Introduction to Engine Cylinder Blocks

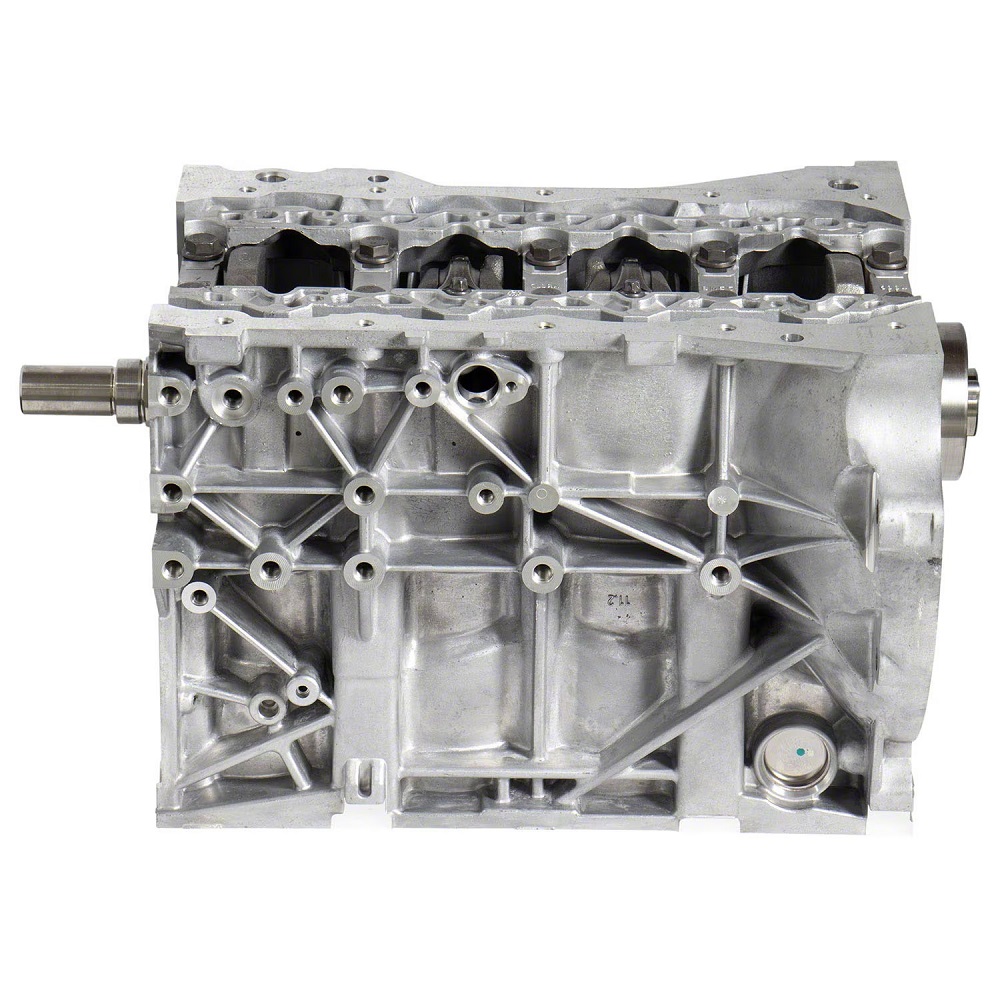

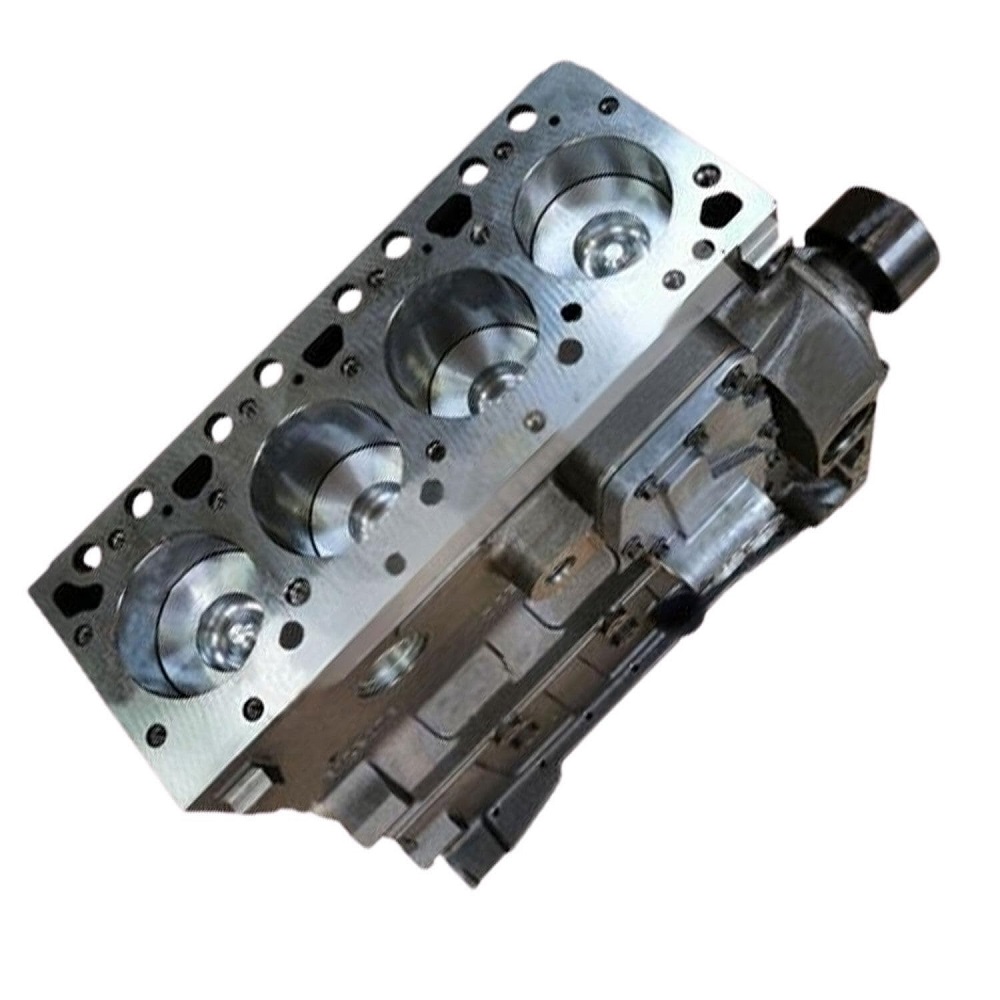

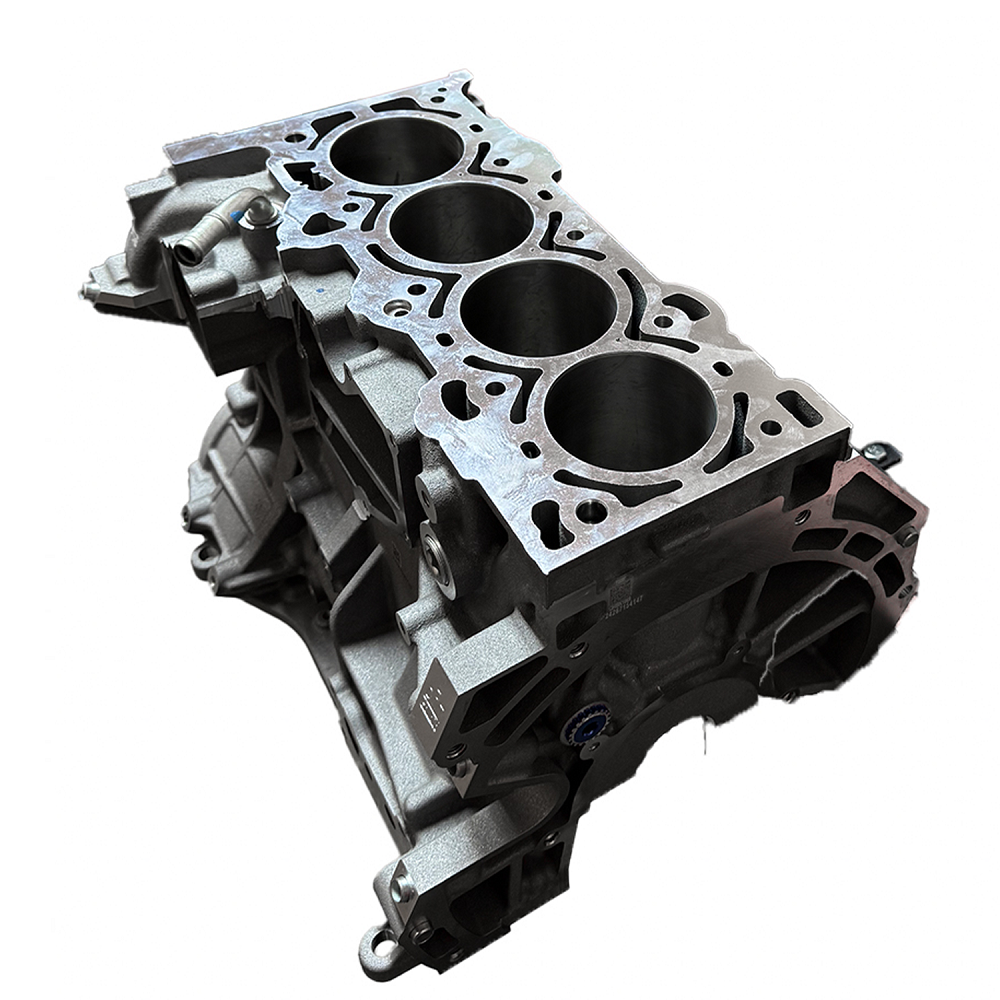

The engine cylinder block is a crucial part of an internal combustion engine. It forms the main structure of the engine and houses several essential components. These include cylinders, which hold the pistons, as well as the crankshaft and connecting rods. The block serves as the foundation for the engine assembly.

Role in Engine Construction

The cylinder block integrates various engine parts into a single unit. It provides support for the cylinder head and the crankcase. It also contains passages for cooling fluids and oil, which ensure the engine runs smoothly.

History and Development

Engine cylinder blocks have evolved over time. Initially, they were made of heavy iron, but materials have shifted towards lighter metals for efficiency. Their designs have also been optimized to improve engine power and lifespan.

Key Features

- Houses engine cylinders, pistons, and connecting rods.

- Supports the crankshaft.

- Provides pathways for cooling and lubrication fluids.

- Ensures structural integrity of the engine.

Understanding the role and construction of an engine cylinder block can highlight its significance in automotive technology. It plays a vital role in engine performance and durability.

Functions of an Engine Cylinder Block

The engine cylinder block performs several vital functions, which are essential for engine operation.

Structural Support

The cylinder block provides structural support for major engine components. It secures the cylinder head and crankcase, ensuring a stable assembly.

Housing for Engine Parts

It houses critical parts such as cylinders, pistons, and connecting rods. These components work together to generate power.

Cooling System Passages

The block contains passages for coolant flow. These passages prevent the engine from overheating.

Lubrication Pathways

Lubrication pathways within the block allow engine oil to flow and reduce friction. This ensures smooth movement of internal parts.

Stability During Operation

The cylinder block maintains stability during engine operation. It minimizes vibrations and enhances the engine’s lifespan.

Pathway for Combustion Process

The block forms a pathway for the combustion process inside the cylinders. This process creates energy to power the vehicle.

The engine cylinder block combines multiple functions to ensure reliable and efficient engine performance. Its design and features influence the overall durability and operation of the vehicle.

Materials Used in Cylinder Blocks

Engine cylinder blocks are made using materials that ensure strength, durability, and efficiency. These materials need to handle high temperatures and pressures during engine operation. Over the years, material choices have evolved to improve performance and reduce costs.

Cast Iron

Cast iron is one of the oldest materials used for engine cylinder blocks. It provides excellent strength and durability. It is resistant to wear and heat, making it ideal for heavy applications. Cast iron blocks are cost-effective but heavier compared to other materials.

Aluminum Alloys

Aluminum alloys are commonly used in modern engine cylinder block. They are lightweight and improve fuel efficiency. Despite being lighter, they provide good strength and heat resistance. Aluminum blocks often include iron cylinder liners for added durability.

Compacted Graphite Iron (CGI)

CGI is a modern material that combines the benefits of cast iron and aluminum. It is stronger than aluminum and lighter than cast iron. CGI is commonly used in high-performance and diesel engines for its durability and heat management properties.

Steel

Steel is less common for cylinder blocks but is used in high-performance engines. It has superior strength and can handle extreme conditions. However, its higher weight makes it less suitable for most vehicles.

Composite Materials

Advanced composite materials are being explored for future engine cylinder blocks. These include fiber-reinforced plastics and carbon composites. They aim to reduce weight while maintaining durability and efficiency.

Choosing the right material for an engine cylinder block is vital. It impacts engine performance, durability, and fuel efficiency. Advances in materials will continue to shape the future of engine technology.

Design and Construction of Cylinder Blocks

Design and construction of engine cylinder blocks are crucial for engine performance. A well-designed block ensures durability, efficiency, and optimal engine functionality. Manufacturers focus on material selection, structural design, and machining precision to enhance the block’s performance. Below are key aspects of their design and construction:

Structural Design

The structural design determines the strength and stability of the engine cylinder block. Engineers design the block to withstand extreme temperatures and high-pressure conditions during engine operation. Key considerations include the number and arrangement of cylinders, which influence performance and fuel efficiency. Inline, V-shaped, and flat designs are common configurations used based on engine requirements.

Material Selection

Materials used directly affect the block’s durability and weight. Lighter materials, like aluminum alloys, are used to improve fuel economy and heat resistance. Cast iron is chosen for its strength and wear resistance in heavy-duty applications. New materials like compacted graphite iron (CGI) and composites offer a balance of weight reduction and strength.

Machining and Precision

Precision machining is essential to ensure high-quality engine cylinder blocks. Tolerances in machining must be incredibly tight to ensure proper alignment with other engine components. Accurate drilling of coolant and lubrication pathways is also critical. CNC machines are commonly used to achieve precision and consistency.

Integration of Features

The cylinder block incorporates multiple internal features. These include coolant and lubrication pathways, supports for the cylinder head, and housings for the crankshaft and pistons. The design blends these features seamlessly, ensuring smooth and efficient operation.

Cooling and Lubrication Design

Cooling passages help dissipate heat, preventing engine overheating. Lubrication pathways reduce friction, ensuring smooth engine movement and reducing wear.

A strong and intelligently designed engine cylinder block improves performance and longevity. Optimizations in each aspect create safer, more efficient, and reliable vehicles.

Types of Engine Cylinder Blocks

Engine cylinder blocks come in different types based on engine design and arrangement. Each type supports specific engine configurations and performance needs. Below are the common types of engine cylinder blocks:

Inline Cylinder Block

An inline cylinder block has cylinders arranged in a straight line. It is compact and cost-effective. This type is widely used in small cars and motorcycles for reliable performance.

V-Type Cylinder Block

The V-type cylinder block has cylinders arranged in a V-shaped pattern. It reduces the engine’s width and height. It provides better balance and more power, making it suitable for larger and high-performance vehicles.

Flat Cylinder Block

A flat cylinder block, also known as a boxer engine, has horizontally opposed cylinders. This type improves stability and reduces vibrations. Flat blocks are ideal for sports cars and some aircraft engines.

Radial Cylinder Block

Radial cylinder blocks have cylinders arranged in a circular pattern around a central crankshaft. They were commonly used in aircraft engines in the past due to their high power output.

Opposed Piston Cylinder Block

This type contains paired cylinders sharing the same combustion chamber. Pistons in each pair move toward each other. It reduces the engine size while improving efficiency and power output.

Multi-Row Cylinder Block

Multi-row cylinder blocks are used in large engines with high power requirements. They combine multiple rows of cylinders to enhance power and performance. These are common in trucks and heavy machinery.

W-Type Engine Cylinder Block

The W-type block has three rows of cylinders in a “W” arrangement. It offers compact design with high power density. This type is used in high-performance and luxury vehicles.

Each type of cylinder block plays a role in optimizing engine performance. The choice of block depends on the vehicle’s purpose and design requirements.

Common Issues and Maintenance of Cylinder Blocks

Engine cylinder blocks face wear and tear due to constant usage. Timely maintenance is essential to prevent larger issues. Below are common problems and tips for maintaining engine cylinder blocks:

Common Issues with Engine Cylinder Blocks

- Cracks: High stress and overheating can cause cracks, leading to coolant or oil leakage.

- Corrosion: Exposure to moisture or chemicals can corrode the block, weakening its structure.

- Overheating: Blocked coolant passages or insufficient cooling can lead to overheating and potential damage.

- Oil Leaks: Worn seals or gaskets can result in oil leaking, affecting engine lubrication.

- Cylinder Wear: Frequent use leads to wear in the cylinders, reducing compression and performance.

- Warping: Excessive heat can cause warping, affecting the alignment of components.

Maintenance Tips for Engine Cylinder Blocks

- Regular Inspections: Check for visible damage, cracks, or leaks regularly to prevent serious issues.

- Ensure Sufficient Cooling: Maintain proper coolant levels and clean the cooling system regularly.

- Use Quality Lubricants: Use high-quality engine oil and replace it as per the recommended schedule.

- Clean the Engine Block: Remove dirt, oil, and debris to prevent blockages in pathways.

- Address Overheating Promptly: Fix any overheating issues to avoid further damage to the cylinder block.

- Repair Cracks Immediately: Use welding or adhesive materials to fix non-severe cracks.

- Replace Worn Components: Replace any worn gaskets, seals, or parts to ensure smooth operation.

- Inspect Coolant and Oil Pathways: Check for blockages and clean or repair as needed.

Proper maintenance extends the engine cylinder block’s lifespan and ensures your engine remains reliable. Addressing issues early can save costly repairs later.

Importance of Cylinder Blocks in Vehicle Performance

Engine cylinder blocks are vital to the performance and efficiency of engines. They serve as the backbone of the engine assembly, ensuring everything works seamlessly.

Structural Integrity

The cylinder block maintains the structural integrity of the engine. It holds key components like cylinders, pistons, and the crankshaft securely in place. Strong construction prevents misalignment and enhances durability.

Power Generation

Cylinder blocks form combustion chambers within the cylinders. These chambers enable precise fuel burning and energy generation. Proper design boosts performance and efficiency.

Temperature Regulation

Cooling passages within the block regulate engine temperature. Efficient cooling prevents overheating, ensuring smooth operation even under extreme conditions.

Lubrication Support

Lubrication pathways in the block allow oil to circulate and reduce friction. Reduced friction minimizes wear and ensures longevity of engine parts.

Vibration Reduction

The block absorbs and reduces vibrations during engine operation. This ensures smoother functioning and minimizes damage to other components.

Impact on Fuel Efficiency

Lightweight materials in cylinder block construction improve fuel efficiency. Aluminum alloy blocks are a common example of material choices related to fuel-saving designs.

Influence on Engine Performance

The design and construction of the cylinder block directly impact engine power output and reliability. Optimized blocks improve acceleration, balance, and overall driving experience.

In summary, engine cylinder blocks play an indispensable role in vehicle performance. Their design, material, and functionality influence how efficiently and reliably an engine operates.

Future Developments in Cylinder Block Technology

Engine cylinder block technology continues to advance with new innovations in design and materials. These developments aim to improve engine performance, reduce weight, and enhance efficiency.

Lightweight Materials

Future engine cylinder blocks will use lightweight materials like carbon composites and advanced alloys. These materials reduce overall vehicle weight, improving fuel economy and emissions.

Strength and Durability Enhancements

New materials will balance lightness with enhanced durability. Innovations like high-strength steel and compacted graphite iron are being researched.

Advanced Cooling Systems

Improved cooling pathways are being developed to manage heat more effectively. Enhanced designs will prevent overheating and boost engine stability.

Integration of Smart Technologies

Cylinder blocks may integrate sensors for real-time monitoring of temperature, pressure, and wear. This will help optimize engine performance and predict maintenance needs.

Improved Manufacturing Techniques

Precision manufacturing methods like 3D printing will increase production speed and accuracy. Advanced machining will allow tighter tolerances for smoother operation.

Eco-Friendly Solutions

Future cylinder block designs aim to support greener solutions, including compatibility with electric engines. This shift will help reduce carbon footprints globally.

Customized Design Approaches

Engine blocks may feature modular designs for tailored performance. Customization will enhance adaptability and meet diverse automotive needs.

Focus on Longevity

Research focuses on extending engine lifespan through smarter designs and better materials. These improvements will reduce repair costs and improve reliability.

Collaboration Across Industries

Automotive manufacturers will collaborate with material science experts to create groundbreaking cylinder block improvements. These partnerships will drive innovation.

Future advancements in engine cylinder block technology promise significant changes. They will make engines lighter, stronger, and smarter, securing a greener and more efficient automotive future.

Understanding Your Engine Cylinder Block

An Integral Component of Engine Performance

The engine cylinder block is a vital part of any vehicle. It serves not only as the housing for various components but also plays a critical role in engine performance. Understanding the features, maintenance, and potential issues with your cylinder block is essential for any car owner. By taking the time to learn about this critical component, you empower yourself as a responsible vehicle owner.

Prioritizing Maintenance and Care

Regular maintenance and careful attention to the cylinder block can go a long way in ensuring your engine runs smoothly. By being proactive about inspections and repairs, you can prevent small issues from escalating into severe problems. The maintenance of your cylinder block should always be a top priority.

Investing in Knowledge

Investing in knowledge about your engine and its components can enhance your overall driving experience. As you learn more about your cylinder block, you gain confidence in your abilities as a car owner. This understanding is key to keeping your vehicle in optimal condition for years to come.

Ready for the Road Ahead

With a solid understanding of the engine cylinder block, you are better prepared for the road ahead. Knowledge empowers you to make informed decisions about your vehicle’s maintenance and upgrades. Armed with this information, take pride in your responsibility as a car owner, ensuring that your engine remains as powerful as the first day you hit the open road. Safe travels!

Leave a Reply