Introduction to Piston and Cylinder Systems

The Purpose of Pistons and Cylinders

In internal combustion engines, the piston and cylinder play crucial roles in converting fuel into mechanical energy. This process is fundamental to how most automobiles, motorcycles, and various machinery operate. The piston is a cylindrical component that moves up and down within the cylinder, creating pressure and facilitating combustion. Together, they form an essential part of the engine assembly, functioning as the heart of the engine. Understanding their interdependence explains how engine efficiency and performance can be optimized.

Types of Engines Utilizing Pistons and Cylinders

Pistons and cylinders are found in several types of engines, including gasoline, diesel, and even some rotary engines. Each engine type has its unique design and operation principles, but the fundamental piston-cylinder relationship remains constant. For instance, in a four-stroke gasoline engine, the piston moves through four distinct phases—intake, compression, power, and exhaust—making the interaction between these two components vital for effective power generation.

Overview of the Article

This article will explore the intricacies of pistons and cylinders, focusing on their construction, types, and how they work together within an engine. We will discuss the importance of materials, design specifications, and maintenance considerations. By examining these aspects, readers will gain a comprehensive understanding of how these components operate in tandem to drive performance and efficiency in various engines.

Basics of Pistons and Cylinders

Pistons and cylinders form the core of internal combustion engines. They work together to generate power efficiently. Understanding their basics is essential for grasping engine mechanics.

What are Pistons?

Pistons are cylindrical components that move up and down inside the cylinder. They are made of strong materials like aluminum or steel. Pistons convert the energy from combustion into mechanical motion. They also create the compression needed for the combustion process.

What are Cylinders?

Cylinders are hollow chambers where the piston operates. They contain fuel and air for combustion. Cylinders guide the piston’s motion in a linear path. They are usually made of cast iron or aluminum alloys for durability. The number of cylinders in an engine affects its power output and performance.

Key Components of the Piston-Cylinder Assembly

The piston-cylinder assembly includes several parts:

- Piston: Moves to compress air and fuel in the cylinder.

- Cylinder: Houses the piston and guides its movement.

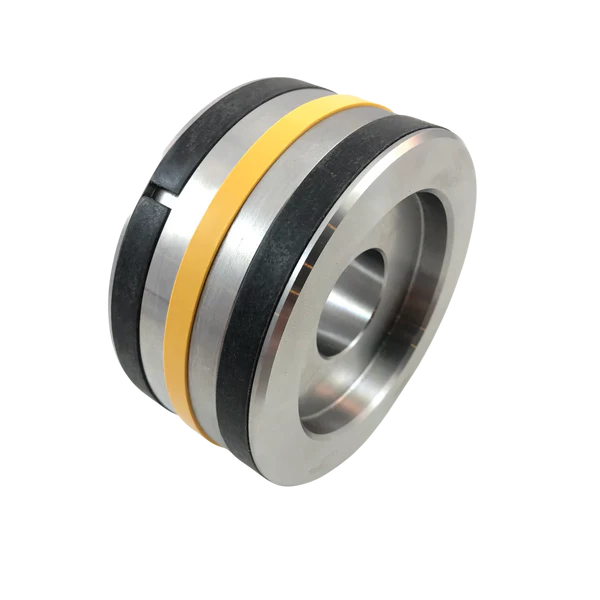

- Piston Rings: Seal the gap between the piston and cylinder wall, preventing gas leakage.

- Connecting Rod: Connects the piston to the crankshaft for motion transfer.

- Crankshaft: Converts linear piston movement into rotational energy.

- Cylinder Head: Closes the top of the cylinder and holds the valves.

All these components work in harmony to provide smooth engine function. Proper maintenance ensures their longevity.

The Role of Pistons in Engines

Pistons play a key role in the workings of internal combustion engines. They convert energy from fuel combustion into mechanical motion, driving the engine’s overall function.

How Pistons Create Motion

Pistons create motion by transferring the energy from combustion to the crankshaft. When fuel and air ignite in the cylinder, they produce high-pressure gases. These gases push the piston downward. This up-and-down motion is called reciprocating motion. The connecting rod links the piston to the crankshaft. The crankshaft then transforms this linear motion into rotational energy. Rotational energy powers components like the wheels or generator.

Pistons ensure the engine operates efficiently. Their precise movement is critical for maintaining consistent power output. Without pistons, fuel energy would not translate into usable mechanical force.

Importance of Piston Design and Materials

Piston design and materials greatly affect engine performance and durability. Pistons face high temperatures and pressures during operation. They need to withstand thermal stress and wear-and-tear.

- Materials Used: Pistons are often made of aluminum alloys. Aluminum is lightweight and durable, ensuring reduced stresses on the engine. Steel is another option for high-performance engines requiring extra strength.

- Shape and Design: Pistons are designed for smooth motion and effective combustion. The top part, called the crown, often has specific contours to optimize the combustion process.

- Heat Resistance and Coatings: Pistons often feature heat-resistant coatings or treatments. These coatings minimize wear and improve efficiency.

Proper design and durable materials ensure pistons function smoothly under tough conditions. Regular maintenance also helps prolong their operational life.

In summary, pistons are vital for converting combustion energy into the motion that powers engines. Their design and material enhancements continue to improve engine performance over time.

The Function of Cylinders in the Engine

Cylinders are central to any internal combustion engine. They enable the conversion of fuel energy into mechanical power. By housing and guiding pistons, they play a crucial role in the engine’s operation.

Purpose of Cylinders in Power Generation

Cylinders create the space for air and fuel to mix and combust. This combustion generates energy in the form of high-pressure gases. These gases push the piston downward, producing motion. Without cylinders, there would be no chamber to contain combustion and harness energy efficiently.

The design and placement of cylinders affect an engine’s power output and efficiency. Engines with more cylinders, like V6 or V8 engines, generally produce greater power. Cylinders also aid in maintaining engine balance, ensuring smoother performance. Properly functioning cylinders ensure efficient energy transfer and improve fuel economy.

Cylinder Design and Types

Cylinder design varies based on engine requirements. Their shape, material, and arrangement impact engine efficiency and durability.

- Materials: Most cylinders are made of cast iron or aluminum alloys. Cast iron offers durability, while aluminum alloys are lightweight and transfer heat effectively.

- Arrangement: Cylinders can be arranged in multiple configurations, such as inline, V-shaped, or flat. Inline engines offer simpler construction, while V-shaped designs are compact and powerful, making them ideal for performance vehicles.

- Types: Cylinders come in dry and wet varieties. Dry cylinders have no contact with engine coolant, whereas wet cylinders are directly encased by coolant to reduce heat.

- Bore and Stroke: Cylinder bore and stroke define the engine’s displacement and power. A larger bore increases combustion volume, while a longer stroke enhances torque.

Modern cylinder designs focus on improving fuel efficiency and reducing emissions. Advanced materials and coatings also improve durability and heat resistance. These innovations ensure that cylinders handle the demands of modern engines effectively.

The Interaction Between Pistons and Cylinders

Pistons and cylinders work closely to generate power in internal combustion engines. Their interaction is crucial for converting fuel energy into motion. Proper synchronization ensures efficiency and smooth engine operation.

The Combustion Process and Its Impact on Pistons and Cylinders

The combustion process is the heart of engine power generation. Inside the cylinder, air mixes with fuel. This mixture ignites due to a spark or compression. The result is a rapid expansion of hot gases. These gases create high pressure, forcing the piston downward.

This intense pressure puts stress on both pistons and cylinders. Pistons must endure high temperatures and aggressive movements. Similarly, cylinders must remain durable and maintain structural integrity. Any failure in this process could reduce engine efficiency or cause serious damage.

The quality of combustion impacts the lifespan of pistons and cylinders. Incomplete combustion leaves carbon deposits, which can cause wear over time. Proper engine tuning ensures optimal combustion, protecting these components.

How Pistons Move Within Cylinders

Pistons move in a straight path within the cylinder, known as reciprocating motion. This motion starts with combustion, pushing the piston downward. The connecting rod links this movement to the crankshaft, converting it into rotational energy.

When the piston moves back up, it compresses air and fuel for the next combustion cycle. The piston rings ensure a tight seal between the piston and the cylinder wall. This prevents gas leakage and maintains compression. Smooth movement depends on precise design and lubrication.

Proper alignment between pistons and cylinders is vital. Misalignment can cause uneven pressure, leading to wear or damage. Regular maintenance checks can identify and fix such issues early.

In summary, pistons and cylinders depend on each other for efficient engine function. Their seamless interaction ensures power generation and engine durability.

Common Issues and Maintenance Tips

Pistons and cylinders are critical engine components, but they can face wear and damage. Proper care and regular inspection can help identify problems early and extend their lifespan.

Signs of Wear in Pistons and Cylinders

Identifying issues early can prevent major engine failures. Here are common signs of piston and cylinder wear:

- Reduced Engine Performance: Loss of power or sluggish response may indicate worn pistons or cylinders.

- Excessive Oil Consumption: Worn piston rings can lead to oil leakage into the combustion chamber.

- Smoke from Exhaust: Blue or gray smoke suggests oil burning due to piston or cylinder problems.

- Knocking or Pinging Noises: Abnormal sounds often point to misalignment or damaged components.

- Carbon Deposits: Build-up inside the cylinder can impair efficiency and cause overheating.

- Compression Loss: Poor compression affects power output and efficiency, usually due to worn parts.

Recognizing these signs early is key to maintaining engine performance. Addressing them promptly can save costly repairs.

Maintenance Techniques to Ensure Longevity

Proper maintenance is essential for pistons and cylinders to function efficiently. Follow these techniques to prolong their life:

- Regular Oil Changes: Fresh oil ensures proper lubrication and reduces wear on moving parts.

- Use Quality Fuel: High-quality fuel minimizes contaminants that can harm pistons and cylinders.

- Keep the Engine Clean: Remove carbon deposits and debris to avoid overheating and component damage.

- Monitor Air Filters: Clean filters ensure optimal air-to-fuel ratio, preventing strain on the engine.

- Check Compression Levels: Test regularly to detect any loss in compression before it worsens.

- Inspect Piston Rings: Replace worn rings to maintain a secure seal and prevent gas leakage.

- Use Coolant Properly: Adequate cooling reduces heat stress on cylinders and pistons.

- Follow Maintenance Schedules: Refer to your vehicle’s manual for recommended check-ups and servicing.

Effective maintenance ensures that both pistons and cylinders operate smoothly and last longer. Always address issues as soon as they arise.

Innovations in Piston and Cylinder Design

Engine efficiency has improved due to innovations in piston and cylinder design. These advancements focus on durability, performance, and sustainability.

Advances in Materials and Coatings

New materials and coatings have enhanced the durability of pistons and cylinders. These advancements improve heat resistance, reduce wear, and boost efficiency.

- Lightweight Materials: Engineers are now using materials like titanium and advanced aluminum alloys. These materials reduce engine weight and improve fuel efficiency.

- Composite Materials: Composite designs combine strength and weight reduction. This helps engines handle extreme stress and temperatures.

- Improved Coatings: Coatings like thermal barriers and anti-friction layers reduce wear and thermal damage. They protect against extreme conditions and extend component life.

- Ceramic Components: Ceramic coatings resist high heat while enhancing combustion efficiency. They improve heat distribution to reduce stress on both pistons and cylinders.

These advancements ensure pistons and cylinders perform under high pressure and intense heat conditions.

Trends in Modern Engine Design

Modern engine designs integrate advanced piston and cylinder technologies. These trends focus on performance and environmental responsibility.

- Turbocharged Engines: Turbocharging increases air intake, delivering more power from smaller pistons and cylinders. It ensures high efficiency while reducing emissions.

- Smaller, More Efficient Cylinders: Downsized engines now use fewer cylinders to save fuel without losing power. Advanced technology compensates for reduced size.

- Hybrid and Electric Integration: Some modern engines use advanced piston-cylinder systems for hybrid applications. This supports the transition to electric vehicles.

- Variable Compression Ratios: New engines can alter cylinder compression ratios dynamically. This allows optimal performance in various driving conditions.

- Focus on Sustainability: Designs now prioritize recyclable and eco-friendly materials, minimizing environmental impact.

These trends reflect the industry’s push toward greater performance and reduced environmental impact. They demonstrate how piston and cylinder design keeps evolving to meet modern demands.

Understanding the Piston-Cylinder Relationship

The Core Components of Riding

In conclusion, the relationship between piston and cylinder is a fundamental aspect of motorcycle performance. These components work together to convert fuel into mechanical energy that powers the bike. Recognizing the significance of this relationship allows riders to appreciate the complexity of their machines and the engineering that supports them. Each ride becomes a culmination of design, function, and experience.

The Importance of Maintenance

Ongoing maintenance and attention to detail are essential for optimizing the performance of your motorcycle. Regular checks, oil changes, and inspections will help prevent significant issues and extend the life of the engine. Riders should also remain educated about their specific motorcycle model’s mechanics, as understanding these elements can lead to better care and performance.

Creating a Rewarding Riding Experience

Ultimately, the goal of understanding the piston-cylinder assembly is to enrich your riding experience. Riders can feel empowered to take control of their motorcycle’s performance through awareness and education. With proper care, attention, and upgrades when necessary, everyone can enjoy the ride fully. Riding is not just about the destination; it’s also about the journey and the connection between rider and machine. So gear up, maintain your motorcycle, and take to the road with confidence, knowing that every twist and turn is supported by the interdependent mechanism of pistons and cylinders working harmoniously.

Leave a Reply