Introduction to 20 Cylinder Engines

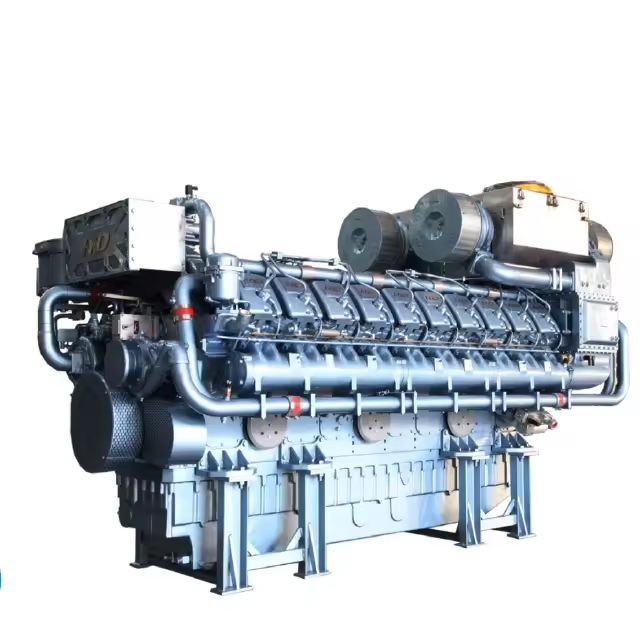

A 20 cylinder engine is a high-performance engine with twenty cylinders working in sync. These engines are designed to deliver massive power outputs and exceptional efficiency. They generally use a V-type or opposed cylinder configuration to handle the large number of cylinders effectively.

Such engines are often employed in heavy-duty applications where reliability and power are paramount. They play a vital role in industries like power generation, marine propulsion, and rail transport. By optimizing combustion in each cylinder, these engines achieve high torque and horsepower.

20 cylinder engines are built to operate under demanding conditions. Their robust design ensures durability and consistent performance. Engineers use advanced materials and engineering techniques to improve reliability and reduce wear over time.

Despite their complexity, these engines represent remarkable engineering achievements. They highlight human ingenuity in creating machines that tackle large-scale challenges efficiently.

Historical Development of Multi-Cylinder Engines

Multi-cylinder engines date back to the early days of automotive history. Engineers sought increased power and efficiency. The first engines were single-cylinder designs, providing limited output and performance. As technology advanced, multi-cylinder engines became more popular to handle higher demands.

Early Innovations in Multi-Cylinder Engines

In the late 19th century, engineers experimented with two-cylinder and four-cylinder designs. These engines improved smoothness and reduced vibrations during operation. Manufacturers used simpler designs to ensure reliability and adaptability.

In 1894, Karl Benz developed a four-cylinder engine, propelling the automotive industry forward. His design proved more efficient than single-cylinder engines at the time.

Evolution During the 20th Century

The 20th century brought rapid innovations in engine designs. V-type and inline engines gained popularity for stability and compactness. Manufacturers sought higher cylinder counts to optimize performance.

World War II accelerated advancements in multi-cylinder engines. Military vehicles demanded robust, high-powered engines like radial and opposed-cylinder configurations. By the 1950s, engines with over eight cylinders entered sports cars and luxury vehicles.

High-Cylinder Engines in Industrial Applications

Industries began using multi-cylinder engines for heavy-duty applications. Locomotives, ships, and power plants required engines with increased torque and horsepower. Engineers designed 12-cylinder and 16-cylinder engines for marine and railway systems.

The late 20th century saw the introduction of 20 cylinder engine. These engines offered unmatched power levels for major industrial tasks. They showcased human ingenuity and engineering expertise.

Recent Advancements

Advancements in materials, fuel systems, and electronics continue to refine multi-cylinder engines. Modern designs optimize fuel efficiency, durability, and emissions. Engineers now focus on maximizing engine power without compromising environmental standards.

Understanding the history of multi-cylinder engines helps us appreciate 20 cylinder engines today. Their development reflects innovation aimed at solving complex mechanical challenges.

Key Features and Specifications of 20 Cylinder

20 cylinder engines boast impressive features tailored for superior performance. Their robust design enables efficient and reliable operation under demanding conditions. Below are key aspects and specifications that make these engines unique:

- Cylinder Configuration: Most 20 cylinder engines use a V-type or opposed layout to enhance compactness and balance. These configurations help manage the stresses from multiple cylinders effectively.

- Power Output: Delivering exceptionally high horsepower and torque, 20 cylinder engines excel at performing heavy-duty tasks. Their design maximizes power generation while maintaining efficiency.

- Fuel Efficiency: These engines utilize advanced fuel injection systems to optimize combustion in each cylinder. This design reduces fuel consumption and ensures consistent power delivery.

- Materials and Durability: High-quality materials like titanium and reinforced steel enhance engine strength and longevity. This reduces wear and tear over extended use.

- Cooling Systems: Efficient cooling systems are integrated to control temperature during intense operation. They safeguard against overheating and improve overall reliability.

- Emission Control: Modern 20 cylinder engines adhere to strict environmental standards, emitting less harmful gases. Engine designs focus on reducing pollution while maintaining high performance.

- Size and Weight: Despite their massive size, engineers work to optimize space utilization without compromising output. Compact designs enable their use in various industrial applications.

- Electronic Controls: Cutting-edge electronic systems monitor engine performance for precision functioning. These controls enhance safety, fuel usage, and response times.

Through these specifications, 20 cylinder engines demonstrate innovative engineering and unparalleled capability in handling large-scale challenges.

Applications of 20 Cylinder in Industries

20 cylinder engines are widely used in industries requiring enormous power and reliability. Their robust design and efficiency make them essential in handling heavy-duty tasks. Below are key industrial applications where these engines shine:

Power Generation

Power plants use 20 cylinder engines to generate electricity for various needs. These engines ensure continuous power supply, even in critical industries like manufacturing and healthcare. Their high efficiency makes them reliable for base load and backup power systems.

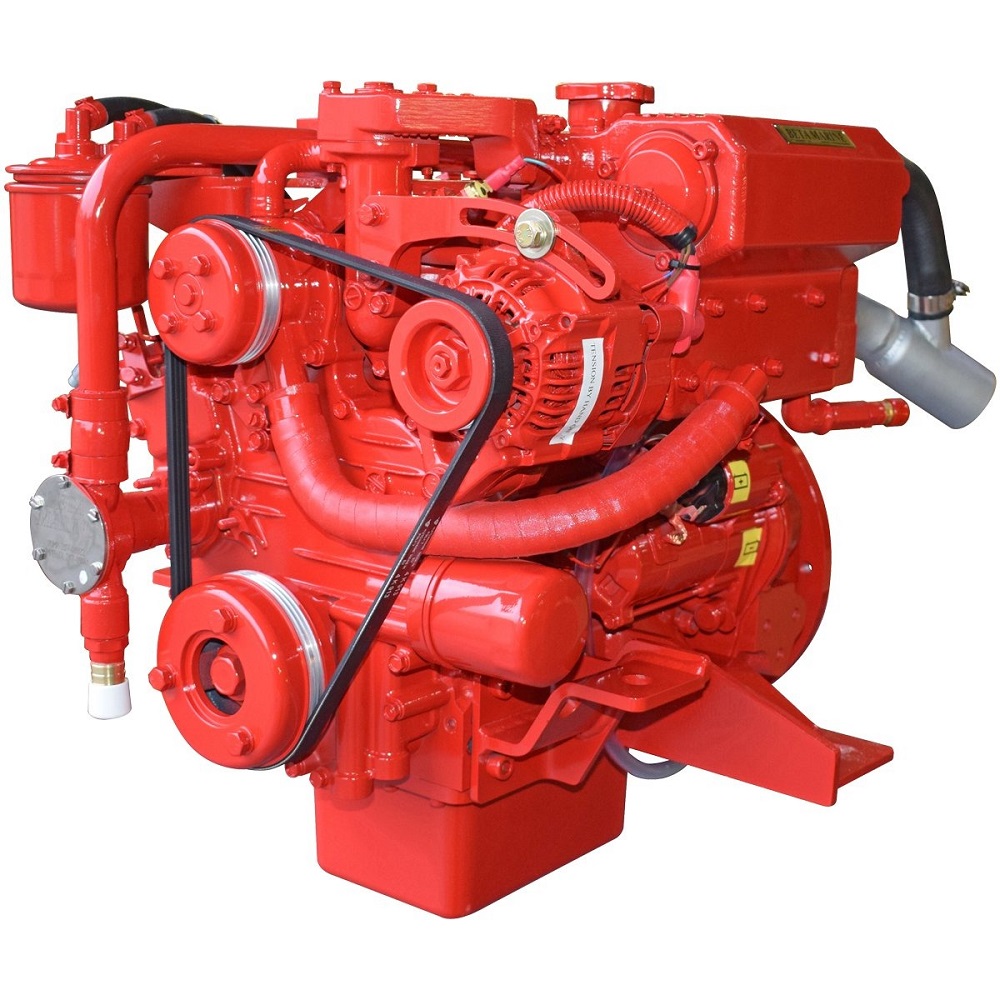

Marine Propulsion

Large ships, including cargo vessels and naval ships, rely on 20 cylinder engines. They provide the necessary horsepower for heavy loads and long voyages. These engines ensure consistent performance under harsh marine conditions.

Rail Transportation

20 cylinder engines play a key role in railway systems. They power freight trains and locomotives with high torque and durability. These engines help transport goods efficiently over long distances, even on steep terrains.

Industrial Machinery

Industries like mining and construction depend on 20 cylinder engines for heavy machinery. Excavators, crushers, and other equipment run on these engines to handle intense workloads. Their efficiency reduces operational costs and improves productivity.

Offshore Applications

Offshore oil rigs and platforms use 20 cylinder engines for their heavy machinery. These engines provide reliable power to operate drilling equipment and ensure smooth operations. Their design can withstand harsh offshore environments.

Emergency Services

Hospitals and data centers depend on 20 cylinder engine for standby power. In case of outages, these engines ensure critical systems continue functioning. Their reliability is crucial in emergencies.

Agriculture

Large-scale agricultural operations benefit from 20 cylinder engines in equipment like tractors and harvesters. These engines deliver high power, enabling farmers to manage large farmlands more efficiently.

In conclusion, 20 cylinder engines are indispensable in industries requiring large-scale power and durability. Their applications underline their importance in driving progress and supporting vital global operations.

Advantages of 20 Cylinder Over Smaller Engines

20 cylinder engines offer numerous advantages over smaller engines, making them ideal for heavy-duty applications. Their unique design ensures superior performance and reliability in demanding conditions. Here’s how they stand out:

- Higher Power Output: 20 cylinder engines generate significantly greater horsepower and torque than smaller engines. This makes them suitable for power-intensive tasks.

- Efficient Performance: Advanced engineering ensures these engines deliver steady performance with optimized fuel consumption.

- Durability and Longevity: Built with high-quality materials, these engines operate reliably and resist wear over extended usage periods.

- Capability in Heavy-Duty Applications: They can manage large workloads in industries like power generation, marine propulsion, and rail transport, which smaller engines cannot handle effectively.

- Reduced Operational Downtime: Their robust design minimizes breakdowns, ensuring continuous operation with fewer interruptions.

- Smooth Operation: The advanced cylinder configuration reduces vibrations, ensuring smoother machine operations and lesser stress on components.

- Adaptability for Diverse Tasks: Their design supports varied applications, from powering ships to generating electricity for entire communities.

- Greater Load Capacity: 20 cylinder engines handle heavier loads, particularly in rail transportation and large-scale machinery.

- Technological Integration: Equipped with advanced electronic controls, these engines provide precise monitoring and improved efficiency over time.

- Environmental Compliance: Modern designs incorporate advanced emission control systems, meeting stricter environmental regulations effectively.

While 20 cylinder engines may seem excessive for minor tasks, their advantages ensure they play a vital role in heavy-duty operations. Their exceptional capacity and robust characteristics cannot be matched by smaller engines.

Challenges and Limitations of 20 Cylinder

While 20 cylinder engines showcase immense power and efficiency, they also come with several challenges. These limitations can affect their adoption and operation in specific applications. Below are the key challenges and limitations:

- High Initial Cost:

- Developing and manufacturing 20 cylinder engines requires advanced materials and precision engineering.

- This results in higher production and initial purchasing costs compared to smaller engines.

- Complex Maintenance:

- These engines have intricate designs with numerous components that need regular servicing.

- They require skilled technicians and specialized tools to perform maintenance effectively.

- Size and Weight:

- 20 cylinder engines are significantly larger and heavier than smaller engines.

- This makes their transportation, installation, and integration into systems more challenging.

- Fuel Consumption:

- Despite high fuel efficiency, they consume large quantities of fuel due to their size and power output.

- This can lead to higher operational costs in long-term use.

- Environmental Impact:

- Even with advanced emission control systems, emissions from 20 cylinder engines remain a concern.

- Stricter environmental regulations pose challenges for these engines in certain markets.

- Specific Applications:

- These engines are highly specialized and may not be suitable for every application.

- Their immense power output often exceeds the needs of medium-sized projects.

- Initial Setup Requirements:

- Setting up a 20 cylinder engine requires significant infrastructural adjustments and space.

- This makes them less feasible for smaller-scale industries or projects.

- Noise Levels:

- These engines can be noisy, requiring advanced soundproofing measures for certain installations.

Though these challenges present obstacles, ongoing advancements in technology aim to address them. Engineers are working on improving fuel efficiency, reducing emissions, and developing lighter designs. These improvements could make 20 cylinder engines more practical while maintaining their unparalleled power and reliability.

Comparison with Other High-Cylinder Engines

20 cylinder engines are among the most powerful, but how do they compare to other high-cylinder engines? Let’s explore key differences and similarities:

Power and Efficiency

- 20 Cylinder Engines: Deliver exceptional power outputs, ideal for large-scale industrial applications.

- 16 Cylinder Engines: Offer slightly lower power but still impressive for heavy-duty tasks.

- 12 Cylinder Engines: Provide balanced performance with less power but greater fuel efficiency.

Applications

- 20 Cylinder Engines: Common in power plants, rail systems, and large ships.

- 16 Cylinder Engines: Found in luxury cars, mid-sized marine vessels, and industrial equipment.

- 12 Cylinder Engines: Suitable for sports cars, small yachts, and mobile machinery.

Size and Weight

- 20 Cylinder Engines: Larger and heavier, requiring more space for installation.

- 16 Cylinder Engines: More compact, easier to integrate in smaller systems.

- 12 Cylinder Engines: Ideal for applications prioritizing lighter designs and reduced space.

Maintenance and Costs

- 20 Cylinder Engines: Need higher investment and specialized maintenance.

- 16 Cylinder Engines: Easier to maintain, with moderate associated costs.

- 12 Cylinder Engines: Lower costs make them more accessible for smaller industries.

Environmental Impact

- 20 Cylinder Engines: Advanced emission controls but higher overall emissions due to their size and power.

- 16 Cylinder Engines: Lower emissions, suited for stricter environmental norms.

- 12 Cylinder Engines: Often the most environmentally friendly in this category.

Technological Advancements

- 20 Cylinder Engines: Integrated with cutting-edge controls to handle large-scale tasks efficiently.

- 16 Cylinder Engines: Incorporate tech innovations for smoother operations in medium-scale applications.

- 12 Cylinder Engines: Continuously evolving to meet performance and efficiency benchmarks in smaller contexts.

In summary, 20 cylinder engines excel in power and large-scale applications but come with higher costs and complexity. Other high-cylinder engines like 16 and 12 cylinder engines provide viable options for smaller-scale tasks with greater efficiency and lower costs. Each engine fits specific needs based on power, size, and application requirements.

Future of 20 Cylinder Engines in Technological Advancements

The future of 20 cylinder engines lies in technological innovation and meeting evolving industry needs. With sectors like power generation, marine propulsion, and rail transport growing rapidly, advancements are crucial. Engineers are focusing on improving efficiency, reducing costs, and ensuring environmentally friendly operations.

Improved Fuel Efficiency

- Fuel efficiency is a priority for future 20 cylinder engine.

- Engineers aim to refine fuel injection systems for optimal combustion.

- Reduced fuel consumption ensures lower operational costs in the long run.

- Hybrid models combining traditional fuel and electric systems are under development.

Enhanced Materials and Durability

- Future engines will use advanced materials like carbon composites for weight reduction.

- Reinforced components will improve durability and reduce wear over time.

- New materials promise to enhance performance under extreme operating conditions.

Better Emission Control

- Engineers are working to reduce greenhouse gas emissions from these engines.

- Modern designs incorporate advanced catalytic converters for cleaner exhaust.

- Future models will adhere to stricter environmental regulations globally.

Integration of Smart Technology

- Advanced sensors will monitor engine performance in real time.

- AI-driven systems will predict potential failures before they occur.

- Smart controls will optimize power output based on workload demands.

- Remote monitoring allows operators to manage engines from anywhere.

Compact and Adaptive Designs

- Engineers are developing more compact versions of 20 cylinder engine.

- Modular designs enable easier installation and adaptability.

- Lighter engines facilitate integration into new industrial and transportation systems.

Renewable Energy Integration

- Renewable fuels such as biodiesel and biofuels are being incorporated into engine designs.

- Research focuses on combining 20 cylinder engine with green energy solutions.

Future Applications

- Space exploration may utilize 20 cylinder engine for power generation.

- Larger renewable energy projects, like solar farms, can benefit from backup power systems.

- Expanding industrial applications in emerging economies will drive demand.

In conclusion, the future of 20 cylinder engine is bright and promising. Technological advancements will ensure greater efficiency, better sustainability, and enhanced versatility across industries. These engines will continue to play a vital role in powering progress worldwide, bridging the gap between traditional energy needs and newer, cleaner solutions.

Leave a Reply