The engine block is often considered the heart of an automobile. It is where the power generation process begins and plays a crucial role in the overall performance of the vehicle. Understanding the various components of a parts of an engine block helps car enthusiasts and mechanics alike appreciate how these parts interact to create power. This article will explore the key elements of a parts of an engine block, their functions, and how they contribute to overall engine performance.

The Basics of an Engine Block

What is an Engine Block?

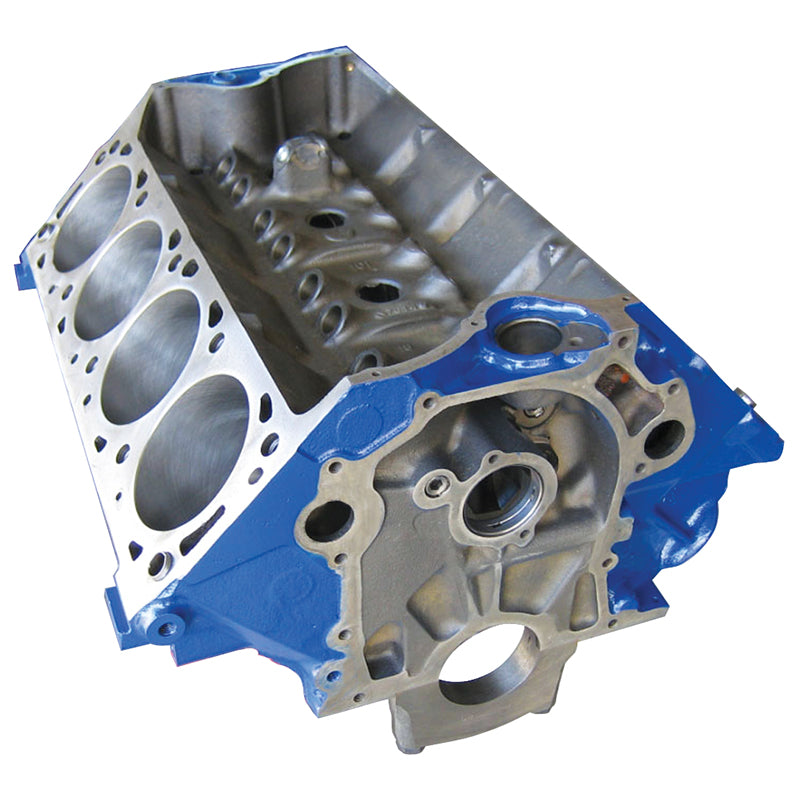

An engine block is a large, metal structure that houses several key components of an internal combustion engine. It serves as the main support structure for the engine, providing stability and alignment for the different parts. The block is typically made from cast iron or aluminum, both of which offer strength and durability under high pressure and temperature conditions.

The engine block contains cylinders, which are essential for the combustion process. Within these cylinders, fuel and air mix and ignite to produce energy, which drives the pistons. The engine block also features passages for coolant and oil, which help to regulate the temperature and lubrication of engine components. Understanding the layout and design of the engine block serves as a foundation for comprehending its performance.

Importance of the Engine Block

The parts of an engine block is vital for a vehicle’s performance and efficiency. It must withstand high pressures and extreme temperatures while maintaining structural integrity. A well-designed engine block ensures that the various components function together cohesively, contributing to the overall efficiency and power output of the engine.

Additionally, the block’s design directly impacts the engine’s weight and size, influencing the vehicle’s handling and performance characteristics. A lighter engine block can improve acceleration and fuel efficiency, while a sturdier block may enhance durability. Knowing about the engine block’s characteristics can help enthusiasts make informed decisions about modifications and upgrades.

Key Components of an Engine Block

Cylinders

Cylinders are one of the most critical components of an engine block. They are the spaces in which the combustion process occurs. Each cylinder contains a piston that moves up and down in a reciprocating motion as the engine operates. The number of cylinders in an engine can vary, with common configurations including four, six, and eight cylinders.

The design and size of the cylinders directly affect engine displacement, which is a measure of the engine’s total volume. Higher displacement typically results in more power output. However, more cylinders can also mean higher fuel consumption. Understanding the relationship between cylinder configuration and performance helps car enthusiasts balance power with efficiency.

Pistons

Pistons work in conjunction with the cylinders to convert the energy produced during combustion into mechanical energy. They are typically made from aluminum or other lightweight materials that can withstand high temperatures. The pistons move within the cylinders, creating a sealed environment that allows for the necessary compression of the air-fuel mixture.

As the pistons move down during the power stroke, they transfer force to the connecting rods and crankshaft. This movement turns the crankshaft, ultimately providing power to the vehicle’s wheels. The design of the piston, including its shape and weight, can significantly affect engine performance. Lighter pistons can reduce inertia, improving acceleration and responsiveness.

Supporting Structures

Crankshaft

The crankshaft is a vital component that transforms the linear motion of the pistons into rotational motion. It is located at the bottom of the engine block and is typically made from forged steel or cast iron for strength. The crankshaft supports the connecting rods that link the pistons, allowing seamless power transmission.

The crankshaft’s design influences the engine’s overall balance and smoothness. A well-balanced crankshaft minimizes vibrations, leading to smoother operation and improved engine longevity. Moreover, the crankshaft contributes to the engine’s stroke length, impacting torque and power output. Understanding the crankshaft’s role helps enthusiasts appreciate its significance in the performance equation.

Connecting Rods

Connecting rods link the pistons to the crankshaft. They are responsible for transferring the force generated by the pistons during combustion to the crankshaft, which then converts this linear power into rotational energy. Usually made from forged steel or aluminum, managing the weight of connecting rods is critical for achieving optimal performance.

The length of the connecting rods also affects engine performance. Longer rods can provide a smoother power transition and reduce vibration, while shorter rods typically yield higher RPMs. Car enthusiasts should consider the implications of connecting rod design when selecting components for performance upgrades.

Cooling and Lubrication Systems

Cooling Passages

The cooling is crucial for maintaining optimal engine temperatures and preventing overheating. The engine block contains a network of cooling passages and channels designed for coolant flow. This cooling system circulates coolant around the engine, absorbing excess heat generated during combustion.

Inadequate cooling can lead to engine failure, especially under heavy load conditions. A well-designed cooling system ensures efficient heat dissipation, prolonging engine life and maintaining performance. Enthusiasts may consider upgrading cooling systems as part of performance enhancements, especially in high-output engines.

Oil Passages

The engine block also includes oil passages essential for proper lubrication. Lubrication reduces friction among engine components, preventing wear and tear. Engine oil circulates through these passages to reach vital areas such as the crankshaft, pistons, and camshaft.

A robust lubrication system is crucial for performance and durability. Insufficient lubrication can lead to engine damage and decreased efficiency. Regular oil changes and maintenance can help ensure the lubrication system operates effectively, keeping the engine running smoothly.

Head and Gasket Connections

Cylinder Head

The cylinder head is the component that seals the top of the engine block. It houses the combustion chamber and contains valves, spark plugs, and fuel injectors. The design of the cylinder head significantly impacts engine efficiency and performance.

An effective cylinder head design allows for better airflow into and out of the combustion chamber. This optimizes the combustion process, leading to improved power output and increased fuel efficiency. Enthusiasts may also explore aftermarket cylinder heads, which can offer enhanced performance characteristics compared to stock designs.

Head Gaskets

Head gaskets play a critical role in sealing the connection between the cylinder head and the engine block. They prevent coolant and oil from leaking into the combustion chamber and ensure a proper seal for the combustion process. A well-functioning head gasket is essential for maintaining optimal engine performance.

Common issues with head gaskets include wear and failure due to high temperatures and pressure within the engine. A blown head gasket can result in significant damage, leading to costly repairs. Understanding the importance of head gaskets can guide maintenance practices and encourage timely inspections to prevent failures.

Aftermarket Modifications and Upgrades

Performance Enhancements

Customizing the engine block through aftermarket modifications is popular among car enthusiasts. Upgrading components such as pistons, connecting rods, and cylinder heads can significantly enhance performance. These modifications can improve airflow, increase compression, and optimize combustion, resulting in higher power output.

Consideration should be given to the entire engine system when making modifications. Enhancements made to the engine block should align with other components, such as exhaust systems and fuel delivery methods. This approach creates a well-balanced powertrain, contributing to overall efficiency and performance.

Compatibility and Tuning

When selecting aftermarket parts, considering compatibility with the existing engine is essential. Not all modifications will work seamlessly together, and improper choices can lead to problems. Working with a knowledgeable mechanic or automotive specialist can help determine the best modifications for your specific engine model.

After upgrades are made, tuning the engine is crucial to optimize performance. Proper tuning ensures that the engine runs efficiently and safely at higher performance levels. This process may require adjustments to fuel maps, ignition timing, and air-fuel ratios, depending on the nature of the modifications made.

Understanding Your Engine Block’s Key Elements

In summary, understanding the parts of an engine block is essential for maximizing performance. Key elements such as cylinders, pistons, crankshafts, connecting rods, and more contribute to the engine’s overall effectiveness in power generation. Additionally, cooling and lubrication systems are vital for durability and efficiency.

Choosing the right parts and considering modifications can significantly enhance engine performance, provided compatibility and tuning aspects are addressed. By gaining knowledge of how these components work together within the engine block, car enthusiasts can make informed decisions about upgrades and maintenance.

Whether you are a casual driver or a dedicated performance enthusiast, this understanding will enhance your appreciation for the complexity of automotive engineering. As you explore more about your vehicle, remember that every component plays a fundamental role in the driving experience, and a well-maintained engine block is the key to a powerful and efficient ride.

Leave a Reply