.

Tips for Proper Maintenance

- Regular Cleaning: Clean the valve stem to avoid carbon deposits and ensure smooth operation.

- Inspect for Damage: Check the stem for wear, cracks, or deformation during routine audits.

- Oil Seal Check: Ensure oil seals are intact to prevent leaks into the combustion chamber.

- Optimize Lubrication: Use high-quality engine oil to reduce friction and prevent stem wear.

- Maintain Valve Clearance: Adjust stem alignment with proper clearance to avoid excessive stress.

- Monitor Engine Temperature: Avoid overheating to protect the stem from thermal damage.

Regular maintenance prolongs valve stem life and improves engine efficiency.

When and How to Replace a Valve Stem

- Signs Replacement is Needed:

- Persistent oil leaks signal failed seals or worn stems.

- Reduced engine compression indicates faulty stems.

- Ticking or knocking noises suggest misaligned or damaged stems.

- Steps to Replace:

- Remove the valve cover and inspect the valve components.

- Detach the damaged valve stem using appropriate tools.

- Install a compatible, high-quality valve stem.

- Test the new stem for proper alignment and sealing.

Valve stem replacement requires precision and may need professional mechanic assistance.

The Relationship Between Valve Stems and Engine Performance

The engine valve stem plays a crucial role in an engine’s operation. Its condition directly affects performance, fuel efficiency, and engine durability. Understanding this relationship helps drivers maintain the reliability of their vehicles.

Impact on Fuel Efficiency

- Precise Air and Fuel Control: The valve stem ensures intake and exhaust valves operate accurately. This improves combustion efficiency.

- Minimized Leaks: A well-maintained valve stem prevents air or fuel leaks that can lower fuel efficiency.

- Optimized Combustion: Proper valve stem function ensures the combustion process uses fuel effectively. This reduces wastage.

- Reduced Friction: Proper lubrication of the valve stem enhances smooth movement. This consumes less power and fuel.

Faulty valve stems, on the other hand, disrupt airflow and fuel delivery. This leads to incomplete combustion and higher fuel consumption. Regular maintenance ensures the valve stem supports optimal fuel efficiency.

Influence on Engine Longevity

- Wear Prevention: A maintained valve stem minimizes wear on engine parts, extending engine life.

- Heat Resistance: High-quality valve stems handle engine heat, preserving engine components from thermal damage.

- Reduced Oil Contamination: Functional valve seals prevent oil from mixing with the air-fuel mixture. This keeps the engine clean.

- Structural Integrity: Durable valve stems withstand stresses during operation, preventing engine breakdowns.

Neglecting valve stem care shortens engine lifespan by causing wear, overheating, and component failure. Timely checks and replacements ensure your engine runs efficiently and lasts longer.

Innovations in Valve Stem Technology

Engine valve stem technology has continuously evolved to meet modern engine demands. Innovation in design and materials enhances performance, efficiency, and durability. In this section, we will explore the latest advancements and future trends in valve systems.

Advances in Design and Materials

- Lightweight Materials: Manufacturers now use lighter materials like titanium to reduce weight. This improves engine performance and fuel efficiency without compromising strength.

- Coatings for Durability: Protective coatings, such as diamond-like carbon (DLC), reduce friction and increase wear resistance. These coatings extend the life of valve stems under high stress and temperature.

- Sodium-Filled Stems: Sodium-filled valve stems enhance heat dissipation. They are highly effective in preventing thermal damage, particularly in exhaust systems.

- Integrated Oil Seals: Advanced oil seals ensure superior sealing. This prevents oil leaks and maintains engine cleanliness.

- Precision Manufacturing: New machining techniques provide tighter tolerances, improving valve alignment and overall engine efficiency.

These innovations allow valve stems to operate effectively under increasingly challenging engine conditions.

Future Trends in Engine Valve Systems

- Electric Actuation: Electronic valve control systems may replace traditional mechanical setups. This offers precise valve timing and improves fuel efficiency.

- Smart Materials: Advanced alloys and composites will improve heat resistance and reduce overall stem weight without sacrificing strength.

- 3D Printing: Additive manufacturing methods may provide customized solutions and faster production of valve components.

- Eco-Friendly Designs: Future designs will focus on reducing emissions while maintaining engine power and reliability.

- Integrated Sensors: Built-in sensors could monitor valve performance in real-time. This will help identify wear or misalignment before failures occur.

The future of engine valve stem technology will likely prioritize performance, fuel efficiency, and environmental compatibility. These innovations ensure that engines will remain powerful, durable, and eco-friendly in years to come.

The Future of Engine Valve Technology

1. The Rise of Electrification

As the automotive industry embraces the shift toward electrification, the role of traditional internal combustion engines is evolving. While electric vehicles have their own unique performance characteristics, the integration of advanced valve technologies into these hybrid systems could allow for enhanced thermal efficiency and power. Research into the adoption of free valve technology in electric or hybrid vehicles may provide additional benefits and performance improvements. The evolution of engine technologies must adapt to the changing landscape of the automotive market.

2. Greater Emphasis on Environmental Impact

The growing focus on sustainability in the automotive industry has sparked interest in improving engine designs to meet stricter emissions regulations. Innovations in valve technology, such as better sealing and optimized combustion processes, can contribute to lower emissions and improved fuel efficiency. Regulatory changes worldwide are pushing manufacturers to invest in cleaner, more efficient technologies that help reduce their carbon footprint. The future of valve technology will likely play a critical role in shaping environmentally conscious engine designs.

3. Continuous Innovation in Mechanical Design

Engine technology will continue to evolve as manufacturers push the boundaries of performance and efficiency. Future developments in valve mechanisms, including hybrid systems that combine mechanical and electronic actuation, have the potential to create even more precise control over engine dynamics. As research progresses, we can expect new innovations that enhance engine performance, smoothness, and reliability. The ongoing quest for efficiency and performance ensures that valve technology will remain at the forefront of automotive engineering.

Conclusion

The engine valve stem is a small yet mighty component that plays a vital role in the overall operation and performance of internal combustion engines. Understanding how valve stems work, their interactions with other engine elements like seats and guides, and the innovative technologies driving their evolution is crucial for anyone involved in the automotive industry. As the focus on efficiency and sustainability continues to grow, advancements in valve technology will shape the future of engine design.

Choosing quality components and maintaining proper care for your engine ensures optimal performance and longevity. As new technologies emerge, riders and enthusiasts should remain informed about the latest innovations that will influence their machines. The road to the future of engine technology is paved with exciting developments that promise to enhance the riding experience while reducing environmental impact.

Embrace the transformation happening within the realm of engine technology. The potential for innovation and improvement is immense, and understanding the mechanics, specifications, and care ensures that each ride is both exhilarating and efficient. The significance of valve stems in engine performance is undeniable, making them an essential focus for anyone passionate about motorcycles and their engineering.

Leave a Reply