Introduction to 18 Cylinder Engines

An 18 cylinder engine is a powerful and complex type of internal combustion engine. It features 18 cylinders arranged in specific configurations to maximize power and efficiency. These engines are often used in high-performance applications that require significant energy output.

The design of an 18 cylinder engine varies based on its intended use. Common arrangements include inline, V-type, or radial configurations. Inline engines align the cylinders in a straight row, while V-type engines create a “V” shape with two banks of cylinders. Radial engines, on the other hand, place the cylinders in a circular layout around the crankshaft.

These engines are typically found in large-scale machinery and specialized vehicles. Examples include ships, aircraft, and large industrial equipment. Their high power output makes them ideal for demanding tasks. However, they are not commonly used in everyday vehicles due to their size and complexity.

The development of an 18 cylinder engine involves advanced engineering. Engineers carefully balance the engine to reduce vibrations. They also optimize airflow and fuel injection to enhance performance. The use of durable materials ensures the engine can handle extreme conditions.

Overall, 18 cylinder engines represent a pinnacle of engine design. Their ability to deliver immense power and reliability makes them indispensable in certain industries. These engines highlight human innovation and engineering expertise.

History and Evolution of 18 Cylinder

The history of 18 cylinder engines highlights their gradual development and innovation. Early internal combustion engines laid the foundation for complex designs like the 18 cylinder.

Early Development and Conceptualization

Engine technology saw significant progress during the late 19th and early 20th centuries. Engineers experimented with increasing the number of cylinders to achieve greater power output. During these early years, multi-cylinder engines were primarily focused on meeting industrial and transportation demands.

18 cylinder engines emerged as a concept to deliver immense power and efficiency. They became practical due to advancements in metallurgy and manufacturing techniques. Early designs were simple, but they helped shape future innovations.

World War II Influence

World War II played a crucial role in the evolution of 18 cylinder engines. Aircraft manufacturers needed engines that could provide unmatched power and reliability. This prompted engineers to utilize radial and other multi-cylinder configurations. Radial 18 cylinder engines became popular during this era, powering several military planes.

The advancements in aviation technology during the war contributed significantly to refining the design and function of these engines. Post-war, these innovations found applications in civilian equipment and large machinery.

Post-War Development and Modern Usage

With the rapid industrialization in the mid-20th century, the demand for high-power engines grew. Engineers continued to improve the design, durability, and efficiency of 18 cylinder engines. These technological enhancements allowed for wider usage in ships, industrial equipment, and specialized vehicles.

Over time, 18 cylinder engines became more efficient and reliable. Modern versions incorporate advanced materials and computerized control systems, ensuring optimal performance. While not widely used in daily vehicles, they remain vital for industries needing superior power output.

The evolution of 18 cylinder engines showcases engineering milestones and highlights their importance in technology-driven industries.

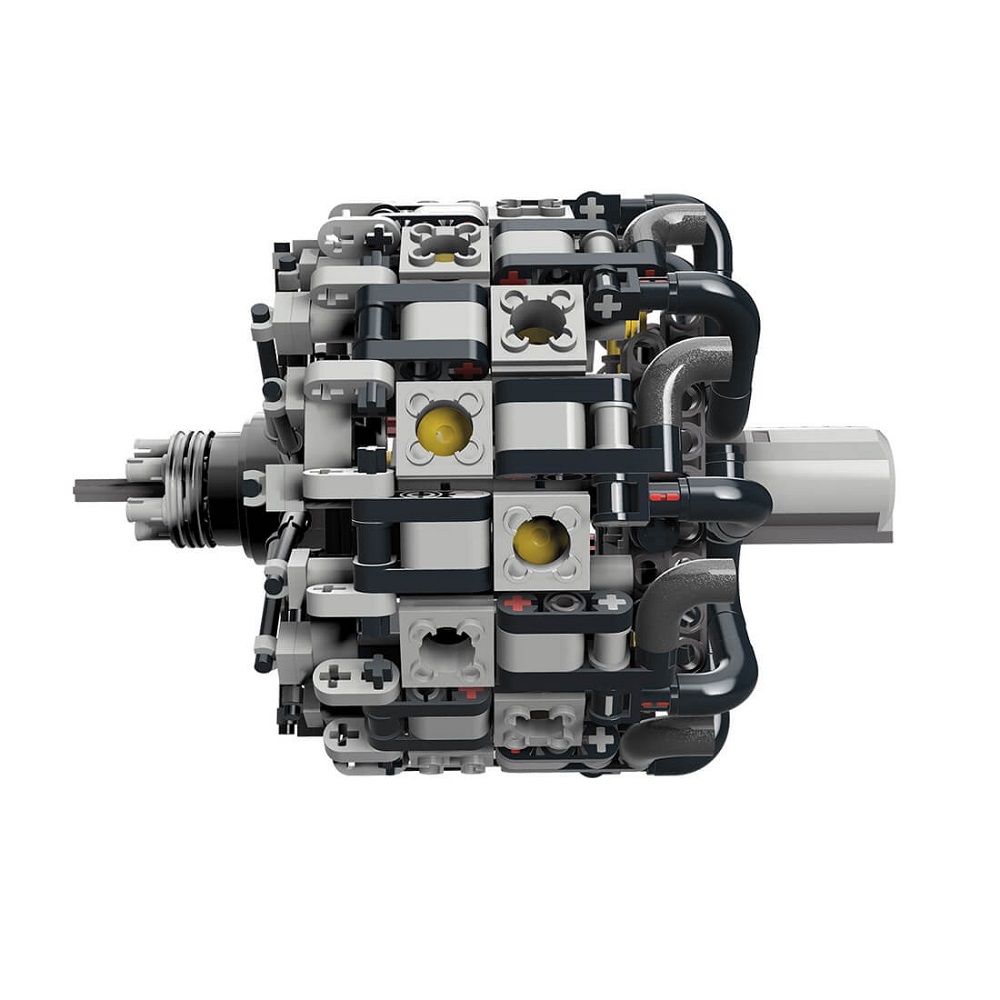

Design and Architecture of an 18 Cylinder

The design of an 18 cylinder engine is intricate and highly specialized. It features 18 cylinders organized in specific configurations to achieve optimal performance. Engineers focus on efficiency, durability, and reducing vibrations while creating these powerful engines.

Common Configurations

- Inline Configuration: Cylinders are arranged in a single straight row. This layout is simple but less common for 18 cylinder engines as it requires substantial space.

- V-Type Configuration: The cylinders are split into two banks, forming a “V” shape. This is one of the most popular designs as it compacts the engine, enhances balance, and maximizes power output.

- Radial Configuration: Cylinders are positioned in a circular arrangement around the crankshaft. It is widely used for aircraft engines due to its compact design and high efficiency.

Structural Elements

- Crankshaft: The crankshaft transfers power from the pistons to the drivetrain. It is designed to handle immense forces while minimizing vibrations.

- Cylinder Heads: The cylinder heads contain valves and spark plugs critical for fuel combustion and engine function.

- Cooling Systems: The cooling system prevents overheating, ensuring the engine operates reliably under extreme conditions.

- Fuel Injection System: This system delivers the precise amount of fuel to each cylinder, optimizing combustion and efficiency.

Materials and Engineering Techniques

Modern 18 cylinder engines are crafted using advanced materials like lightweight alloys. These materials enhance durability, reduce weight, and improve thermal conductivity. Engineers employ computer simulations to assess airflow, fuel consumption, and stress points before manufacturing begins.

Overall, the design and architecture of an 18 cylinder engine combine expert engineering, modern materials, and innovative configurations to achieve superior performance in demanding applications.

Key Components and Their Functions

An 18 cylinder engine relies on several crucial components for smooth operation and optimal power. Understanding these key parts explains how the engine works effectively.

Crankshaft

The crankshaft is the backbone of the engine. It converts linear piston motion into rotational energy. This rotational energy powers the drivetrain and ultimately moves the vehicle or equipment. The crankshaft must endure high levels of stress while minimizing vibrations.

Pistons and Cylinders

Each cylinder houses a piston that moves up and down during combustion. Pistons help compress air and fuel mixture before ignition. Their linear motion is transferred to the crankshaft. Durable materials are used to withstand high heat and pressure.

Cylinder Heads

Cylinder heads contain valves and spark plugs essential for combustion. Valves control airflow into and out of cylinders. Spark plugs ignite the fuel mixture, creating the explosion required for power generation. Efficient cylinder head design boosts engine performance.

Fuel Injection System

This system ensures precise fuel delivery to each cylinder. It optimizes combustion to achieve better efficiency and power output. Modern engines use advanced injectors for precise control of fuel spray.

Cooling System

An 18 cylinder engine generates a significant amount of heat during operation. The cooling system prevents overheating and ensures stable performance. It includes radiators, water pumps, and coolants to regulate temperature effectively.

Lubrication System

The lubrication system reduces friction between moving parts. It distributes oil throughout the engine to protect components. Proper lubrication ensures smooth operation and extends the lifespan of the engine.

Exhaust System

The exhaust system removes waste gases produced during combustion. It maintains environmental standards by reducing harmful emissions. Advanced designs improve airflow and support engine efficiency.

Control Module and Sensors

Modern 18 cylinder engines feature computerized control modules. Sensors monitor operations like temperature, pressure, and fuel usage. These systems ensure optimal performance by adjusting parameters in real time.

Each component plays a vital role in the function and efficiency of an 18 cylinder engine. The combination of advanced design and engineering ensures reliable operation under demanding conditions.

How Combustion Occurs in an 18 Cylinder

Combustion in an 18 cylinder engine involves a highly organized process to generate power efficiently. Each cylinder plays a role in ensuring controlled fuel burning and energy conversion. The process is divided into several stages:

- Air Intake: Fresh air enters each cylinder through the intake valves. This air provides oxygen for combustion.

- Fuel Injection: Precise amounts of fuel are injected into the cylinders. Modern engines use advanced fuel injectors for accuracy.

- Compression: The piston moves upward to compress the air-fuel mixture. This increases pressure and temperature.

- Ignition: A spark plug produces a spark at the right moment. The spark ignites the compressed air-fuel mixture.

- Combustion: The ignition causes a rapid and controlled explosion. This releases energy and pushes the piston downward.

- Exhaust: Burnt gases are expelled from the cylinder through exhaust valves. This completes the cycle for the cylinder.

The Four-Stroke Cycle

Most 18 cylinder engines use a four-stroke cycle:

- Intake Stroke: The piston moves down, drawing air into the cylinder.

- Compression Stroke: The piston moves up, compressing the air-fuel mixture.

- Power Stroke: Combustion occurs, forcing the piston downward.

- Exhaust Stroke: The piston moves back up, expelling burnt gases.

Each cylinder undergoes this cycle, one after another, ensuring continuous power output.

Synchronization and Timing

The engine’s timing system coordinates the process across all 18 cylinders. It ensures precise air-fuel delivery and ignition. Proper synchronization avoids misfires and maximizes efficiency.

Heat and Energy Distribution

Combustion produces immense heat. The cooling system dissipates this heat, avoiding damage. The rotational energy from the crankshaft is evenly distributed to the drivetrain for smooth performance.

Effective combustion is the heart of an 18 cylinder engine’s operation. Advanced engineering ensures optimal performance and reliability in high-demand applications.

Efficiency and Performance of 18 Cylinder

18 cylinder engines are designed for high efficiency and impressive performance. Engineers focus on optimizing these engines to maximize power output while minimizing wasted energy.

Factors Driving Efficiency

- Advanced Fuel Systems: Precision fuel injection ensures optimal fuel combustion.

- Aerodynamic Design: Streamlined internal components improve airflow and reduce drag.

- High-Quality Materials: Lightweight alloys improve heat conductivity and reduce energy loss.

- Cooling Systems: Efficient cooling prevents overheating, keeping the engine effective under pressure.

- Lubrication: Engine oil reduces friction and ensures smooth operation.

Performance-Focused Features

- Highly Responsive Configuration: Each cylinder delivers consistent and synchronized power.

- Power Density: The engine produces exceptional horsepower in a compact size.

- Real-Time Control Systems: Sensors and modules regulate variables to maintain optimal operations.

Balancing Efficiency and Performance

Efficient engines deliver power without wasting resources. Engineers align combustion with mechanical output. Proper timing and synchronization help achieve peak performance.

Challenges in Achieving Efficiency

- Complex Engineering: Designing 18 cylinders demands advanced techniques.

- Maintenance: Regular upkeep ensures long-term reliability.

- Energy Loss: Reducing inefficiencies needs ongoing innovation.

Modern developments and precision engineering help 18 cylinder engines excel. These engines stand out for their reliability, performance, and efficiency in demanding situations.

Applications of 18 Cylinder in Various Industries

18 cylinder engines are used in industries demanding exceptional power and reliability. Their advanced design adapts to challenging applications. Here are the key areas where these engines provide immense value:

Aerospace Industry

- 18 cylinder engines drive aircraft for commercial and military purposes.

- Radial configurations ensure compact size and high efficiency for aviation needs.

- Their reliability makes them ideal for long-distance flights and heavy cargo planes.

Marine Industry

- Ships and submarines rely on these engines for propulsion and energy generation.

- The powerful output is suited for large vessels needing stamina in rough waters.

- Efficient designs enhance fuel economy, crucial for extended marine operations.

Industrial Machinery

- Heavy machinery like power generators and construction equipment uses these engines.

- They handle demanding tasks such as lifting or digging with impressive force.

- Their durability ensures consistent operation in harsh industrial environments.

Automotive Specializations

- Some high-performance or experimental vehicles deploy 18 cylinder engines.

- They cater to niche markets needing unmatched speed and power.

- Such engines highlight engineering innovation in unique automobile designs.

Energy Sector

- These engines generate electricity for remote locations and critical setups.

- Their superior efficiency supports energy sustainability.

- They are often integrated into renewable energy projects for reliable backup power.

Defense and Military Operations

- Military vehicles and aircraft require robust and reliable engines.

- Their compact and powerful build fits demanding military applications.

- They operate seamlessly under extreme conditions, supporting defense objectives.

Research and Development

- Engineers use these engines to explore new technologies and capabilities.

- They are tested in experimental projects aimed at advancing engine designs.

Conclusion

18 cylinder engine serve diverse industries due to their unparalleled power and consistency. Their unique configurations and efficient systems unlock performance needed for specialized tasks. Industries continue relying on these engines to meet their most challenging demands.

Advantages and Challenges of Using 18 Cylinder Engines

Advantages

- High Power Output: 18 cylinder engines deliver immense power for heavy-duty applications.

- Efficiency in Performance: Advanced fuel systems ensure optimal combustion and minimal energy waste.

- Reliability: These engines operate consistently even in extreme conditions.

- Versatility: They serve multiple industries such as aerospace, marine, and industrial machinery.

- Compact Design: Radial and V-type configurations save space without compromising performance.

- Durability: High-quality materials enhance their lifespan and withstand harsh conditions.

- Advanced Control Systems: Real-time sensors maintain optimal operation and performance.

Challenges

- High Cost: Manufacturing and maintenance are expensive due to complex designs.

- Large Size: Some configurations require significant space, limiting their usage.

- Complex Engineering: Designing and assembling involve intricate processes and expert skills.

- Fuel Consumption: They consume more fuel, reducing their environmental efficiency.

- Noise and Vibrations: High power levels can lead to increased noise and vibrations.

- Maintenance Requirements: Regular inspections are necessary to sustain performance.

- Limited Applications: Their size and power make them unsuitable for everyday vehicles.

While 18 cylinder engine excel in power and reliability, they involve challenges like cost and complexity. Industries weigh their advantages and limitations before adopting them.

Leave a Reply