Introduction to the Engine Cylinder Head

What Is an Engine Cylinder Head?

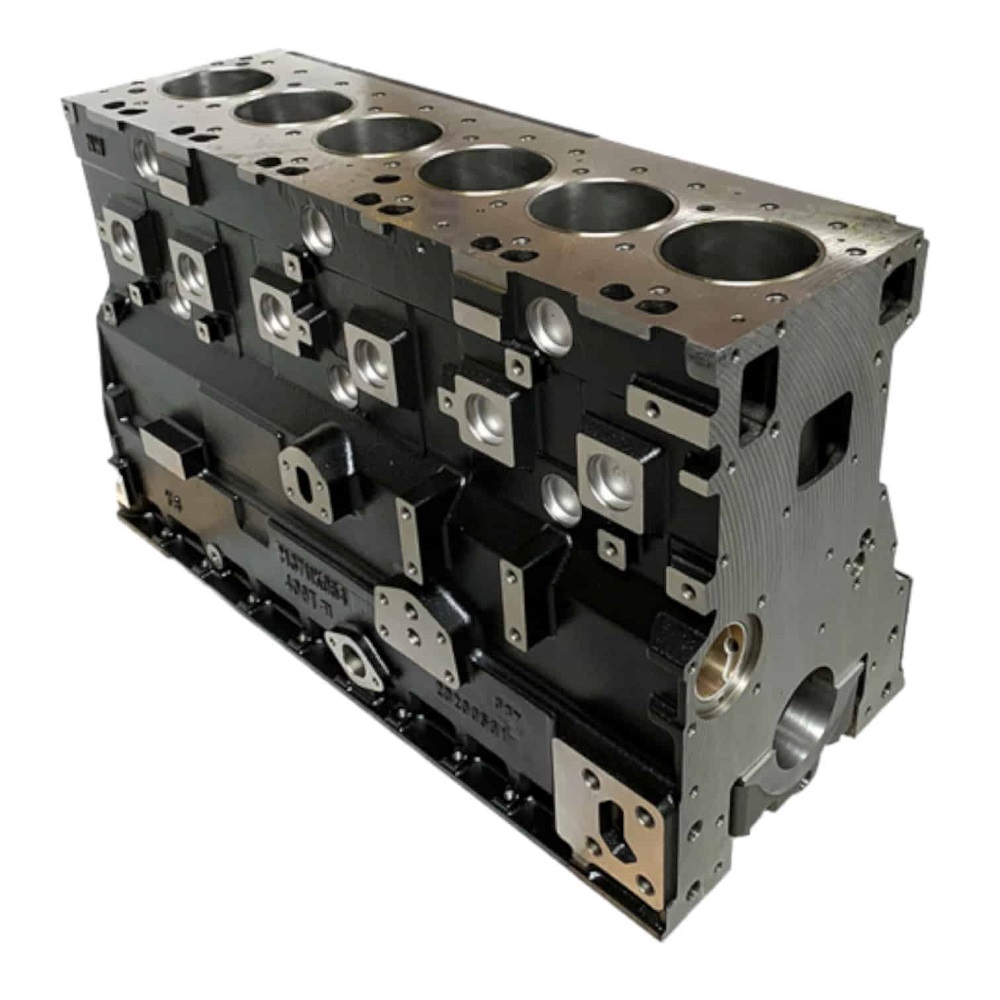

An engine cylinder head is a key component of an internal combustion engine. It is mounted on top of the engine block and seals the cylinders. The cylinder head contains vital parts, including valves, spark plugs, and passages for coolant and fuel. It plays a crucial role in the engine’s overall functioning by housing combustion chambers. Additionally, it ensures that the air-fuel mixture and exhaust gases flow smoothly.

Importance of Cylinder Heads in Engine Performance

The cylinder head directly impacts engine performance and efficiency. It controls the air and fuel mixture that enters the cylinders, enabling efficient combustion. Proper sealing by the cylinder head prevents engine leaks and ensures compression. High-quality cylinder heads enhance power output and fuel economy. Cylinder heads also regulate engine temperature through integrated cooling systems, preventing overheating. Without a functional cylinder head, an engine cannot operate effectively.

Core Functions of an Engine Cylinder Head

The engine cylinder head is vital to engine operation. It performs multiple functions that ensure the engine runs smoothly and efficiently. These roles involve managing air and fuel mixtures, directing exhaust gases, and regulating engine temperature.

Role in Air and Fuel Mixture Management

The cylinder head controls how air and fuel enter the combustion chamber. It houses intake valves that regulate the flow of fuel and air into the cylinders. Proper management allows for optimal combustion, leading to better efficiency and power output. Additionally, its sealing ensures no leaks, maintaining the engine’s compression.

Facilitating Exhaust Gas Removal

The cylinder head helps expel exhaust gases after combustion. It contains exhaust valves and ports that guide gases out of the engine. Efficient removal ensures clean chambers for the next combustion cycle. This function also reduces harmful emissions and improves engine performance.

Cooling System Integration for Temperature Regulation

The cylinder head helps regulate engine temperature through integrated coolant passages. These passages circulate coolant to prevent overheating. Proper temperature management ensures engine longevity and reliable operation. Without effective cooling, engine components could suffer wear or damage.

Common Materials Used for Cylinder Heads

Cylinder heads are crafted from durable materials to withstand extreme heat and pressure. The choice of material directly impacts engine efficiency, durability, and cost. Two common materials used for cylinder heads are aluminum and cast iron. Each offers unique benefits, depending on the engine’s requirements.

Aluminum Cylinder Heads

Aluminum cylinder heads are lightweight and provide excellent thermal conductivity. Their reduced weight contributes to better fuel efficiency and enhances vehicle performance. High thermal conductivity allows quick heat dissipation, reducing the risk of overheating. Aluminum heads are easier to machine, making them ideal for complex shapes and designs. While durable, they are less resistant to stress compared to cast iron. Aluminum heads are commonly used in modern engines, especially in performance and luxury vehicles.

Cast Iron Cylinder Heads

Cast iron cylinder heads are heavier than aluminum but offer superior strength and durability. They can withstand higher stress levels, making them ideal for heavy-duty engines. Cast iron’s lower thermal conductivity leads to slower heat dissipation, which may increase the risk of overheating. However, the material’s sturdiness ensures a longer lifespan and resistance to cracking under extreme conditions. These heads are frequently used in industrial and commercial vehicles due to their toughness and reliability.

Design Features of Modern Cylinder Heads

Modern cylinder heads are designed with advanced features to improve engine performance and efficiency. These designs enhance combustion, heat management, and overall reliability. Two critical aspects of these designs are valve arrangement and combustion chamber configuration.

Valve Arrangement and Placement

Valve arrangement determines how air, fuel, and exhaust flow in the engine. A well-planned valve placement boosts efficiency and performance. Most modern cylinder heads use overhead valve (OHV) or overhead camshaft (OHC) designs. These setups position valves directly above the combustion chamber. This arrangement ensures smooth airflow and optimized fuel intake.

Two-valve, three-valve, or four-valve-per-cylinder designs are common. More valves manage airflow better, increasing power output and fuel efficiency. Multi-valve designs are particularly popular in performance engines. Variable valve timing (VVT) is another innovation. It adjusts the valve timing to improve performance at different speeds and loads.

Compression and Combustion Chamber Design

The combustion chamber design impacts the engine’s efficiency and power. A well-designed chamber supports even fuel-air mixing and complete combustion. Achieving the right compression ratio is vital. Higher compression ratios improve power and fuel economy but require precise engineering.

Modern cylinder heads incorporate technologies like direct injection. This delivers fuel directly into the chamber for better combustion. Manufacturers also design chambers to reduce harmful emissions. The aim is to balance power, efficiency, and environmental concerns.

Special coatings and materials enhance durability under extreme conditions. Lightweight materials like aluminum help reduce engine weight and improve thermal management. These innovations ensure modern cylinder heads meet diverse performance needs.

Signs of Cylinder Head Issues

Cylinder heads are critical to engine operation. When they fail, it can lead to severe problems. Understanding the signs of cylinder head issues helps to prevent costly repairs.

Symptoms of a Faulty Cylinder Head

- Overheating Engine: A damaged cylinder head often disrupts engine cooling, leading to overheating.

- Loss of Engine Power: Faulty heads reduce compression, resulting in noticeable power loss.

- White Smoke from Exhaust: Leaking coolant into combustion chambers produces dense white smoke from the exhaust.

- Coolant and Oil Mixing: Cracks in the cylinder head may allow coolant to mix with engine oil.

- Poor Fuel Efficiency: Inefficient combustion caused by defects can increase fuel consumption.

Pay attention to these symptoms to address potential cylinder head issues early.

Common Causes of Cylinder Head Damage

- Overheating: Prolonged exposure to high temperatures weakens the cylinder head.

- Engine Detonation: Sudden, uncontrolled combustion can crack or warp the cylinder head.

- Poor Maintenance: Neglecting regular checks may allow minor issues to escalate.

- Manufacturing Defects: In rare cases, flaws in design or materials lead to early failures.

- Excessive Stress: Heavy-duty uses or modifications can strain the head beyond its limits.

Understanding these causes can help address issues proactively, extending the life of your engine cylinder head.

Maintenance and Repair of Cylinder Heads

Proper maintenance and timely repairs are crucial for ensuring the cylinder head’s efficiency and longevity. Regular checks can prevent costly damages and engine malfunctions. Below are key practices for maintaining and troubleshooting cylinder heads.

Regular Inspection and Cleaning Tips

- Visual Inspection: Check for cracks, warping, or other physical defects on the cylinder head surface.

- Coolant Flow Analysis: Ensure coolant passages are clear to prevent overheating of the cylinder head.

- Oil Condition Check: Inspect oil for contamination, which could indicate leaks or internal failures.

- Clean Deposits: Remove carbon buildup and debris from valves and combustion chambers using proper tools.

- Sealing Verification: Confirm gasket sealing to avoid leaks, which can affect compression and engine performance.

- Monitor Engine Temperatures: Keep an eye on temperature readings to identify early signs of overheat damage.

Frequent cleaning and inspections ensure the cylinder head works optimally. Small issues caught early prevent major repairs later.

Troubleshooting and Repair Techniques

- Compression Test: Perform a compression test to check for sealing issues and identify cylinder head problems.

- Repair Cracks: Weld minor cracks if possible, or replace the cylinder head for severe damages.

- Surface Resurfacing: Resurface warped heads to restore proper sealing and alignment.

- Gasket Replacement: Replace damaged or worn gaskets to maintain airtight sealing over time.

- Valve Adjustment: Adjust valves to prevent power loss and inefficient combustion.

- Coolant Passage Cleaning: Clear clogged coolant passages to restore effective heat dissipation.

Timely troubleshooting and repairs prevent permanent engine damage. Regular checks can extend the life of the cylinder head and improve engine performance.

Innovations in Cylinder Head Technology

Modern advancements in cylinder head technology focus on improving engine efficiency, power, and durability. These innovations help meet industry demands for lightweight designs, better thermal management, and enhanced performance.

Developments in Lightweight Materials

Lightweight materials like aluminum and composite alloys are revolutionizing cylinder head designs. These materials reduce overall engine weight, increasing fuel efficiency and vehicle speed. Aluminum heads are preferred for performance engines, offering low weight and effective heat dissipation. Some manufacturers now combine aluminum with reinforced composites for added strength without sacrificing weight. These materials also minimize environmental impact by supporting sustainable production practices. Using lightweight cylinder heads can extend engine life by reducing mechanical stress and wear.

Improved Thermal Efficiency and Performance

Modern cylinder heads use advanced thermal management systems for better heat dissipation. Improved coolant passages and specialized coatings help regulate engine temperature effectively. Enhanced thermal conductivity prevents overheating, ensuring reliable engine performance during high-stress usage. Direct fuel injection systems are increasingly integrated into cylinder heads, ensuring precise fuel delivery for optimal combustion. Variable valve timing (VVT), a popular innovation, adjusts valve timing for improved power and fuel efficiency. These technologies make modern engines more eco-friendly and performance-oriented.

Innovations in cylinder head technology continue to improve engine reliability and meet evolving automotive standards.

The Influence of Aftermarket Modifications

Benefits of Aftermarket Parts

Many car enthusiasts consider aftermarket modifications to enhance engine efficiency. Aftermarket cylinder heads can offer improved performance through better flow characteristics and weight savings. These modifications may also introduce new technologies that original designs lack, resulting in significant performance gains. For those looking to boost their engine’s power, aftermarket options can present viable solutions.

Potential Drawbacks

It’s important to approach aftermarket modifications with caution. While they can enhance performance, poorly chosen parts can lead to compatibility issues or even engine damage. Research and consult with professionals to ensure that your modifications align well with your vehicle’s existing systems. Additionally, keep in mind that some modifications could void warranties or violate local regulations, requiring careful consideration.

Holistic Approach to Modifications

When modifying the cylinder head, it’s best to take a holistic approach to performance enhancements. Upgrading the cylinder head should coincide with improvements to other engine components, such as the intake and exhaust systems. Ensuring that all parts work harmoniously together maximizes benefits and creates an engine setup that performs efficiently across the board.

Future Trends in Engine Cylinder Technology

Innovations in Design

The future of engine cylinder head technology promises exciting innovations aimed at maximizing efficiency and performance. Research into materials such as lightweight composites and advanced metals can lead to even better heat resistance and performance characteristics. Additionally, new manufacturing techniques, including 3D printing, may revolutionize how cylinder heads are designed and produced. These advancements could allow for more complex geometries and reduction in material waste, which are essential for environmental considerations.

Integration with Electrical Components

As the automotive industry moves toward electrification, integrating traditional internal combustion engines with electric components is becoming a reality. Cylinder head designs will likely evolve to accommodate hybrid systems that enhance power while reducing emissions. This integration could lead to more efficient combustion processes and lower reliance on fossil fuels.

Adopting Sustainable Practices

With growing awareness of environmental issues, there is a push towards sustainable practices in engine design. The focus on reducing emissions and improving fuel efficiency has never been more critical. Future cylinder head designs will likely prioritize eco-friendly materials and contribute to the overall objectives of more sustainable vehicles. Engineers are expected to create efficient combustion systems that minimize environmental impact while maintaining performance.

Conclusion: Optimizing Engine Efficiency Through Cylinder Head Design

Importance of Thoughtful Design

In conclusion, the design and functionality of the engine cylinder head significantly influence overall engine efficiency. Factors like airflow, combustion chamber design, and materials are key components that can enhance or hinder performance. Understanding these elements allows car enthusiasts and owners to make informed decisions about maintenance, upgrades, and modifications.

The Balance of Performance and Responsibility

Achieving optimal engine efficiency involves balancing performance with responsible practices. Regular maintenance, thoughtful upgrades, and understanding when modifications are necessary can all contribute to an engine that functions at its best. This balanced approach helps owners maximize the potential of their vehicles while ensuring longevity and reliability.

Embracing Future Developments

As technology advances, the next generation of cylinder heads is poised to offer exciting possibilities for performance enhancement. The emphasis on efficiency, sustainability, and innovative engineering will guide the evolution of engine designs. By staying informed and adaptable, vehicle owners can embrace the future of automotive technology while continuing to enjoy the power and excitement of their vehicles.

Leave a Reply