Introduction to Free Valve Technology

What Are Free Valve Engines?

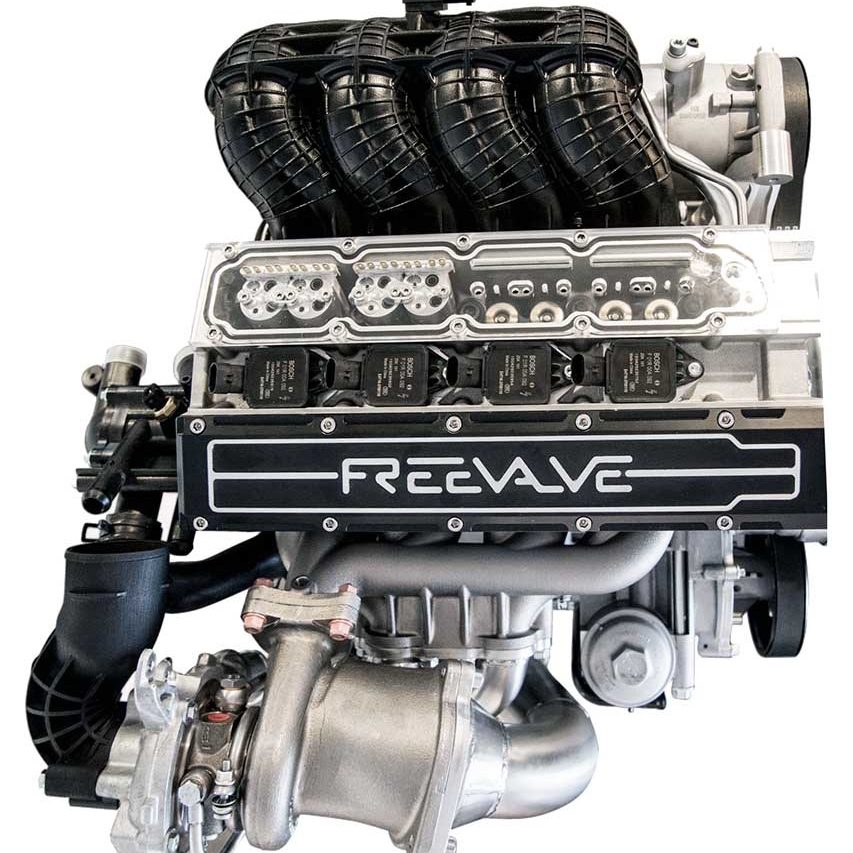

Free valve engine feature a system where each valve is independently controlled. The system uses electrical or pneumatic actuators to open and close the intake and exhaust valves. This allows for customized valve timing based on the current needs of the engine. Unlike conventional engines, free valve systems do not rely on mechanical linkages or cams. This design reduces mechanical complexity and increases control precision. By using advanced electronics, free valve engine achieve more adaptable and optimized engine operations.

History and Development of Free Valve Systems

The concept of free valve systems emerged as engineers sought to improve engine control and efficiency. Early attempts to eliminate camshafts faced technological limitations, particularly in actuator speed and reliability. Over time, advancements in electronics and pneumatics enabled more practical implementations. Koenigsegg, a known innovator in high-performance vehicles, pioneered modern free valve technology. Their FreeValve system became a leading example of this technology. Today, free valve engines are gaining interest for their potential to redefine engine design and performance.

How Free Valve Technology Works

Free valve technology represents a significant evolution in internal combustion engine design. This section explores its working principles and underlying components, as well as how it differs from traditional engines.

Core Principles and Components

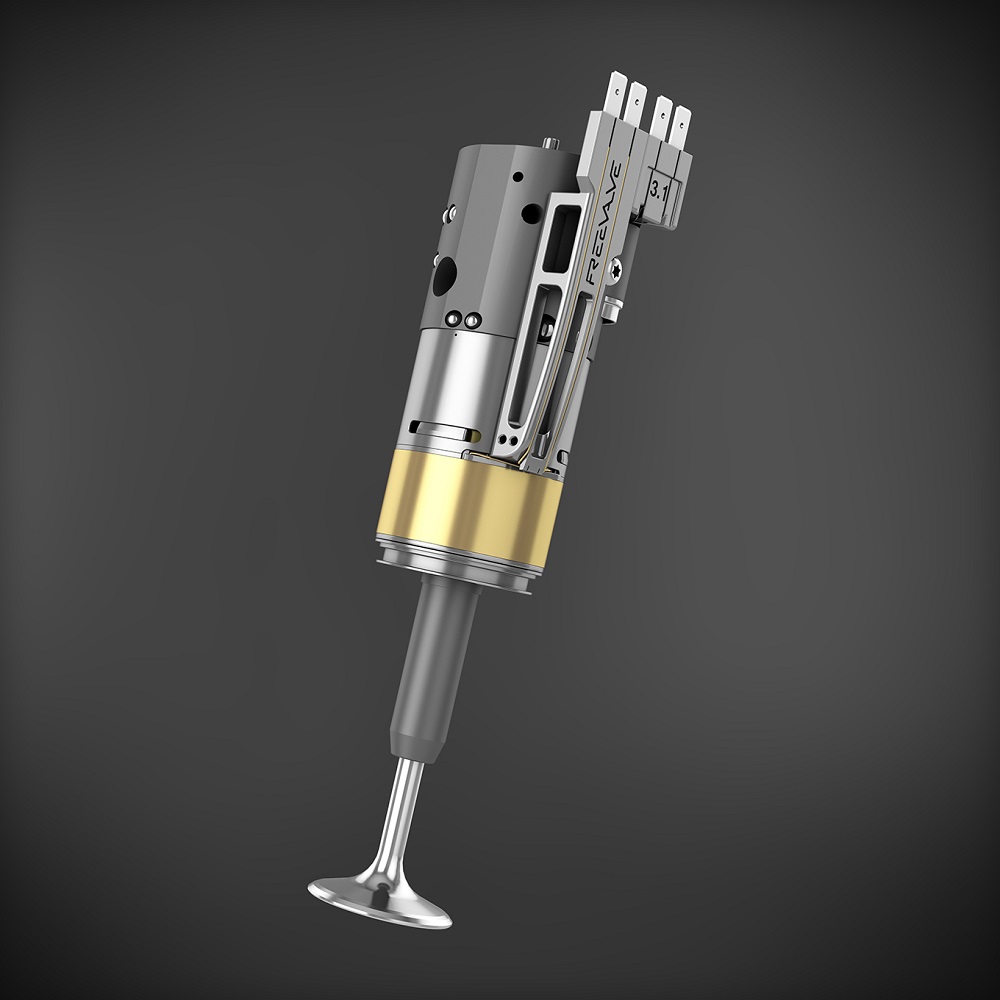

Free valve engines operate without a traditional camshaft. Each intake and exhaust valve works independently. Electronic or pneumatic actuators control the valves precisely based on real-time engine demands. These actuators adjust valve timing, duration, and lift for optimal performance.

Sensors play a crucial role by monitoring engine conditions. They provide real-time data to the electronic control unit (ECU). The ECU acts as the brain, ensuring precise actuator operation. This system allows greater flexibility in engine behavior, improving fuel efficiency and power.

Free valve systems also minimize mechanical complexity. The elimination of camshafts reduces moving parts and potential mechanical wear. This simplification also reduces overall engine weight, enhancing efficiency.

Differences Between Traditional and Free Valve Engines

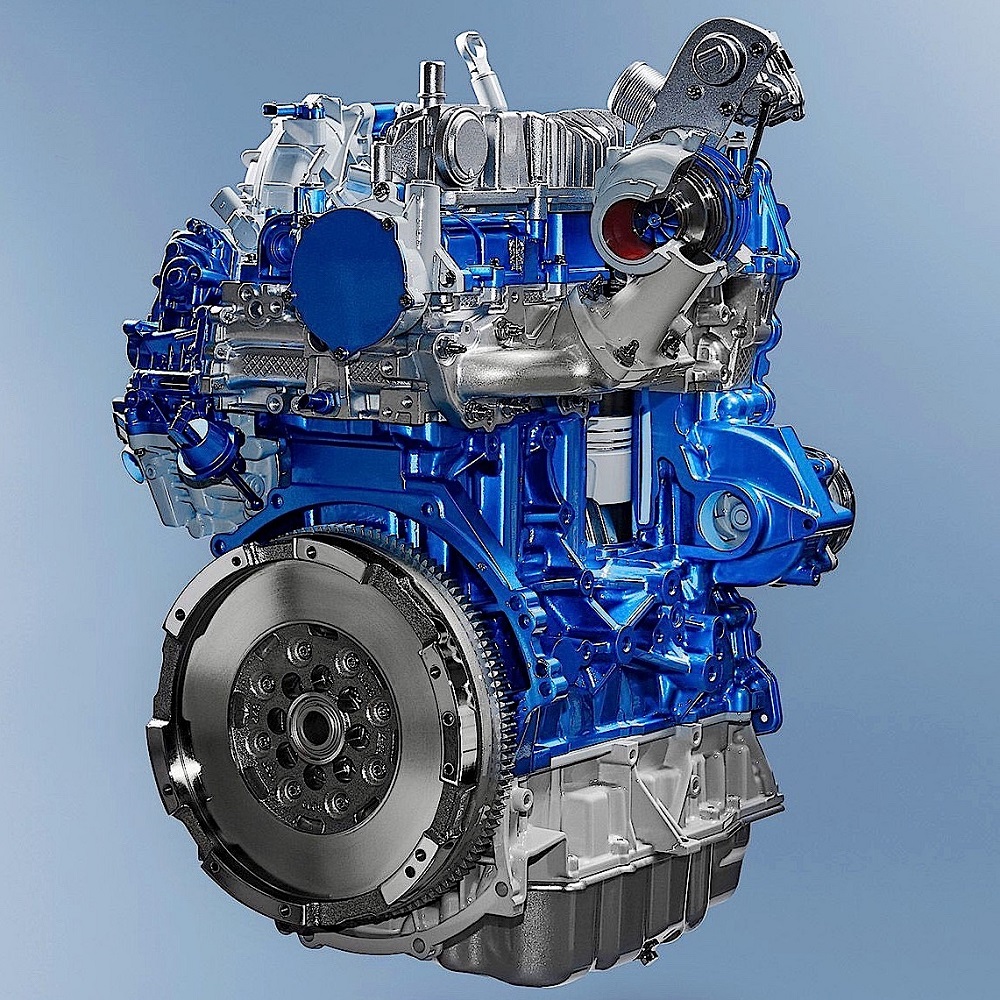

Traditional engines rely on camshafts to control valve operations. Camshafts are mechanical devices that use rotating lobes to open and close valves. The timing and duration of these operations are fixed and cannot adapt to varying conditions.

Free valve engines do not use camshafts. Instead, advanced actuators manage valve movements. This allows adaptive and precise control over each valve’s operation. Traditional systems are constrained by mechanical limitations, while free valve systems offer dynamic customization.

Mechanical camshafts require consistent maintenance due to wear and tear. Free valve engines reduce maintenance frequency by eliminating these components. Additionally, they provide better combustion efficiency due to more precise valve timing.

In summary, free valve systems revolutionize valve operation. They replace mechanical components with intelligent electronic control. This leads to improved performance, flexibility, and efficiency compared to conventional engines.

Benefits of Free Valve Engines

Free valve engines bring revolutionary advantages to modern internal combustion systems. Their innovative design fosters better performance, efficiency, and environmental compatibility than traditional camshaft-based engines.

Performance Optimizations

Free valve engines offer precise control over valve timing, duration, and lift. This fine-tuned control optimizes the air-fuel mixture, enhancing combustion efficiency and engine power. Unlike traditional systems, which use fixed camshaft mechanisms, free valve engines adapt to real-time driving conditions. This adaptability improves torque delivery and fuel efficiency across different speeds and loads.

The independent valve operation also reduces engine vibrations and wear. Free valve technology eliminates unnecessary mechanical stress caused by camshaft movement, leading to smoother operation and longer engine life. Moreover, the reduction in mechanical components lowers weight and increases power-to-weight ratios, contributing to superior vehicle acceleration and handling.

Environmental Impact and Emission Reductions

Free valve engines significantly reduce harmful emissions. Their precise control ensures complete combustion of fuel, minimizing unburned hydrocarbons and particulate matter. By adjusting valve operations to optimize combustion, these engines achieve cleaner exhaust output compared to traditional systems.

The improved thermal efficiency of free valve engines reduces carbon emissions. Lower fuel consumption directly translates to decreased carbon dioxide output, supporting global efforts to combat climate change. Additionally, free valve systems can easily integrate with hybrid or alternative energy drivetrains, further reducing environmental impact.

Overall, free valve technology offers a greener alternative while maintaining high performance standards. This pioneering innovation paves the way for a more sustainable and efficient automotive future.

Challenges and Limitations

Free valve engines bring great promise but face challenges in widespread adoption. These obstacles include technical hurdles and economic considerations.

Technical Challenges in Implementation

Implementing free valve technology involves overcoming complex engineering issues. Actuators must operate at high speeds with durability. Reliable real-time valve control is essential for peak engine performance.

The system requires advanced sensors and an efficient electronic control unit (ECU). Both must handle large volumes of data quickly. Failures in any part of the system could lead to operational issues.

Heat is another challenge. Engines generate intense heat during operation. Actuators and sensors in free valve systems must resist high temperatures. Ensuring components work properly under thermal stress increases design complexity.

Noise and vibrations also complicate implementation. Actuators can add noise and decrease engine quietness. Engineers must focus on reducing these effects for better user experience.

Cost and Manufacturing Considerations

Free valve technology is costly to produce compared to traditional engines. Using advanced actuators and sensors requires higher-grade materials. Manufacturing free valve engines demands precise engineering, leading to increased production costs.

Training staff to build and maintain these engines adds to expenses. Industries need skilled workers familiar with this advanced technology.

Costs also rise for consumers. Vehicles equipped with free valve systems are priced higher. Widespread adoption may be delayed due to these economic factors.

Furthermore, retrofitting existing engines with free valve systems is expensive. This limits the scope of integration in older vehicles.

In summary, technical and cost challenges hinder widespread use of free valve engines. Overcoming these issues requires innovation and investment from manufacturers.

Applications of Free Valve Engines

Free valve engines have versatile applications, particularly in the automotive sector. Their flexibility and efficiency make them ideal for modern vehicle design. Industries are exploring their potential for mainstream production and specialized uses.

Free Valve Technology in Automotive Industry

Free valve engines are transforming the automotive industry. They provide improved performance and reduced emissions. Automakers value their adaptability and efficiency for modern vehicles. Sports cars benefit from increased power due to precise valve control. This technology enhances torque delivery and engine responsiveness.

Electric vehicles can integrate free valve systems with hybrid designs. This helps reduce fuel consumption and provides cleaner energy options. Manufacturers can also use free valve engines in heavy-duty vehicles. Trucks and buses enjoy better fuel economy and durability with reduced mechanical components. Luxury cars benefit too, offering smooth rides and lower environmental footprints.

Examples of Vehicles Using Free Valve Engines

Koenigsegg leads in applying free valve engines. Their cars use FreeValve technology for unmatched performance. Koenigsegg’s Gemera showcases this innovation by combining high power with lower emissions.

Some automakers have started testing free valve engines in prototype vehicles. These include models in hybrid and performance categories. While adoption remains limited, interest is growing across the industry.

Specialty vehicles also explore free valve engines. Drones and autonomous vehicles use this technology for efficient operation. These applications highlight free valve engines’ adaptability and effectiveness in diverse sectors.

Future of Free Valve Engines

Free valve engines are not just a current innovation; they represent the future of automotive technology. Researchers and engineers are working on solving existing challenges while exploring new possibilities. Advancements in this area could redefine the engines we know today.

Potential Innovations and Advancements

The future of free valve engines promises exciting innovations. Engineers are focusing on making actuators faster and more durable. Enhanced heat-resistant materials may solve challenges related to high temperatures during engine operation.

Smart sensors and machine learning could improve valve control precision further. These technologies help engines adapt to complex driving environments in real time. Integration of free valve engines with hybrid and electric drivetrains is another promising advancement. This could create eco-friendly systems with better fuel efficiency and lower emissions.

Manufacturing processes may also become more efficient. Innovations in 3D printing and automation could cut costs and simplify production. These changes may make free valve technology more accessible to the mainstream market.

Predictions for Market Adoption

The widespread adoption of free valve engines depends on overcoming several barriers. High manufacturing and consumer costs currently limit market penetration. As production technologies improve, prices are expected to decrease.

Automotive industries will likely prioritize free valve systems in sports cars, luxury vehicles, and prototypes. Over time, adoption may extend to larger markets like heavy-duty trucks and buses. Electric and hybrid vehicle makers could accelerate demand, given the technology’s compatibility.

Consumer awareness will play a key role. As buyers learn about performance and environmental benefits, interest may rise. Government policies promoting lower emissions could also drive adoption.

In conclusion, free valve engines hold vast potential for the future of transport. Advancements in technology and manufacturing will determine their journey towards widespread use.

Innovations Driving Free Valve Technology

1. Advanced Materials

One of the significant innovations in the development of free valve engines has been the use of advanced materials. Lightweight yet durable materials can significantly affect the efficiency and performance of engine components. Manufacturers are exploring options like carbon fiber, specialized alloys, and high-temperature plastics. These materials can reduce weight, increase strength, and improve the longevity of the valves and actuators, ultimately enhancing overall engine performance.

2. Electromechanical Actuation Systems

The heart of free valve technology lies in its innovative actuation systems. Electromechanical actuators are designed to control each valve’s opening and closing dynamically. Unlike traditional systems that rely on mechanical linkages, these electric actuators can provide precise control and rapid response times. Continuous improvements in actuator technology are making them more compact and efficient, paving the way for integration into production engines. As these systems become more reliable and cost-effective, they will contribute to the widespread adoption of free valve technology.

3. Integration with Hybrid Systems

As the automotive industry shifts towards hybrid and electric vehicles, free valve technology can play a vital role in these systems as well. The ability to fine-tune engine parameters aligns perfectly with hybrid powertrains, where fuel efficiency and power output must be optimized. Strategically integrating free valve technology can enhance hybrid systems by allowing for more efficient combustion while maintaining a lighter and more compact engine design. As automotive manufacturers focus on creating sustainable, high-performance vehicles, the synergy between free valve technology and hybrid systems will likely be explored further.

The Competitive Landscape

1. Industry Partnerships

As free valve technology gains traction, industry partnerships are emerging to accelerate development and implementation. Collaborations between engine manufacturers, technology companies, and research institutions can facilitate knowledge exchange and technological advancements. Working together, these entities can enhance the development process and accelerate the time to market for free valve engines. Establishing strategic partnerships will be crucial in overcoming the challenges associated with integrating this technology into existing platforms.

2. Competition and Market Forces

With the potential benefits of free valve technology becoming clearer, other manufacturers are likely to enter the fray as well. The competitive landscape will play a significant role in shaping the future adoption of these systems. Competitors in the automotive and motorcycle industries will evaluate the performance gains associated with free valve systems and may decide to invest in similar technologies. This competition can lead to faster innovations and improvements, ultimately benefiting consumers and pushing manufacturers to continually raise the bar regarding performance and efficiency.

3. Consumer Awareness and Demand

As riding enthusiasts become more aware of free valve technology, consumer demand will likely drive further advancements. Riders seeking improved performance, comfort, and efficiency will actively seek out vehicles equipped with this cutting-edge technology. Awareness campaigns and educational initiatives by manufacturers can play a vital role in informing potential customers about the benefits of free valve engines. As consumer interest builds, manufacturers can respond with tailored products, featuring enhanced performance and cutting-edge solutions that meet rider needs.

Conclusion

Free valve engine technology is on the cusp of revolutionizing the automotive industry by offering unparalleled benefits in efficiency, performance, and emissions reduction. As the development progresses, both manufacturers and consumers will play an active role in shaping its future. The combination of advanced materials, electromechanical actuation, and integration with emerging powertrains ensures that free valve technology remains at the forefront of innovation.

With a commitment to sustainability and performance, free valve engine represent the next evolution in motorcycle design. As the market responds to increased consumer awareness and demand for improved performance, we are likely to see accelerated adoption across various segments. This evolution will empower riders to explore new levels of performance while minimizing their environmental impact.

Ultimately, free valve technology is a compelling testament to the power of innovation within the motorcycle industry. As we witness the capability of these engines on the road, the expectation is high for an exciting new chapter in motorcycling history. The future of free valve engine holds great promise for riders, positioning them at the intersection of comfort, performance, and sustainability. Embrace this technological shift and look forward to countless rides filled with excitement and efficiency.

Leave a Reply