The crankshaft is one of the most crucial components of an internal combustion engine. It translates the linear motion of the pistons into rotational motion, driving the vehicle forward. Understanding how the engine crankshaft functions and its advantages can shed light on the overall performance and efficiency of an engine. In this article, we will explore the essential roles of the engine crankshaft, various designs, advantages in engine performance, and maintenance practices to ensure its longevity.

What is an Engine Crankshaft?

The engine crankshaft is a vital component in any internal combustion engine. It converts the linear motion of pistons into rotational motion, enabling the engine to transfer power to the wheels. Crankshafts are precision-engineered to endure tremendous forces and ensure smooth engine operation.

Definition and Overview

An engine crankshaft is a mechanical part that transforms piston movement into rotation. This rotation drives the vehicle’s transmission system, enabling motion. Made from durable materials like steel and alloys, it withstands stress and heat. It consists of key parts like main bearings, counterweights, and crankpins.

History and Evolution of Crankshafts

Crankshafts date back to ancient times. Early crank mechanisms were simple hand-operated designs. Industrial advancements led to stronger, more complex crankshafts for modern engines. Today’s crankshafts use advanced materials and manufacturing methods for enhanced performance and durability.

Key Functions of an Engine Crankshaft

An engine crankshaft plays several critical roles in the operation of internal combustion engines. By transferring motion and power, it ensures the smooth functioning of the entire engine system. Its design enables it to handle immense stress, making it indispensable for engine performance.

Converting Linear Motion to Rotational Motion

The crankshaft converts the pistons’ up-and-down motion into rotational energy. As the pistons move due to combustion, the crankshaft transforms this linear motion into rotation. This rotation drives the transmission system, ultimately powering the vehicle’s wheels. This process is the foundation of a functioning engine.

Role in Engine Performance

The crankshaft significantly influences engine efficiency and performance. It helps maintain the right balance and smooth rotation under extreme forces. A well-designed crankshaft ensures that the engine delivers consistent power output. Engine performance depends on its ability to transfer energy effectively, and the crankshaft is central to achieving this.

Synchronizing Piston Movements

The crankshaft synchronizes the movement of all pistons within the engine. It ensures accurate timing of pistons for optimal combustion and power generation. Any imbalance in piston movement can disrupt engine operation, making synchronization vital. By maintaining precision, the crankshaft keeps engine components working seamlessly.

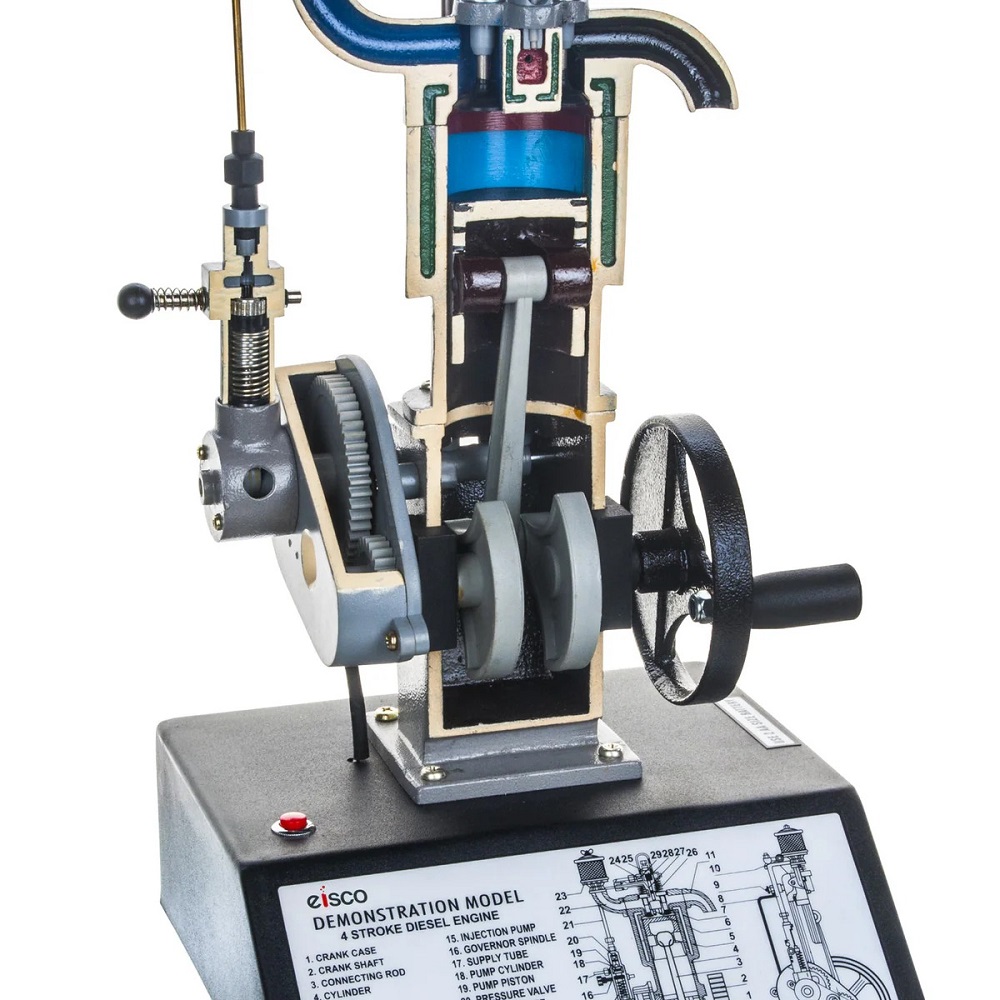

Components of a Crankshaft

An engine crankshaft consists of multiple components working together to deliver efficient performance. Each part plays a significant role in its functionality, ensuring durability and smooth operation. Below are the key components that make up a crankshaft.

Main Bearings and Journals

Main bearings support the crankshaft within the engine block. They minimize friction during rotation. Journals are surfaces where bearings are seated. These allow the crankshaft to rotate freely. Together, they ensure smooth and stable motion under high stress.

Counterweights and Their Importance

Counterweights balance the crankshaft as it rotates. They offset the forces generated by pistons’ movement. This prevents vibration and reduces stress on the engine. Balanced counterweights improve engine performance and enhance durability.

Crankpins and Throw Design

Crankpins connect the connecting rods to the crankshaft. They serve as pivot points for rotation. The throw design determines the crankshaft’s stroke and, consequently, the engine’s power output. Precise crankpin placement ensures smooth energy transfer and engine efficiency.

Types of Engine Crankshafts

Engine crankshafts come in different designs and manufacturing processes. Each type offers specific advantages and is suited to particular applications. Understanding the variations helps in choosing the right crankshaft for optimal engine performance.

Cast vs. Forged Crankshafts

Cast crankshafts are made by pouring molten metal into molds. They are cost-efficient and lighter in weight. However, they are less durable under extreme stress compared to forged crankshafts.

Forged crankshafts are formed by compressing heated metal into shape. They offer superior strength and durability. These crankshafts perform well in high-performance engines that handle extreme forces. While stronger, they also come with a higher price tag.

Billet Crankshafts

Billet crankshafts are machined from a single block of metal. They are fully customizable and provide unmatched precision and strength. These crankshafts are ideal for race cars and high-performance vehicles. Despite their incredible durability, they are the most expensive option.

Crossplane and Flatplane Crankshafts

Crossplane crankshafts are commonly found in V8 engines. Their unique design increases smoothness and reduces vibration. This design enhances drivability and produces a distinctive engine sound.

Flatplane crankshafts are lighter and simpler in construction. They improve engine responsiveness and are often used in high-revving sports vehicles. However, they can generate more vibration compared to crossplane designs.

Common Materials Used in Crankshafts

The materials used in engine crankshafts are critical to their performance and durability. These materials must withstand extreme stress, heat, and wear during operation. Choosing the right material ensures the crankshaft performs well and lasts longer.

Steel and Alloy Options

Most crankshafts are made from steel or alloys due to their high strength and reliability. Steel crankshafts, particularly those forged from high-carbon or chromium-molybdenum steel, are common in high-performance engines. They offer excellent toughness and can handle extreme forces.

Alloy crankshafts use blends of metals like nickel, molybdenum, or vanadium. These materials improve the crankshaft’s resistance to heat and wear. Alloy crankshafts are often lighter than pure steel versions, providing better fuel efficiency without sacrificing strength. Manufacturers select specific alloys based on engine needs, ensuring optimal performance.

Durability and Strength Considerations

The durability of a crankshaft directly impacts engine performance and longevity. Materials must resist fatigue and cracking under repeated stress. Strong crankshafts ensure smooth engine operation and reduce risks of mechanical failure.

Heat resistance also plays a key role. Crankshafts endure high temperatures from combustion. Materials must maintain their properties, even under intense heat. Steel and alloy options excel in this regard, making them the preferred choice for most designs.

Lastly, machinability is important in manufacturing crankshafts. The chosen material must allow precise shaping and finishing. This ensures a perfect fit within the engine for balanced and seamless operation. Selecting durable materials optimizes performance and lengthens the crankshaft’s service life.

Benefits of a Quality Engine Crankshaft

A quality engine crankshaft provides numerous benefits for the engine and overall vehicle performance. It ensures smooth operation, reduces wear and tear, and enhances efficiency. Below, we explore its significant advantages.

Impact on Fuel Efficiency

A well-designed crankshaft improves energy transfer within the engine. This leads to better fuel efficiency. Balanced components reduce friction and energy loss. Optimal fuel usage saves money and benefits the environment. Drivers experience greater mileage and lower fuel costs over time.

Enhancing Engine Longevity

Durable crankshafts withstand high stress and extreme temperatures. Reliable materials prevent fatigue and cracking. Properly functioning crankshafts reduce stress on other engine parts. With less wear and tear, engines last longer. Investing in quality crankshafts lowers repair costs and extends engine life.

Improving Performance Output

High-quality crankshafts optimize power delivery. They ensure smooth piston operation and balanced rotation. Reliable designs improve torque and horsepower. Performance vehicles benefit greatly from advanced crankshaft designs. A strong crankshaft helps the engine reach peak output efficiently. Smooth performance enhances driving experiences for all types of vehicles.

Maintenance and Troubleshooting for Crankshafts

Proper maintenance of the engine crankshaft is essential for engine performance and durability. Recognizing wear and damage early can prevent costly repairs or breakdowns. Regular inspections and timely actions ensure the crankshaft functions efficiently over its lifespan.

Identifying Signs of Wear or Damage

Crankshaft wear or damage can cause engine issues. Look for these common signs:

- Unusual noises: Knocking or grinding sounds might indicate misalignment or wear.

- Reduced performance: A damaged crankshaft can decrease engine efficiency and power output.

- Excessive vibration: Engine vibrations may signal an imbalance in the crankshaft.

- Oil leaks: Damaged seals around the crankshaft can lead to oil leaks.

Visual inspection can also reveal cracks, fractures, or worn bearings. Addressing these signs promptly prevents further damage.

Repair vs. Replacement: Making the Right Choice

Determining whether to repair or replace the crankshaft depends on the severity of damage:

- Repair: Minor wear like scratches or small cracks can often be fixed through machining or grinding. Bearings or other components may also need replacement.

- Replacement: If the crankshaft has severe damage, such as deep cracks or warping, replacement is the better option. A new crankshaft ensures optimal engine performance and long-term reliability.

Always consult a professional mechanic for accurate assessment and recommendations.

Importance of Regular Inspections

Routine inspections are vital for preventing crankshaft failure. Regular maintenance offers several benefits:

- Early detection: Regular checks help identify wear or damage before serious issues arise.

- Extended lifespan: Maintenance prevents excessive stress and wear, ensuring the crankshaft lasts longer.

- Cost savings: Catching small problems early reduces the need for expensive repairs or replacements.

Follow the manufacturer’s maintenance schedule for crankshaft inspections and servicing. Ensure proper lubrication and address any warning signs immediately. Investing in regular care protects your engine and enhances driving safety.

Innovations and Future of Crankshaft Design

Advancements in crankshaft design have continually improved engine performance, efficiency, and durability. Modern innovations focus on optimizing materials, manufacturing methods, and adapting to emerging technologies. These developments play a key role in shaping the future of internal combustion and hybrid engines.

Advancements in Materials and Manufacturing

Crankshaft materials and manufacturing processes have advanced significantly over the years. These improvements enhance strength, reduce weight, and boost efficiency:

- Advanced Alloys: New alloy combinations resist heat, stress, and wear better than traditional materials. Engineers use blends like titanium or carbon composites for improved durability.

- Precision Engineering: Manufacturing techniques like CNC machining ensure exact dimensions for perfect fits. This enhances balance and minimizes vibrations in the engine.

- Lighter Designs: Lightweight crankshafts reduce the engine’s overall weight. This contributes to better fuel efficiency and lower emissions.

- 3D Printing Applications: Additive manufacturing enables intricate designs and reduces material waste during production. It provides customization options for high-performance engines.

These advancements aim to create crankshafts that are stronger, more efficient, and longer-lasting.

Crankshafts in Electric and Hybrid Engines

The shift towards electric and hybrid vehicles has impacted crankshaft design. Though electric engines don’t use traditional crankshafts, hybrids require modified versions to combine combustion and electric systems effectively.

- Integrated Design: Hybrid engines use crankshafts that link combustion power and electric motor torque seamlessly. This ensures smooth transitions between the two sources.

- High-Efficiency Components: Crankshafts in hybrid engines are engineered for reduced energy loss. They maximize efficiency while managing power delivery.

- Electric Adaptations: While pure electric engines don’t need crankshafts, some innovative designs mimic crankshaft functions. These adaptations optimize rotational motion in motor assemblies.

- Focus on Sustainability: Manufacturers prioritize eco-friendly materials and energy-efficient production methods. This aligns crankshaft design with global sustainability goals.

In the future, crankshafts will play a specialized role in hybrid systems and may evolve further for electric applications.

Understanding innovations in engine crankshaft design provides insights into the future of automotive technologies. Advanced methods and sustainable materials will redefine engine efficiency and vehicle performance.

The Crankshaft’s Role in Engine Performance

Vital Component for Functionality

In conclusion, the engine crankshaft is a vital component in the functionality of an internal combustion engine. It plays essential roles in converting energy, maintaining balance, and facilitating fluid dynamics. Understanding these functions can provide insights into the overall performance of an engine, enhancing your knowledge as a motorcycle or vehicle owner.

Prioritize Quality and Maintenance

Choosing a high-quality engine crankshaft designed for your specific engine needs contributes to optimal performance. Regular maintenance practices, including inspections and lubrication checks, can prevent issues and extend the life of your crankshaft. Proper care will keep your engine in top shape and improve the overall riding experience.

Embrace Advancements in Technology

As technology continues to evolve, staying informed about advancements in crankshaft design and materials is essential. Innovations such as lightweight materials and integrated sensors are shaping the future of automotive performance. By embracing these changes and understanding the crankshaft’s critical role, you can enjoy the benefits they bring to your riding experience.

Leave a Reply