The car engine cylinder is a crucial component in internal combustion engines. It serves as the chamber where fuel and air mix, igniting to create the power needed for propulsion. Understanding the significance of the car engine cylinder is vital for anyone interested in automotive engineering or simply looking to grasp how their vehicle operates. In this article, we will explore the types of car engine cylinder, their functions, and their role in enhancing engine performance. We will also discuss maintenance considerations and advancements in cylinder technology within modern engines.

What is a Car Engine Cylinder?

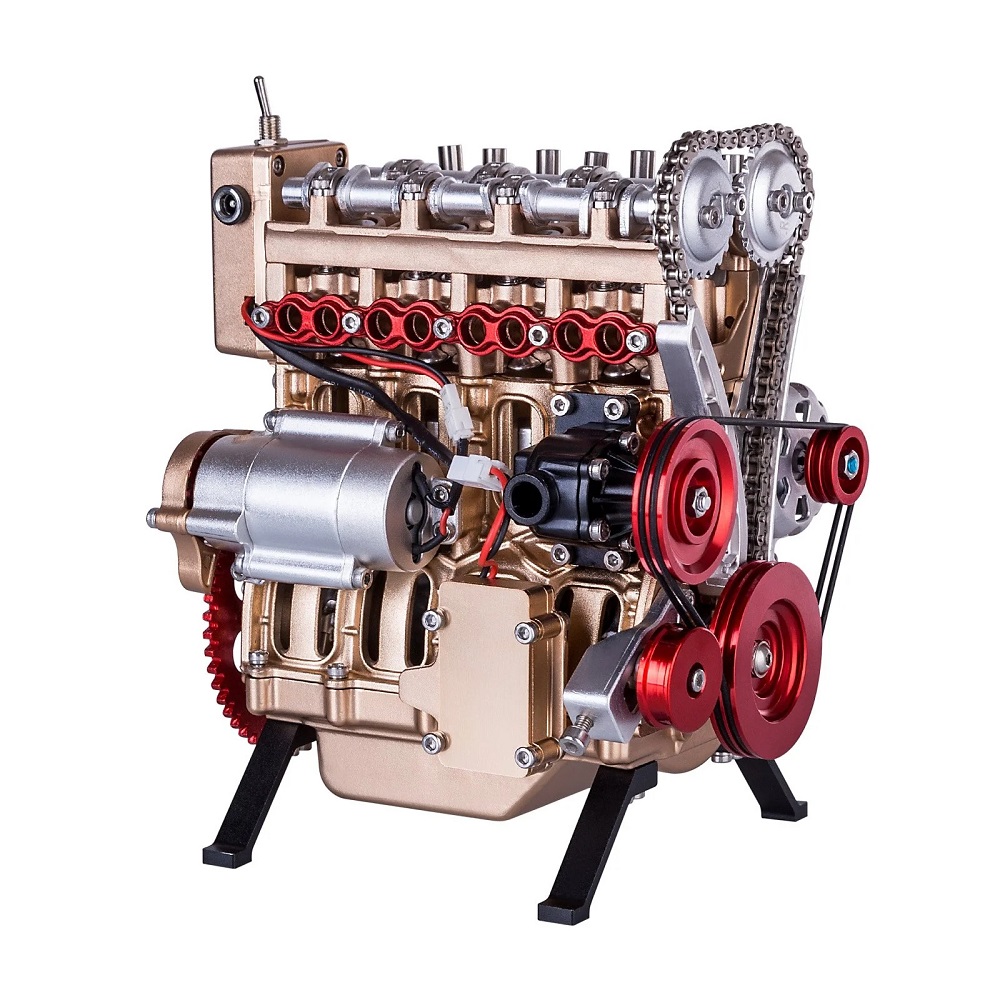

A car engine cylinder is a key component of the engine. It is a cylindrical space where the fuel combustion process occurs. Inside the cylinder, fuel and air mix and ignite, producing energy. This energy drives the movement of the pistons, which, in turn, powers the vehicle.

Cylinders are arranged in different configurations based on engine design. Common configurations include inline, V-type, and flat cylinders. The number of cylinders in a car engine can vary, usually ranging from three to twelve. Engines with more cylinders often produce higher power and smoother performance.

The cylinder houses important components like the piston, spark plug, and valves. The piston moves up and down within the cylinder during the engine’s operation. The spark plug ignites the fuel-air mixture, while valves control the entry and exit of gases. Cylinders are generally made from durable materials to withstand high temperatures and pressure during combustion.

Understanding the purpose and working of a car engine cylinder is essential for car owners. It highlights how energy is generated within the engine to drive the vehicle.

How Engine Cylinders Work

Engine cylinders play a crucial role in powering a car. The working process involves several steps:

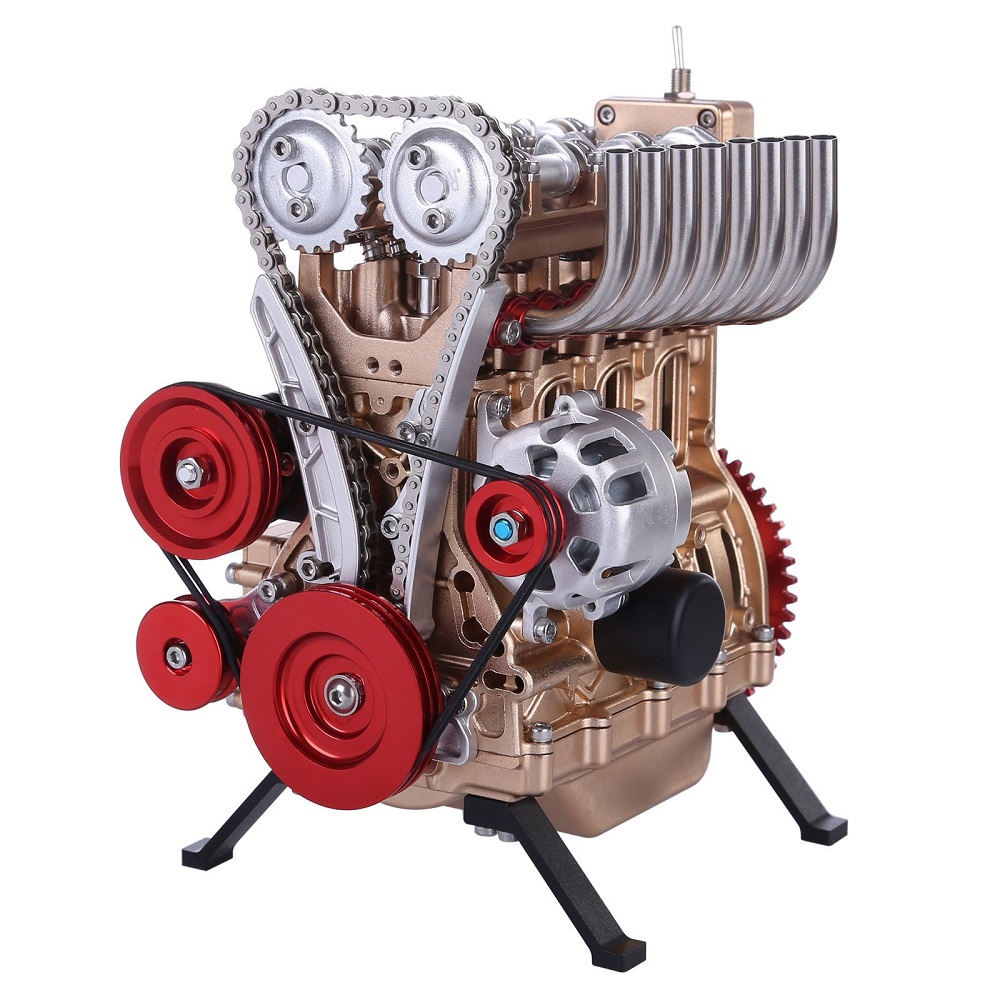

- Intake Stroke: During this phase, a mixture of air and fuel enters the cylinder. The intake valves open, and the piston moves downward, creating space and drawing in the mixture.

- Compression Stroke: The piston moves upward, compressing the fuel-air mixture. This step prepares the mixture for ignition, increasing its energy potential.

- Combustion Stroke: The spark plug ignites the compressed mixture. This explosion generates power, pushing the piston downward forcefully. This movement converts fuel energy into mechanical energy.

- Exhaust Stroke: The piston moves upward again, pushing burned gases out of the cylinder. The exhaust valves open to release these gases into the exhaust system.

This four-step cycle repeats continuously while the engine runs. It ensures the engine produces power efficiently. The precise timing of these events, controlled by engine components, is critical for optimal performance. Understanding how engine cylinders work helps car owners better maintain their vehicles.

Types of Engine Cylinders

Engine cylinders come in various configurations to suit different car engine designs. Each type of cylinder arrangement has unique characteristics, advantages, and limitations. Here, we will explore the three common types: inline cylinders, V-type cylinders, and flat cylinders.

Inline Cylinders

Inline cylinders, also known as straight cylinders, are arranged in a straight line. This configuration is highly common in smaller vehicles and offers several advantages:

- Efficient Design: Inline cylinders are compact and simple in construction. They are easy to manufacture and maintain.

- Smooth Operation: These engines typically deliver smoother performance due to reduced vibration.

- Space Saving: They take up less space in the engine bay, allowing for more compact car designs.

Most inline engines come in configurations such as 4-cylinder or 6-cylinder variants. However, while they are efficient, they may lack the power output of more complex cylinder arrangements.

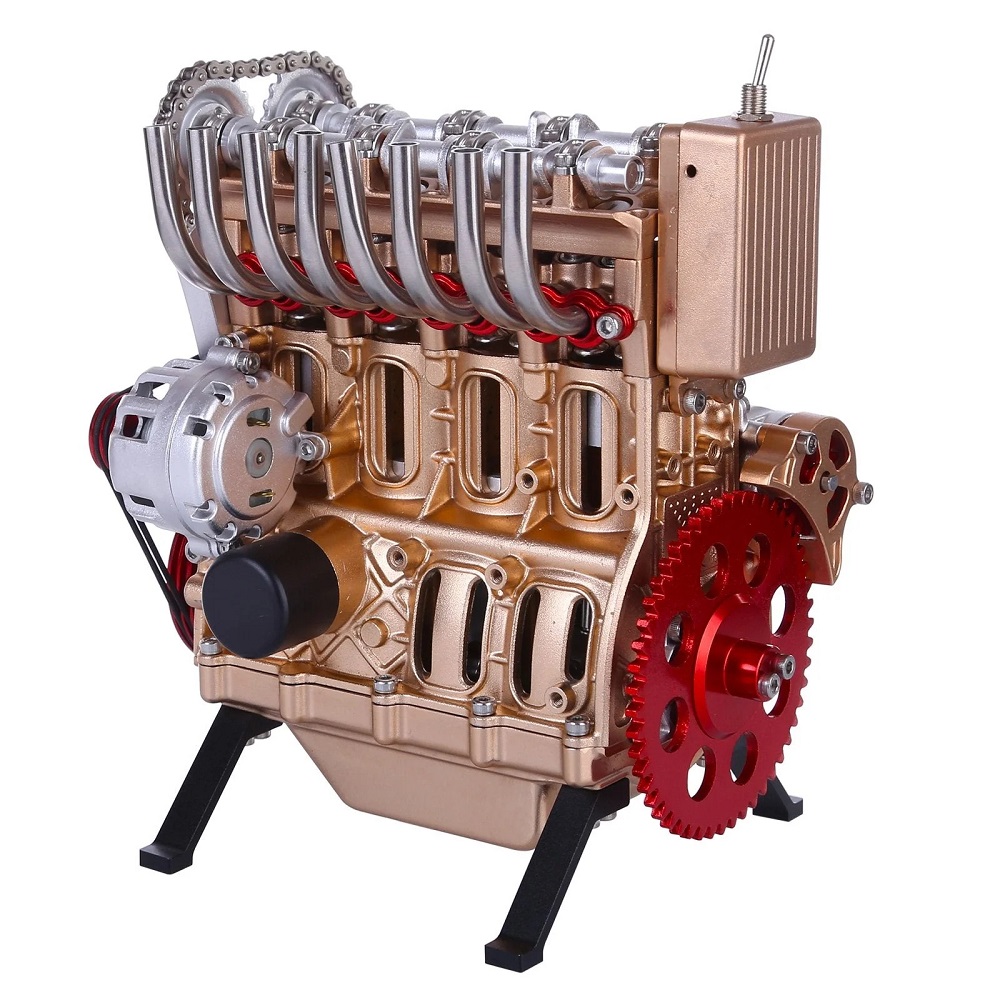

V-Type Cylinders

V-type cylinders are configured in two angled rows, forming a “V” shape. This configuration is commonly used in high-performance vehicles. Key features include:

- Compact Power: V-type engines can fit more cylinders into a smaller space compared to inline designs.

- High Performance: They provide greater power output and better balance for larger vehicles.

- Enhanced Efficiency: These cylinders improve engine torque and acceleration.

However, V-type engines often have higher maintenance costs due to their complexity. They are ideal for sports cars and larger luxury vehicles.

Flat Cylinders

Flat cylinders, also known as horizontally opposed or “boxer” engines, have cylinders positioned flat and opposite each other. This design is favored in specialty vehicles such as Porsche cars and Subaru models. Benefits include:

- Low Center of Gravity: The flat arrangement improves vehicle stability and handling.

- Balanced Performance: This configuration reduces engine vibration, offering smoother driving experiences.

- Unique Design: Flat cylinders provide a distinctive sound and driving feel.

Flat engines may be more expensive and harder to repair compared to inline engines. However, they deliver an exceptional driving experience for those who value performance and balance.

Understanding the various types of engine cylinders helps in recognizing their role in vehicle performance. Each type is suited to specific vehicle needs and offers unique advantages depending on driving preferences.

Importance of Engine Cylinders in Combustion Process

Engine cylinders are essential for vehicle performance and fuel efficiency. They are the heart of combustion inside the engine. The combustion process converts fuel into energy which powers the vehicle.

Role in Combustion Process

- Fuel Mixing: Inside the cylinder, fuel combines with air to create a combustible mixture.

- Compression: The piston compresses this mixture, increasing its energy potential.

- Ignition: The spark plug ignites the compressed mixture, starting the explosion.

- Energy Transfer: This combustion generates force, pushing the pistons for mechanical energy.

Efficient Energy Generation

Engine cylinders ensure the efficient transfer of energy. Multiple cylinders in an engine allow smoother power generation. They reduce downtime in the power cycle and maintain constant motion of the vehicle.

Influence on Engine Performance

- Power Output: The number of cylinders directly impacts the engine’s power.

- Smooth Performance: Cylinders help in balancing engine vibration and ensuring smoother operation.

- Fuel Utilization: Efficient cylinders maximize fuel utilization, saving costs.

Understanding the importance of engine cylinders emphasizes their role in powering vehicles. Properly working cylinders result in reliable and efficient vehicle performance.

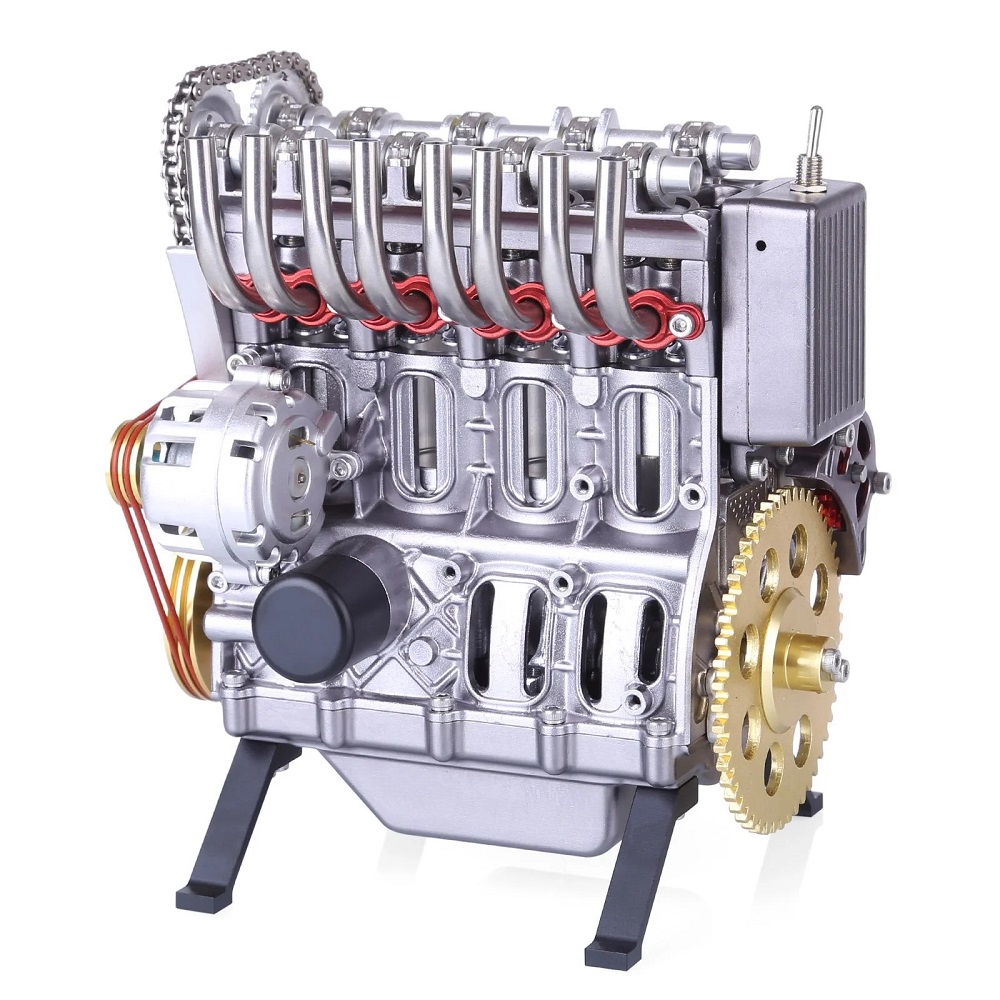

Materials Used in Manufacturing Engine Cylinders

Engine cylinders endure high temperatures and pressures. Hence, they require robust and durable materials.

Common Materials Used

- Cast Iron:

- Cast iron is widely used due to its durability and strength.

- It resists wear and tolerates combustion heat effectively.

- Cast iron cylinders are cost-effective and easy to produce.

- Aluminum Alloys:

- Aluminum alloys are lightweight and improve vehicle fuel efficiency.

- They help dissipate heat faster, preventing engine overheating.

- Though pricier, they are preferred in modern engines for better performance.

- Steel:

- Steel is an excellent choice for high-performance engines.

- It is tough, durable, and resists extreme conditions.

- Some steel alloys are corrosion-resistant, improving cylinder lifespan.

- Nickel and Chromium Alloys:

- These are used for specialized, high-temperature cylinders.

- They offer excellent endurance under pressure but are expensive.

Material Properties Considered

Engine cylinder materials are chosen based on key properties:

- Heat Resistance: Materials must endure combustion heat without deforming.

- Durability: They need to resist wear over long periods of operation.

- Lightweight: Lighter cylinders enhance engine efficiency and reduce fuel consumption.

- Corrosion Resistance: This prevents damage from exposure to fuel and other substances.

Understanding the materials used highlights their role in engine durability and efficiency.

Common Issues with Engine Cylinders

Engine cylinders are vital parts of a vehicle’s engine. Despite their durability, they are prone to issues. Timely identification and resolution of these problems can save costly repairs.

Cylinder Misfires

Cylinder misfires occur when the engine fails to ignite fuel properly. Common causes include:

- Faulty Spark Plug: A worn-out spark plug may fail to ignite the fuel-air mixture.

- Ignition Coil Issues: Malfunctioning ignition coils disrupt the firing process.

- Fuel Injector Problems: Blocked injectors prevent proper fuel delivery into the cylinder.

- Compression Loss: Lower compression reduces the effectiveness of combustion, causing misfires.

- Sensor Malfunction: Faulty sensors fail to monitor and adjust engine conditions efficiently.

Misfires reduce engine efficiency and power. They may also cause the engine to run unevenly. Regular engine checks can help identify these problems early.

Cylinder Wear and Tear

Wear and tear in cylinders happen due to prolonged use and extreme operating conditions. Key reasons include:

- High Temperatures: Continuous exposure to heat causes material degradation.

- Abrasion: Friction between moving parts such as pistons and cylinder walls leads to wear.

- Improper Lubrication: Lack of lubrication increases friction and accelerates damage.

- Contaminants: Dirt and debris inside the cylinder can cause scratches and damage.

- Corrosion: Over time, cylinders may corrode due to exposure to moisture or chemicals.

Symptoms of wear and tear include reduced engine performance and excessive oil consumption. Replacing worn-out components helps maintain engine efficiency.

Understanding these issues ensures car owners can better maintain car engine cylinder. Preventative measures and regular inspections are essential for avoiding these problems.

Maintenance Tips for Car Engine Cylinders

Proper maintenance of car engine cylinder ensures optimal performance and a longer engine life. Follow these tips to keep your engine cylinders in good condition.

- Regular Oil Changes:

- Fresh oil lubricates the cylinders and reduces wear.

- Replace engine oil and oil filters as per the manufacturer’s recommendations.

- Use High-Quality Fuel:

- Opt for fuel that meets the engine’s requirements.

- Quality fuel reduces carbon deposits inside the cylinders.

- Inspect Spark Plugs Regularly:

- Clean or replace dirty or worn-out spark plugs.

- Ensure proper ignition for a smooth combustion process.

- Avoid Engine Overheating:

- Monitor coolant levels and ensure the cooling system functions properly.

- Regularly check for leaks and maintain radiator efficiency.

- Clean Air Filters:

- Replace clogged air filters to ensure proper airflow.

- Clean air filters improve combustion efficiency and reduce strain on cylinders.

- Monitor Engine Performance:

- Pay attention to rough idling or reduced power.

- Address misfires, unusual noises, or warning lights promptly.

- Use Correct Lubricants:

- Use manufacturer-recommended lubricants to avoid cylinder abrasion.

- Proper lubrication prevents damage and enhances performance.

- Prevent Carbon Build-up:

- Regularly clean fuel injectors.

- Use decarbonizing treatments to maintain cylinder cleanliness.

- Control Driving Habits:

- Avoid aggressive acceleration and hard braking.

- Drive smoothly to reduce cylinder stress.

- Get Professional Inspections:

- Schedule regular check-ups with a trusted mechanic.

- Address minor issues before they escalate into major problems.

Consistent cylinder maintenance protects the engine and ensures a smooth driving experience.

Innovations in Cylinder Technology

Advancements in technology have brought significant improvements to car engine cylinder. These innovations enhance performance, efficiency, and durability.

Lightweight Materials

Modern cylinders use lightweight materials like aluminum alloys and composite metals. These materials reduce engine weight and fuel consumption. They also improve heat dissipation, preventing overheating during extended usage.

Advanced Coatings

Engine cylinders now feature advanced coatings to reduce friction and wear. Coatings include ceramic or diamond-like carbon materials. They safeguard the cylinder walls during high-pressure and high-temperature operations.

Cylinder Deactivation Technology

Cylinder deactivation systems optimize fuel efficiency. They turn off certain cylinders when full power is unnecessary. This technology helps reduce fuel usage during cruising or low-load driving conditions.

Enhanced Cooling Systems

Innovative cooling systems improve cylinder temperature management. Better heat control prevents engine damage and enhances combustion consistency. This leads to improved performance and longer engine longevity.

Laser Precision Manufacturing

Laser precision manufacturing ensures accurate cylinder dimensions. This process enhances the fitment of pistons and reduces gaps. Accurate crafting lowers friction and boosts overall engine efficiency.

Hybrid Features

Hybrid cylinders are designed for electric-assist engines. They integrate seamlessly with hybrid powertrains to enable superior fuel economy. Such designs also contribute to reducing vehicle emissions.

Smart Sensors

Smart sensors now monitor cylinder activity in real-time. They provide data on pressure, temperature, and combustion rates. This helps ensure optimal functioning and quick troubleshooting of issues.

Variable Valve Technology

Variable valve timing systems aid in improving air-fuel mixture delivery for combustion. This technology optimizes cylinder performance at different speeds and load conditions.

3D Printing Technology

3D printing enables rapid prototyping and customized cylinder designs. It adds to manufacturing flexibility and cuts production time considerably.

Future Trends

Ongoing research focuses on carbon-neutral cylinders. Efforts aim to maximize efficiency while minimizing environmental impact. Innovations promise continuous enhancements in cylinder technology for better engines ahead.

The Vital Role of Engine Cylinders

Engine cylinders are a fundamental component of every internal combustion engine, playing a critical role in the performance and efficiency of vehicles. Their ability to generate power through controlled combustion processes is essential for every ride. Understanding the various types of cylinders, their configurations, and the innovations in engine technology showcases their importance.

Regular maintenance and technological advancements, such as variable valve timing and cylinder deactivation, enhance the overall performance of car engine cylinder. As vehicles continue to evolve, cylinder design and technology will remain pivotal in shaping the future of automotive engineering. Embracing these advancements allows riders and drivers alike to enjoy safer, more efficient, and powerful vehicles, making the journey on the road even more enjoyable.

Leave a Reply