Introduction: Understanding Axial Piston Pumps

What Is an Axial Piston Pump?

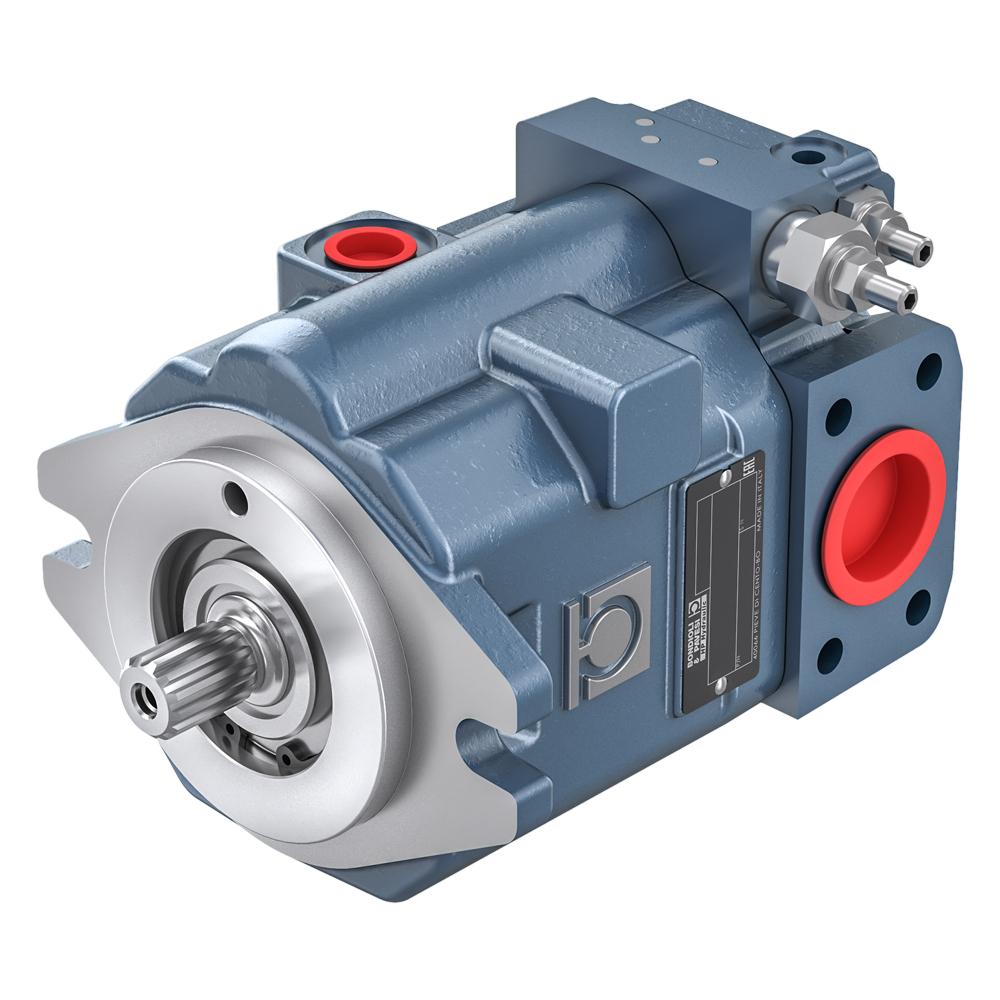

An axial piston pump is a type of hydraulic pump that uses a series of pistons arranged parallel to the axis of the pump shaft to create fluid flow. These pumps are designed for high-pressure applications and are known for their efficiency and reliability. The working principle involves the pistons moving in and out of cylindrical chambers as the pump shaft rotates. This movement generates the pressure required to move hydraulic fluid through a system. Axial piston pumps are available in variable displacement and fixed displacement designs, making them versatile for various applications.

Importance in Hydraulic Systems

Hydraulic systems are crucial in numerous industries, providing the power needed to operate machinery and equipment. Axial piston pumps play a vital role in these systems by maintaining fluid flow and pressure. Their ability to handle high pressures is particularly important in demanding applications, making them an essential component in hydraulic circuits. Understanding how axial piston pumps work and their applications helps machinery operators make informed decisions regarding equipment selection and maintenance.

Overview of This Guide

This article will explore the applications and benefits of axial piston pumps in hydraulic systems. We will examine various industries that utilize these pumps, their advantages, and best practices for maintenance. By the end of this guide, readers will understand the significance of axial piston pumps and how they contribute to the efficiency and effectiveness of hydraulic systems.

Applications of Piston Pumps

Construction and Heavy Machinery

Axial piston pumps are commonly used in construction equipment, such as excavators, loaders, and cranes. These machines require powerful hydraulic systems to lift heavy loads, operate attachments, and provide precise control. The ability of axial piston pumps to generate high pressure ensures that construction machinery can perform demanding tasks efficiently. Their robust design and reliability make them suitable for the harsh conditions often encountered on construction sites.

Agricultural Equipment

In agriculture, axial piston pumps are vital for powering hydraulic systems in various machinery, including tractors and harvesters. They facilitate operations such as lifting, lowering, and steering while also controlling attachments like plows and seeders. The precise control offered by axial piston pumps enhances the overall productivity of agricultural tasks, making them invaluable to modern farming practices.

Manufacturing and Automation

In manufacturing settings, axial piston pumps are employed in machinery that requires consistent and high-pressure fluid power. Applications include injection molding machines, material handling systems, and robotic automation. The efficiency of axial piston pumps allows factories to maintain production speed and precision. Reliable hydraulic systems equipped with these pumps are crucial for meeting stringent production schedules and quality standards.

Benefits of Using Piston Pumps

High Efficiency

One of the most significant advantages of axial piston pumps is their high efficiency. These pumps are capable of converting mechanical energy into hydraulic energy with minimal losses. The design allows for less internal leakage, which ultimately contributes to more efficient operation. The high efficiency of axial piston pumps translates into improved performance and reduced energy consumption. For industries looking to lower operational costs, this feature is particularly beneficial.

Compact Design

Axial piston pumps are characterized by a compact and lightweight design compared to other hydraulic pumps. This compactness allows for easier integration into various systems without taking up excessive space. Their small footprint is especially advantageous in applications where available space is limited. Additionally, the lightweight nature of these pumps facilitates easier installation and maintenance.

Versatility in Applications

The versatility of axial piston pumps makes them suitable for a wide range of applications across different industries. Whether in construction, agriculture, or manufacturing, these pumps adapt to meet the specific needs of hydraulic systems. Availability in both fixed and variable displacement options allows users to select the right pump for their requirements. This adaptability contributes to increased efficiency and performance across diverse applications, making it a valuable choice for many industries.

Choosing the Right Piston Pump

Assessing Hydraulic System Requirements

When selecting an axial piston pump, it is essential to assess the requirements of your hydraulic system. This includes factors such as the desired flow rate, operating pressure, and the type of hydraulic fluid to be used. Understanding system requirements ensures that the chosen pump will perform optimally and provide the necessary power for your application.

Considering Displacement Options

Fixed and variable displacement axial piston pumps serve different purposes. Fixed displacement pumps deliver a constant flow rate regardless of pressure conditions. These pumps are beneficial in systems with steady hydraulic demands. Conversely, variable displacement pumps adjust flow rates based on system pressure, making them ideal for applications with fluctuating hydraulic needs. Evaluating your system’s flow requirements will help determine which displacement option is most suitable.

Consulting with Experts

When in doubt, it is beneficial to consult with hydraulic system experts or manufacturers. They can provide valuable insights into the best axial piston pump for your specific needs. Professional input ensures that you choose a pump that will function efficiently within your system parameters. Whether you are designing a new system or upgrading an existing one, expert guidance can lead to successful outcomes.

Maintenance Tips for Axial Piston Pumps

Regular Inspection and Monitoring

Routine inspections are vital for maintaining the health of axial piston pumps. Regularly check for signs of leaks, wear, and unusual noises during operation. Monitoring the hydraulic fluid levels and quality is also important; contamination can lead to premature wear and pump failure. Establishing a preventive maintenance schedule will help detect issues early and ensure consistent performance.

Keeping Hydraulic Fluid Clean

Clean hydraulic fluid is essential for the longevity of axial piston pumps. Contaminants such as dirt, moisture, and metal particles can cause significant damage to the pump components. Implementing a filtration system can help keep hydraulic fluid clean and free of impurities. Regularly changing the hydraulic fluid according to the manufacturer’s recommendations will also minimize contaminants and promote smooth operation.

Lubrication for Longevity

Lubrication plays a crucial role in maintaining axial piston pumps. Proper lubrication reduces friction between moving parts, preventing overheating and wear. Follow the manufacturer’s guidelines regarding lubrication intervals and product recommendations. Insufficient lubrication can lead to catastrophic failures, making it essential to prioritize adequate maintenance.

Troubleshooting Common Issues

Identifying Performance Problems

Performance issues in axial piston pumps may manifest as decreased efficiency or abnormal noises. If you notice a drop in hydraulic pressure or irregular operation, it’s essential to diagnose the problem quickly. Common causes include worn piston rings, valve malfunctions, or contamination in the hydraulic fluid. Conduct a thorough inspection to pinpoint the issue and take appropriate corrective actions. Addressing performance problems early is crucial for maintaining optimal pump operation.

Dealing with Overheating

Overheating can significantly impact the performance and durability of axial piston pumps. Causes of overheating may include insufficient lubrication, excessive return line temperature, or overpressure conditions. If overheating symptoms appear, check the lubrication and fluid temperature first. Cooling systems may need inspection or repair to ensure proper functioning. Taking preventive measures against overheating will help maintain longevity and performance.

Addressing Leaks

Leaks represent another common issue that can affect axial piston pumps. Leaks can occur due to worn seals, improper assembly, or contaminants causing damage to internal components. If a leak is detected, it is crucial to address it promptly to prevent further damage and reduce fluid loss. Regular inspection and maintenance can help detect leaks early, which can help you avoid costly repairs and improve system efficiency.

Innovations in Axial Piston Technology

Advancements in Materials

Recent advancements in materials used for manufacturing axial pistons have combined improved durability with weight reduction. New alloys and composites are being developed to enhance strength while minimizing wear. These innovations contribute to better performance, especially in high-stress applications. The use of advanced materials allows for the creation of lighter and more efficient pumps, improving the overall hydraulic system’s efficiency.

Enhanced Control Systems

The integration of advanced control systems in axial piston pumps has revolutionized performance management. Electronic controls allow for precise regulation of flow rates and pressures, improving efficiency across various applications. These modern systems enable real-time monitoring of pump operation, offering insights into performance that allow users to fine-tune their hydraulic systems. The continual evolution of control technology ensures that axial piston pumps remain at the forefront of hydraulic innovation.

Sustainable Practices

Sustainability has become a critical focus in modern hydraulic systems. Innovations in the design and manufacturing of axial piston pumps now emphasize energy efficiency and reduced environmental impact. Manufacturers are striving to decrease emissions and improve overall energy consumption of hydraulic systems. By implementing sustainable practices and designing more eco-friendly pumps, the hydraulic industry works toward a greener future.

FAQ:

- What is an axial piston pump?

An axial piston pump is a type of hydraulic pump that uses a series of pistons arranged parallel to the drive shaft. It converts mechanical energy into hydraulic energy, enabling fluid movement in various hydraulic systems. - What are the main applications of axial piston pumps?

Axial piston pumps are commonly used in mobile equipment, industrial machinery, and automotive applications. They are ideal for applications that require high pressure and flow rates, such as excavators, forklifts, and hydraulic presses. - What are the benefits of using an axial piston pump in hydraulic systems?

The benefits of axial piston pumps include high efficiency, excellent performance at high pressures, compact design, and versatility in various applications. They also provide precise control of flow rates, making them suitable for demanding hydraulic tasks. - How do I maintain an axial piston pump?

To maintain an axial piston pump, ensure regular inspection and replacement of hydraulic fluids, monitor for leaks, and check the pump for unusual noises or vibrations. Following the manufacturer’s maintenance guidelines is essential for optimal performance. -

What factors should I consider when selecting an axial piston pump?

When selecting an axial piston pump, consider parameters such as the required pressure and flow rate, the working fluid, operating temperature, installation space, and compatibility with other hydraulic components. Proper sizing and specifications are crucial for efficient operation.

Conclusion: Maximizing the Benefits of Axial Piston Pumps

Understanding the Importance

In conclusion, axial piston pumps play a vital role in hydraulic systems across various industries. Their efficiency and adaptability make them a preferred choice for many applications. Understanding how these pumps work, along with their benefits and requirements, empowers users to make informed decisions that enhance their systems.

Commitment to Maintenance

Prioritizing regular maintenance practices is essential for maximizing the benefits of axial piston pumps. By conducting routine inspections, addressing performance issues, and ensuring clean hydraulic fluids, users can prolong the life of their pumps and improve overall performance. A strong commitment to maintenance will pay off in the long run, leading to reduced downtime and increased reliability.

Embrace the Future of Hydraulic Systems

As technology continues to evolve, so do the advancements in axial piston pump design and their applications in industrial machinery. Staying informed about innovations helps users adapt to emerging trends and further enhance their hydraulic systems’ performance. Embrace the efficiency, versatility, and reliability that axial piston pumps offer, and you’ll discover how integral they are to powering modern operations. By taking the right steps today, you can ensure efficient and reliable hydraulic performance in your machinery for years to come.

Leave a Reply