Piston engine aircraft are a popular choice among private pilots and aviation enthusiasts due to their reliability, lower operating costs, and simplicity. These aircraft utilize traditional internal combustion engines that drive the propeller, making them a familiar presence in both general aviation and flight training environments. However, proper maintenance is essential for ensuring the safety, performance, and longevity of these aircraft. Pilots who understand and implement effective maintenance practices can enjoy a safer flying experience and preserve the value of their investment. This article will provide essential maintenance tips specifically tailored for pilots flying piston engine aircraft.

Understanding Piston Engine Basics

The Mechanics of Piston Engines

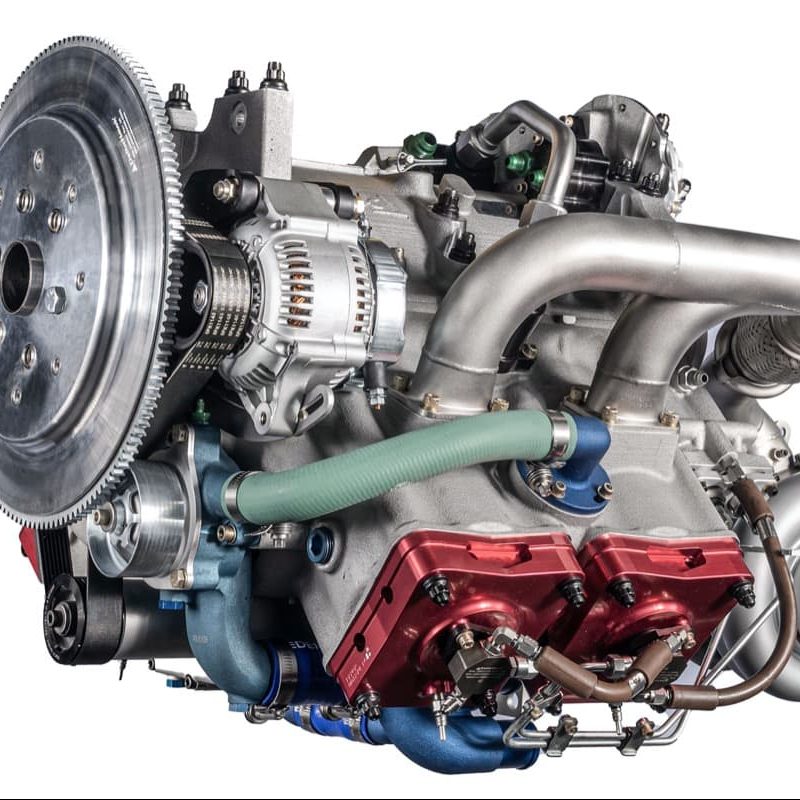

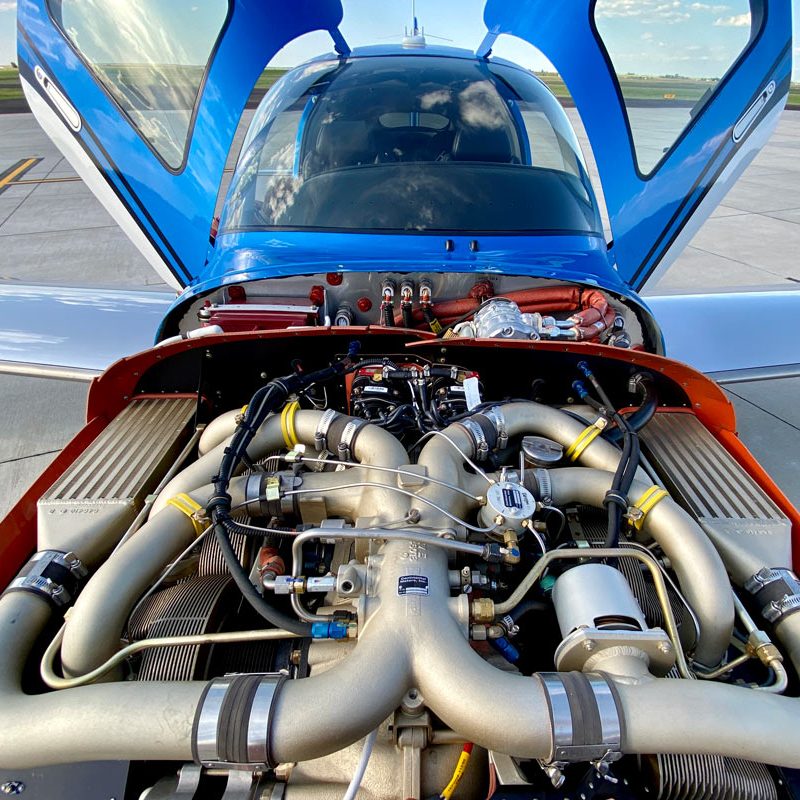

Piston engines operate through a series of mechanical movements in which the pistons reciprocate within the cylinders. The engine works by drawing in air and fuel mixtures, which are compressed and ignited to create power. This power is transmitted to the crankshaft, which drives the propeller. The efficiency and performance of a piston engine depend on multiple factors, including fuel quality, ignition timing, and overall maintenance.

Pilots must have a fundamental understanding of how these engines function to comprehend the maintenance needs. Being familiar with the engine components, such as pistons, crankshaft, valves, and carburetors, is crucial. This knowledge allows pilots to recognize potential issues early and seek appropriate maintenance solutions.

Common Types of Piston Engines

Several types of piston engines are commonly used in aircraft, including horizontally opposed engines and radial engines. Horizontally opposed engines, such as the Lycoming and Continental models, are typically found in smaller general aviation aircraft. These engines feature two or more horizontally arranged cylinders, which provide a compact design and balanced weight distribution.

Radial engines, once popular in military and larger aircraft, have cylinders arranged in a circular pattern around a central crankshaft. Although less common today, they still provide unique performance characteristics. Understanding the differences between these engine types will help pilots tailor their maintenance approaches to specific aircraft models.

Engine Power Ratings

Piston engines are characterized by their power ratings, measured in horsepower (HP) or kilowatts (KW). This rating indicates the engine’s ability to produce thrust and maintain flight under various conditions. Knowing the power rating is vital when performing maintenance tasks, as it ensures that the aircraft operates within its designed parameters.

Additionally, pilots should be aware that engine performance may vary depending on factors such as altitude, temperature, and humidity. Routine checks and maintenance help ensure that power output remains at optimal levels, leading to improved efficiency and a safer flying experience.

Regular Pre-Flight Inspections

The Importance of Pre-Flight Checks

Conducting thorough pre-flight inspections is one of the most effective ways to maintain piston aircraft. Pilots should perform these checks before every flight to ensure safety and reliability. A comprehensive inspection allows pilots to identify potential problems before takeoff, reducing the risk of in-flight issues.

During the pre-flight inspection, pilots should assess the condition of the engine, fuel system, control surfaces, and other essential components. This proactive approach can prevent more significant issues that may arise due to negligence or oversight.

Checklist for Pre-Flight Inspections

Creating and using a detailed checklist for pre-flight inspections can help pilots stay organized and ensure that no critical steps are overlooked. Key areas to cover during the inspection include:

- Visual Checks: Inspect the aircraft’s exterior for any signs of damage, corrosion, or fluid leaks. Pay attention to the propellers, leading edges, and control surfaces.

- Fuel System: Check fuel levels and ensure there are no contaminants in the fuel. Water and debris can negatively affect engine performance.

- Oil Levels: Confirm that the engine oil is at the appropriate level. Inspect for any leaks around the engine compartment. Proper lubrication is essential for engine health.

- Battery and Electrical Systems: Test the battery charge and assess the condition of electrical connections. Staying prepared for day and night operations ensures readiness.

Documentation of Inspections

After each inspection, pilots should document their findings in a maintenance log. This log serves as a record of any discrepancies or repairs needed, providing essential information for future readings. Keeping track of maintenance history enhances the understanding of the aircraft’s condition over time.

Documentation also plays a crucial role in maintaining regulatory compliance. Aviation authorities often require detailed logs for inspections and repairs, helping ensure the safety and airworthiness of the aircraft.

Routine Engine Maintenance

Scheduled Maintenance Intervals

Routine engine maintenance is vital for the longevity and performance of piston engines. Most manufacturers provide recommended maintenance schedules, outlining necessary tasks such as oil changes, filter replacements, and valve adjustments. Pilots should diligently adhere to these schedules to keep the engine running smoothly.

Typically, oil changes are due every 25 to 50 flight hours, or as specified by the engine manufacturer. Regular oil changes help remove contaminants and ensure efficient lubrication of engine components. Staying on top of these maintenance intervals minimizes the risk of engine failure and promotes reliable performance.

Oil Quality and Selection

Choosing the right oil type is essential for effective engine maintenance. Piston engines usually require specific types of aviation oil, often designated by the manufacturer. Pilots should select oils that meet the appropriate certification standards. The oil should also match the engine’s operating environment, which can vary between standard and high-performance operations.

Regularly checking the oil level and condition is also crucial. Pilots should assess the oil’s viscosity and look for signs of contaminants. Any abnormalities, such as unusual coloration or metal particles, may indicate underlying issues that require immediate attention.

Spark Plug Maintenance

Spark plugs play a critical role in ensuring the proper ignition of the fuel-air mixture in the engine. Routinely inspecting and servicing spark plugs helps facilitate efficient engine performance. Pilots should check for wear, excessive carbon build-up, and correct gap settings. Depending on the engine and manufacturer recommendations, spark plugs may need replacement every few hundred flight hours.

Using the proper spark plugs that match the aircraft’s specifications is essential. When replacing spark plugs, pilots should perform both visual inspections and gap adjustments to ensure optimal performance. Maintaining the spark plugs contributes to the engine’s reliability and efficiency in firing.

Fuel System Management

Understanding Fuel Types

The type of fuel used in piston engine aircraft significantly impacts performance. Common fuels include 100LL avgas and Mogas (automotive gasoline). Selecting the appropriate fuel is vital for engine health and performance. Piston engines may be sensitive to fuel quality, so sourcing fuel from reputable suppliers is important.

When using Mogas, ensure that the fuel meets the necessary specifications for aviation use. Fuel characteristics, such as octane rating and additives, affect engine performance and combustion efficiency. Adhering to the manufacturer’s guidelines for fuel selection is crucial for long-term maintenance.

Fuel System Inspection

Regularly inspecting the fuel system is essential for ensuring proper functionality. During pre-flight checks, pilots should visually assess the fuel lines, pumps, and filters for any signs of leaks or damage. Checking fuel quality is equally important; there should be no contaminants such as water or rust present.

Draining a small amount of fuel from the lowest point in the system, often referred to as a “fuel drain test,” can help identify any contaminants. Fuel samples should be clear without any discoloration, ensuring that only clean fuel enters the engine.

Storage and Fueling Practices

Proper storage and fueling practices also contribute to the overall maintenance of the fuel system. Aircraft should be stored in environments that protect fuel from contamination. Using fuel stabilizers can help maintain fuel quality, especially for aircraft that may not be flown regularly.

When fueling the aircraft, ensure proper grounding to avoid static electricity buildup. Fueling should be conducted in a calm environment, avoiding windy conditions that can stir up contamination. Following safe fueling procedures helps prevent accidents and ensure the integrity of the fuel system.

Understanding Airframe Maintenance

Importance of Airframe Inspections

In addition to engine maintenance, pilots should regularly inspect the aircraft’s airframe. The airframe’s structural integrity is essential for safe flight operations. Regular inspections should cover key components such as wings, fuselage, landing gear, and control surfaces.

Inspecting for cracks, corrosion, and other forms of wear is crucial. Damage to the airframe can lead to serious safety concerns. Pilots must be vigilant and report any discrepancies for further evaluation.

Control Surface Functionality

Control surfaces play a significant role in aircraft maneuverability. Regularly checking the functionality of ailerons, elevators, and rudders is critical. Ensure that they move freely and are not obstructed by any foreign objects or debris. Lubrication of moving parts can enhance functionality and reduce wear.

Routine inspections can also reveal any signs of damage or misalignment. Even minor issues can significantly impact performance. Addressing control surface problems promptly can prevent larger issues that may develop over time.

Corrosion Control

Corrosion is a common challenge in aviation maintenance, particularly for piston engine aircraft. These aircraft often operate in varying weather conditions and environments that can contribute to corrosion. Regular inspections should include checks for rust or corrosion on metal parts, paint deterioration, and signs of water intrusion.

Applying protective coatings is an effective measure against corrosion. Ensure that maintenance practices follow industry standards for paint and prevention systems. Addressing corrosion quickly will extend the life of the aircraft and maintain its airworthiness.

Keeping up with Regulatory Requirements

Understanding FAA Regulations

Pilots must be aware of Federal Aviation Administration (FAA) regulations that govern aircraft maintenance. Routine maintenance, inspections, and records must comply with regulatory standards. Staying up to date with these requirements is crucial to ensuring airworthiness. Maintaining proper documentation demonstrates compliance and provides accountability for the aircraft’s condition.

Required Maintenance Records

Keeping detailed maintenance records is essential for aircraft safety and operational compliance. Pilots should document every maintenance event, repair, and inspection conducted on the aircraft. This information is invaluable for future inspections and for establishing the aircraft’s maintenance history.

When selling or transferring ownership, these records serve to validate the condition and reliability of the aircraft. Investors and buyers often look for thorough maintenance documentation before making purchasing decisions.

Engaging Qualified Professionals

Although pilots can conduct many routine maintenance tasks, some jobs require the expertise of certified aircraft mechanics. Engaging qualified professionals ensures that repairs and maintenance are performed according to industry standards. Regular consultations with maintenance experts can provide insights into best practices and ongoing maintenance needs.

Establishing a solid relationship with a trusted mechanic or maintenance facility enhances the safety and operation of the aircraft. This collaboration allows pilots to stay informed about any potential issues and ensures that recommendations align with regulatory requirements.

Emergency Preparedness

Developing Maintenance Contingency Plans

In aviation, preparedness is key. Pilots should develop maintenance contingency plans to address unforeseen circumstances. Whether it’s an unexpected engine issue or an airframe discrepancy, having a plan in place can mitigate risks and maintain safety. Regular training and discussions surrounding emergency maintenance procedures can improve a pilot’s ability to manage unexpected situations.

Ensuring Proper Emergency Equipment

Piston aircraft should be equipped with emergency gear, including fire extinguishers, first aid kits, and basic tools for on-the-spot repairs. Pilots should check the status of these emergency supplies regularly to ensure functionality. Familiarizing oneself with how to use this equipment can save lives in critical situations.

Aircraft must also have reliable communication devices to report issues or communicate with air traffic control. Establishing protocols for emergencies ensures that everyone in the aircraft is prepared and calm during potential crises.

Continual Safety Education

Participating in ongoing safety education can further enhance emergency preparedness. Pilots should seek training opportunities, workshops, and seminars focused on aircraft maintenance and emergencies. Staying informed about best practices and current industry standards can significantly reduce risks associated with flying.

Establishing a mindset centered on safety ensures that pilots approach flying with a proactive mentality. Reinforcing systematic practices bolsters confidence and helps create lifelong learning habits for aviation enthusiasts.

FAQ:

- What is a piston engine aircraft?

A piston engine aircraft uses one or more reciprocating engines (piston engines) to generate thrust. These engines work by converting fuel into mechanical energy through the movement of pistons within cylinders, commonly found in small general aviation aircraft. - What are the key maintenance tasks for piston engine aircraft?

Key maintenance tasks include regular oil changes, checking and replacing air filters, inspecting spark plugs, monitoring fuel quality, and conducting regular inspections of the engine and airframe for signs of wear, corrosion, or damage. Adhering to the manufacturer’s maintenance schedule is essential. - How often should I perform routine maintenance on my piston engine aircraft?

Routine maintenance should generally follow the aircraft manufacturer’s recommended schedule, which often specifies checks based on flight hours or calendar intervals (e.g., annually or bi-annually). Additionally, pre-flight inspections should be conducted before each flight. - What should I look for during pre-flight inspections of piston engine aircraft?

During pre-flight inspections, pilots should check oil levels, fuel quality, and coolant levels. Inspect physical components for signs of wear or damage, look for fluid leaks, and ensure that the cowling, propeller, and other critical parts are secure and in good condition. -

How can I identify potential engine problems in piston engine aircraft?

Potential engine problems can often be identified through unusual sounds, changes in engine performance (such as RPM fluctuations), loss of power, excessive vibration, or abnormal temperatures on gauges. Any of these signs should prompt immediate investigation and possible maintenance action.

Conclusion: The Path to Proficient Aircraft Maintenance

In conclusion, maintaining a piston engine aircraft requires diligence, understanding, and proactive practices. Pilots must familiarize themselves with the fundamental mechanics of their aircraft to ensure optimal performance. Conducting regular inspections, adhering to manufacturer maintenance schedules, and maintaining thorough records all contribute to the longevity and safety of the aircraft.

While piston engine aircraft come with their own unique considerations, following best practices for maintaining piston aircraft engines can significantly enhance reliability and performance. Emphasizing emergency preparedness, adhering to regulatory requirements, and continually improving knowledge about maintenance procedures will further ensure safety for both pilots and passengers.

By understanding and embracing these essential maintenance tips, pilots can enjoy the freedom and excitement of flying while ensuring that their aircraft remains a dependable partner in the sky. With dedication and commitment to maintenance, every flying experience can be safe, enjoyable, and successful.

Leave a Reply