Introduction to Small Engines

Parts of a small engine is vital for powering various machines and equipment. They are compact, efficient, and widely used in everyday devices. Understanding their structure and functionality is essential for optimal use and maintenance.

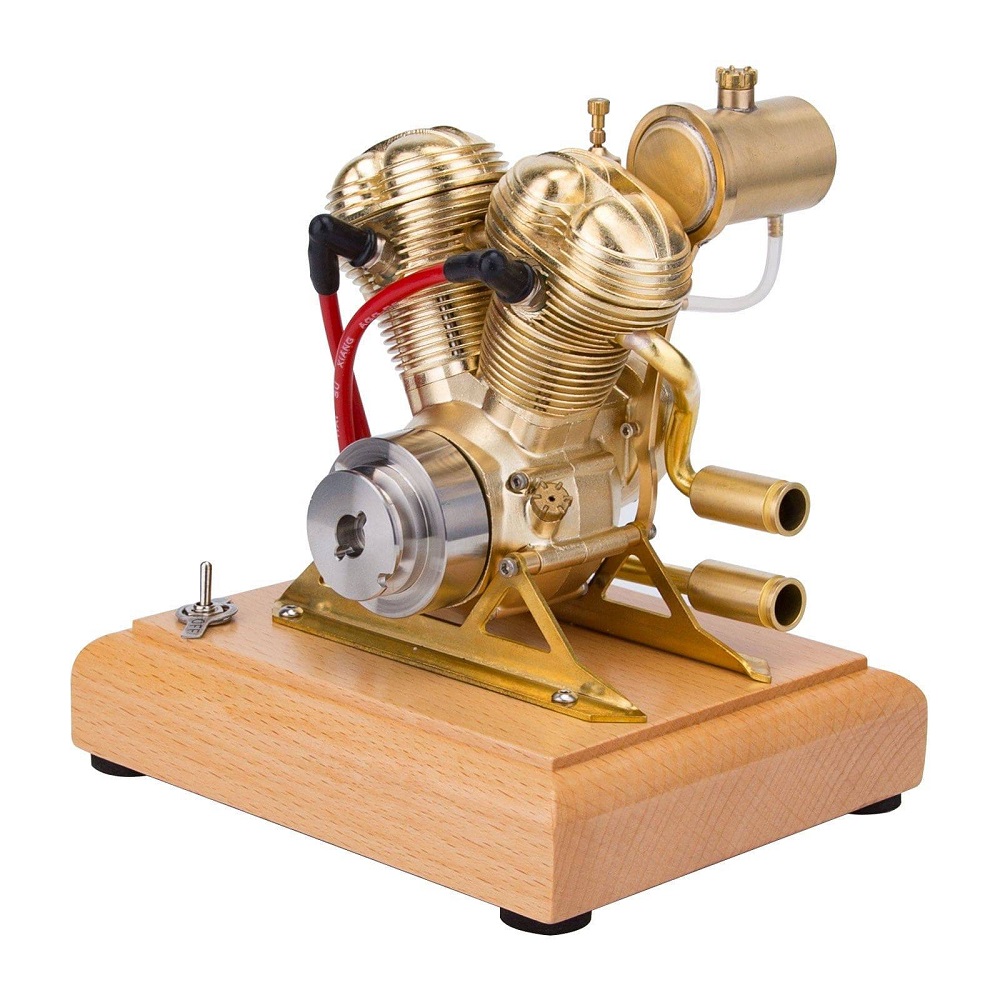

What Defines a Small Engine?

A small engine is an internal combustion engine with a power output under 25 horsepower. These engines are lightweight and designed for portable equipment. They typically run on gasoline but can also use other fuels. Key characteristics include single-cylinder designs and air cooling mechanisms.

Common Uses and Applications of Small Engines

Small engines power many common tools and machines. They are found in lawnmowers, generators, chainsaws, and snowblowers. Construction and farming equipment also rely on these engines. Additionally, small engines are crucial for recreational vehicles like go-karts and boats. Their versatility makes them indispensable in many industries and households.

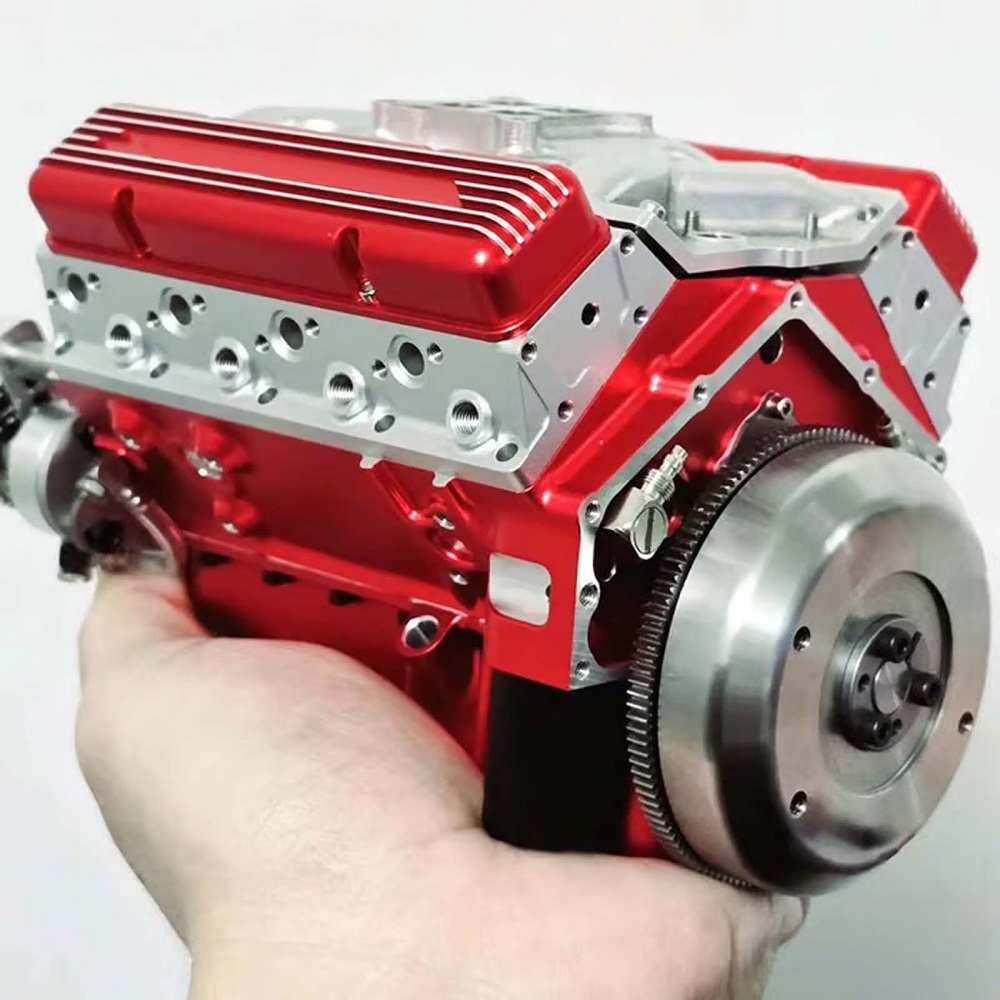

Key Components of a Small Engine

Understanding the key components of a small engine is crucial. Each part plays a role in ensuring performance and efficiency.

Engine Block and Cylinder

The engine block is the foundation of the small engine. It houses the cylinder, a crucial chamber where combustion occurs. The cylinder’s size and design affect power output. A well-designed engine block ensures durability and efficient heat dissipation.

Crankshaft and Connecting Rod

The crankshaft converts linear motion from the piston into rotational motion. It drives the engine’s output shaft. The connecting rod links the piston to the crankshaft. Both must work seamlessly for smooth operation. Proper alignment reduces wear and increases longevity.

Piston and Combustion Chamber

The piston moves within the cylinder, compressing the air-fuel mixture. Combustion occurs above the piston in the combustion chamber. This action produces energy to power the engine. The piston must fit tightly to prevent leaks and maintain efficiency. A clean combustion chamber ensures optimal performance.

Ignition System Components

The ignition system is essential in starting and running a small engine. It delivers the spark needed to ignite the air-fuel mixture in the combustion chamber, enabling the engine’s operation. Proper ignition system maintenance ensures consistent engine performance.

Spark Plug

The spark plug is vital for igniting the air-fuel mixture. It generates an electric spark that triggers combustion. Positioned in the engine’s cylinder head, it must be clean and free from debris. If worn or damaged, it can cause misfires or hard starting. Regular inspection and cleaning of the spark plug improve engine reliability and fuel efficiency.

Flywheel and Magneto

The flywheel and magneto work together to create the electrical charge for the spark plug. The flywheel has magnets embedded in it, which pass near the magneto when the engine rotates. This generates electricity for the ignition system. A well-functioning flywheel ensures smooth operation and consistent spark delivery. Proper alignment and maintenance of these components are crucial for optimal ignition performance.

Fuel and Air System Components

The fuel and air systems are essential for the efficient functioning of small engines. They ensure the proper mix of fuel and air necessary for combustion.

Carburetor

The carburetor mixes fuel and air accurately for engine combustion. A well-adjusted carburetor helps the engine run smoothly. It requires regular cleaning to avoid blockages caused by dirt. Malfunctions in the carburetor can lead to poor engine performance or starting issues. Inspect it routinely to ensure optimal operations.

Air Filter

The air filter prevents dirt and debris from entering the carburetor and engine. A clean air filter ensures smooth airflow, maintaining proper fuel combustion. Over time, filters can clog, reducing engine efficiency. Replace or clean the air filter as part of regular maintenance. This enhances engine longevity and prevents damage.

Fuel Tank and Lines

The fuel tank stores the gasoline or other fuel used by the engine. Fuel lines transport fuel from the tank to the carburetor. Cracks or leaks in the tank or lines can disrupt fuel flow. Inspect them periodically for damages or blockages. Keeping them clean ensures uninterrupted fuel delivery for consistent engine performance.

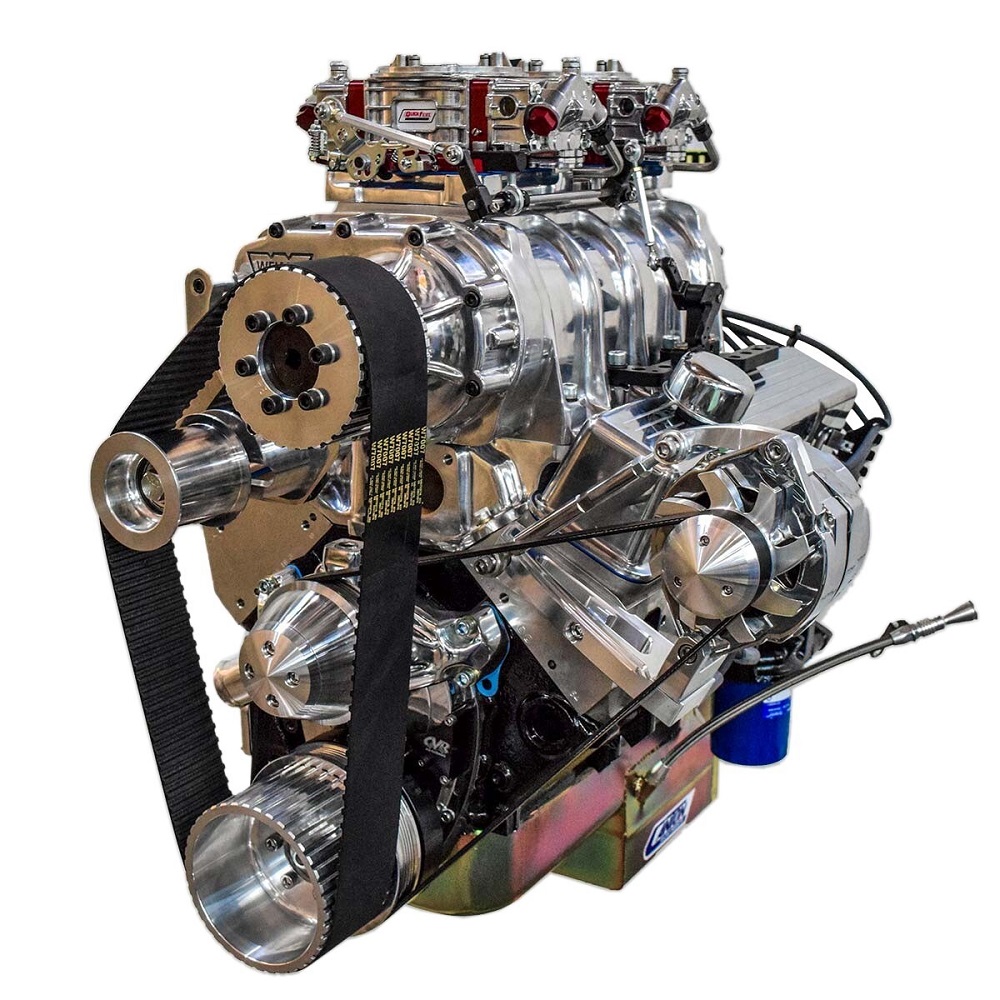

Cooling and Lubrication Systems

Cooling and lubrication are essential for ensuring the smooth operation of a small engine. They prevent overheating and reduce friction, preserving the engine’s efficiency and lifespan. Proper maintenance of these systems is necessary for optimal performance.

Cooling Fins and Fans

Cooling fins and fans are designed to dissipate heat generated during engine operation. The fins are located on the cylinder and engine surface, increasing the area for heat transfer. Fans, usually mounted on the flywheel, circulate air over the fins to enhance cooling. Regularly clean the fins to remove dirt, ensuring proper airflow. A dirty or damaged cooling system can lead to overheating and engine failure. Inspections should be frequent, especially in dusty environments.

Oil and Lubrication Mechanisms

Lubrication reduces friction between moving engine parts and prevents wear. Small engines typically use splash lubrication or pressurized oil systems. Check the oil level regularly and maintain the correct viscosity. Dirty or low oil can cause severe engine damage. Replace the oil as recommended by the manufacturer. Inspect seals and gaskets to prevent oil leaks. Additives in oil also help maintain engine cleanliness and protect against corrosion. Proper lubrication improves overall efficiency and extends engine life.

Small Engine Starting Systems

Starting systems in small engines are designed to initiate operation quickly and efficiently. Understanding these systems ensures proper use and troubleshooting.

Recoil Starter

The recoil starter is the most common system in small engines. It uses a pull cord to create the initial motion needed to start the engine. The cord wraps around a pulley with a spring inside the mechanism. When you pull the cord, the pulley spins the crankshaft to initiate combustion.

To ensure durability, always pull the cord smoothly without excessive force. Frayed or broken cords should be replaced promptly. The spring mechanism can also wear out over time, requiring inspection and maintenance. Proper care of the recoil starter ensures reliable engine operation.

Electric Starter Options

Electric starters are often found in larger or newer small engines. These systems use an electric motor powered by a battery to start the engine. With just a push of a button or a key turn, the engine begins operation. Electric starters provide convenience, especially for those who struggle with pull cords.

To maintain the electric starter, regularly inspect the battery and connections for corrosion. Ensure the battery stays charged, especially during infrequent use. Faulty wiring or weak batteries can hinder the starter’s performance. Routine checks help extend the life of electric starters and ensure ease of use.

Both recoil and electric starters require proper maintenance to guarantee dependable starting. Understanding these systems fosters confidence in operating small engines.

Maintenance of Small Engine Parts

Maintaining the parts of a small engine is essential for its long-lasting performance. Proper care helps the engine run smoothly and prevents unexpected breakdowns. Regular maintenance also saves money by avoiding costly repairs.

Cleaning and Servicing Components

Regular cleaning of engine parts ensures efficient performance and avoids long-term damage. Dirt and debris can block essential areas and affect engine operations.

- Air Filter: Keep the air filter clean to maintain proper airflow. A clogged filter can reduce engine efficiency. Clean or replace it based on usage frequency and manufacturer recommendations.

- Carburetor: Service the carburetor by removing dirt and deposits. A clean carburetor ensures the correct air-fuel mixture.

- Cooling Fins and Fans: Dust buildup decreases cooling efficiency. Regularly clean fins and fans to prevent overheating.

- Spark Plug: Clean the spark plug to ensure a strong spark. Remove carbon deposits from the tip.

Use the right tools for cleaning and follow the equipment manual for specific guidelines.

Replacing Worn-Out Parts

Engine parts naturally wear out over time. Replacing them in time ensures peak performance and safety.

- Spark Plug: Replace it if the electrode shows heavy wear or excessive buildup.

- Fuel Lines: Check for cracks or leaks and replace damaged lines to maintain proper fuel flow.

- Oil and Filters: Change the engine oil and oil filter regularly to remove contaminants and ensure lubrication.

- Starter Cord or Battery: Replace frayed pull cords or weak starter batteries. Faulty starting mechanisms can cause delays.

Inspect all parts regularly to identify wear or damage. Always use compatible replacements recommended by the manufacturer.

By cleaning and replacing components timely, small engines remain reliable and efficient. Routine care extends their lifespan and improves their overall performance.

Expanding Your Knowledge

Researching Resources

To deepen your understanding of small engines, various resources are available. Books, online courses, and tutorials can provide valuable insights into engine mechanics and maintenance. Additionally, many forums and online communities focus on small-engine enthusiasts. Engaging with these communities allows you to ask questions, share experiences, and learn from others who share your passion. The quest for knowledge can enhance your skills and improve your confidence as a rider or mechanic.

Practical Hands-On Experience

Nothing replaces hands-on experience when it comes to learning about small engines. Consider taking the time to work on your engine, whether that means performing routine maintenance or tackling minor repairs. Start with simple tasks, such as changing the oil or cleaning the air filter. As you gain confidence, gradually move on to more complex tasks. This practical experience will deepen your understanding and prepare you for tackling issues with your engine effectively.

Safety Considerations

Prioritizing Safety During Maintenance

When working on small engines, safety should always be a top priority. Always use personal protective equipment, like gloves and safety glasses, to protect yourself from potential hazards. Ensure you work in a well-ventilated area when dealing with fuel and oils. Additionally, familiarize yourself with the tools you use and their proper handling. Taking these precautions can help prevent accidents and injuries while maintaining your engine.

Knowing When to Seek Help

While many maintenance tasks can be handled independently, it’s important to recognize when a professional’s intervention is needed. If you encounter a problem that you cannot resolve or lack the tools for, don’t hesitate to consult a qualified technician. Attempting to fix complex issues without adequate knowledge can lead to further damage and increased repair costs. Knowing your limits is a crucial aspect of responsible engine maintenance.

The Community of Motorcycling Enthusiasts

Connecting with Other Riders

Being part of the motorcycle community can significantly enhance your experience with small engines. Joining local clubs or online forums allows you to connect with fellow riders who share your interests. These communities offer a wealth of knowledge, tips, and advice regarding motorcycle maintenance and modifications. Participating in group rides or events fosters a sense of camaraderie and support. Whether you’re seeking guidance on specific issues or sharing your experiences, the community can be an invaluable resource throughout your riding journey.

Sharing Knowledge and Skills

As you gather knowledge about small engines, consider sharing your insights with others. Teaching fellow riders about maintenance practices or troubleshooting techniques strengthens the community. Hosting workshops, contributing to forums, or simply helping a friend with their bike can create a collaborative atmosphere. Sharing knowledge not only empowers others but also reinforces your understanding of the subject. This collective learning approach enriches your riding experience and makes it more fulfilling, ensuring that the joy of motorcycling continues to thrive in your community.

Exploring Customization Options

Personalizing Your Motorcycle

Customization is an exciting aspect of motorcycle ownership that allows riders to express their personal style and preferences. Once you gain a solid understanding of your small engine, consider customizing various elements of your motorcycle. This could include adding features such as unique exhaust systems, tailored seats, or custom paint jobs. Each modification can reflect your personality and enhance your riding experience.

Benefits of Customization

Customizing your motorcycle can improve both its performance and aesthetics. Upgrading components like the suspension or brakes can enhance handling and comfort during rides. Additionally, cosmetic changes can turn your motorcycle into a one-of-a-kind machine that stands out on the road. Engaging in custom projects can also serve as a fulfilling way to spend time, blend creativity with mechanics, and connect with other enthusiasts who appreciate the art of customization.

Conclusion: The Journey of Small Engine Maintenance

Embracing the Challenge

Engaging with parts of a small engine maintenance is a rewarding journey that enhances your riding experience. By understanding the parts of the engine and how they work together, you become more attuned to its needs. Whether you’re a casual rider or a serious enthusiast, maintaining your engine allows you to take pride in your ride. It’s not simply about fixing problems but about taking ownership of your motorcycle’s performance.

Celebrating Your Progress

As you continue to learn and grow in your understanding of small engines, celebrate your progress. Each step you take towards greater knowledge and competence is an achievement. Embrace the rewards of your hard work, which can lead to smoother rides and fewer mechanical issues. Enjoy the freedom that comes with riding a well-maintained motorcycle, knowing that you have the skills to keep it in top condition.

Leave a Reply