Introduction to Rotary Pistons

Rotary pistons are a key innovation in engine technology. Unlike traditional engines, rotary piston operate without reciprocating motion. They use a smooth rotary motion to convert combustion energy into mechanical power. This unique design offers several advantages, making rotary piston ideal for specific applications. Let’s explore what rotary pistons are and how they evolved over time.

What Are Rotary Pistons?

Rotary pistons, also called rotary engines, use a rotating triangular rotor. The rotor spins inside an oval-shaped chamber to create power. As the rotor moves, it passes through intake, compression, combustion, and exhaust phases. This continuous motion ensures smooth operation without the need for heavy moving parts. Rotary pistons are compact, efficient, and produce less vibration than traditional engines.

Their unique design eliminates the need for valves, crankshaft, and connecting rods. Instead, they rely on precise sealing points and chambers. This makes rotary pistons lightweight and compact compared to reciprocating engines.

Evolution and History of Rotary Pistons

Rotary piston engines were invented in the early 20th century. Felix Wankel developed the first working rotary piston engine in the 1950s. His innovative design attracted attention for its lightweight and efficient performance.

The Mazda Motor Corporation popularized rotary engines in the 1960s. Mazda’s RX series became a symbol of rotary piston technology. These vehicles demonstrated the engine’s potential for high performance and compact design. Despite initial success, the engines faced challenges with fuel efficiency and emissions.

Over the years, rotary engines saw limited use in the automotive, aviation, and industrial sectors. However, ongoing research in materials and technology aims to overcome their limitations. Rotary pistons continue to inspire engineers seeking innovative power solutions.

Mechanism of Rotary Pistons

Key Components of a Rotary Piston Engine

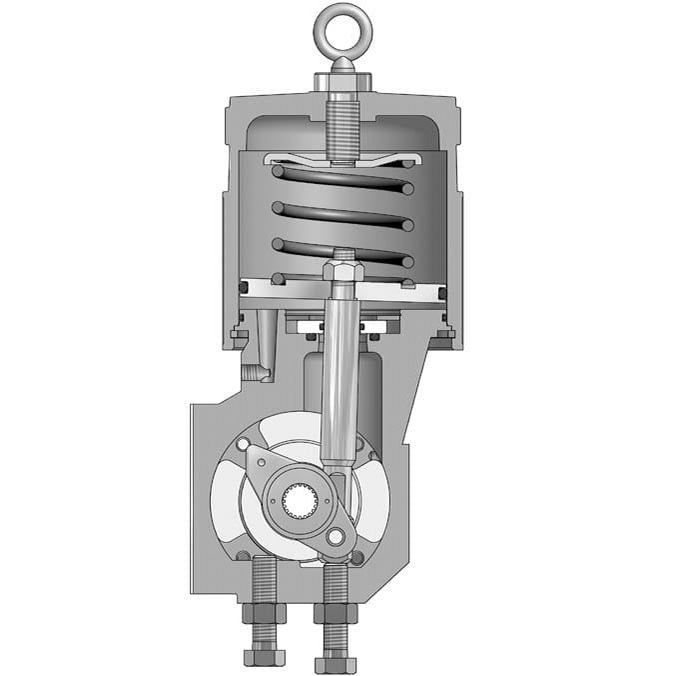

The rotary piston engine has unique components that set it apart from conventional engines. The main parts include:

- Rotor: A triangular rotor replaces the pistons found in traditional engines. It performs the intake, compression, combustion, and exhaust processes within the chamber.

- Housing (Chamber): The oval-shaped chamber surrounds the rotor. It ensures proper sealing and smooth operation.

- Eccentric Shaft: This shaft connects to the rotor and transforms its motion into mechanical energy.

- Sealing Points: Special seals ensure no leaks of gases during the various engine phases.

- Port Openings: Intake and exhaust ports allow air and fuel to enter and exit the chamber.

These parts work together to deliver power efficiently and effectively.

How the Rotary Motion Works

The rotary piston engine operates in a continuous, circular motion. Here’s how it works step-by-step:

- Intake Phase: The rotor creates a vacuum that pulls the air-fuel mixture into the chamber.

- Compression Phase: The rotor compresses the mixture as it rotates, preparing it for ignition.

- Combustion Phase: The spark plug ignites the mixture, generating energy that pushes the rotor.

- Exhaust Phase: The rotor pushes burned gases out of the exhaust port.

This constant rotary motion eliminates the up-and-down movement of pistons in traditional engines. It results in smoother operation and simpler mechanical design.

Comparison with Traditional Reciprocating Pistons

Rotary piston engines differ significantly from reciprocating piston engines:

- Design Simplicity: Rotary engines have fewer parts like valves and crankshafts, making them simpler.

- Compact Size: They are smaller and lighter compared to reciprocating engines.

- Smooth Operation: Without reciprocating parts, rotary engines have less vibration.

- Efficiency Challenges: Traditional engines are often more fuel-efficient for everyday usage.

- Maintenance: Reciprocating engines tend to have higher reliability over time due to known technology.

In summary, rotary engines offer unique mechanical advantages despite some trade-offs in efficiency and durability.

Advantages of Pistons

Rotary pistons offer several advantages that make them valuable in specific applications. Their unique design provides benefits like improved efficiency, compactness, and reduced noise and vibration.

Efficiency and Performance Benefits

Rotary piston engines deliver consistent power output with fewer mechanical parts. The lack of reciprocating components enables smoother operation, reducing energy loss during movement. This design improves efficiency under specific operating conditions. Rotary engines also perform exceptionally at high RPMs, enhancing their suitability for high-performance vehicles. While fuel efficiency can be a challenge, their ability to produce strong power in a lightweight structure is a notable advantage.

Compact Design and Lightweight Structure

One key advantage of rotary pistons is their small size. Compared to traditional engines, rotary piston engines are compact and lightweight due to fewer components. The absence of crankshafts, valves, and connecting rods results in reduced engine weight. This makes them appealing for applications where space and weight are limited, such as in certain aircraft and sports cars. Their compact design also contributes to flexibility in engineering solutions.

Reduced Vibration and Noise Levels

Rotary engines reduce vibration significantly because they use continuous rotary motion, not reciprocating parts. This results in smoother functioning and minimizes wear on components. Additionally, fewer moving pieces translate to lower noise levels during operation. These advantages make rotary piston engines suitable for environments requiring quiet and smooth performance. Users benefit from a less disruptive and more refined engine experience.

Common Applications of Pistons

Rotary pistons are versatile and have been applied across various industries. Their unique design and features make them suitable for specific purposes. Below are key sectors where rotary pistons play an important role.

Rotary Pistons in Automotive Industry

Rotary piston engines have been used in high-performance cars. The Mazda RX series is a famous example. These engines deliver strong power in compact and lightweight designs. This makes them ideal for sports cars and racing applications. The smooth operation of rotary pistons also enhances driving experience by reducing vibration and noise.

In addition to performance cars, some motorcycles have also implemented rotary engines. However, their use in traditional passenger vehicles is limited. This limitation arises from challenges like fuel efficiency and long-term reliability.

Industrial and Aerospace Uses

Rotary pistons also serve industrial and aerospace sectors. In aviation, their lightweight structure is a key advantage. Small aircraft and drones benefit from the compact and efficient power they provide. Rotary engines are used in some unmanned aerial vehicles (UAVs) for the same reasons.

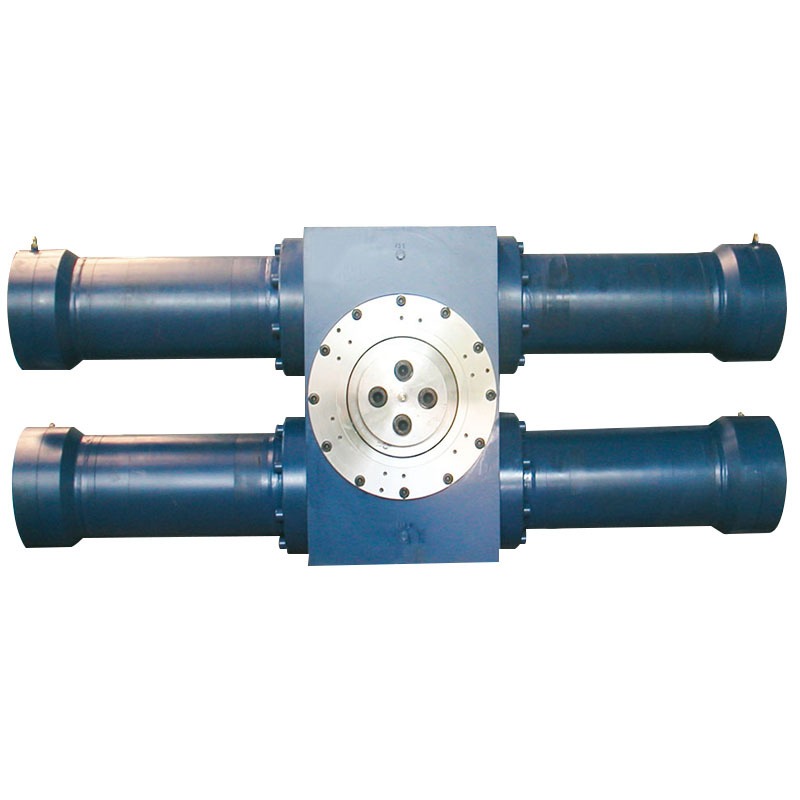

In industrial settings, rotary piston engines power specific machinery where compact size is critical. Some generators, pumps, and compressors rely on rotary engines for consistent performance and reduced vibration. Their smooth operation makes them effective in applications requiring minimal maintenance.

Other Niche Applications

Beyond automotive and industrial uses, rotary pistons appear in niche markets. Marine applications include smaller boats and watercraft where compact engines are advantageous. In the military, rotary engines are found in certain vehicles and drones, thanks to their reduced noise and lightweight properties.

Rotary engines are also popular in hobbyist projects, showcasing their flexibility. Engineers and enthusiasts continue to explore new ways to utilize rotary pistons in unique and innovative applications.

Rotary pistons remain relevant due to their adaptability across diverse sectors. Despite their challenges, they provide unique benefits for specific uses.

Challenges and Limitations

Rotary pistons offer many benefits, but they face several challenges. These limitations have restricted their widespread adoption. Below are the key challenges rotary piston engines encounter.

Durability and Maintenance Issues

Rotary piston engines have durability concerns due to the high demands on their internal seals. These seals wear down quickly because of continuous motion and high pressure. Over time, the deterioration affects engine performance and reliability.

Maintenance for rotary engines can be complex and expensive. Unlike traditional engines, repairing worn seals and rotor housings requires specialized expertise. The unusual engine design also makes finding replacement parts more difficult. As a result, long-term reliability is often less certain compared to reciprocating engines.

Fuel Efficiency Concerns

Fuel efficiency remains a significant drawback for rotary piston engines. Their unique design consumes more fuel due to combustion inefficiencies. Leaks in the chamber contribute to increased fuel consumption, making them less economical for everyday use.

Traditional engines often outperform rotary pistons in fuel economy. This inefficiency limits the appeal of rotary engines for standard vehicles. The added cost of fuel further discourages manufacturers and users from relying on rotary engines in most applications.

Environmental Impact of Rotary Engines

Rotary piston engines face environmental challenges due to higher emissions. The engine’s design leads to incomplete combustion, producing more harmful pollutants. This characteristic makes rotary engines less eco-friendly compared to up-to-date reciprocating engines.

Stricter environmental regulations have made it harder for rotary engines to compete in modern markets. Companies need advanced technology to reduce emissions, which increases costs. However, continued innovation may help solve these environmental hurdles.

Innovations and Future of Pistons

Rotary piston engines have unique benefits, but they also face limitations. Innovations aim to enhance their performance and broaden their applications. Engineers and researchers continue to find ways to make these engines more efficient, reliable, and environmentally friendly. Below are key areas where advancements and future potential are actively explored.

Advances in Materials and Technology

New materials and technologies improve the durability of rotary piston engines. High-performance coatings extend seal life and reduce wear. Lightweight alloys and composites make components stronger while keeping the engine compact. Advances in engineering design reduce leaks and improve combustion.

Precision manufacturing techniques ensure tighter tolerances for key parts. This enhances overall efficiency by minimizing gas losses. Innovations in lubricant formulations also lower friction and improve durability. Together, these developments aim to overcome traditional weaknesses in rotary engines, such as durability and emissions.

Potential Role in Electric and Hybrid Vehicles

Rotary pistons could power extended-range electric hybrids. Their compact size makes them ideal as range extenders for electric cars. They provide backup power without adding extra bulk or weight to the vehicle.

The continuous motion of rotary engines is well-suited for generators. Hybrid systems benefit from the smooth and efficient operation these engines offer. Ongoing research looks to improve their fuel economy and emissions for broader adoption in greener vehicles.

Upcoming Trends and Developments

Innovation paves the way for new applications of rotary piston engines. Engineers explore alternative fuels, like hydrogen, to reduce emissions and improve sustainability. Rotary engines are also being adapted for small aircraft and drones.

Research into micro rotary engines unlocks potential in robotics and portable generators. These compact engines promise high power-to-weight ratios for specialized applications. As technology evolves, rotary pistons remain relevant in industries seeking efficient and adaptable solutions.

Conclusion

Summary of Key Points

Rotary pistons are a distinct innovation in engine technology. They utilize rotary motion instead of traditional reciprocating motion, providing smoother operation. The design reduces vibration, offers compactness, and allows for lightweight engines with high performance. Despite these advantages, rotary piston engines face challenges like durability issues, fuel inefficiency, and higher emissions. Innovations in materials, engineering, and technology aim to address these limitations and improve their reliability. Rotary pistons remain suitable for applications requiring compact design and strong power-to-weight ratios, like sports cars, drones, and hybrid vehicles.

The Role of Rotary Pistons in Modern Engineering

Rotary pistons contribute to engineering by offering a novel approach to converting energy into motion. Their unique advantages allow their use in specialized industries, including aerospace, automotive, and industrial equipment. Though they have limitations, ongoing research holds promise for optimizing rotary piston engines for modern needs. By embracing advanced materials, sustainable fuels, and hybrid configurations, rotary pistons continue to inspire innovation in power solutions. They remain relevant in engineering, providing adaptable and efficient technology for niche applications.

The Significance of Rotary Piston Design

Emphasizing Innovation and Efficiency

In conclusion, the rotary piston serves as an essential component in various engine designs, contributing to efficiency and performance in unique ways. Understanding the mechanics behind its operation is critical for ensuring successful implementation in motorcycle, automotive, and industrial applications. As engineers push the boundaries of traditional engine design, that understanding will drive innovation in rotary engine technology. The evolution of rotary piston mechanics will continue to shape the future of transportation and power generation.

Investing in the Future

Investing in rotary piston technology means more than simply choosing an alternative to traditional engines; it represents a commitment to innovation and efficiency. The benefits of rotary engines must be weighed against their challenges, but ongoing research and advancements make them an exciting option for the future. By embracing this technology, individuals and industries alike can contribute to a more sustainable future while enjoying the remarkable performance that rotary engines offer.

A Journey Forward

As we continue to explore the potential of rotary piston technology, it is clear that a journey filled with possibilities lies ahead. Innovators remain dedicated to optimizing performance, reducing emissions, and improving durability. The advancements in this field not only benefit the automotive industry but also extend into aerospace and other sectors. The significance of the rotary piston cannot be understated, as it represents the drive towards higher efficiency and responsible engineering.

The Road to Tomorrow

As we look toward the future, the road to adopting rotary piston technology is paved with excitement and promise. Its ability to adapt to changing industry demands and technological advancements makes it a valuable asset in the evolving landscape of transportation. The journey of rotary piston design promises to unfold new discoveries, offering solutions that will enhance the way we think about engines and machines. Embrace the journey ahead, recognizing the vital role the rotary piston will play in creating a smarter, more efficient tomorrow.

Leave a Reply