History and Background of the 12 Valve Cummins

Introduction to the 12 Valve Platform

The 12 valve Cummins engine is a landmark in diesel engineering. First introduced in 1989, it has become synonymous with durability and performance. Designed specifically for heavy-duty applications, this inline-six engine gained widespread popularity in trucks and industrial equipment. Its mechanical simplicity and robust design made it a preferred choice for many users. The platform is also famous for its use of a mechanical fuel injection system, which provides unmatched reliability compared to modern electronic systems.

Key Milestones in Development

The development of the 12 valve Cummins engine spanned several years of research and engineering. In 1989, Cummins partnered with Dodge to feature the engine in their Ram trucks. This collaboration marked a key milestone, leading to immediate success in the heavy-duty truck market. By 1994, refinement in design enhanced its power and torque output, solidifying its dominance. Though production ended in 1998, the engine retained a massive aftermarket appeal due to its legendary durability. Today, it remains a sought-after choice for modifications and rebuilds, signifying its lasting impact on diesel technology.

Specifications and Performance

The 12 valve Cummins engine is renowned for its robust performance and simple design. Below, we delve into the technical details and showcase why this engine remains a staple in diesel engineering.

Engine Specifications

The 12 valve Cummins features a 5.9L inline-six configuration. It employs a cast iron block and head for strength and durability. The engine uses a mechanical Bosch P7100 fuel injection pump, which ensures precise and reliable fueling. Key specifications include:

- Bore and stroke dimensions of 4.02 inches by 4.72 inches.

- Compression ratio of 17.5:1.

- Maximum RPM of 2,700 for factory settings.

- Cylinders configured with 2 valves per cylinder, totaling 12 valves.

These specifications contributed to the engine’s reliability across varied applications, from trucks to industrial machinery.

Power and Torque Output

The 12 valve Cummins engine delivers impressive power and torque numbers:

- Factory power output ranges between 160 to 215 horsepower, depending on the model year.

- Torque figures range from 400 to 440 lb-ft, providing excellent hauling capability.

- Turbocharging enhances performance, with the Holset H1C or HX35 turbo as standard configurations.

These figures made it ideal for heavy-duty applications, including towing and high-load scenarios. The performance also laid the foundation for aftermarket upgrades, where users could push its limits even further.

Fuel Economy and Efficiency

The 12 valve Cummins is recognized for its fuel efficiency compared to competing diesel engines. Its mechanical injection system optimizes fuel consumption without sacrificing performance. Typical fuel economy ratings range from 15 to 20 mpg in trucks, depending on driving conditions and load. This fuel efficiency made it an attractive choice for cost-conscious operators seeking durability and lower operational costs.

Advantages of the 12 Valve Cummins

The 12 valve Cummins engine stands out due to its unique advantages. Its strong design ensures lasting performance. This section explores its key benefits, which include durability, mechanical simplicity, and adaptability for modifications.

Durability and Longevity

The 12 valve Cummins engine is famous for its rugged build and long lifespan. Its cast iron block and cylinder head resist wear and tear. The mechanical fuel injection system increases reliability by avoiding electronic failures. Many engines have surpassed 500,000 miles with proper maintenance. For heavy-duty users, this durability is unmatched.

Mechanical Simplicity

The engine’s mechanical design reduces complexity. Unlike modern engines, it lacks electronic controls, making repairs easier. The Bosch P7100 injection pump is simple yet efficient. This simplicity appeals to owners seeking low-maintenance solutions. Minimal electronics also enhance reliability in challenging environments.

Adaptability for Modifications

The 12 valve Cummins engine offers incredible flexibility for upgrades. Its robust design handles increased power without major issues. Users often enhance performance with aftermarket turbochargers, injectors, and fuel pumps. The platform also supports performance tuning for added horsepower and torque. This adaptability makes it a favorite among diesel enthusiasts.

These qualities make the 12 valve Cummins engine legendary. Its balance of durability, simplicity, and modifiability continues to set it apart from competitors.

Common Issues and Maintenance Tips

The 12 valve Cummins engine is reliable but not without its challenges. Knowing common issues and maintenance practices can keep it performing at its best.

Known Problems with the 12 Valve Cummins

Some common problems with the 12 valve Cummins engine include:

- Fuel System Wear: Over time, the mechanical Bosch P7100 injection pump may experience wear. This can lead to reduced fuel delivery or leaking seals.

- Killer Dowel Pin (KDP): A notorious issue in these engines is the Killer Dowel Pin. The pin, located in the timing gear housing, can loosen. If it falls into the engine, it can cause significant damage.

- Head Gasket Failures: High power levels or overheating can lead to blown head gaskets. This is especially common in modified engines.

- Valve Train Wear: Over time, valves, rockers, and push rods may wear, causing noise or reduced performance.

- Oil Leaks: Oil leaks from gaskets or seals, particularly around the timing cover or valve cover, are frequent.

Addressing these issues promptly can prevent costly repairs and prolonged downtime.

Preventative Maintenance Practices

Preventative maintenance is crucial for extending the life of the 12 valve Cummins engine. Here are some best practices:

- Regular Oil Changes: Change the oil every 5,000 miles to keep the engine lubricated and clean.

- Inspect and Tighten Bolts: Regularly check and tighten bolts, especially around the timing cover, to prevent the KDP issue.

- Coolant Monitoring: Use proper coolant and maintain its level to avoid overheating and head gasket issues.

- Fuel System Maintenance: Replace fuel filters every 10,000 miles. Check the injection pump for wear or leaks.

- Valve Adjustments: Adjust valves every 15,000 miles to maintain proper operation and avoid excessive wear.

- Check for Oil Leaks: Inspect gaskets and seals during routine maintenance to address any early signs of leaks.

- Turbo Care: Inspect the turbocharger for wear and clean it if necessary to maintain performance.

Following these maintenance routines ensures consistent performance and reduces the chances of unexpected failures. With diligence, the legendary durability of the 12 valve Cummins engine can be fully realized.

Applications and Popularity

The 12 valve Cummins engine has earned recognition for its versatility and lasting appeal. This section discusses how the engine is utilized in various fields and why it remains a favorite among truck enthusiasts and hobbyists.

Use in Trucks and Industrial Equipment

The 12 valve Cummins engine is widely used in trucks and industrial machinery. Its robust design and powerful performance made it ideal for heavy-duty applications. These include hauling, towing, and operating equipment in demanding conditions.

- Trucks: The engine was featured in Dodge Ram trucks from 1989 to 1998. It delivered excellent torque and reliability for hauling and driving in harsh environments.

- Agricultural Equipment: Many tractors and farming machinery rely on its durability and consistent power output.

- Construction: Construction equipment often benefits from its longevity and ability to handle heavy loads.

Its mechanical fuel injection system provided reliability, making it suitable for jobs requiring long operational hours.

Enthusiast and Aftermarket Appeal

Among diesel enthusiasts, the 12 valve Cummins engine has a cult-like following. Its engineering simplicity and adaptability contribute to this popularity.

- Ease of Modification: Owners can easily upgrade the engine using aftermarket parts. Turbochargers, injectors, and fuel systems are common enhancements.

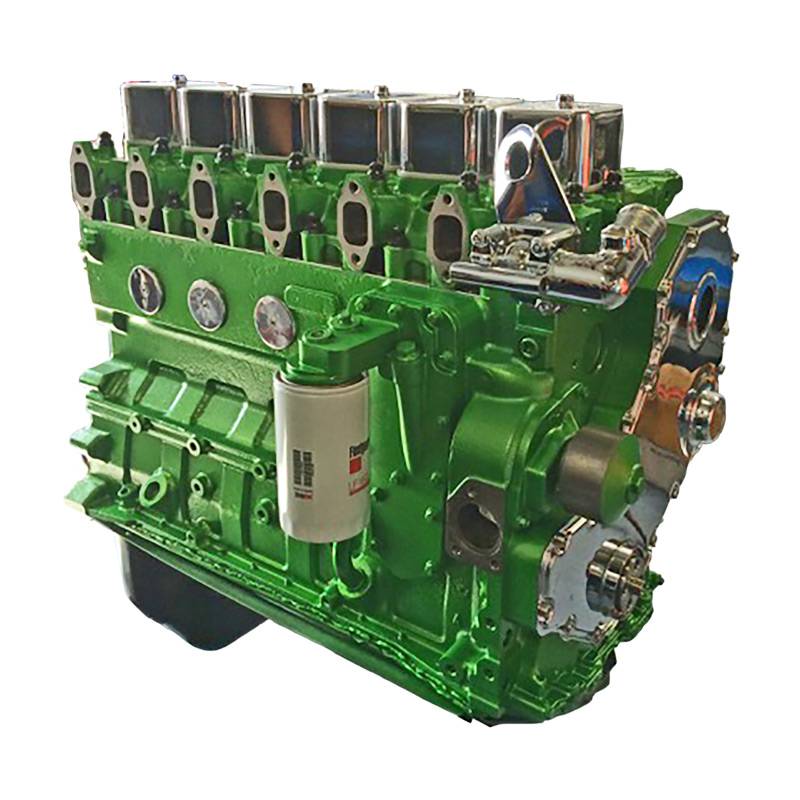

- Rebuild Potential: The engine’s durable cast iron components allow for cost-effective rebuilding after long-term use.

- Performance Tuning: Enthusiasts often perform tuning to achieve higher horsepower and torque levels.

- Classic Appeal: Diesel fans admire its mechanical design, which sets it apart from engines reliant on electronics.

Even years after its production ended, the 12 valve Cummins engine remains relevant in the aftermarket scene. Its reliability and modification-friendly structure keep it a sought-after choice.

Cost and Availability

The 12 valve Cummins engine continues to hold value in today’s market. Its reputation for durability and performance has fueled high demand among buyers. Below, we explore its cost range and the factors influencing its availability.

Price Ranges for Used Engines

Used 12 valve Cummins engines vary in price based on several factors. Here’s a general breakdown:

- Basic Condition: Engines in stock condition usually cost between $3,000 and $6,000. Prices depend on mileage and wear.

- Rebuilt Units: Rebuilt engines with new components are priced higher, ranging from $6,000 to $10,000 or more.

- Modified Engines: Modified engines with aftermarket parts and tuning can exceed $10,000, especially for performance builds.

- Parts-Only Units: Non-running engines or parts-only units are cheaper, often found for $1,500 to $3,000.

Prices also fluctuate based on the seller, such as private owners, salvage yards, or specialized dealers.

Factors Affecting Market Demand

Several factors influence the demand and availability of the 12 valve Cummins engine:

- Durability and Reputation: Its legendary longevity maintains high interest, especially among truck owners and diesel enthusiasts.

- Aftermarket Popularity: The engine’s modifiability has increased demand in the performance and hobbyist market.

- Limited Supply: Production ended in 1998, making them harder to find as years go by.

- Applications: Popularity in both trucks and industrial machinery keeps demand strong across various industries.

- Geographic Location: Availability may vary depending on regions where diesel engines are more popular.

Finding a well-priced 12 valve Cummins engine requires patience and research. Its value in reliability, performance, and adaptability ensures ongoing market interest.

Upgrades and Modifications

The 12 valve Cummins engine is valued for its upgrade potential and tuning capability. Owners often explore modifications to boost power, reliability, and efficiency. Below, we cover popular upgrades and tuning options.

Popular Aftermarket Upgrades

Enhancing the 12 valve Cummins engine is straightforward. Diesel enthusiasts use many aftermarket parts to improve performance and durability.

- Turbocharger Upgrades: Swapping the stock turbo with a larger one increases horsepower and torque. Common choices include the Holset HX40 or BorgWarner S300.

- High-Performance Injectors: Upgraded fuel injectors deliver more fuel for increased power. Brands such as Dynomite Diesel are popular.

- Fuel Pumps: Modifications to the Bosch P7100 pump include larger plungers or higher-pressure adjustments for enhanced fueling.

- Aftermarket Gauges: Installing gauges, such as boost and EGT monitors, gives real-time engine performance feedback.

- Air Intake Enhancements: High-flow intake systems provide better airflow, supporting turbocharger upgrades.

- Exhaust Systems: Free-flowing exhaust systems, such as 4-inch pipes, reduce backpressure and improve turbo efficiency.

- Head Stud Kits: Stronger head studs protect the head gasket when running higher turbo pressure.

These upgrades improve reliability and push performance boundaries, making the engine more resilient under stress.

Performance Tuning Options

Performance tuning is a favorite among 12 valve Cummins owners. It allows custom adjustments to optimize engine output.

- Fuel Plate Adjustments: Sliding or upgrading the fuel plate increases fuel delivery for boosted power. This is a common starter modification.

- Governor Spring Kits: Installing 3,000 or 4,000 RPM spring kits raises maximum engine operating speed.

- Timing Advancements: Advancing injection timing sharpens engine response and increases fuel efficiency.

- Custom Tuning on the P7100 Pump: Specialists tailor each pump’s settings for specific power goals, enhancing accuracy.

- Turbo Tuning: Pairing custom boost levels with engine tuning ensures balanced performance without overloading components.

- Combination Modifications: Experienced tuners combine various upgrades for holistic performance improvement.

By carefully mixing upgrades and tuning strategies, users achieve desired outcomes, ranging from fuel economy to maximum power output. The 12 valve Cummins remains a favorite platform for customization.

Comparisons with Other Diesel Engines

12 Valve Cummins vs. 24 Valve Cummins

The 12 valve Cummins and 24 valve Cummins engines differ in design, power, and complexity. Here’s a breakdown:

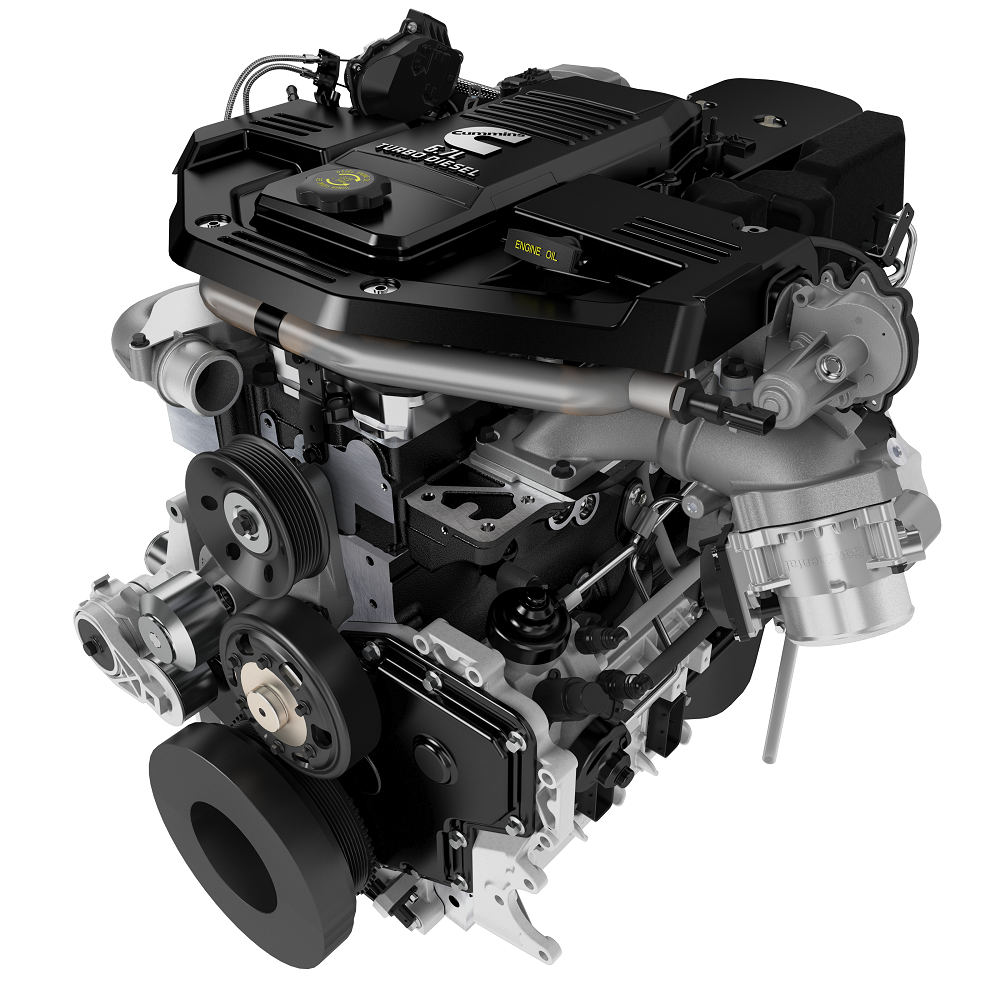

- Fuel Injection System: The 12 valve uses a mechanical Bosch P7100 pump, known for reliability. The 24 valve features an electronically controlled VP44 pump, offering advanced timing but with increased failure risk.

- Performance: Out of the factory, the 24 valve delivers more horsepower and torque due to electronic controls. However, the 12 valve’s mechanical simplicity makes it easier to modify for high performance.

- Durability: The 12 valve’s simplicity makes it highly durable and less prone to electrical issues. The 24 valve, with added electronics, requires more careful maintenance for long-term reliability.

- Maintenance: The 12 valve is easier to maintain due to the lack of complex electronics. The 24 valve demands specialized knowledge for troubleshooting.

- Aftermarket Support: Both engines have strong aftermarket communities, but the 12 valve is often preferred for custom builds due to its adaptability.

For enthusiasts who value simplicity and durability, the 12 valve is ideal. The 24 valve suits those needing more power out of the box.

Competitors in the Heavy-Duty Diesel Market

The 12 valve Cummins faces competition from other heavy-duty diesel engines. Here’s how it compares:

- Powerstroke Diesel (Ford): Ford’s Powerstroke engines rival the 12 valve in power and torque. However, they rely more on electronics, making repairs complex.

- Duramax Diesel (GM): Duramax engines combine power with comfort, featuring quieter operation. Despite this, they lack the simplicity and durability of the 12 valve.

- International DT466: This engine shares the 12 valve’s reputation for durability but is more common in industrial applications than trucks.

- Cummins ISB 5.9L (Post-1998): While newer Cummins engines offer advanced performance and emissions compliance, they sacrifice mechanical simplicity.

Key advantages of the 12 valve Cummins engine include proven reliability, cost-effective maintenance, and ease of modification. While competitors offer advancements in comfort and technology, few match the ruggedness and simplicity of the 12 valve platform. This comparison highlights why the 12 valve Cummins remains a favorite among diesel enthusiasts and heavy-duty users.

Leave a Reply