Introduction: Understanding Hydraulic Piston Seals

What Are Hydraulic Piston Seals?

Hydraulic piston seals are crucial components used in hydraulic systems to ensure effective sealing between moving parts. They prevent fluid leakage and maintain pressure within cylinders, enabling smooth operation. These seals are vital in various applications, including construction equipment, automotive systems, and industrial machinery. Understanding the mechanics of these seals helps ensure optimal performance and longevity of hydraulic systems.

Why Seals Matter in Hydraulics

Seals play a critical role in hydraulic systems. They maintain the integrity of the hydraulic fluid within a cylinder, preventing contamination and loss of pressure. A well-designed seal reduces wear and tear on hydraulic components, leading to enhanced efficiency and durability. Innovations in seal technology continuously improve their performance and resilience, making them an important area of focus for engineers and manufacturers.

The Evolution of Seal Technology

The development of hydraulic piston seals has evolved over the years, driven by advancements in materials and design. As technology progresses, new manufacturing techniques and seal designs are emerging. These innovations aim to improve performance, reduce maintenance needs, and increase the lifespan of hydraulic components. Understanding the current trends and innovations will help you make informed decisions when selecting seals for hydraulic systems.

1. Types of Hydraulic Piston Seals

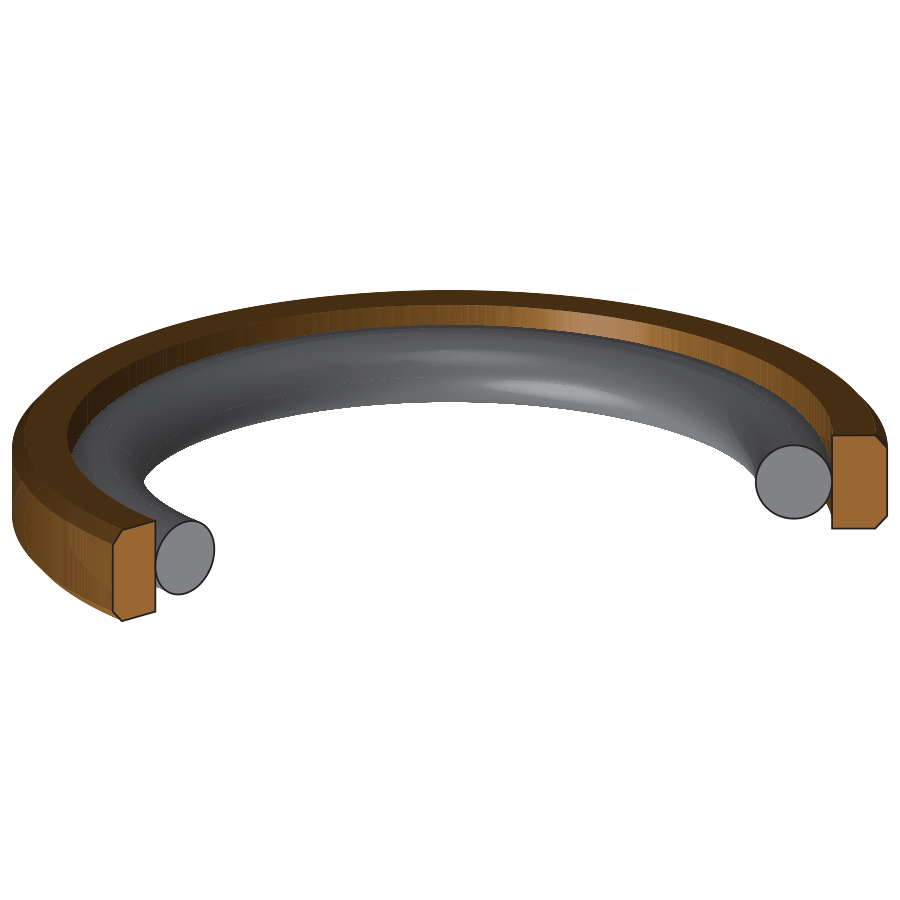

O-Ring Seals

O-rings are one of the most common types of hydraulic piston seals. They are circular seals that fit into a groove and create a seal when compressed. O-rings are versatile and can be made from various materials, including rubber, silicone, andPolyurethane. They are suitable for a range of hydraulic applications due to their effectiveness in containing fluids and preventing leaks.

U-Cups

U-cup seals, shaped like a “U,” are often used in hydraulic cylinders. They are designed to provide sealing on one side while allowing dynamic movement on the other. Their design is effective for both static and dynamic applications. U-cups are popular because they can handle higher pressures and are easy to install, making them ideal for many hydraulic systems.

V-Rings

V-rings are single-direction seals designed to fit onto rotating shafts. They provide excellent sealing against contaminants and are suitable for applications where dirt and moisture may be present. V-rings are commonly used in hydraulic applications because of their ability to accommodate axial movement and their durability in harsh environments.

2. Material Innovations

Common Seal Materials

The material used for hydraulic piston seals affects their performance and longevity. Common materials include rubber, synthetic elastomers, and thermoplastics. Each material has unique properties that make it suitable for different applications. Understanding these materials helps you choose the right seal for your specific needs.

Advancements in Elastomer Technology

Recent advancements have led to the development of high-performance elastomers. These materials offer superior resistance to wear, temperature fluctuations, and chemical exposure. Innovations in material science have resulted in seals that last longer and perform better, even in challenging environments. This is particularly important in industries demanding reliability and efficiency.

The Rise of Synthetic Materials

Synthetic materials are gaining popularity in seal manufacturing due to their enhanced properties. These materials often provide better resistance against oils, fuels, and chemicals. They also offer improved durability and lifespan when exposed to harsh conditions. Choosing synthetic materials for hydraulic seals can lead to reduced breakdowns and lower maintenance costs.

3. Performance Metrics

Understanding Seal Performance

When choosing hydraulic piston seals, it is important to evaluate their performance metrics. Key metrics include pressure rating, operating temperature range, and wear resistance. These factors help determine how well the seal will perform in specific applications. Understanding performance metrics allows you to make an informed choice when selecting a seal.

Pressure Ratings

Pressure ratings indicate the maximum pressure a seal can withstand before failure. Selecting a seal with an appropriate pressure rating is crucial in ensuring the integrity of the hydraulic system. If a seal operates under excessive pressure, it can lead to leaks and system failure. Always choose seals with a pressure rating that exceeds your system’s maximum operating pressure.

Operating Temperature Range

The operating temperature range is another essential performance metric. Hydraulics often operate in extreme temperatures, which can affect seal performance. It is crucial to choose seals made from materials that maintain their properties and integrity within the required temperature range. This ensures reliable sealing and minimizes maintenance needs.

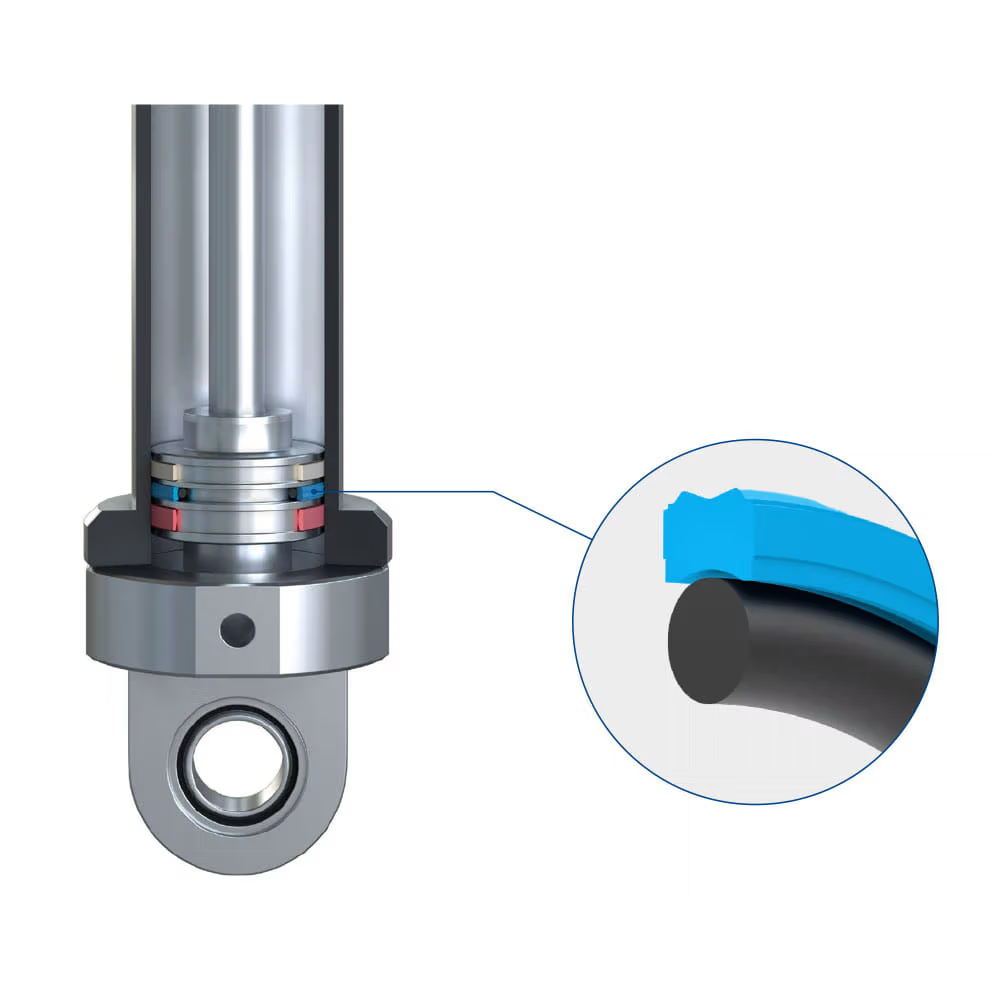

4. Innovations in Seal Design

Advanced Seal Geometries

Recent innovations in seal design have introduced advanced geometries that enhance sealing performance. These designs focus on optimizing the sealing surface and reducing friction. By improving the contact area between the seal and the housing, these geometries can maintain effectiveness under dynamic pressures and movement.

Self-Lubricating Seals

Self-lubricating seals are a groundbreaking development in seal technology. These seals contain additives that provide lubrication, reducing friction and wear. This innovation extends the lifespan of the seal and the components they serve. Self-lubricating seals are ideal for applications with limited maintenance opportunities and high-speed movement.

Innovative Compression Designs

New compression designs have emerged to address the effects of thermal expansion and contraction in seals. These designs enable seals to maintain their integrity under various temperatures and pressures. Improved compression technology is important for ensuring consistent performance and minimizing leaks in hydraulic systems.

5. Environmental Considerations

Eco-Friendly Seal Solutions

As industries become more environmentally conscious, the demand for eco-friendly seal solutions is on the rise. Manufacturers are focusing on developing seals made from sustainable materials. These environmentally friendly options help reduce waste and minimize harmful effects on ecosystems. Choosing eco-friendly seals can contribute to your company’s sustainability goals.

Addressing Contamination Risks

Hydraulic systems often face contamination challenges from dirt, moisture, and chemicals. Seals designed to withstand such contaminants can prolong the life of hydraulic systems. Innovations in sealing materials address these risks, ensuring that contamination does not lead to significant damage. Opting for seals that offer superior protection against contaminants is crucial in maintaining hydraulic health.

Regulatory Compliance

In various industries, regulations surrounding the use of materials are important. Understanding the regulations applicable to hydraulic seals in your sector will help ensure compliance. Selecting seals that meet environmental and safety standards is critical to avoiding potential fines and ensuring safe operations.

6. Selecting the Right Seal for Your Application

Assessing Application Needs

When choosing a hydraulic piston seal, thoroughly assess your application’s specific requirements. Consider factors such as operating conditions, pressure levels, and environmental influences. This evaluation will inform your decision and help you select the most suitable seal.

Consulting with Experts

If you’re unsure which seal to choose, consult with experts in the field. Many manufacturers and suppliers have knowledgeable staff who can guide you through the selection process. They can share insights based on industry experience, ensuring you make informed decisions tailored to your application.

Conducting Tests

Testing different seals under actual working conditions can provide valuable feedback. Conducting trials can help confirm whether a seal meets your expectations regarding performance and longevity. This practical approach helps identify the best seal for your specific environment and requirements.

7. Cost Considerations

Understanding the Costs Involved

Cost is a significant factor when selecting hydraulic piston seals. While cheaper options may seem appealing, they may not provide the performance and durability needed for long-term use. Assessing the total cost of ownership, including maintenance and replacements, is essential for making sound financial decisions.

Weighing Quality Against Price

Investing in high-quality seals may require a greater upfront cost but can yield long-term savings. Higher-quality seals often require less frequent replacement and decrease the risk of hydraulic system failures. Balancing cost with quality ensures that you receive a good return on your investment.

Exploring Bulk Purchase Options

If your business requires multiple seals, consider bulk purchasing options. Many manufacturers offer discounts for larger orders, which can lead to significant savings. Purchasing in bulk can help streamline inventory management and procurement processes.

8. Maintenance and Care

The Role of Regular Maintenance

Regular maintenance is crucial for extending the life of hydraulic systems and seals. Implementing a preventive maintenance program can help avoid costly repairs and downtime. Regular inspections can catch problems early, preventing more severe issues from developing.

Conducting Routine Checks

Perform routine checks on the seals as part of your maintenance plan. Look for signs of wear, leaks, or damage. Regularly examining seals allows you to address any concerns before they escalate, ensuring the continued efficiency of your hydraulic systems.

Proper Lubrication

Proper lubrication is essential for maintaining hydraulic seals. Insufficient lubrication can lead to premature wear and failure. Follow manufacturer recommendations for lubrication intervals and types. This practice promotes smoother operations and contributes to the longevity of your seals.

9. Innovations in Manufacturing Technology

Advances in Production Techniques

Recent advancements in manufacturing technology have significantly improved seal production. Techniques such as 3D printing allow for rapid prototyping of different seal designs. This enables manufacturers to test and refine designs more quickly, leading to innovative solutions that meet industry needs.

Quality Control Improvements

Modern manufacturing processes incorporate enhanced quality control measures. This ensures that seals are consistently produced to high standards. Regular inspections and testing during production lead to lower defect rates and improved performance.

The Future of Seal Manufacturing

As technology continues to evolve, the future of seal manufacturing looks promising. Innovations in materials and production methods will lead to ever-improving products. Staying informed about these advancements will help businesses remain competitive in the market.

10. The Role of Education in Seal Selection

Educating Yourself

Understanding the different types of hydraulic piston seals and their characteristics is essential. Educating yourself on seal technology helps you make informed decisions when selecting products. Knowledgeable choices lead to improved performance and customer satisfaction.

Seeking Training Opportunities

Consider attending workshops, webinars, or industry conferences. These events often provide insights into the latest trends and technologies in seal manufacturing. Networking with industry experts can also lead to valuable information on selecting the right seals for your needs.

Utilizing Online Resources

There are various online resources available to assist with learning about hydraulic seals. Articles, videos, and forums provide a wealth of information about different seal types, materials, and applications. Exploring these resources enhances your understanding and boosts your confidence in making seal selections.

11. Environmental and Safety Considerations

The Importance of Environmental Impact

As companies evolve, awareness of environmental impact is paramount. Choosing seals that adhere to sustainable practices contributes to a company’s overall environmental goals. Many consumers prefer to support brands committed to greener practices, impacting your brand’s reputation.

Ensuring Safety Compliance

Regulatory compliance is critical in industries where hydraulic systems are involved. Ensuring that seals meet required safety standards is essential to protect workers and equipment. Using compliant products helps mitigate risks associated with component failures.

Supply Chain Considerations

When selecting suppliers, consider their commitment to sustainable and ethical practices. Understanding your supply chain, from materials used to production methods, is vital in promoting responsible business practices. Knowing your suppliers’ values can build trust and reinforce your commitment to safety and sustainability.

FAQ:

1. What are hydraulic piston seals, and how do they work?

Answer: Hydraulic piston seals are components used in hydraulic systems to prevent fluid leakage between moving parts, specifically between the piston and the cylinder. They create a tight seal that allows for pressure build-up, enabling the efficient transfer of hydraulic power. Typically made from materials resistant to high pressure and temperatures, these seals come in various designs, such as O-rings, lip seals, and U-cups.

2. What materials are commonly used for hydraulic piston seals?

Answer: Common materials for hydraulic piston seals include:

- Nitrile Rubber (NBR): Offers good resistance to oils and fuels.

- Polyurethane (PU): Known for its high wear resistance and ability to handle high pressure.

- Fluorocarbon (FKM): Provides excellent chemical resistance at high temperatures.

- PTFE (Teflon): Ideal for extreme temperature ranges and offers low friction.

The choice of material is crucial for performance, as it affects the seal’s durability and effectiveness in specific applications.

3. What are the latest trends in hydraulic seal technology?

Answer: Recent trends in hydraulic seal technology include:

- Advanced Materials: Development of new polymer compounds that offer enhanced chemical and thermal resistance.

- Smart Seals: Integration of sensors that monitor seal performance and predict failures before they occur.

- Sustainability: A focus on environmentally friendly materials and processes in the manufacturing of seals to reduce the ecological footprint.

- Customization: Manufacturers are increasingly offering customized sealing solutions tailored to specific application needs, enhancing performance and reliability.

4. How can I determine the correct seal size for my application?

Answer: To determine the correct seal size:

- Measure the Cylinder Bore Diameter: Use calipers to measure the internal diameter of the cylinder where the seal will sit.

- Measure the Piston Diameter: Measure the external diameter of the piston that the seal will slide against.

- Consider the Seal Width: Check the required seal width for your specific application, as this can differ based on design.

- Check Manufacturer Specifications: Refer to the manufacturer’s sizing charts or guidelines for the specific seals they produce to ensure compatibility.

5. What maintenance practices can prolong the life of hydraulic piston seals?

Answer: To prolong the life of hydraulic piston seals, consider the following maintenance practices:

- Regular Inspections: Frequently check for wear, damage, or any signs of leakage.

- Fluid Quality: Ensure the hydraulic fluid is clean and free of contaminants, as impurities can degrade seal materials.

- Proper Installation: Follow manufacturer guidelines for installation to avoid damaging the seals.

- Operating Conditions: Make sure the hydraulic system operates within recommended temperature and pressure ranges to prevent unnecessary stress on the seals.

- Lubrication: If applicable, ensure that moving parts are adequately lubricated to reduce friction on the seals.

Embrace the Innovations in Seal Technology

The Future of Hydraulic Piston Seals

Hydraulic piston seals are essential components in various industries. The continual innovation in materials, designs, and manufacturing processes will shape the future of this technology. Staying informed and adaptable ensures that users can benefit from these advancements.

Investing in Quality and Performance

Understanding the critical features of seals will allow you to select high-quality products. This investment will pay dividends in terms of operational efficiency and equipment longevity. Regular maintenance and education can extend the life of seals and improve performance.

Join the Journey of Improvement

As you explore the options available in hydraulic piston seals, embrace the journey of continuous improvement. By refining your knowledge and practices, you contribute to better operations in your field. The right seals, including the benefits of advanced hydraulic piston seals, can make a significant difference, providing reliability and performance in your hydraulic systems. Make informed choices and enjoy the advantages of effective seal technology.

Leave a Reply