Overview of Diesel Engines

Diesel engines are widely used due to their efficiency and durability. Known for generating power through compression ignition, they are integral to various industries like transportation, construction, and agriculture. Understanding how parts of a diesel engine work and their differences from gasoline engines helps in appreciating their unique advantages.

How Diesel Engines Work

Diesel engines operate on the principle of compression ignition. First, air enters the cylinders and is compressed, heating it intensely. Fuel is then injected into the heated air, causing ignition without the need for spark plugs. This controlled combustion pushes pistons to generate mechanical power. Diesel engines are tough and handle higher workloads efficiently compared to gasoline engines.

Key Differences Between Diesel and Gasoline Engines

While both diesel and gasoline engines convert fuel into energy, they have distinct processes. Diesel engines use compression ignition, while gasoline engines rely on spark ignition. Diesel engines are generally more robust and fuel-efficient. They produce more torque, which makes them ideal for heavy-duty applications. However, gasoline engines are often smoother, quieter, and better suited for smaller, lightweight vehicles.

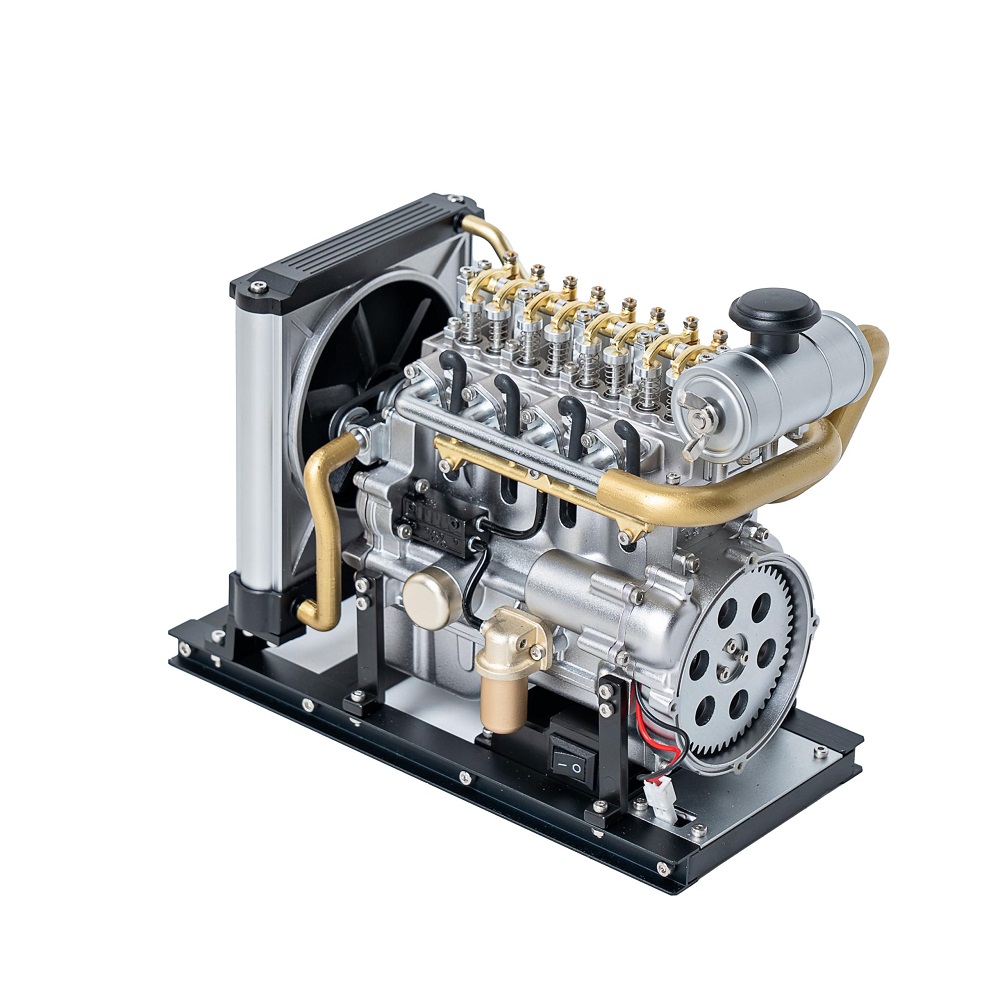

Main Components of a Diesel Engine

Diesel engines consist of several key components that work in harmony to generate power. Each part plays a crucial role in ensuring efficiency, durability, and smooth operation. Below are the fundamental components of a diesel engine and their functions.

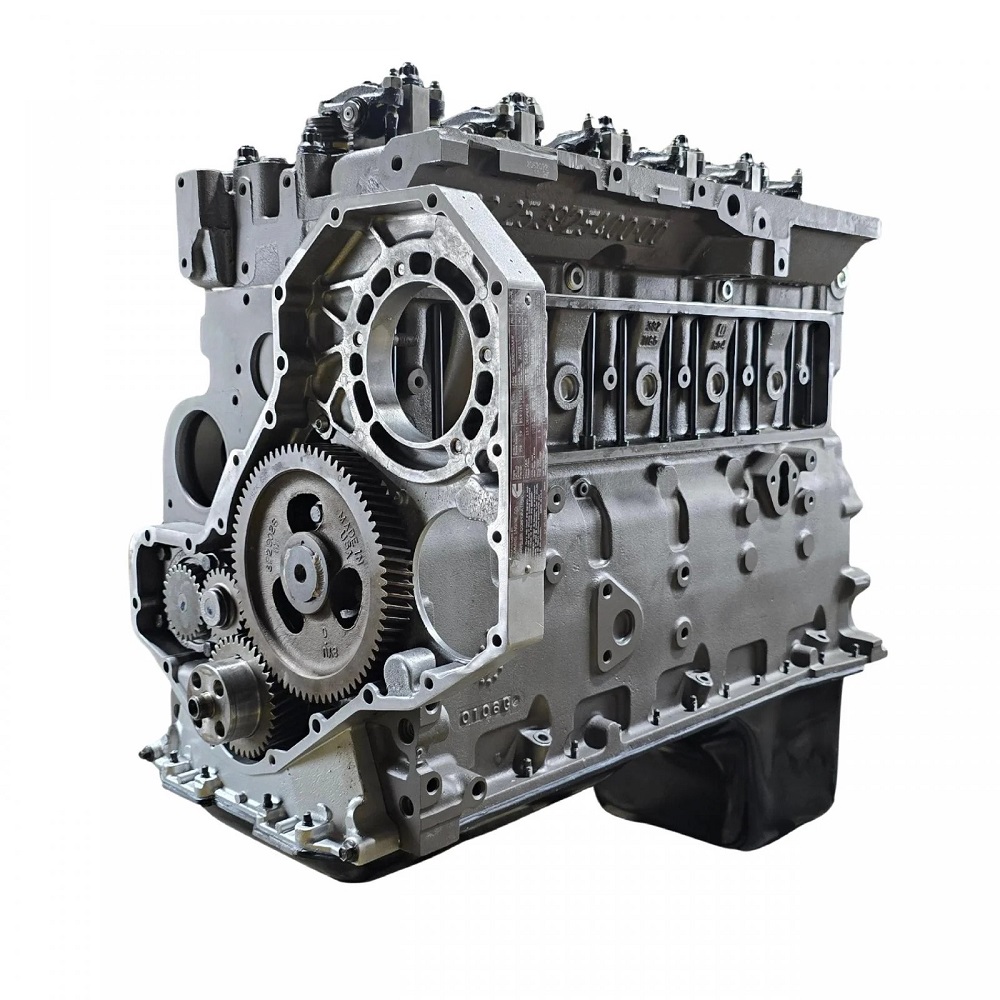

Engine Block and Cylinders

The engine block is the core of the diesel engine and houses the cylinders. Cylinders are chambers where air is compressed and fuel is ignited. The engine block is typically made of cast iron or aluminum for strength and durability. It also provides the foundation for the pistons and crankshaft to operate.

Piston, Connecting Rod, and Crankshaft

Pistons move up and down within each cylinder to create mechanical energy. Connecting rods link the pistons to the crankshaft. The crankshaft converts the pistons’ linear motion into rotational energy. This rotational energy powers the vehicle’s drivetrain and various mechanical systems.

Cylinder Head and Valves

The cylinder head seals the top of the engine block and contains intake and exhaust valves. Intake valves allow air or fuel mixture into the cylinders, while exhaust valves release burnt gases. The cylinder head also houses components like fuel injectors and glow plugs. It ensures efficient combustion and supports high-pressure sealing for the engine’s operation.

Fuel System Components

The fuel system in a diesel engine is crucial for delivering fuel effectively. It ensures combustion processes are carried out efficiently, contributing to the engine’s performance and durability.

Fuel Injectors and Fuel Pump

Fuel injectors spray fuel directly into the engine’s cylinders. They atomize the fuel for efficient mixing with air. Precise injection timing ensures smooth combustion and optimal engine output.

The fuel pump is responsible for supplying fuel to the injectors under high pressure. Diesel fuel pumps are designed to generate the pressure needed for direct injection. This high-pressure system allows controlled ignition and improved energy efficiency.

Fuel Filters and Lines

Fuel filters remove impurities and debris from fuel before reaching the injectors. Clean fuel ensures consistent engine performance and protects critical components from damage.

Fuel lines are the pathways that connect the tank, pump, and injectors. They resist pressure and heat, ensuring smooth and safe fuel delivery. Proper maintenance of filters and lines prevents blockages and ensures reliable engine operation.

Air Intake and Exhaust System

The air intake and exhaust system in diesel engines is vital for their efficiency. It ensures proper airflow for combustion and removes exhaust gases after combustion. These systems are designed to optimize performance and fuel efficiency while reducing emissions.

Turbocharger and Intercooler

The turbocharger boosts engine power by compressing air before it enters the cylinders. Compressed air improves combustion efficiency and enables higher power output. This component is especially useful in heavy-duty diesel engines requiring greater performance.

The intercooler cools the air compressed by the turbocharger. Cooling air improves its density, leading to better combustion. This helps enhance engine performance while reducing the risk of overheating.

Exhaust Manifold and Muffler

The exhaust manifold collects exhaust gases from the cylinders. It channels these gases to the exhaust system for disposal. Properly designed manifolds reduce backpressure, enhancing engine efficiency.

The muffler minimizes noise produced by exhaust gases exiting the engine. It ensures smoother operation and compliance with noise regulations. A well-maintained muffler contributes to quieter diesel engine operations.

Lubrication System

The lubrication system in a diesel engine is vital for reducing wear and tear. It ensures smooth operation by minimizing friction among moving parts. Proper lubrication also controls heat and prevents damage caused by excessive metal contact. A well-maintained lubrication system improves engine efficiency and extends its life.

Oil Pump and Oil Pan

The oil pump circulates oil throughout the engine to lubricate vital components. It delivers oil under pressure to areas like bearings and pistons. This constant lubrication reduces friction and protects parts from overheating.

The oil pan is a reservoir that stores engine oil. It is placed at the base of the engine block. The oil pan also helps cool the engine by dissipating heat absorbed by the oil. Regular checks ensure the oil pan doesn’t leak and stores enough oil for the system.

Filters and Cooling Mechanism

Oil filters remove dirt, metal particles, and contaminants from the engine oil. Clean oil prevents damage to sensitive engine parts like bearings and cylinders. Filters must be checked regularly to ensure they aren’t clogged.

The cooling mechanism within the lubrication system helps reduce engine temperature. Some systems use oil coolers to lower the oil’s temperature. Cooler oil ensures consistent performance and prevents heat-related damage to parts of a diesel engine.

Cooling System

Efficient cooling is crucial for diesel engines. The cooling system regulates engine temperature, protecting it from overheating or freezing. It extends the engine’s life and ensures consistent performance under varying conditions. Key components like the radiator, coolant, water pump, and thermostat work together to maintain optimal temperature levels.

Radiator and Coolant

The radiator dissipates heat from the engine. It transfers excess heat to the surrounding air. Coolant, a mix of water and antifreeze, flows through the radiator. It absorbs heat from the engine and releases it in the radiator. Proper coolant levels and clean radiators are essential for maintaining temperature balance.

Water Pump and Thermostat

The water pump circulates coolant throughout the engine. It ensures effective heat transfer and cooling. The thermostat regulates coolant flow based on engine temperature. It prevents coolant from circulating until the engine reaches the optimal operating temperature. A functional thermostat and water pump are necessary for efficient cooling system performance.

Electrical System in Diesel Engines

The electrical system in a diesel engine is essential for starting, running, and auxiliary operations. It powers key functions that ensure the engine runs smoothly and efficiently. Components like the starter motor, alternator, battery, and glow plugs are vital for proper operation.

Starter Motor and Alternator

The starter motor initiates the engine startup process. It uses electrical energy from the battery to crank the engine until combustion begins. Its reliability is crucial for consistent engine performance, especially in cold or challenging conditions.

The alternator generates electricity while the engine runs. It powers electrical systems and recharges the battery. Efficient alternators ensure stable power supply, supporting lights, sensors, and other electronic components.

Battery and Glow Plugs

The battery stores the electrical energy needed to start the engine. It also powers electrical components when the engine is off. Regular maintenance ensures the battery delivers adequate power during ignition.

Glow plugs are essential in diesel engines for starting, especially in cold weather. They preheat engine cylinders to aid smooth fuel combustion. Functioning glow plugs prevent startup delays and ensure efficient operation.

Maintenance Tips for Diesel Engine Components

Proper maintenance is essential for keeping diesel engines efficient and extending their life span. Consistent care not only ensures smooth operation but also prevents costly repairs.

Regular Inspection and Cleaning

- Inspect Components Frequently: Regularly check parts like the fuel system, air intake, and cooling system for wear or leaks.

- Clean Filters: Replace or clean air, fuel, and oil filters as needed to maintain performance.

- Monitor Fluids: Ensure oil, coolant, and fuel are at proper levels. Replace them according to the schedule.

- Examine Belts and Hoses: Check for cracks, wear, or looseness to avoid unexpected failures.

- Inspect Electrical Components: Verify the battery, alternator, and glow plugs. Clean terminals to ensure proper connections.

- Prevent Carbon Build-Up: Clean injectors and intake manifolds to improve fuel efficiency and reduce emissions.

Common Issues and Troubleshooting

- Starting Problems: If the engine has difficulty starting, inspect the starter motor, battery, and glow plugs.

- Excessive Smoke: Black smoke may indicate fuel injector issues. Blue smoke often points to oil leaks.

- Overheating: Check the radiator, coolant levels, and water pump. Replace damaged components promptly.

- Loss of Power: Inspect the turbocharger, air filters, and fuel injectors. Clean or replace if needed.

- Oil Leaks: Examine the oil pan, seals, and gaskets. Fix leaks immediately to prevent engine damage.

- Noises or Vibrations: Irregular sounds may indicate piston, crankshaft, or cylinder head problems. Have a professional inspect these parts.

By following these tips, you can ensure that the parts of a diesel engine perform optimally and last longer.

The Evolution of Diesel Engine Technology

Advancements in Engine Design

The design of diesel engines has undergone significant advancements over the years. Modern diesel engines incorporate sophisticated technologies such as turbocharging and intercooling. Turbocharging utilizes exhaust gases to boost air intake, significantly improving engine performance and efficiency. Intercoolers work to reduce the temperature of compressed air entering the combustion chamber, allowing for denser air and better combustion efficiency. These advancements ensure that contemporary diesel engines deliver greater power while also achieving lower emissions.

Cleaner Fuel Options

The introduction of cleaner fuel options has also transformed diesel engine technology. Ultra-low sulfur diesel (ULSD) has been developed to meet stricter environmental regulations, significantly reducing harmful emissions. The use of biodiesel blends is further enhancing sustainability in diesel engines. Many manufacturers are designing engines that operate efficiently with biodiesel, demonstrating a commitment to greener technologies. These advancements not only improve engine performance but also align with global efforts to reduce the automotive industry’s carbon footprint.

The Importance of Fuel Quality

Impact on Performance

Fuel quality is critical for the optimal functioning of any diesel engine. Higher quality fuels result in better combustion, leading to increased power output and fuel efficiency. Low-quality diesel fuels can cause deposits to accumulate in the engine, leading to injector clogging and reduced engine performance. Using reputable fuel brands and adhering to manufacturer recommendations for fuel type can significantly enhance the reliability and responsiveness of your diesel engine.

Strategies for Ensuring Quality Fuel

To ensure the quality of the diesel fuel you use, consider purchasing it from well-established gas stations with a good reputation. Keep an eye out for local fuel suppliers that maintain high standards and clean fuel storage facilities. Regularly filling your tank and avoiding running low on fuel can also minimize the risk of contaminants entering the tank. Taking these measures not only protects your engine but also improves overall performance.

Future Trends in Diesel Engines

The Shift Towards Electrification

The automotive industry is slowly shifting towards electrification, and diesel engines are also experiencing changes in this landscape. Hybrid systems that combine diesel engines with electric motors are becoming more common. This combination can improve fuel efficiency while reducing emissions. Manufacturers are exploring ways to integrate electric technology into existing diesel architecture, paving the way for a hybrid future. This transition helps address environmental concerns while maintaining the robust performance that diesel engines are known for.

Continuous Innovation

Despite the rise of electric vehicles, diesel engines continue to experience innovation and improvement. Ongoing research focuses on enhancing combustion efficiency and reducing emissions. Advanced combustion technologies, such as dual-fuel systems and improvements in fuel injection, are being developed to provide better torque and fuel efficiency. The diesel engine’s ability to evolve in the face of new challenges is a testament to its enduring relevance and strength in the automotive world.

Conclusion: The Legacy of Diesel Engines

The parts of a diesel engine work harmoniously together to provide reliable performance and efficiency that have made these engines popular. Understanding the functionality of each component allows owners to appreciate the advanced engineering behind their vehicles. By keeping up-to-date with the latest advancements and committing to proper maintenance, you can ensure that your diesel engine remains in peak condition.

As the motorcycle and automotive industries continue to evolve, diesel engines will adapt to new technologies while retaining their core principles of power and reliability. Embracing modern innovations while staying connected to the diesel community enriches the ownership experience. Whether you use your diesel engine for work or leisure, enjoy the journey that comes with it.

Diesel engines will always hold a special place in the hearts of automotive enthusiasts. From their significant contribution to performance and efficiency to their ongoing evolution and adaptation, these engines are more than just machinery; they are a way of life. As technology progresses, the future will only enhance the power and resilience of diesel engines, ensuring their place for years to come.

Leave a Reply