Introduction to 3 Cylinder Engines

3 cylinder engine is widely used in modern vehicles and machinery. They serve as a compact and efficient alternative to traditional 4 or 6 cylinder engines. Over the years, these engines have evolved, adapting to new technologies and market demands. Before understanding their advantages and applications, it is essential to explore their structure and history.

What is a 3 Cylinder Engine?

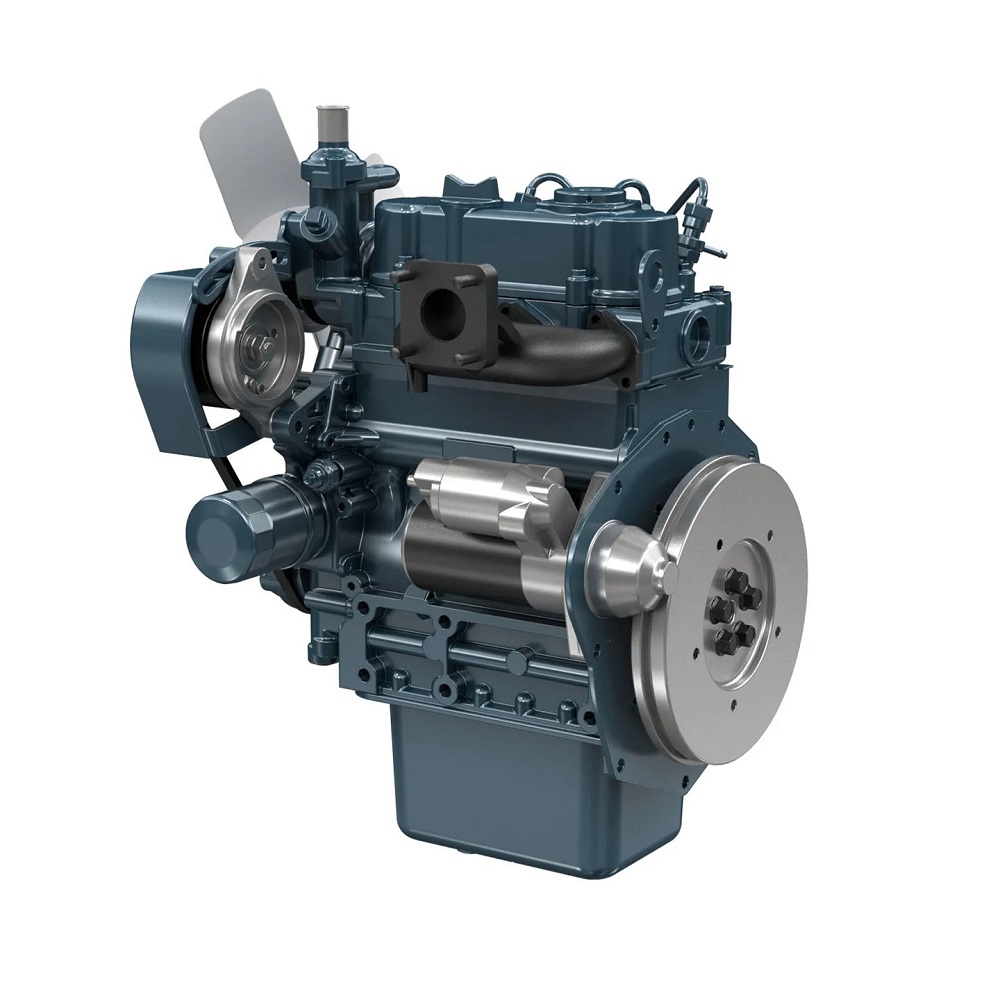

A 3 cylinder engine consists of three combustion chambers, or cylinders, arranged in a line or triangular configuration. Each cylinder plays a role in the combustion process to produce power efficiently. These engines are typically inline, meaning the cylinders are aligned in a straight row. Their simple design contributes to reduced weight and greater fuel economy.

Smaller in size compared to engines with more cylinders, they are preferred for compact cars and small machinery. Despite their size, they can deliver effective power and torque for various applications. Manufacturers often use turbocharging technology to enhance their performance.

Historical Background and Evolution

The development of 3 cylinder engines began in the early 20th century. Initially used in small cars and motorcycles, they gained popularity due to their simplicity. Over the years, advancements in materials and engineering improved their durability and efficiency.

During the 1980s and 1990s, car manufacturers focused on fuel economy. This shift made 3 cylinder engines more desirable. Their compact design allowed automakers to create lighter vehicles with better mileage. With stricter emission standards and a greater emphasis on sustainability, manufacturers refined these engines further.

Modern 3 cylinder engines now feature advanced technology. Innovations like direct fuel injection, variable valve timing, and turbocharging enhance their performance. These engines continue to play a vital role in creating fuel-efficient, low-emission vehicles for a greener future.

Advantages of Using a 3 Cylinder

3 cylinder engines provide several advantages that make them a popular choice among manufacturers. Their design promotes efficiency, cost savings, and compactness, making them ideal for modern vehicles and machinery. Below, we explore the key benefits of these engines.

Enhanced Fuel Efficiency

Fuel efficiency is one of the primary advantages of a 3 cylinder engine. The smaller engine size uses less fuel, saving money for drivers. The reduced number of cylinders minimizes energy loss, ensuring efficient combustion. Turbocharging technology in modern engines further boosts mileage without compromising performance. These engines meet fuel economy demands, aligning with sustainability goals.

Reduced Weight and Compact Design

3 cylinder engines are lighter and smaller compared to 4 or 6 cylinder engines. This compact design makes them suitable for small cars and machinery. The lighter weight improves vehicle handling and reduces overall weight. Less material use contributes to eco-friendly production and better space optimization. Manufacturers appreciate the compactness, which allows versatile design options.

Lower Manufacturing Costs

Producing 3 cylinder engines is cost-effective due to fewer components used in their assembly. Fewer cylinders mean less material and simpler production processes. Lower costs enable manufacturers to offer affordable vehicle options to consumers. The simplicity of their construction also reduces maintenance expenses over time. These engines are efficient, economical, and provide value for money.

Common Applications of 3 Cylinder Engines

3 cylinder engines are versatile and used across various industries and applications. Their compact design, fuel efficiency, and cost-effectiveness make them suitable for diverse usage. From everyday vehicles to specific industrial equipment, these engines prove their reliability and adaptability in various fields.

Popular Vehicles That Use 3 Cylinder Engines

Many popular vehicles utilize 3 cylinder engines for their efficiency and performance benefits. Compact cars, in particular, find these engines ideal due to their small size and light weight. For example, the Ford EcoSport, Ford Fiesta, and BMW i8 use 3 cylinder engines. These engines are built to provide optimal fuel efficiency while ensuring adequate power for city and highway driving.

Hybrid vehicles like the Toyota Yaris Hybrid also take advantage of 3 cylinder engines. They combine electric motors with an efficient internal combustion engine, leading to reduced emissions and better fuel economy. Additionally, entry-level cars from brands like Suzuki and Hyundai commonly feature 3 cylinder engines due to their cost-effectiveness.

In emerging markets, manufacturers offer smaller cars with 3 cylinder engines to attract budget-conscious users. These engines keep vehicle costs low while catering to the growing demand for fuel-efficient and affordable transportation solutions.

Industrial Applications

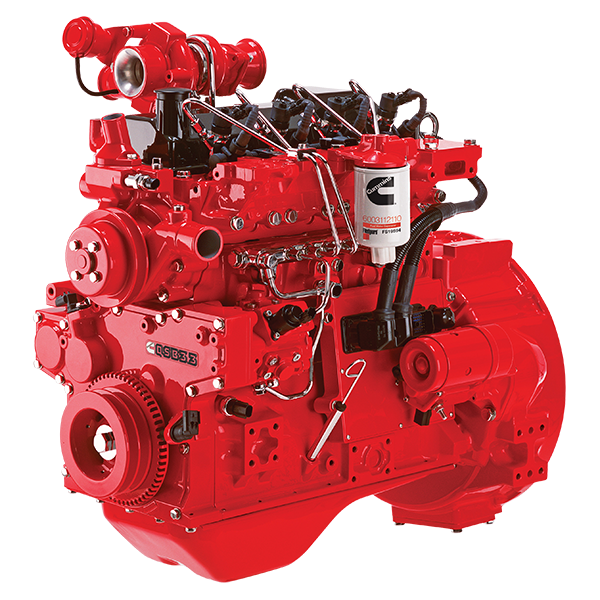

Beyond passenger vehicles, 3 cylinder engines are utilized in various industrial applications. Their compactness and reliability make them ideal for equipment in fields like agriculture, construction, and marine use. Small boats, for instance, use 3 cylinder marine engines to power their operation efficiently.

In the agricultural sector, compact tractors and machines often incorporate 3 cylinder engines. They deliver sufficient power for tasks like plowing, tilling, and planting. Their lightweight design also ensures machinery can work smoothly on uneven surfaces.

In the construction industry, small equipment such as compact loaders and mini-excavators often rely on 3 cylinder engines. These engines can handle demanding tasks while maintaining fuel efficiency, reducing operational costs.

Whether in vehicles or industrial machinery, 3 cylinder engines provide reliable and cost-effective solutions. Their versatility continues to expand their applications, reinforcing their relevance in modern technology and sustainable designs.

Performance Characteristics

Performance characteristics are crucial to understanding how a 3 cylinder engine functions under different conditions. This section delves into power output, torque behavior, and vibration control.

Power Output Comparisons

Power output in a 3 cylinder engine is effective despite fewer cylinders. Modern engines use technologies like turbocharging to boost performance significantly. While not matching the output of larger engines, they ensure sufficient power for compact applications. Enhanced combustion efficiency allows them to produce adequate horsepower for small cars, boats, and machinery.

Compared to 4 or 6 cylinder engines, 3 cylinder engines are more fuel-efficient. They require less fuel per combustion cycle, optimizing energy use. Though their horsepower may be lower, advancements like direct fuel injection help bridge performance gaps.

Torque Behavior

Torque output in 3 cylinder engines is balanced and adaptable. These engines focus on delivering steady performance in everyday driving and industrial tasks. Their torque curves are designed to provide maximum output at lower RPMs. This feature improves drivability and efficiency in various conditions.

Turbocharging increases torque levels, compensating for the smaller engine size. It ensures responsive acceleration and power delivery. While peak torque might be lower compared to larger engines, the overall balance suits small vehicles and machines.

Vibration and Noise Control

Managing vibration and noise is vital in 3 cylinder engines due to uneven firing intervals. Innovative engineering minimizes vibrations to improve comfort and durability. Balancing shafts and advanced mounts are used to reduce engine vibrations.

Noise levels are controlled through insulated engine designs and improved materials. Manufacturers also use strategies like soundproofing and better fuel combustion to minimize disturbances. Overall, modern designs focus on enhancing the driving experience through reduced noise and smoother operation.

Understanding these performance aspects highlights the strengths of 3 cylinder engines. They provide efficient power, balanced torque, and reduced vibration, meeting modern standards of reliability.

Challenges and Limitations

While 3 cylinder engines are efficient, compact, and cost-effective, they come with certain challenges. Understanding these drawbacks is important for users and manufacturers to make informed decisions.

Potential Drawbacks

- Reduced Power Output: 3 cylinder engines may produce less horsepower than 4 or 6 cylinder engines. This limitation affects performance in demanding applications, such as towing heavy loads or high-speed driving.

- Increased Vibrations: Due to uneven firing intervals, 3 cylinder engines often generate higher vibrations. This can impact comfort and lead to additional design requirements to counterbalance these effects.

- Noise Levels: These engines can be noisier than larger engines. Manufacturers add soundproofing materials, but this may increase production costs.

- Limited Applications: Their smaller size restricts usage in heavy-duty vehicles or machinery. Larger engines are still preferred for tasks requiring substantial power.

Common Issues Faced in Usage

- Strain at High Speeds: Under prolonged high-speed driving, these engines may experience strain due to their compact size. This can affect fuel efficiency and durability over time.

- Turbocharger Dependency: Many modern 3 cylinder engines rely on turbocharging to boost performance. Turbochargers can wear out and may lead to expensive repairs or replacements.

- Maintenance Needs: The specific components of a 3 cylinder engine, like balancing shafts, require regular upkeep. Neglecting maintenance may result in noise or vibration issues.

- Fuel Economy Variations: While fuel efficient, depending on the driving conditions, efficiency may vary. Increased load or uneven terrain can reduce mileage.

- Market Perception: Some consumers perceive 3 cylinder engines as less powerful compared to traditional engines. This perception may affect market acceptance, especially for premium vehicles.

Despite these challenges, manufacturers continue improving designs to minimize drawbacks. Advances in technology aim to make 3 cylinder engines more reliable and durable while retaining their benefits.

Innovations and Future Trends in 3 Cylinder Design

3 cylinder engines are evolving to meet modern needs. Innovations focus on efficiency, performance, and sustainability. These advancements aim to address challenges while enhancing their adaptability for different uses.

Technological Developments

Advancements in technology are transforming 3 cylinder engines. Engineers are integrating new systems for better performance and reliability. Below are key technological trends:

- Turbocharging Innovations: Modern turbochargers provide more power while improving fuel efficiency. They improve engine output without increasing size.

- Direct Fuel Injection Systems: These systems improve combustion efficiency, resulting in better power and lower emissions.

- Variable Valve Timing (VVT): VVT improves engine response by adjusting valve operation based on driving conditions.

- Lightweight Materials: New materials make engines lighter and more durable. This helps improve vehicle efficiency and handling.

- Advanced Vibration Control: Enhanced balancing shafts and mounts reduce vibration and noise for better user comfort.

These innovations enable 3 cylinder engines to deliver improved performance, making them more competitive in various industries.

Hybrid and Electric Integration

The future of 3 cylinder engines includes integration with hybrid and electric systems. This allows better efficiency and reduces environmental impact. Here are some key integrations:

- Plug-In Hybrid Systems: 3 cylinder engines work with electric motors to enhance fuel efficiency and lower emissions.

- Range Extenders: Small 3 cylinder engines support electric vehicles (EVs) by recharging batteries on the go.

- Efficient Internal Combustion: Hybrid vehicles use these engines for optimized combustion and reduced fuel consumption.

- Eco-Friendly Designs: Combining compact engines with electric systems aligns with sustainability trends and emission norms.

Manufacturers are focusing on hybrid systems as they appeal to eco-conscious consumers. This integration ensures the engines remain relevant in the electric vehicle era.

3 cylinder engines are adapting to future demands. Advanced technologies and hybrid integration make them indispensable. These trends promise fuel-efficient, environmentally friendly designs for years to come.

Maintenance and Care

Proper maintenance is crucial to ensure the optimal performance and durability of a 3 cylinder engine. Regular care not only improves efficiency but also extends the engine’s lifespan. Here are some essential tips to keep your engine running smoothly and considerations for its long-term use.

Essential Maintenance Tips

- Regular Oil Changes: Change the engine oil and oil filter at regular intervals. This reduces wear and tear on moving parts, keeping the engine lubricated and free from contaminants.

- Inspect Air Filters: Clean or replace air filters frequently to ensure optimal air intake and engine performance. Clogged filters can reduce fuel efficiency and power.

- Monitor Coolant Levels: Keep coolant levels consistent to prevent overheating. Check for leaks periodically.

- Fuel Quality: Use high-quality fuel to ensure smooth and efficient engine operation. Low-quality fuel can cause blockages and carbon deposits.

- Check Spark Plugs: Ensure spark plugs are clean and free of deposits. Replace them if they show signs of wear or corrosion.

- Maintain Drive Belts: Regularly inspect drive belts for any signs of cracks or wear. Replace damaged belts immediately to avoid further engine damage.

- Inspect Exhaust System: Ensure that the exhaust system is free of blockages or leaks. Clean or replace components as required.

- Follow Manufacturer’s Recommendations: Adhere to the specific maintenance schedule outlined in your vehicle or engine’s manual.

Longevity and Durability Considerations

- Avoid Overloading: Do not push the engine beyond its capacity. Consistent overloading can lead to severe damage.

- Warm-Up Engine Properly: Allow the engine to warm up before driving at high speeds. This helps reduce wear.

- Use Turbocharger Responsibly: For turbocharged 3 cylinder engines, avoid sudden accelerations when the engine is cold. Let it cool down after heavy use.

- Address Vibrations Promptly: If excessive vibrations occur, check engine mounts or balancing shafts immediately.

- Routine Check-Ups: Schedule regular professional inspections for early detection of potential issues.

- Avoid Prolonged High RPMs: Continuous driving at high engine speeds can lead to overheating and reduced lifespan.

- Store Responsibly: For machinery, store it in a clean and dry environment to prevent rust and wear.

By following these maintenance tips and longevity considerations, you can maximize the efficiency and life of your 3 cylinder engine. Regular care reduces repair costs and enhances overall performance, ensuring a reliable and cost-effective experience with your engine.

Leave a Reply