Harley-Davidson motorcycles are renowned for their powerful engines and iconic designs. For motorcycle enthusiasts and owners, understanding the anatomy of a Harley engine is essential for maintenance, repair, and performance enhancement. A detailed exploration of the various components that make up a Harley engine can help riders troubleshoot issues and ensure their bikes run smoothly. In this article, we will provide an in-depth look at the parts of a Harley engine parts diagram, their functions, and how they contribute to the overall performance of the motorcycle.

Introduction to Harley Engines

The Legacy of Harley-Davidson Engines

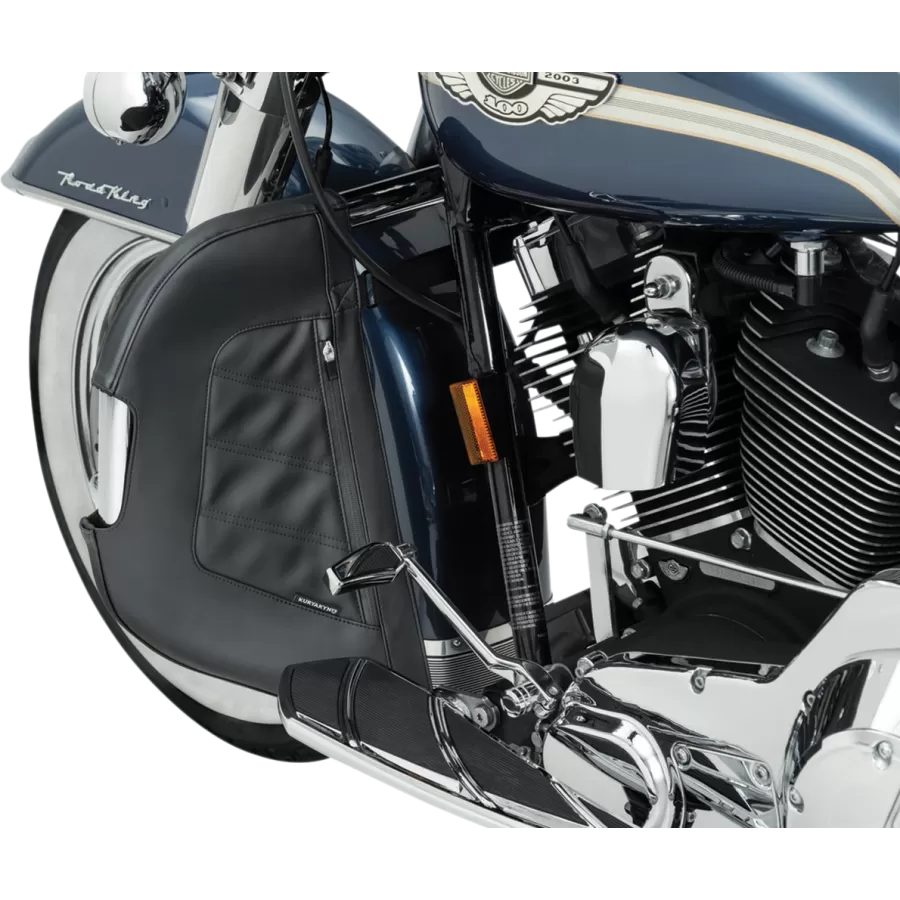

Harley-Davidson has been a prominent name in the motorcycle industry since 1903. One of the main reasons behind its enduring popularity is the development of powerful and reliable engines. Harley engine parts diagram have evolved significantly over the years, moving from simple designs to more advanced, multi-cylinder configurations. Modern Harley engines are known for their performance, distinctive sound, and characteristic appearance.

The company demonstrates its commitment to engineering excellence through the various engine models it has produced over the years, including the Evolution, Twin Cam, and Milwaukee-Eight engines. Each engine series has unique features and specifications, showcasing Harley-Davidson’s dedication to innovation and performance. Understanding the design and function of these engines can greatly enhance a rider’s experience.

Purpose of This Overview

This article aims to provide a comprehensive overview of Harley engine parts diagram, featuring diagrams that illustrate the various components. By breaking down the anatomy of a Harley engine, readers will gain insight into how each part interacts with others, ultimately contributing to the motorcycle’s performance.

The Engine Block: The Heart of the Motorcycle

What is the Engine Block?

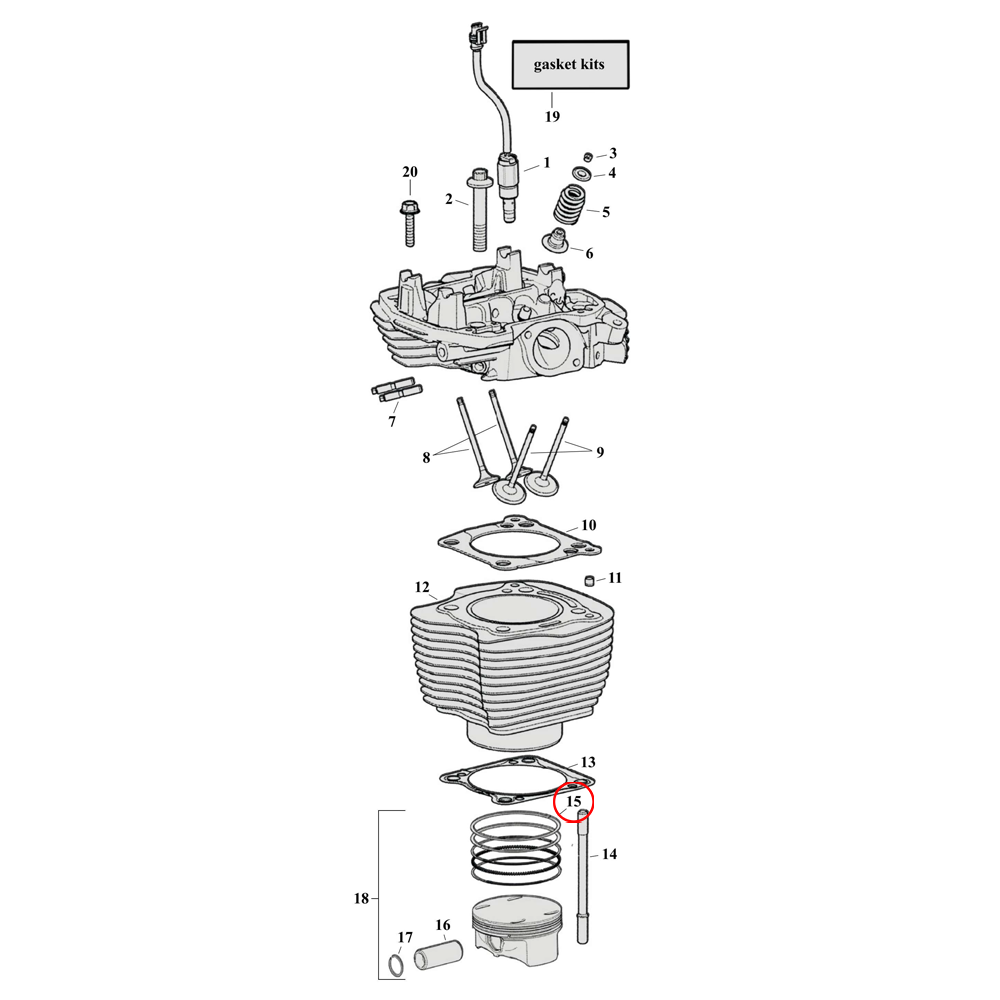

The engine block is the core structure that houses many critical components of a Harley engine. Typically made from cast iron or aluminum, the engine block contains the cylinders, where the combustion process takes place. The durability and strength of the block are essential for withstanding the pressures generated during engine operation.

Over the years, Harley has used two primary designs for its engines: V-Twin and inline configurations. The V-Twin design, which features two cylinders arranged in a “V” formation, is the most iconic engine style associated with Harley-Davidson. This arrangement contributes to the motorcycle’s distinct sound and character.

Functions of the Engine Block

The engine block contains several important features, including cylinder bores, coolant passages, and oil galleries. The cylinder bores are where the pistons move up and down, igniting the air-fuel mixture and generating power. The combustion process generates high-pressure gases that push down on the pistons, ultimately turning the crankshaft.

Coolant passages play a critical role in maintaining optimal engine temperature. Overheating can lead to engine failure, so proper coolant flow is essential for preventing damage. Oil galleries ensure that lubricating oil reaches the necessary components, minimizing friction and reducing wear. The engine block’s construction and design contribute to its overall performance and longevity.

Pistons and Crankshaft: Generating Power

Understanding Pistons

Pistons are cylindrical components that move in and out of the engine’s cylinders. Each piston is linked to the crankshaft via a connecting rod, allowing the linear motion of the piston to be transformed into rotational motion. In a V-Twin Harley engine, there are typically two pistons working in harmony to generate power.

The design of the piston is crucial for engine performance. Engineers design Harley pistons for strength and durability, often using high-quality aluminum alloys. They optimize the shape of the piston for combustion efficiency, ensuring a tight seal within the cylinder. This design reduces blow-by and enhances overall power output.

The Crankshaft’s Role

The crankshaft is another vital component responsible for converting the piston’s linear motion into rotational motion. It rotates as the pistons move up and down, transferring power to the transmission and ultimately to the rear wheel. The crankshaft’s configuration is essential for achieving smooth engine operation, especially in a V-Twin engine where balance is key.

This component is supported by main bearings, which help reduce friction during rotation. Proper lubrication is critical for the crankshaft’s operation, as it prevents wear and prolongs its life. The crankshaft’s design and alignment affect the engine’s overall performance and efficiency, highlighting its importance in the engine assembly.

Cylinder Head: Governing Air and Fuel Flow

Composition of the Cylinder Head

The cylinder head sits atop the engine block, sealing the combustion chambers and housing various components such as valves and spark plugs. It is typically made from aluminum to reduce weight while providing high thermal efficiency. The cylinder head’s design is crucial for maintaining proper airflow and combustion efficiency.

In the context of Harley engine parts diagram, the cylinder head also features complex shapes that contribute to increased performance. The configuration of combustion chambers directly affects the compression ratio, influencing power output and efficiency.

Functions of the Cylinder Head

The primary role of the cylinder head is to facilitate the intake of air and fuel, as well as the expulsion of exhaust gases. Inside the cylinder head, intake and exhaust valves open and close at precisely timed intervals, allowing for the proper flow of gases during each stroke of the engine.

The camshaft, located either within the cylinder head or driven by the engine itself, controls the opening and closing of the valves. The synchronization of the camshaft with the crankshaft ensures that the intake and exhaust processes occur efficiently. Additionally, spark plugs are housed within the cylinder head, igniting the air-fuel mixture to generate power.

Fuel System Components: Delivering Power Efficiently

Fuel Delivery Systems

The fuel system of a Harley engine is designed to deliver the right amount of fuel to the combustion chamber efficiently. Depending on the model and year, Harley engines may feature different types of fuel systems, including carburetors and fuel injection systems. Understanding these systems is essential for maintaining optimal performance and efficiency.

In carbureted models, the carburetor mixes air and fuel, ensuring that the proper ratio reaches the engine. Fuel injection systems, on the other hand, deliver fuel directly into the combustion chamber for improved efficiency. Many modern Harley engines utilize electronic fuel injection (EFI) for precise fuel delivery, resulting in better throttle response and fuel economy.

Components of the Fuel System

The fuel system consists of several key components, including the fuel pump, filter, and injectors. The fuel pump is responsible for drawing fuel from the tank and delivering it to the engine. A properly functioning pump is critical for ensuring that the engine receives an adequate fuel supply, particularly during heavy acceleration or high-speed situations.

The fuel filter prevents contaminants from entering the engine, protecting delicate components from damage. Additionally, fuel injectors are designed to atomize the fuel, creating a fine mist that mixes easily with air for efficient combustion. Regular inspection and maintenance of the fuel system are vital for optimal engine performance.

Ignition and Exhaust Systems: Essential for Performance

The Ignition System

The ignition system is crucial for initiating the combustion process within the engine. Harley engines typically feature an electronic ignition system that provides precise timing for firing each spark plug. This ensures that the air-fuel mixture is ignited at the optimal moment, maximizing performance while minimizing emissions.

Key components of the ignition system include the ignition coil, spark plugs, and control module. The ignition coil generates the high voltage needed to create a spark at the spark plugs. The control module manages timing and ignition sequences, helping to optimize engine performance under various conditions.

The Exhaust System

The exhaust system plays a critical role in controlling emissions and improving engine performance. Once combustion occurs, exhaust gases must exit the engine efficiently to allow for a fresh charge of air and fuel. The exhaust manifold collects these gases and directs them through the exhaust system.

Harley exhaust systems often feature distinct designs that enhance performance and produce the signature Harley sound. Catalytic converters and mufflers are integral components that help reduce harmful emissions and control noise levels. Proper exhaust flow is essential for maintaining engine efficiency and ensuring compliance with emissions regulations.

Maintenance Tips for Harley Engine Parts

Importance of Regular Maintenance

Maintaining your Harley engine’s components is crucial for ensuring performance and longevity. Regular maintenance helps identify potential issues before they escalate, preserving the integrity of your engine. Adhering to the manufacturer’s recommended maintenance schedule will aid in promoting optimal performance.

Regularly inspect key components such as spark plugs, fuel filters, and air filters to ensure they are in good condition. Replacing worn parts promptly can prevent further damage and enhance engine efficiency. Simple tasks, such as checking the oil level and changing the oil regularly, can significantly extend the life of your engine.

Knowing When to Seek Professional Help

While knowledgeable motorcycle owners can perform many maintenance tasks, some repairs require professional expertise. If you encounter persistent issues or complex repairs, consider consulting a certified Harley-Davidson mechanic. Their experience and training can ensure that you service your engine correctly, preserving its performance and reliability.

In conclusion, understanding the anatomy of a Harley engine parts diagram is vital for any motorcycle owner or enthusiast. By familiarizing yourself with the various engine parts and their functions, you can ensure that your Harley runs smoothly and efficiently. Regular maintenance and appropriate part replacements are key to maximizing the performance of your motorcycle. With a solid grasp of your engine’s components and proper care, you can enjoy the freedom and excitement that comes with riding a Harley-Davidson.

Leave a Reply