What is a Rotary Valve Engine?

Rotary valve engine is a unique category of internal combustion engines. They replace traditional poppet valves with rotary valves to control air-fuel intake and exhaust. The design eliminates the need for valve springs, rockers, or camshafts typically found in conventional engines.

Definition and Key Components

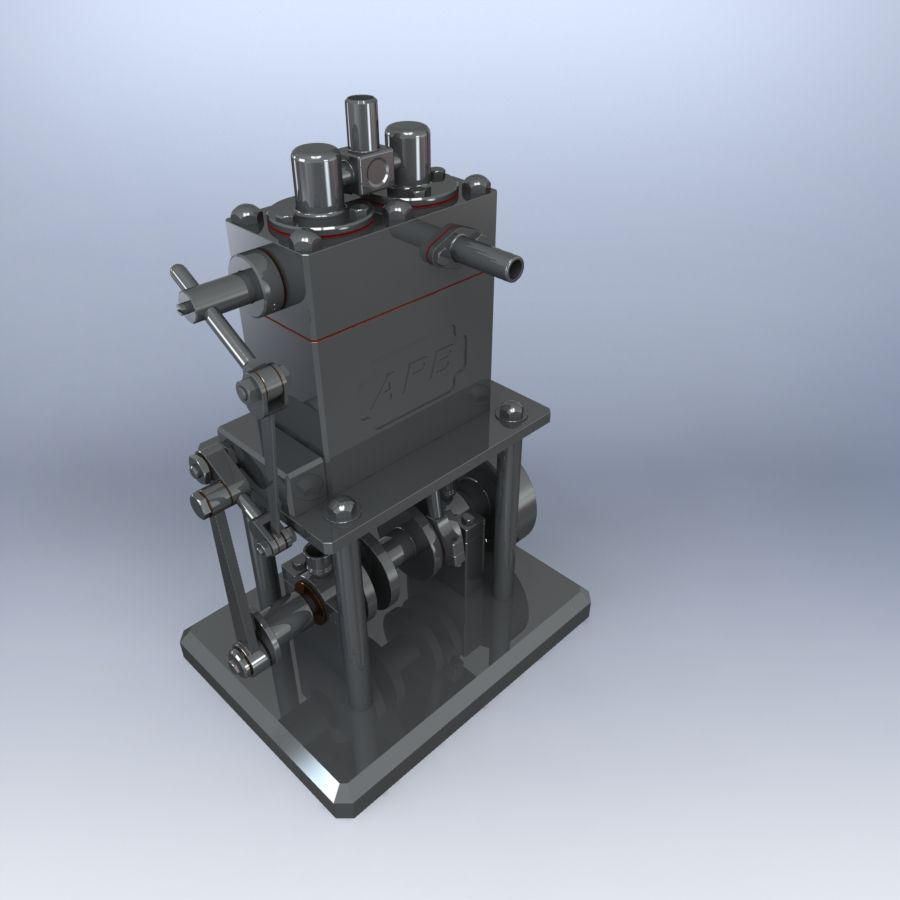

A rotary valve engine uses a rotating valve mechanism instead of sliding components. These rotary valves are often cylindrical or disk-shaped and rotate synchronously with the engine’s cycle. The key components include:

- Rotary Valve: Controls airflow and combustion gas exchange.

- Cylinders: Holds the air-fuel mixture for combustion.

- Crankshaft: Transfers engine power to the drive system.

- Housing: Encases the rotating valve for smooth operation.

This design leads to a simplified structure with fewer moving parts.

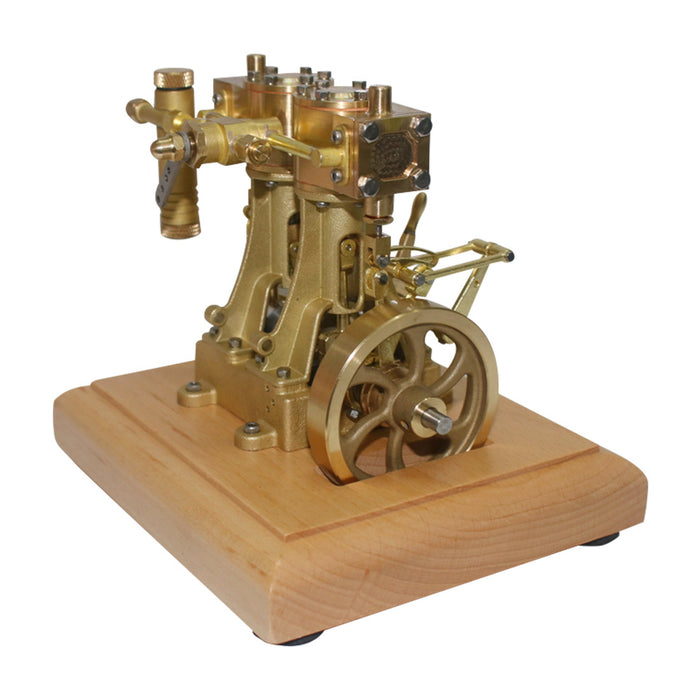

Historical Overview of the Rotary Valve Engine

The rotary valve engine concept dates back to the early 20th century. Early models appeared in experimental designs for motorcycles and cars. By mid-century, engineers explored the design for aviation and military applications. Notably, rotary valve engines gained attention for small-scale high-performance uses. However, the challenges of sealing and manufacturing limited widespread adoption.

Modern advancements aim to overcome these limitations through better materials and precise machining. This renewed interest could lead to broader applications in the future.

Working Principles of Valve Engines

Understanding the working principles of rotary valve engines is essential to appreciate their unique design. These engines differ significantly from conventional poppet valve engines, particularly in air-fuel management and exhaust systems.

How Rotary Valves Operate Compared to Traditional Valves

Rotary valve engines use spinning valves to handle intake and exhaust. Traditional valves, like poppet valves, open and close vertically with springs and camshafts. In rotary valve engines, the valve’s rotation synchronizes with the engine cycle to control airflow and combustion gases.

Key differences in operation include:

- Fewer Moving Parts: Rotary valves remove springs, rockers, and camshafts. This creates a more straightforward mechanism.

- Improved Airflow: Rotating valves provide smoother and more consistent airflow.

- Higher RPM Capability: Fewer moving parts allow the engine to run at higher revolutions per minute.

These differences result in a compact design and faster response compared to traditional systems.

Internal Mechanics of a Rotary Valve Engine

The internals of a rotary valve engine centers around its rotating valve. The main mechanical components involved include:

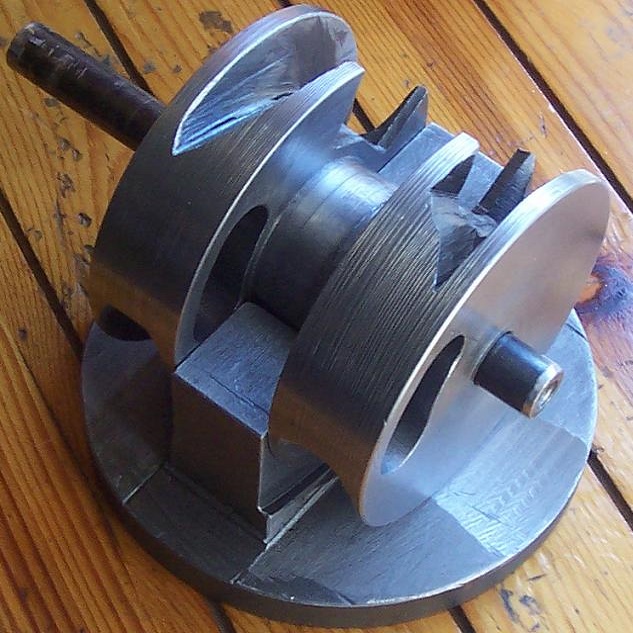

- Cylindrical or Disk Valves: These rotate to align their openings with intake and exhaust ports.

- Valve Housing: Encases the rotary valve for proper alignment and sealing.

- Crankshaft Synchronization: The rotary valve’s motion aligns with the piston’s cycle, ensuring precise timing.

- Lubrication System: Keeps the moving parts cool and functional.

The rotary valve’s rotation is carefully timed with the piston’s movement. When the piston ascends during the exhaust stroke, the valve opens the corresponding port to release combustion gases. Similarly, during the intake stroke, the valve aligns with the intake port to allow air-fuel mixture entry.

Unlike conventional designs, rotary valve engines create a consistent seal with fewer risks of engine wear. This contributes to smoother operation and potentially higher efficiency.

Advantages of Rotary Valve Engines

Rotary valve engines offer several benefits over traditional internal combustion engines. These advantages make them a promising technology for specific uses. Let’s explore their key strengths.

Performance Benefits

Rotary valve engines deliver superior performance compared to conventional poppet valve systems. This is due to their unique design and operation:

- Higher RPM Capability: With fewer moving parts, rotary valve engines can run at higher revolutions per minute. This results in better power output and efficiency.

- Enhanced Airflow: Rotating valves ensure smoother and more consistent air-fuel flow. This reduces turbulence and increases engine efficiency.

- Compact Design: Without bulky valve trains, these engines are lighter and smaller. This makes them suitable for high-performance and space-constrained applications.

These performance enhancements make rotary valve engines ideal for motorsport and high-speed uses.

Efficiency and Fuel Economy Improvements

One of the notable benefits of rotary valve engines is improved fuel efficiency. Key factors include:

- Optimized Combustion: Better airflow ensures a more uniform air-fuel mixture and efficient combustion.

- Reduced Friction: Fewer moving components lead to less energy loss from friction.

- Precise Timing: Rotary valves maintain accurate timing, improving engine responsiveness and fuel use.

These factors together contribute to fuel savings and reduced emissions, which are critical for modern engines.

Potential Design Simplicity

Rotary valve engines also stand out for their simpler construction. Their design eliminates unnecessary parts:

- No Rockers or Valve Springs: The lack of these parts reduces complexity and minimizes potential failure points.

- Fewer Components: This results in improved reliability and easier assembly.

- Simplified Maintenance: With fewer parts to wear down, upkeep becomes simpler and more cost-effective.

This simplicity not only lowers production costs but also enhances longevity when properly maintained.

In summary, rotary valve engines excel in performance, efficiency, and streamlined design. These attributes make them an innovative alternative to conventional engine systems.

Challenges and Limitations

Rotary valve engines offer many advantages but also face several challenges and limitations. These issues have historically hindered their widespread adoption and full potential.

Technical and Mechanical Issues

Rotary valve engines have unique technical challenges compared to traditional engines:

- Sealing Problems: Ensuring an airtight seal remains difficult due to the rotating parts. Poor sealing can reduce efficiency and increase emissions.

- Thermal Management: The rotary valve operates under high temperatures. Without proper cooling, overheating can lead to wear.

- Complex Timing: Synchronizing the rotary valve with the piston cycle requires extreme precision.

- Lubrication Needs: The constant rotation of the valve requires a reliable lubrication system to prevent wear.

These mechanical complexities demand advanced engineering and precise manufacturing techniques.

Manufacturing Challenges

Producing rotary valve engines involves specific challenges that affect feasibility:

- High Production Costs: The precise machining of rotary valves increases manufacturing expenses.

- Material Constraints: Rotary valves need durable materials to handle high pressure and heat.

- Limited Scalability: Manufacturing rotary valves on a large scale remains challenging due to complexity.

- Tooling Requirements: Specialized equipment is necessary for producing and assembling rotary systems.

These issues make mass production more expensive compared to traditional engines, limiting their appeal.

Durability and Maintenance Concerns

While rotary valve engines simplify some aspects, they introduce new durability and maintenance concerns:

- Valve Wear: Continuous rotation may cause wear on the valve and related components.

- Frequent Repairs: Sealing and lubrication systems often require regular inspection and servicing.

- Material Fatigue: Over time, high stress can lead to cracks or deformation in engine parts.

- Specialized Repairs: Fixing rotary valve systems requires expertise and specific tools, increasing maintenance costs.

These durability concerns impact the long-term reliability of the system.

In conclusion, overcoming these challenges remains vital for the broader adoption of rotary valve engines.

Applications of Rotary Valve Engines

Rotary valve engines have unique features that make them suitable for diverse applications. Their compact design, high performance, and efficiency cater to specific industries. Let’s explore their most notable use cases.

Automotive Industry

The automotive industry has shown interest in rotary valve engines for high-performance vehicles. Key advantages make them appealing:

- Enhanced Power Output: Higher RPM capability translates to greater power for sports cars and race vehicles.

- Compact Size: Their smaller footprint fits well in space-constrained car designs.

- Improved Efficiency: Better airflow and combustion support fuel economy goals.

Performance-focused automakers and racing teams see potential in these engines for track and performance applications. However, adoption remains limited due to sealing and manufacturing challenges.

Aerospace and High-Performance Uses

The aerospace sector benefits from rotary valve engines’ ability to operate at high RPMs. Applications include:

- Light Aircraft: The compact and lightweight structure suits smaller aviation engines.

- Drones and UAVs: Their high power-to-weight ratio is essential for unmanned systems.

- Military Applications: Studies have used these engines in aircraft requiring efficient and durable components.

These engines shine in environments needing compact designs and reliability. Engineers continue exploring solutions to adapt them for larger aircraft systems.

Other Industrial Applications

Beyond vehicles and aerospace, rotary valve engines find utility in industries requiring specialized solutions:

- Small-Scale Power Generation: Their high efficiency is valuable in portable and emergency generators.

- Marine Engines: Compact sizes and performance appeal to high-speed boats and jet skis.

- Specialized Machinery: Industries like agriculture and mining benefit from efficient, durable engines.

In such contexts, their streamlined design helps lower operating costs and maintenance efforts.

In summary, rotary valve engines offer considerable potential across transportation, aerospace, and industrial markets. While niche today, technological advancements may soon expand their use.

Comparison to Traditional Poppet Valve Engines

Rotary valve engines stand apart from traditional poppet valve designs in many ways. Their innovative approach changes how air-fuel intake and exhaust are managed. Let’s explore these differences and compare their performance and reliability.

Key Differences in Design and Operation

Rotary valve engines and traditional poppet valve engines differ significantly in structure and functionality:

- Valve Mechanism: Rotary valve engines use rotating valves, while poppet valves open and close vertically.

- Parts Count: Rotary systems eliminate springs, camshafts, and rockers, leading to fewer moving components.

- Airflow Control: Rotary valves provide smoother airflow, minimizing turbulence compared to poppet valves.

- Engine Compactness: The absence of bulky valve trains makes rotary engines smaller and lighter.

- Timing Precision: Rotary valves sync directly with the engine cycle, offering highly accurate timing control.

These design differences make rotary valve engines unique, simplifying certain operations and creating new possibilities.

Performance and Reliability Comparison

Rotary valve engines deliver many performance advantages over traditional poppet valve systems:

- Higher RPM Limits: With fewer parts, rotary engines can handle higher revolutions per minute.

- Improved Efficiency: They maintain better airflow, optimizing combustion and boosting fuel economy.

- Enhanced Power Output: Rotary valve designs help directly increase engine power in high-performance applications.

However, when it comes to reliability, challenges exist:

- Thermal Management: Rotary engines face higher risks of overheating without effective cooling systems.

- Seal Durability: Ensuring long-lasting airtight seals under stress is harder for rotary valves.

- Maintenance: Rotary valve systems need specialized care, which increases upkeep costs.

In summary, rotary valve engines outperform in performance aspects but face durability and reliability challenges. These factors influence their feasibility for widespread use compared to traditional engines.

Innovations and Developments in Rotary Valve Technology

Rotary valve engines have evolved significantly over time. Modern advancements address many earlier challenges. Innovations in design, materials, and performance are paving the way for broader adoption.

Modern Designs and Materials

Recent engineering efforts have focused on improving rotary valve designs. These efforts include:

- Advanced Sealing Technology: Modern sealing systems now withstand higher pressures and temperatures, ensuring better efficiency.

- Heat-Resistant Materials: Components use ceramics and specialized alloys to reduce wear and handle extreme heat.

- Precision Manufacturing: Advanced machining techniques improve part alignment, minimizing failures and improving reliability.

- Reduced Friction Coatings: New coatings help reduce friction and extend component life.

These new designs and materials significantly enhance the performance and longevity of rotary valve engines.

Recent Projects and Prototypes

Many companies and institutions continue experimenting with rotary valve engines. Notable recent projects include:

- High-Performance Automotive Engines: Manufacturers explore these engines for racing and high-speed vehicles.

- Aerospace Applications: Lightweight prototypes are being tested for drones and small aircraft.

- Marine Implementations: Engineers experiment with rotary valves for compact yet powerful boat engines.

- Portable Generators: Prototypes aim to deliver efficient and reliable power solutions.

By testing these engines in real-world conditions, their practicality and limitations are being assessed.

Future Potential of Rotary Valves in Engines

The future of rotary valve engines looks optimistic. Key factors driving their potential include:

- Broader Applications: Improved designs may suit cars, airplanes, and industrial equipment.

- Environmental Benefits: Reduced emissions and higher efficiency support environmental goals.

- Cost Improvements: Mass production techniques could lower manufacturing expenses over time.

- Technological Synergy: Integration with electric-hybrid systems could unlock new possibilities.

While challenges remain, technological advancements are steadily bridging the gaps. Rotary valve engines may soon compete with or complement traditional systems in several sectors.

Conclusion

The rotary valve engine stands out as a compelling option for those looking for innovative and efficient alternatives to traditional designs. Its inner workings set it apart, emphasizing the benefits of unique designs that efficient engineering can bring. Riders and manufacturers alike can appreciate the advantages that rotary technology offers, ranging from improved performance to environmental sustainability.

Exploring the capabilities of rotary valve engine inspires excitement for the future. As manufacturers innovate and adapt, rotary engines may pave the way for a new era in automotive design. The continuous evolution of technology promises that rotary engines will play a prominent role in shaping the future of mobility, both on the road and in industrial applications.

By embracing this innovative approach, riders and engineers can create motorcycles and vehicles that meet modern demands while reflecting a commitment to sustainability and efficiency. As the journey of the rotary valve engine continues, its potential will undoubtedly impress enthusiasts and innovators alike, marking a thrilling chapter in the evolution of transportation.

Leave a Reply