Owning a boat equipped with a MerCruiser engine brings the joys of cruising and fishing, but it also comes with the responsibility of maintaining the engine. The MerCruiser brand is known for its reliability and performance, making it a popular choice for boat owners. However, understanding the various parts of the engine and their functions is essential for proper maintenance and ensuring longevity. This complete guide will outline the key MerCruiser engine parts, common maintenance practices, and tips for replacement.

Understanding MerCruiser Engines

Overview of MerCruiser Engines

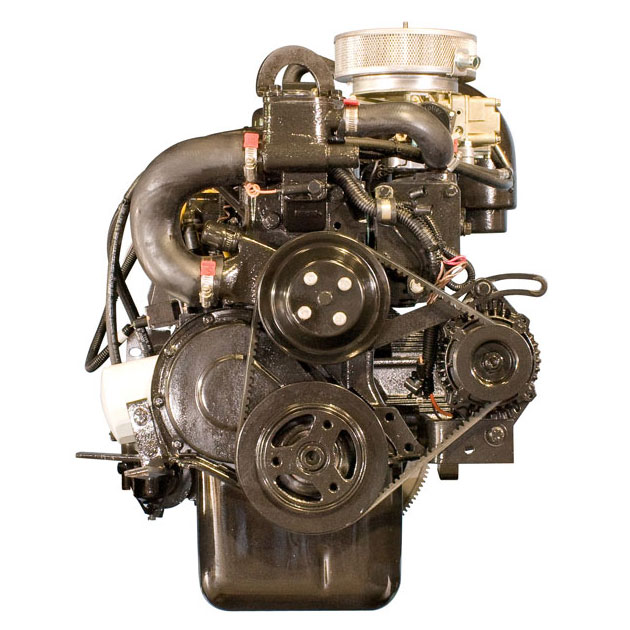

MerCruiser engines are marine engines manufactured by Mercury Marine. They provide power for various types of boats, including leisure boats, fishing boats, and cruisers. These engines come in different configurations, including inboard, sterndrive, and outboard models, each designed to meet the specific needs of boat owners.

The engine’s construction consists of a combination of high-quality materials to withstand the unique demands of marine environments. Boats are often exposed to water, salt, and humidity, so engine components are designed with corrosion resistance in mind. Understanding the mechanics of MerCruiser engines can help boat owners make informed decisions related to maintenance and repairs.

Key Benefits of MerCruiser Engines

MerCruiser engines offer several benefits that make them appealing to boat owners. One of the most significant advantages is their performance. These engines deliver reliable horsepower and torque, allowing for impressive acceleration and smooth cruising experiences.

Additionally, MerCruiser engine parts are known for their fuel efficiency. Modern MerCruiser models are equipped with advanced fuel management systems, which optimize power consumption and reduce emissions. This feature not only helps save on fuel costs but is also beneficial for the environment.

Essential Engine Parts

Engine Block

The engine block is the main component of the MerCruiser engine and serves as the foundation for other parts. It houses the cylinders where combustion takes place. Manufacturers typically forge the engine block from cast iron or aluminum, each offering unique benefits. Aluminum is lighter, promoting better speed and handling, while engineers know that cast iron is renowned for its durability.

Understanding the engine block’s structure is essential because it affects overall performance and reliability. It must endure high pressure and temperatures, so regular inspections for signs of wear are important. Issues such as cracks or warping can significantly affect engine performance and may necessitate costly repairs.

Cylinder Heads

Cylinder heads sit atop the engine block and contain critical components such as the intake and exhaust valves. This part plays a vital role in the combustion process, managing the airflow and fuel mixture going into the cylinders while allowing exhaust gases to escape. Some MerCruiser engines feature multi-valve designs for improved performance and efficiency.

Regular inspection of the cylinder heads is important, as they can often endure an excessive amount of heat. Over time, exhaust valves may become worn or damaged, leading to compression losses. Keeping an eye on the condition of the cylinder heads can help prevent engine problems down the road.

Fuel and Ignition Systems

Fuel Pump

The fuel pump is a critical component responsible for delivering fuel from the tank to the engine. MerCruiser systems often use electric fuel pumps for consistency and efficiency. These pumps maintain adequate pressure to ensure the engine receives the appropriate amount of fuel for combustion.

It’s important to maintain the fuel pump to prevent issues such as fuel starvation or leaks. Owners should periodically check for any fuel line blockages and replace the fuel filter as necessary to ensure optimal performance. If you notice a decrease in engine performance or difficulty starting, the fuel pump may require inspection.

Ignition System

The ignition system in a MerCruiser engine consists of components such as spark plugs, ignition coils, and the distributor. This system is responsible for igniting the air-fuel mixture within the combustion chambers. Proper functioning of the ignition system is crucial for maintaining efficient engine performance.

Regular maintenance, including checking and replacing spark plugs according to the manufacturer’s recommendations, can prevent ignition system failures. Spark plugs can wear over time, affecting engine efficiency and fuel consumption. Ensuring that the ignition system is well-maintained is key to reliable engine starts and smooth operation.

Lubrication and Cooling Systems

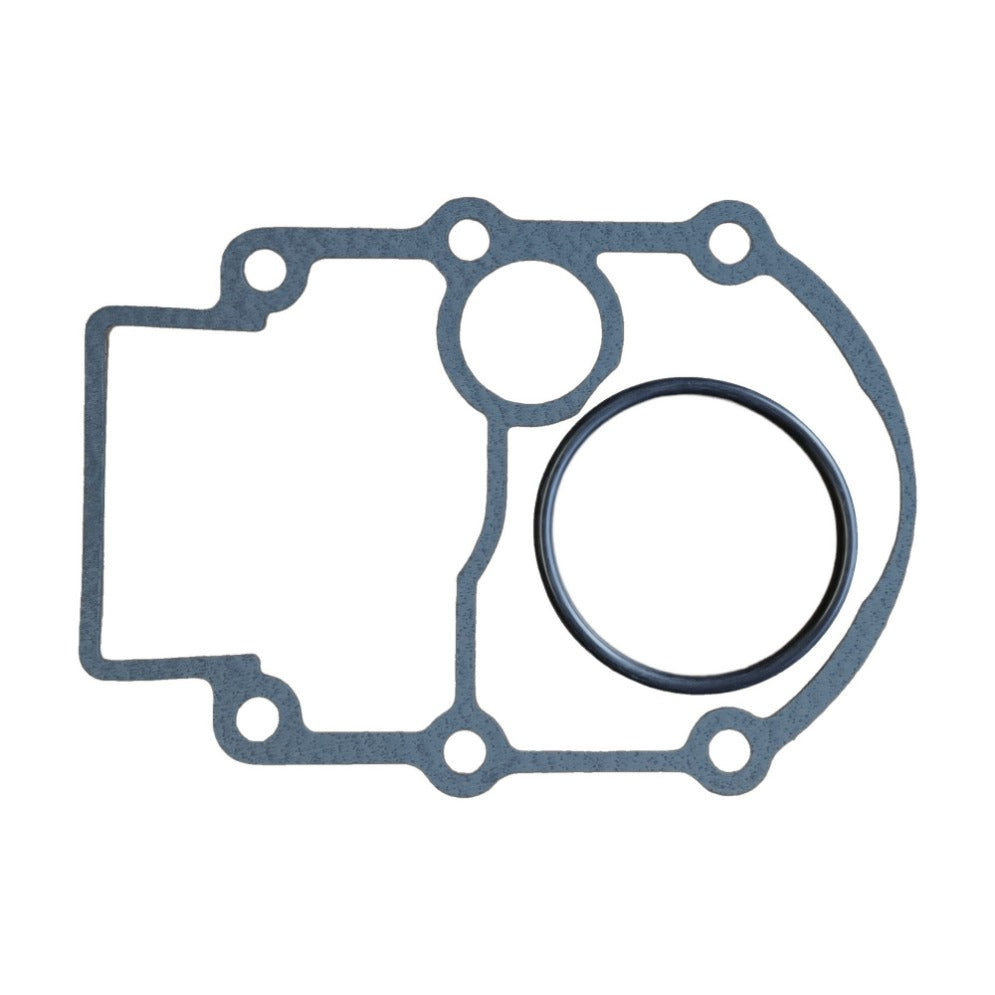

Oil Filter

The oil filter plays an essential role in the lubrication system of the MerCruiser engine parts. It removes contaminants and debris from the oil before it circulates through the engine’s components. This filtration process helps maintain the cleanliness of the oil, ensuring that moving parts are lubricated effectively.

To extend engine life, it is critical to change the oil and oil filter at recommended intervals. Regular oil changes help to prevent sludge buildup and degradation of engine components. Keep an eye out for any leaks around the oil filter area, as this may indicate a need for replacement or tightening.

Cooling System

The cooling system prevents the MerCruiser engine parts from overheating, a crucial aspect of engine maintenance. This system typically includes the water pump, heat exchanger, and various hoses. Freshwater or seawater is circulated to absorb heat generated during combustion, maintaining optimal operating temperatures.

Regular checks of the cooling system components are essential for preventing overheating. Inspect water pumps for wear, as they can degrade over time and impact cooling efficiency. Flushing the cooling system and replacing any worn hoses can help prevent issues before they escalate, ensuring that the engine operates within safe temperature ranges.

Common Maintenance Practices

Regular Inspections

One of the best ways to ensure the longevity and performance of a MerCruiser engine is through regular inspections. Checking for signs of wear on components, including hoses, belts, and electrical connections, can help identify potential problems before they worsen. Pay particular attention to any signs of leaks, corrosion, or abnormal wear.

Creating a maintenance checklist can simplify this process. Include regular inspections of the oil level, coolant level, and battery condition. Note any unusual sounds or vibrations while operating the boat, as these can indicate underlying engine problems.

Seasonal Maintenance

Because many boaters don’t use their vessels year-round, seasonal maintenance practices are crucial. Before launching your boat in the spring, it is important to perform a thorough check of the engine and related components. This may involve changing the oil, inspecting the fuel system, and checking the exhaust system for any blockages or wear.

Conversely, winterizing your MerCruiser engine is essential if it will sit unused for several months. Winterization typically involves draining the cooling system, adding antifreeze, and stabilizing the fuel. Proper winterization prevents freezing and other damage that can occur from extended disuse in cold environments.

Parts Replacement Considerations

When to Replace Parts

Understanding when to replace components of your MerCruiser engine is key for maintaining optimal performance. Some parts may wear out faster than others, and knowing the average lifespan can help you plan for replacements effectively.

For example, you should replace spark plugs approximately every 30,000 to 100,000 miles, depending on usage and type. Similarly, you should change oil filters every time you replace the oil. Keeping track of maintenance schedules and logs can help you ensure that you replace parts at the right intervals.

Sourcing Quality Parts

When it comes time for replacement, sourcing quality parts is essential. MerCruiser designs OEM (Original Equipment Manufacturer) parts specifically for your engine model, and experts typically recommend them for replacements. These parts are manufactured to the same standards as the original components, ensuring compatibility and reliability.

While aftermarket parts may be more cost-effective, it is crucial to ensure their quality. Always do thorough research and purchase from reputable sources. Using low-quality components can affect engine performance and might lead to premature wear or failure.

Professional Assistance and Resources

Working with Professionals

While many aspects of MerCruiser engine parts maintenance can be performed by the boat owner, there are times when professional assistance is necessary. Certified marine technicians possess the expertise and tools to handle more complex repairs and diagnostics. They can conduct thorough inspections, identify issues, and recommend solutions based on their findings.

If a significant problem arises or if you’re uncomfortable performing certain maintenance tasks, seek professional help. Establishing a relationship with a trusted marine service provider can be beneficial for your long-term engine care.

Utilizing Owner Resources

MerCruiser provides several resources to help boat owners maintain their engines effectively. The owner’s manual is a vital resource that includes information about recommended maintenance schedules and specific part requirements. Additionally, many online forums and websites focus on MerCruiser engine parts, offering forums for discussion, troubleshooting advice, and part sourcing.

Consider joining local boating clubs or online communities, where members share experiences and provide valuable tips on maintenance practices and recommendations. Engaging with experienced boat owners can deepen your understanding of MerCruiser engines and enhance your overall boating experience.

Conclusion: Ensuring Longevity for Your MerCruiser Engine

In conclusion, understanding the components and maintenance needs of your MerCruiser engine parts are vital for optimal performance and durability. Regular inspections, timely replacements, and professional assistance when needed will help ensure your engine remains in excellent condition.

Familiarizing yourself with essential parts such as the engine block, fuel system, and cooling systems can empower you to take proactive steps in maintenance. Utilizing quality parts for replacements and leveraging available resources will further enhance engine longevity.

By being diligent about the care of your MerCruiser engine parts, you can enjoy a reliable and enjoyable boating experience for years to come. Embrace the responsibility of engine care, and your well-maintained MerCruiser will continue to provide the thrills of the open water.

Leave a Reply