Introduction to Single Cylinder Diesel Engines

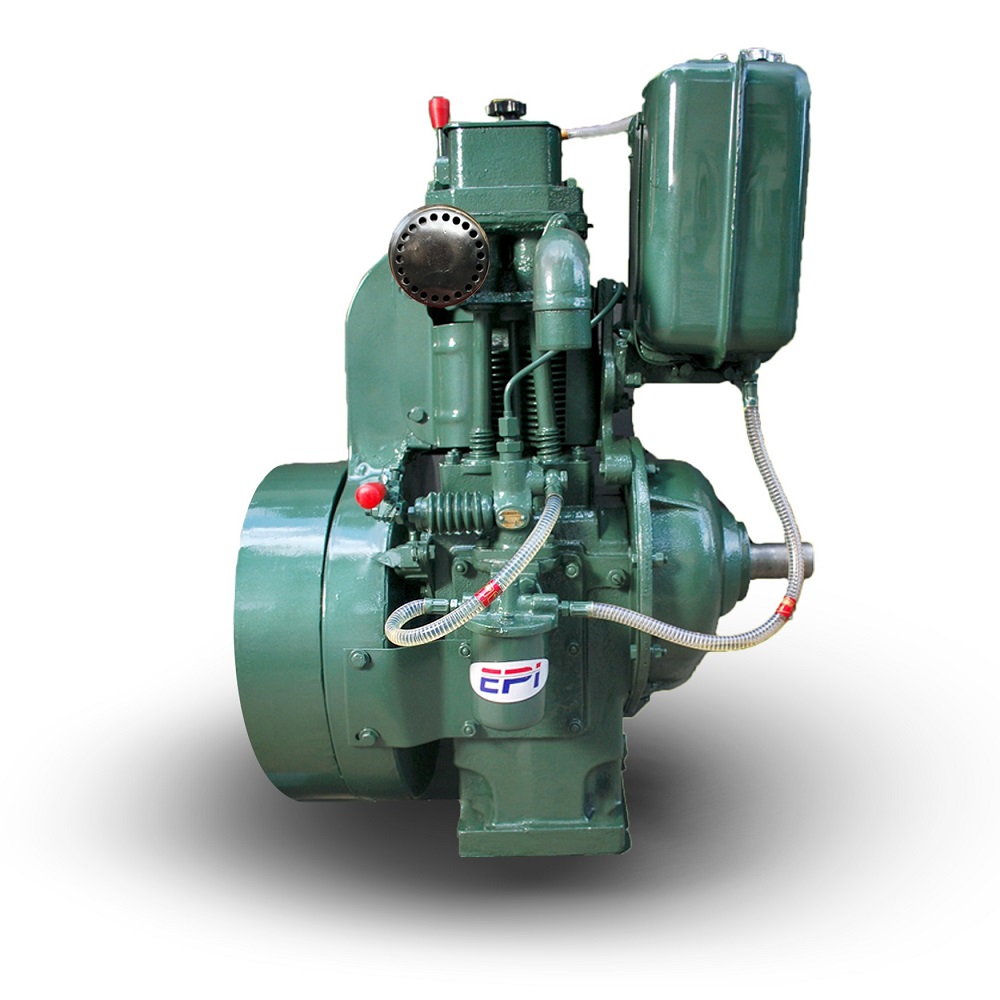

A single cylinder diesel engine is a compact and efficient type of engine. It operates using one piston, which completes power cycles to generate energy. These engines rely on diesel fuel for combustion. This makes them robust and suited for tough tasks.

Single cylinder diesel engines are widely used in small-scale applications. They power equipment requiring less energy compared to multi-cylinder engines. Examples include agricultural machines, pumps, and generators.

The design of such engines is simpler compared to multi-cylinder options. Fewer moving parts make them easier to maintain and repair. Their lightweight construction allows for easier mobility and installation.

Additionally, single cylinder diesel engines are known for their fuel efficiency. Diesel fuel burns slower, providing more energy per liter consumed. This results in lower operating costs over time.

In terms of environmental impact, these engines emit lower carbon dioxide compared to gasoline engines. Modern versions often come with enhanced technologies to reduce emissions further.

Single cylinder diesel engines are reliable and versatile. Their simplicity and efficiency make them ideal for many industries.

How Single Cylinder Engines Work

A single cylinder diesel engine operates using a simple yet effective mechanism. It converts chemical energy from diesel fuel into mechanical energy. This process involves four main strokes: intake, compression, power, and exhaust.

1. The Intake Stroke

The operation begins with the intake stroke. The piston moves down, creating a vacuum in the cylinder. This draws in air through the intake valve while the diesel fuel is injected into the chamber.

2. The Compression Stroke

Next, the piston travels upward, compressing the air and fuel mixture tightly. Compression generates a high temperature and pressure in the cylinder.

3. The Power Stroke

During the power stroke, the compressed fuel-air mixture is ignited. Diesel engines rely on high pressure and temperature to ignite the fuel, eliminating the need for spark plugs. The combustion produces energy, forcing the piston downward with power.

4. The Exhaust Stroke

Finally, the piston moves upward again, expelling gases produced by combustion through the exhaust valve. This prepares the cylinder for the next cycle.

This four-stroke process repeats continuously, creating the energy needed to power machines. The single piston moves up and down in a linear motion, which is converted into rotational motion using the crankshaft.

Single cylinder diesel engines are efficient in their operation. Diesel burns slower compared to gasoline, providing better energy output. The heat and energy generated during combustion are maximized to perform work effectively.

Additionally, these engines are known for their simplicity. With fewer parts, they experience less friction and are easier to maintain. Their streamlined design ensures smooth operation, even under heavy workloads.

Understanding how a single cylinder diesel engine works provides insight into its performance and reliability. This knowledge can guide you in using and maintaining your engine efficiently.

Key Features of Single Cylinder Engines

Single cylinder diesel engines are known for their compact design and effectiveness. Their specific features make them highly desirable for various applications. Below are the key features that set them apart:

1. Compact and Lightweight Design

Single cylinder diesel engines are small and easy to handle. Their lightweight construction ensures portability and simple installation. This makes them suitable for many tasks, especially in remote locations.

2. Fuel Efficiency

These engines are highly fuel-efficient because diesel burns slowly and provides more energy per liter. Lower fuel consumption helps reduce operational costs, making them economical in the long run.

3. Simple Structure

The design of a single cylinder diesel engine is straightforward. With fewer moving parts, maintenance becomes easier and less costly. A simplified structure also ensures fewer chances of mechanical failures.

4. High Durability

Single cylinder diesel engines are built to handle tough conditions. Their robust construction makes them suitable for rugged and heavy-duty applications. With proper maintenance, they can last a long time even under heavy workloads.

5. Reliable Starting Mechanism

These engines often include reliable starting mechanisms like manual recoil or electric start. They eliminate the need for spark plugs by relying on compression-based ignition, ensuring fewer start-up issues.

6. Lower Emissions

Modern single cylinder diesel engines produce lower carbon dioxide emissions compared to gasoline engines. They are often equipped with emission control technologies, making them environmentally friendly.

7. Cost-Effectiveness

Thanks to their simple design, these engines are often more affordable than multi-cylinder counterparts. They require less maintenance, further reducing overall expenditure over their lifetime.

8. Versatility

Single cylinder diesel engines are versatile and can be used in various industries. They power tractors, water pumps, generators, small boats, and construction machinery, among other equipment.

These features make single cylinder diesel engines a practical choice for individuals and industries alike. Their simplicity, efficiency, and robust performance ensure reliable operation in a wide range of applications.

Common Applications and Uses

Single cylinder diesel engines are versatile and widely used in various industries. Their compact design allows them to perform tasks efficiently in applications requiring moderate power.

Agricultural Equipment

Single cylinder diesel engines power small tractors and tillers used in agriculture. They help farmers with plowing, harvesting, and irrigation tasks. Their fuel efficiency makes them suitable for long hours in the field.

Water Pumps

These engines are frequently used to operate water pumps. They are ideal for irrigation, draining, or supplying water in remote areas. Their robust design ensures uninterrupted operation even under challenging conditions.

Generators

Single cylinder diesel engines are reliable for powering small and portable generators. They are perfect for homes, businesses, or outdoor activities where backup electricity is essential.

Construction Machinery

They are commonly installed in construction equipment such as concrete mixers and compactors. These engines provide consistent power for tasks in rugged environments. Their durability ensures strong performance across heavy workloads.

Marine Applications

Small boats and fishing vessels use single cylinder diesel engines for propulsion. Their fuel economy and reliability make them a preferred choice for marine applications.

Forestry Equipment

Chainsaws and portable wood chippers often use these engines. Their simplicity and efficiency help in clearing trees and managing forestry tasks.

Industrial Uses

Single cylinder diesel engines are found in small compressors and other compact machines for industrial work. They support operations that require consistent, moderate power in challenging environments.

Backup Power Supply

In case of power outages, these engines provide an affordable solution for backup electricity. They can run continuously for hours and are easy to maintain.

The versatility of single cylinder diesel engines makes them essential in various areas. Their efficiency and durability provide a reliable power source for numerous tasks.

Advantages of Single Cylinder Engines

Single cylinder diesel engines come with numerous advantages that make them highly practical and reliable. These benefits contribute to their widespread use in various applications.

1. Simplicity in Design

The design of single cylinder diesel engines is straightforward and less complex. With fewer moving parts, they are easier to assemble, maintain, and repair. This simplicity reduces the chances of mechanical failures and makes them more dependable.

2. Cost-Effectiveness

Single cylinder diesel engines are cheaper to build and maintain compared to multi-cylinder engines. They consume less fuel, leading to lower operational costs over time. The economical nature also makes them accessible for small-scale operations.

3. Compact and Lightweight

Their lightweight and small size make them easy to transport and install. This feature allows for mobility and flexibility in different working environments, including remote areas or locations with limited space.

4. Fuel Efficiency

Diesel fuel burns slowly, providing higher energy output per liter. Single cylinder diesel engines maximize this efficiency, reducing fuel consumption and operating costs.

5. Durability and Reliability

These engines are designed to handle tough environments and workloads. Their sturdy construction ensures consistent output and longevity with proper care. Reliability makes them a trusted choice across industries.

6. Environmentally Friendly

Compared to gasoline engines, single cylinder diesel engines produce fewer carbon emissions. Many modern versions include emission control technologies to minimize their environmental impact.

7. Versatility

Single cylinder diesel engines are suitable for various tasks like farming, power generation, and machinery operation. This adaptability helps fulfill diverse energy needs effectively.

The combination of simplicity, efficiency, and durability makes single cylinder diesel engines advantageous over other options. These traits ensure they meet the demands of users in different fields.

Maintenance Tips for Single Cylinder Engines

Proper maintenance keeps a single cylinder diesel engine functioning efficiently. Follow these tips to enhance its performance and lifespan:

1. Regular Oil Changes

Change the engine oil regularly to ensure smooth operation. Dirty oil reduces efficiency and causes damage over time. Always use the recommended oil type for your engine.

2. Clean and Replace Filters

Inspect and clean air and fuel filters frequently. Dirty filters reduce airflow and fuel efficiency. Replace them as per the manufacturer’s recommendations to maintain performance.

3. Check Fuel Quality

Always use high-quality diesel fuel to prevent engine issues. Contaminated or low-grade fuel can clog parts and reduce efficiency. Store fuel in a clean and dry place to avoid contamination.

4. Monitor Cooling System

Ensure the cooling system is functioning properly to prevent overheating. Check coolant levels and clean the radiator to remove dirt or debris. Overheating can cause severe damage to the engine.

5. Inspect Belts and Hoses

Frequently inspect belts and hoses for signs of wear or cracks. Replace them immediately if damaged. Faulty belts or hoses can disrupt engine performance.

6. Check Engine Components

Regularly inspect parts such as the piston, valves, and cylinder for wear. Replace damaged components promptly. Neglected issues can lead to costly repairs or engine breakdown.

7. Follow a Maintenance Schedule

Stick to the manufacturer’s recommended maintenance schedule. Timely servicing helps identify and fix issues before they escalate.

8. Keep the Engine Clean

Wipe off dirt, grease, and debris from the engine surface. A clean engine enhances heat dissipation and prevents overheating. Avoid using water directly as it can damage engine parts.

9. Store Properly

When not in use, store the engine in a dry and ventilated area. Cover it to protect from dust and moisture. Proper storage prevents rust and corrosion.

10. Use Genuine Parts

Always use manufacturer-recommended replacement parts. Non-genuine parts may not fit properly and can harm performance.

By following these maintenance tips, you can ensure smooth operation and extend the life of your single cylinder diesel engine. Proper upkeep minimizes downtime and maximizes productivity.

Comparing Single Cylinder with Multi Cylinder Diesel Engines

When considering diesel engines, it’s important to know the differences between single cylinder and multi cylinder designs. Each engine type has unique characteristics, suited for different needs and applications. Here’s a detailed comparison:

1. Design and Complexity

- Single cylinder engines have simpler designs with fewer moving parts.

- Multi cylinder engines are more complex and include multiple cylinders and additional components.

- The simplicity of single cylinder designs makes them easier to maintain and repair.

2. Size and Weight

- Single cylinder diesel engines are small and lightweight.

- Multi cylinder engines are larger and heavier due to additional cylinders and parts.

- Single cylinder engines are ideal for portable and lightweight applications.

3. Power Output

- Single cylinder engines produce less power, usually suitable for low to medium workloads.

- Multi cylinder engines provide higher power output, suitable for heavy-duty tasks.

4. Fuel Efficiency

- Single cylinder engines are more fuel-efficient for small-scale tasks. They consume less diesel.

- Multi cylinder engines may consume more fuel but deliver greater power.

5. Durability

- Single cylinder engines are durable. They handle moderate tasks for long periods.

- Multi cylinder engines are designed to endure heavy workloads and perform well in tough conditions.

6. Cost

- Single cylinder engines are less expensive to purchase and maintain.

- Multi cylinder engines often have a higher initial and maintenance cost due to complexity.

7. Applications

- Single cylinder engines are used in small tractors, water pumps, generators, and small tools.

- Multi cylinder engines are used in cars, heavy machinery, ships, and industrial applications.

8. Performance

- Single cylinder engines provide reliable performance for their size, but are limited in power.

- Multi cylinder engines offer smoother operation and can handle diverse performance requirements.

Which One to Choose?

- If cost, portability, and simplicity are priorities, go for single cylinder engines.

- If higher power, performance, and heavy-duty tasks are required, choose multi cylinder engines.

In summary, select the engine type based on your specific application and power needs. Both designs have their strengths and are useful in different scenarios.

Selecting the Right Single Cylinder Diesel Engine

Choosing the right single cylinder diesel engine requires careful consideration. This ensures optimal performance for specific tasks. Here are key factors to guide your selection process:

1. Purpose of Use

Define how you plan to use the engine. Will it power agricultural equipment, a generator, or a pump? Each application may require different power outputs and designs.

2. Power Output

Check the engine’s horsepower or kilowatt rating. Ensure it matches your equipment’s needs. Higher horsepower is better for heavy-duty tasks, while smaller jobs may need lower power engines.

3. Fuel Efficiency

Select an engine with good fuel efficiency. This reduces operational costs over time. For long hours of operation, prioritize models that stretch fuel economy.

4. Size and Weight

Assess the size and weight of the engine. Compact and lightweight engines are ideal for portable tools or small spaces. Choose bigger engines for stationary, high-power tasks.

5. Durability and Build Quality

Consider engines built for rugged conditions. High-quality materials ensure better durability and longer life.

6. Noise and Vibration Levels

Low-noise engines enhance comfort. Opt for models designed with minimal vibration, especially for residential areas.

7. Ease of Maintenance

Look for engines with a simple design and fewer moving parts. They are easier to maintain and repair.

8. Brand and Warranty

Choose trusted and well-established brands with good after-sales service. Verify warranty details before purchase.

9. Emission Standards

Ensure the engine meets current environmental standards. Look for models with emission control features.

10. Budget-Friendly Option

Determine your budget. Balance the cost with features suitable for your needs. Remember, fuel efficiency can save costs in the long run.

Comparing multiple options and considering these factors will help you select the perfect single cylinder diesel engine. Make a choice that aligns with your specific requirements and budget.

Leave a Reply