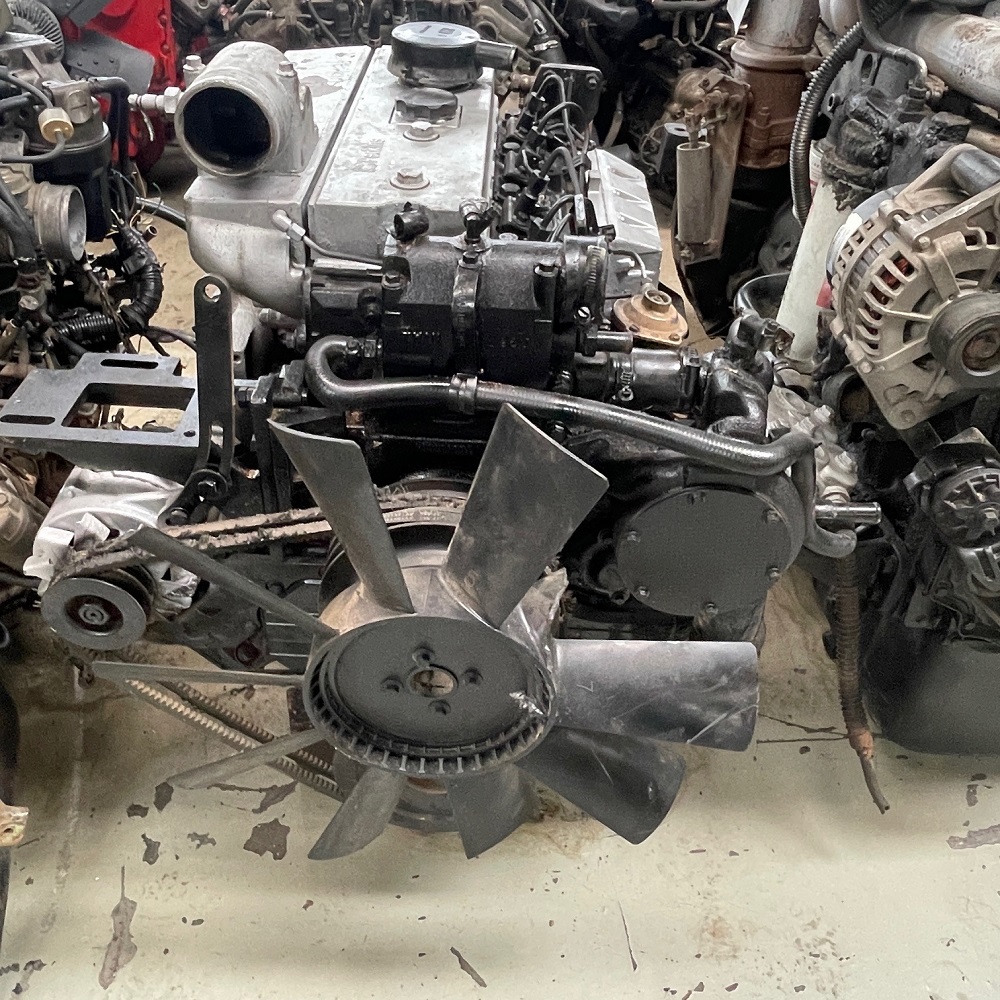

Introduction to 4 Cylinder Diesel Engines

What Is a 4 Cylinder Diesel Engine?

A 4 cylinder diesel engine is an internal combustion engine with four cylinders. Diesel engines work by compressing air and then injecting fuel to ignite. These engines are known for efficiency and durability. Each cylinder has a piston that moves to produce power. In a 4 cylinder engine, the small size helps reduce weight and space usage while maintaining performance.

Brief History and Evolution

Diesel engines were invented by Rudolf Diesel in the late 19th century. Early designs were large and used mainly in industries. Over time, 4 cylinder diesel engines became smaller and lighter. Advancements in materials and technology enhanced their efficiency and reliability. Today, they are common in compact cars, light trucks, and machinery.

Common Applications and Popularity

These engines are widely used in vehicles and machinery. They are popular in cars for their fuel efficiency. Trucks and SUVs use them for better torque and towing capacity. Industries also rely on them for generators and equipment. Their global popularity is due to durability and lower operating costs.

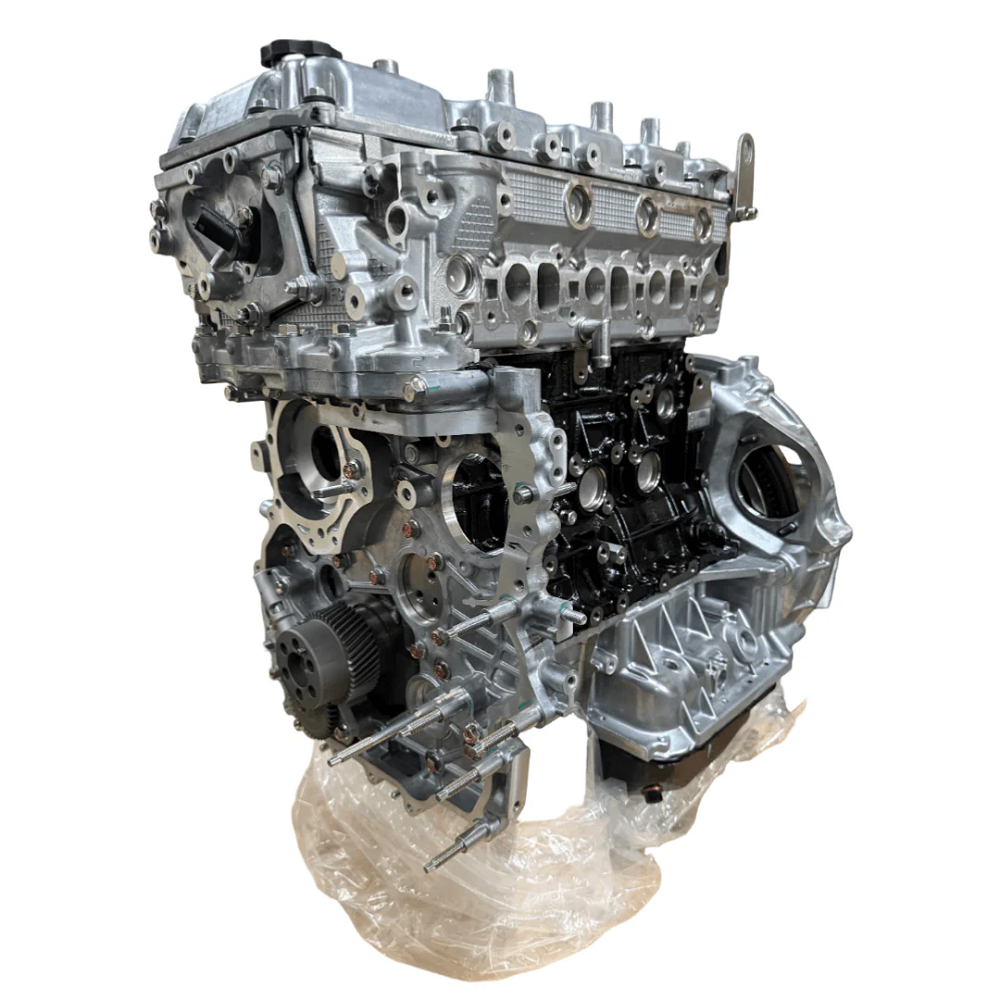

Key Components of a 4 Cylinder Engine

4 cylinder diesel engines rely on key components to deliver power efficiently. Each part plays a crucial role in the engine’s performance, durability, and efficiency. Below are the essential components and their functions:

Cylinders and Pistons

Cylinders house pistons that create power through controlled explosions. Pistons move up and down inside the cylinders. This motion converts chemical energy from fuel into mechanical energy. In a 4 cylinder diesel engine, the four pistons work sequentially for smooth operation. Strong materials like aluminum or steel are used for durability.

Fuel Injection Systems

Fuel injection systems deliver the fuel into the engine’s cylinders. Diesel engines rely on precision injections. Modern systems use electronic controls to calculate the optimal fuel amount. This improves fuel efficiency and reduces emissions. Proper timing of injections is critical for engine performance.

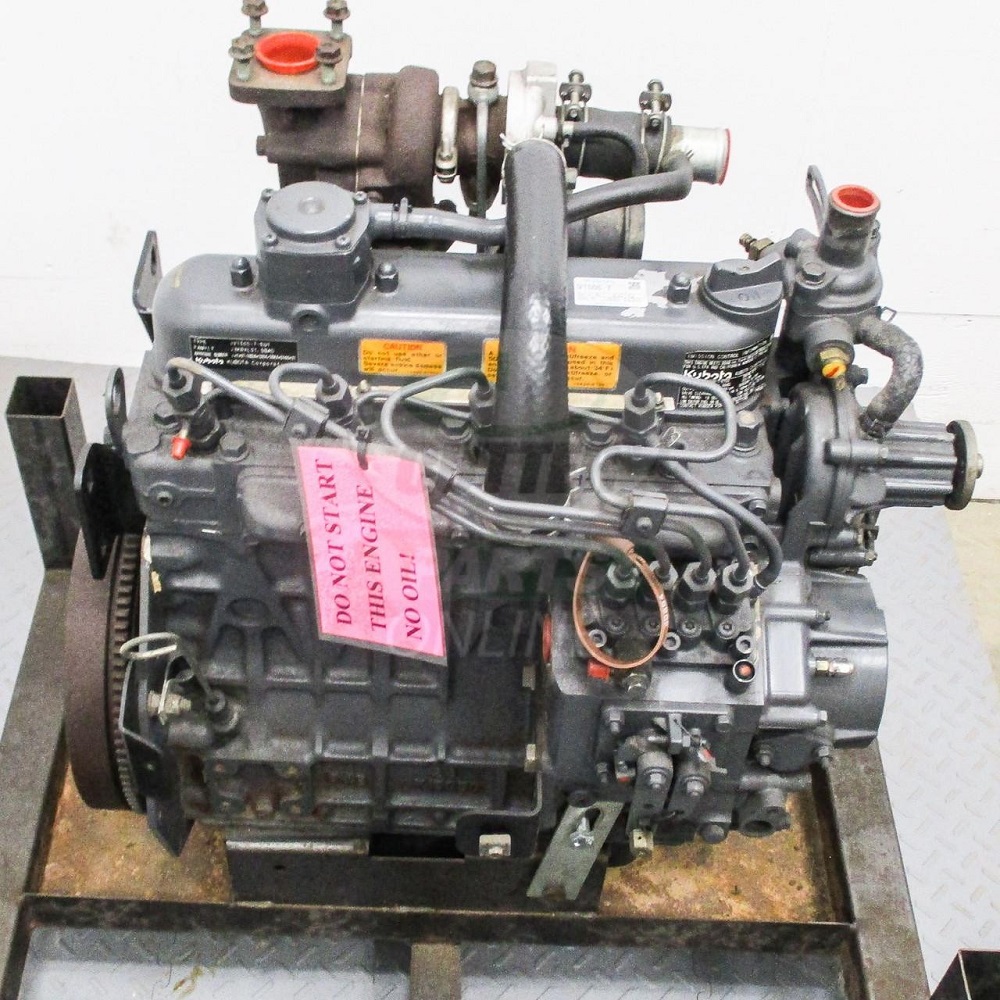

Turbochargers and Intercoolers

Turbochargers increase engine power by compressing more air into the cylinders. This allows more fuel to burn, creating extra energy. Intercoolers cool the compressed air before entering the engine. Cooler air improves combustion efficiency and reduces engine temperature. Together, they enhance overall performance.

Cooling Systems

Cooling systems regulate the engine temperature to prevent overheating. They include water pumps, radiators, and coolant liquids. Diesel engines generate high heat due to their compression process. Effective cooling ensures the engine runs efficiently and safely over time. Regular maintenance is vital for a long engine life.

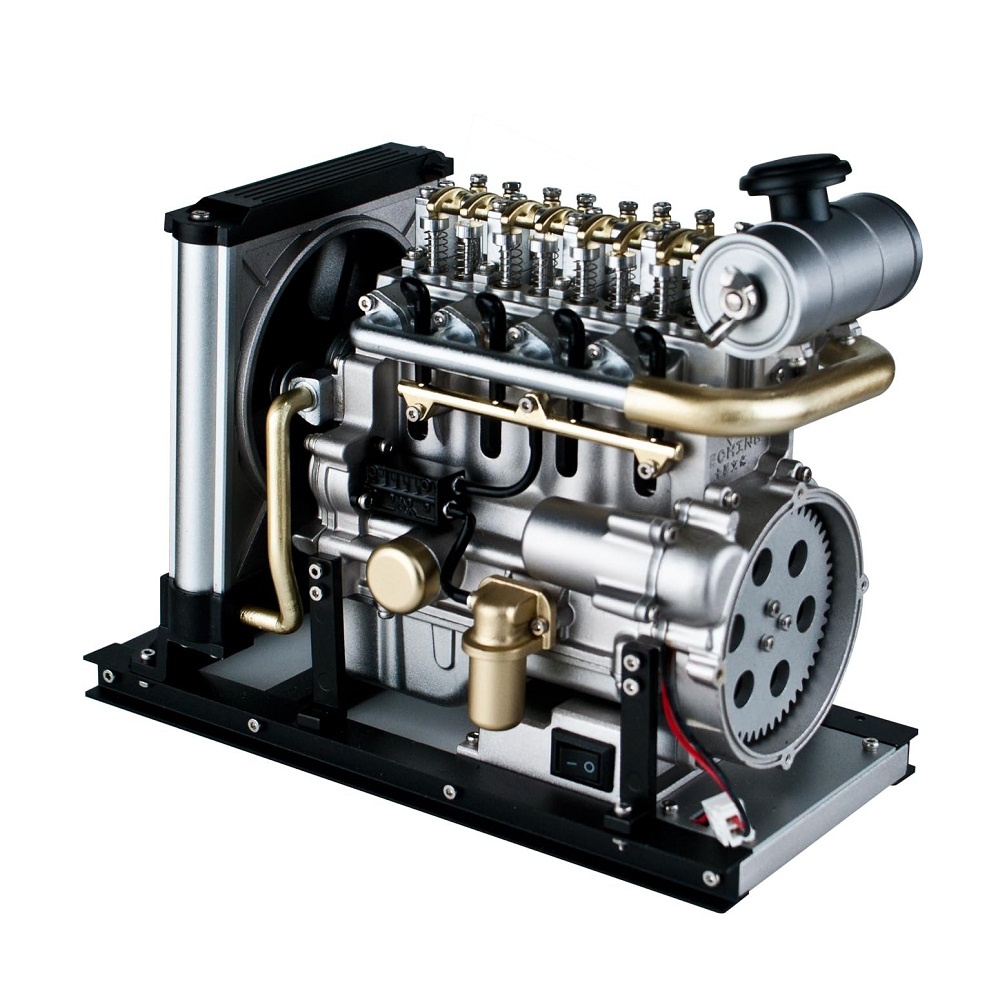

How a 4 Cylinder Engine Operates

Understanding how a 4 cylinder diesel engine operates helps in appreciating its efficiency and design. These engines rely on precise processes to convert fuel energy into mechanical power. Below are the core principles that make them function effectively.

The Diesel Combustion Process

The diesel combustion process starts with air compression in the cylinders. Diesel engines compress air to very high pressures, which heats the air significantly. Once heated, fuel is injected into the cylinder. The high temperature causes the diesel fuel to ignite instantly, creating powerful energy. This controlled explosion drives the piston, generating mechanical energy. Unlike gasoline engines, diesel combustion does not require spark plugs.

The Four-Stroke Cycle Explained

A 4 cylinder diesel engine uses the four-stroke cycle for power generation. These strokes include:

- Intake Stroke: Air is drawn into the cylinder as the piston moves down.

- Compression Stroke: The piston moves up, compressing the air to high pressure.

- Power Stroke: Fuel is injected, ignites, and forces the piston downward, creating energy.

- Exhaust Stroke: The piston pushes exhaust gases out of the cylinder.

Each cylinder completes this cycle sequentially, ensuring smooth and efficient operation.

Role of Compression in Diesel Engines

Compression plays a key role in diesel engine functionality. Diesel engines rely on higher compression ratios than gasoline engines. High compression creates heat that ignites the fuel without a spark. This results in better fuel efficiency and more torque. The durability of components is crucial to withstand intense compression forces. Proper maintenance ensures the compression process remains optimal for long-term performance.

Advantages of 4 Cylinder Engines

4 cylinder diesel engines offer many advantages, making them a popular choice for vehicles and machinery. Below are the key benefits explained in detail.

Fuel Efficiency and Economy

4 cylinder diesel engines are highly fuel-efficient. They burn less fuel than gasoline engines to cover the same distance. This makes them ideal for long trips and heavy loads. Diesel fuel delivers more energy per gallon, enhancing mileage. Their efficient design helps reduce overall fuel costs, especially for frequent drivers or businesses.

Durability and Longevity

These engines are known for their long lifespan. Strong materials like steel or cast iron ensure durability. They operate at lower RPMs, which reduces wear over time. Regular maintenance can help them run efficiently for decades. Diesel engines also handle high loads better, making them an excellent investment.

Low-End Torque Benefits

4 cylinder diesel engines provide excellent low-end torque. This means they generate more power at low speeds. It makes them ideal for pulling heavy loads or driving uphill. This feature is especially valuable in trucks and SUVs. Low-end torque also improves performance in stop-and-go traffic. Both professionals and regular drivers benefit from strong torque performance.

Disadvantages of 4 Cylinder Engines

While 4 cylinder diesel engines offer many advantages, they also come with certain drawbacks. Understanding these disadvantages helps in making informed decisions.

Common Maintenance Challenges

Maintaining 4 cylinder diesel engines can be more demanding than gasoline engines. Their components, like fuel injectors and turbochargers, require precise care. Improper maintenance often leads to soot buildup and clogged injectors. Diesel fuel systems need regular checks to avoid contaminations or air issues. Repairs for diesel engines can also be more costly compared to gasoline counterparts.

Noise and Vibration Issues

4 cylinder diesel engines are noisier than gasoline engines. Their high compression process generates louder sounds. Vibrations, especially at lower speeds, are often noticeable. These aspects may reduce comfort, particularly in passenger vehicles. Advanced technologies like soundproofing and engine mounts help, but cannot eliminate the problem entirely.

Initial Cost Considerations

The upfront cost of vehicles with diesel engines is higher. This is due to the materials, technology, and manufacturing involved. Diesel vehicles may also incur additional expenses, such as higher road taxes in some regions. While operational savings exist through fuel efficiency, the initial financial barrier can cause hesitation for buyers.

Overall, while the benefits of 4 cylinder diesel engines are significant, these disadvantages should also be carefully evaluated before choosing one.

Comparing 4 Cylinder Engines to Other Engine Types

Diesel vs. Gasoline Engines

Diesel engines compress air to high pressures before injecting fuel, while gasoline engines mix air and fuel before compression. A 4 cylinder diesel engine is more fuel-efficient than a gasoline engine. Diesel delivers better mileage and generates more power at lower speeds. However, diesel engines are noisier and produce more vibrations compared to gasoline engines. Maintenance for diesel engines is often more specialized and expensive. On the other hand, gasoline engines are easier and cheaper to repair. When choosing, consider fuel cost, performance needs, and overall maintenance.

4 Cylinder vs. 6 Cylinder Engines

A 4 cylinder diesel engine is lighter and more compact than a 6 cylinder engine. Its design offers better fuel efficiency and is ideal for everyday vehicles. However, 6 cylinder engines provide more power and faster acceleration. They are better suited for larger vehicles and heavy-duty applications. In terms of maintenance, 4 cylinder engines tend to cost less to repair. They also fit into smaller spaces, making them ideal for compact cars. Choose a 4 cylinder engine when fuel economy and space are priorities. Opt for a 6 cylinder engine when power and towing capacity are essential.

When to Choose a 4 Cylinder Diesel Engine

A 4 cylinder diesel engine is perfect for individuals prioritizing fuel efficiency. It is ideal for long-distance drivers or commuters who want to reduce fuel costs. These engines are also great for vehicles requiring good low-end torque, like pick-up trucks or SUVs. Additionally, they suit compact vehicles where lighter engines improve overall efficiency. On the downside, avoid a 4 cylinder diesel engine if maximum speed or high horsepower is a priority. Analyze your needs for performance, efficiency, and cost before making a decision.

Maintenance Tips for 4 Cylinder Diesel Engines

Regular maintenance is essential for keeping your 4 cylinder diesel engine running efficiently. Proper care helps extend the engine’s life, ensures performance, and prevents costly repairs. Below are key maintenance tips:

Regular Oil Changes

Changing the oil regularly is vital for the engine’s health. Diesel engines operate at high pressures, which can break down oil faster. Fresh oil reduces friction and protects engine components from wear. Use quality diesel-engine-specific oil and follow the manufacturer’s recommended schedule. Regular oil changes prevent contamination and ensure smooth engine operations.

Monitoring Fuel System Performance

Diesel engines rely on precise fuel delivery for optimal performance. Regularly inspect the fuel system for clogs or leaks. Clean or replace fuel filters as needed to ensure dirt-free fuel flow. Diesel injectors should be professionally cleaned to prevent buildup. Monitoring fuel quality is also essential. Use clean, high-quality diesel to reduce the risk of contaminants damaging the system.

Inspecting Turbochargers and Cooling Systems

Turbochargers enhance engine power, but they need proper care to last. Inspect turbochargers regularly for damage or leaks. Ensure that intercoolers are clean and free of obstruction for efficient cooling. Cooling systems are equally critical for regulating engine temperature. Check radiators, water pumps, and coolant levels frequently. Replace coolant according to the manufacturer’s schedule to avoid overheating.

By focusing on regular maintenance, your 4 cylinder diesel engine will perform reliably for years. These simple practices save money and keep your engine in peak condition.

Innovations and Future Trends in Diesel Engine Technology

Modern diesel engine technology is evolving rapidly to meet environmental and efficiency goals. These advancements aim to enhance performance, reduce emissions, and integrate hybrid solutions. Below are key trends shaping the future of diesel engines.

Cleaner Emission Technologies

Emission reduction is a major focus in diesel engine innovation. Technologies like selective catalytic reduction (SCR) help lower nitrogen oxides (NOx). Diesel particulate filters (DPFs) capture harmful soot particles, reducing air pollution. Advanced exhaust gas recirculation (EGR) systems optimize combustion to limit emissions. Manufacturers continuously improve these systems to meet stricter environmental regulations. Cleaner emissions make diesel engines more sustainable and eco-friendly for global use.

Advances in Engine Materials and Design

New materials and designs improve engine efficiency and durability. Lightweight alloys like aluminum reduce engine weight, boosting fuel efficiency. Strong metals, such as steel, help components resist compression forces, extending lifespan. Improved cooling designs ensure engines operate safely under high pressure. Aerodynamic pistons and cylinder designs enhance combustion, generating more power. These innovations offer better reliability and performance over traditional diesel engines.

The Role of Hybrid and Electric Systems

Diesel-electric hybrid systems combine diesel engines with electric motors. This setup improves fuel efficiency and emission control. Hybrid engines reduce the reliance on diesel during low-speed operations. Plug-in hybrid variants allow partial operation on electricity, further saving fuel. Electric systems are integrated into certain diesel vehicles for urban driving. These engines balance power and sustainability, paving the way for greener transportation.

Diesel engine technology continues to advance, addressing environmental concerns and performance demands. Innovations like cleaner emissions, improved materials, and hybrid systems ensure a promising future for these engines.

Keeping Your 4 Cylinder Diesel Engine Running Smoothly

The Joy of Riding

Owning a 4 cylinder diesel engine presents a unique sense of freedom and joy for riders. Whether traveling long distances or navigating daily commutes, these engines offer reliability and efficiency. Understanding how to care for your engine through proactive maintenance is crucial for ensuring a smooth and enjoyable riding experience. By taking the time to learn about your engine, you can make informed decisions that keep your motorcycle or vehicle performing at its best.

The Value of Knowledge

Knowledge is power when it comes to motorcycle maintenance. Equipping yourself with information about the workings and care of your 4 cylinder diesel engine allows you to address issues confidently. Understanding basic mechanics, fuel types, and potential breakdowns prepares you for any riding situation. This strong foundation of knowledge can help you avoid costly repairs and enhance the overall enjoyment of your vehicle.

Enjoy the Journey Ahead

In the end, the journey with your 4 cylinder diesel engine is what truly matters. Whether you are riding for leisure or utility, each experience on the road should be cherished. By prioritizing maintenance, understanding your engine’s needs, and cultivating a passion for riding, you can ensure that countless hours of adventure and enjoyment lie ahead. So prepare your 4 cylinder diesel engine for the open road, learn from every experience, and embrace the thrill of the ride.

Leave a Reply