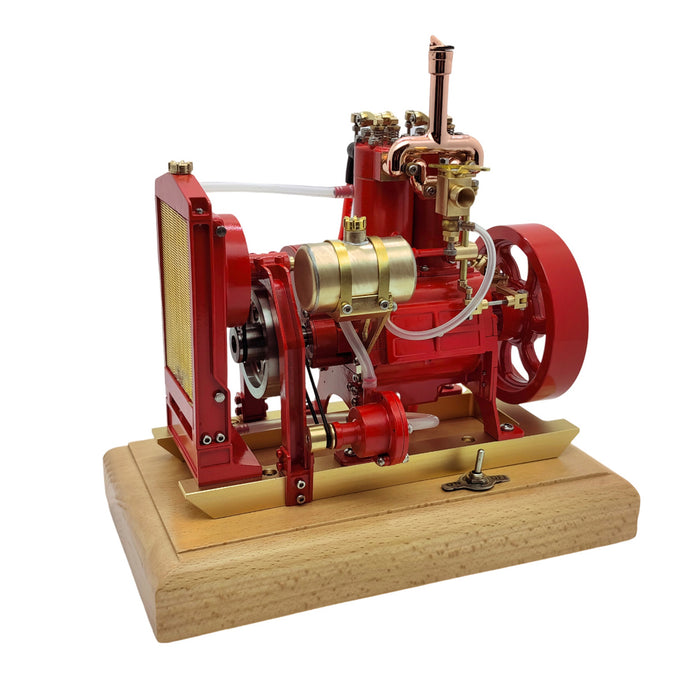

Introduction to Overhead Valve Engines

Overhead Valve engine is widely used in various machinery and vehicles. They are celebrated for their durability, efficiency, and compact design.

What is an Overhead Valve Engine?

An Overhead Valve (OHV) engine is a type of internal combustion engine. In this design, the intake and exhaust valves are positioned above the cylinders. The camshaft, often located near the crankshaft, uses pushrods and rocker arms to control the valves. This layout optimizes engine performance, improves power delivery, and ensures better heat dissipation. OHV engines are commonly known for simplicity and ease of maintenance.

Historical Development of Overhead Valve Engines

The history of OHV engines dates back to the early 20th century. These engines replaced older flathead engine designs, which had the valves located in the block beside the cylinders. The OHV design offered improved airflow and combustion efficiency. In the 1940s and 1950s, automakers widely adopted OHV engines for their reliability and power. Over the decades, OHV engines have evolved, with manufacturers incorporating modern materials and technologies to enhance performance. Despite new engine designs like Overhead Camshaft (OHC) engines, OHV engines remain relevant for various applications.

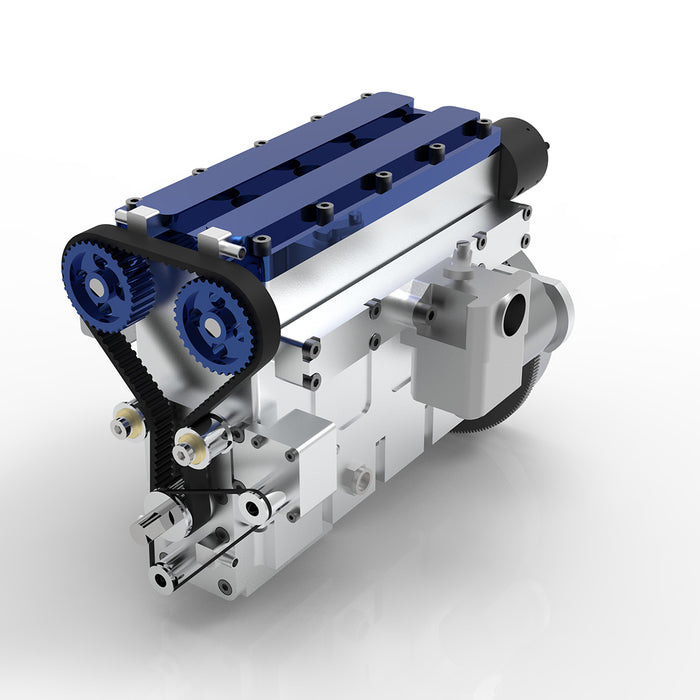

Key Components of an OHV Engine

Understanding the key components of an overhead valve engine helps us appreciate its efficiency and reliability. Below, we break down the main parts that make an OHV engine function.

Cylinder Head and Valve System

The cylinder head sits on top of the engine block and houses key parts. The valve system within the cylinder head includes intake and exhaust valves. Intake valves allow fuel and air mixture into the combustion chamber. Exhaust valves release burnt gases after combustion. The positioning of these valves in the cylinder head improves efficiency and airflow, setting OHV engines apart from older designs.

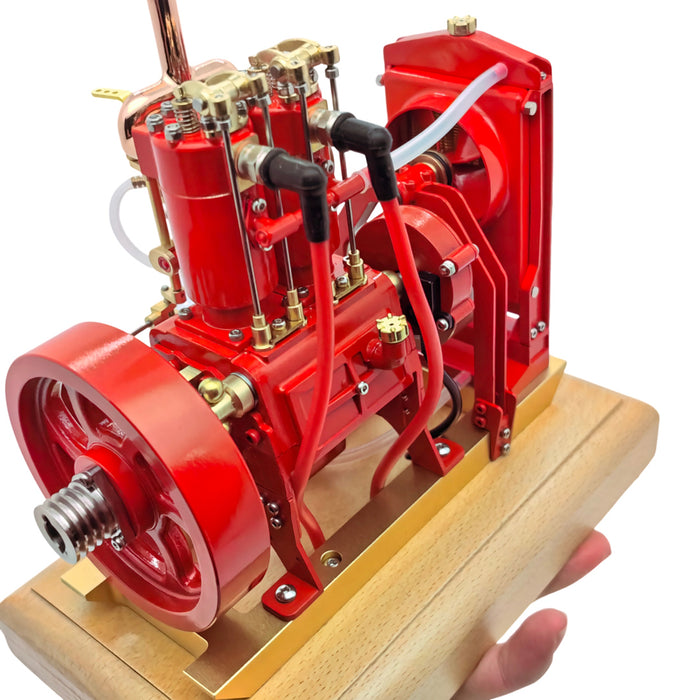

Camshaft and Pushrods

The camshaft is a rotating shaft that controls valve timing. It is located near the engine’s crankshaft in OHV engines. Pushrods connect the camshaft to the rocker arms and transmit motion to operate the valves. This configuration simplifies the engine’s design and reduces its overall size. Proper functioning of the camshaft and pushrods is vital for synchronized valve movement.

Rocker Arms and Valve Springs

Rocker arms play a critical role in opening and closing the valves. They pivot when pushed by the pushrods, transmitting motion to the valves. Valve springs, attached to the valves, ensure they close tightly after opening. This precise operation ensures efficient fuel combustion and exhaust expulsion. Together, rocker arms and valve springs maintain the engine’s performance and reduce mechanical wear.

Each of these components works harmoniously to ensure the OHV engine operates efficiently. Their compact and practical design is key to the engine’s renowned durability and efficiency.

How Overhead Valve Engines Operate

Understanding how overhead valve engines operate provides insights into their efficiency and performance. These engines follow a systematic process during operation, known as the four-stroke cycle. Each stroke plays a vital role in generating power.

The Four-Stroke Cycle in OHV Engines

Overhead valve engines work based on the four-stroke cycle: intake, compression, power, and exhaust.

- Intake Stroke: The piston moves down. The intake valve opens, allowing air and fuel to enter.

- Compression Stroke: The piston moves upward. Both valves are closed, compressing the air-fuel mixture tightly.

- Power Stroke: The compressed mixture ignites. The explosion pushes the piston downward, generating power.

- Exhaust Stroke: The piston moves up again. The exhaust valve opens, expelling burnt gases from the chamber.

Each cycle ensures the engine runs smoothly and delivers the required power output.

Role of Valves in Air and Fuel Intake

Valves control air and fuel entry into the combustion chamber.

- Intake Valves: Open during the intake stroke, letting fuel and air flow into the chamber.

- Precise Timing: Valves open and close accurately, governed by the camshaft and pushrods.

- Improved Distribution: Their position above the cylinder ensures even mixing and combustion of air-fuel.

Exhaust Process in OHV Engines

The exhaust process removes burnt gases after combustion.

- Exhaust Valve Control: The camshaft and rocker arms operate this valve during the exhaust stroke.

- Gas Expulsion: Burned gases exit through the exhaust valve and system.

- Heat Dissipation: The valve placement enhances heat dispersion, protecting engine components.

Together, these processes harmonize to deliver efficient engine operation. The simplicity of OHV engine mechanics makes them durable and reliable across applications.

Advantages of OHV Engines

Overhead valve (OHV) engines are known for their performance, reliability, and versatility. They offer key advantages that make them popular across various applications. Below, we explore these benefits in detail.

Enhanced Durability and Longevity

OHV engines are built to last, with a simple and sturdy design.

- Sturdy Construction: Their compact design reduces mechanical complexities, enhancing durability.

- Reduced Wear: Fewer moving parts and simpler mechanics decrease the chances of component wear.

- Heat Resistance: Efficient heat dissipation prevents overheating, ensuring long-term engine health.

- Proven Track Record: Decades of reliable performance have established OHV engines as durable systems.

Their robust design ensures consistent operation, even under challenging conditions.

Compact and Lightweight Design

The design of OHV engines prioritizes efficiency and functionality in a smaller package.

- Space Efficiency: Compact cylinder head placement minimizes engine size.

- Lightweight Materials: Modern materials keep the weight manageable without compromising strength.

- Versatility: The size allows installation in cars, small machinery, and other equipment.

- Ease of Maintenance: Minimal parts simplify servicing and reduce upkeep costs.

This design is ideal for applications where space and weight are limited.

Improved Fuel Efficiency

OHV engines are optimized to make the most out of each drop of fuel.

- Effective Combustion: The valve placement allows precise air-fuel mixing and burning.

- Optimized Airflow: Enhanced airflow achieves better fuel burning and reduces wastage.

- Reduced Energy Loss: Fewer parts mean minimal energy loss in power delivery.

- Cost Savings: Improved fuel efficiency results in lower fuel consumption and reduced expenses.

These engines are perfect for those seeking cost-effective and sustainable solutions.

Each of these features contributes to the appeal of OHV engines, making them a favored choice.

Common Applications of OHV Engines

Overhead valve (OHV) engines are renowned for their versatility and functionality. Their durable and compact design makes them suitable for various practical uses. Below, we highlight their common applications.

Usage in Automobiles

OHV engines have been a popular choice in the automotive industry for decades.

- Passenger Vehicles: Many cars use OHV engines because of their efficiency and reliability.

- Trucks: OHV engines deliver the consistent power needed for hauling and towing.

- Sports Cars: Some performance vehicles use OHV engines for their compact size and quick power delivery.

- Durability: Their robustness allows them to stand up to long-term use and challenging driving conditions.

These qualities make OHV engines an attractive option for a wide range of vehicles.

Role in Small Machinery and Equipment

OHV engines are also commonly found in smaller machines and equipment.

- Lawn Mowers: Their lightweight design ensures ease of use in lawn care machinery.

- Generators: They provide reliable power for portable and backup generators.

- Small Tractors: OHV engines power compact tractors used in landscaping and gardening.

- Power Tools: Many industrial tools rely on OHV engines for dependable operation.

Their compact size and durability make them perfect for these applications.

In both automobiles and machinery, OHV engines offer a balance of power, efficiency, and reliability. These strengths continue to make them a preferred engine design for diverse uses.

Comparison with Other Engine Designs

Understanding how overhead valve (OHV) engines compare to other designs helps with choosing the right engine. Let’s look at key differences between OHV, Overhead Camshaft (OHC), and flathead engines.

Overhead Valve (OHV) vs Overhead Camshaft (OHC) Engines

- Valve Placement: OHV engines have valves above the cylinder with pushrods, while OHC engines place the camshaft directly above the valves, eliminating pushrods.

- Complexity: OHC engines often have more components and are mechanically complex compared to OHV. This makes OHV engines easier to maintain.

- Size: OHV engines are generally smaller and more compact. They fit well in tighter spaces like lawnmowers or smaller vehicles.

- Efficiency: OHC engines provide smoother and higher RPM operation due to a more direct control of valves.

- Cost: OHV engines are cost-effective and easier to manufacture, while OHC engines tend to be pricier due to their intricate design.

Overall, OHV engines are favored for durability and simplicity, while OHC engines are better for high-performance needs.

OHV vs Flathead Engines

- Valve Placement: OHV engines have valves in the cylinder head, whereas flathead engines house valves beside the cylinder in the block.

- Performance: OHV engines improve air and fuel flow, delivering superior performance and combustion compared to flathead engines.

- Heat Dissipation: OHV designs offer better cooling and heat dispersion. Flathead engines are prone to overheating.

- Efficiency: Flathead engines have lower power output due to restricted airflow in their design.

- Maintenance: OHV engines are easier to repair and more widely used, while flathead designs are outdated.

The overhead valve engine replaced flathead engines thanks to its better power, efficiency, and durability. Because of these advantages, OHV engines remain a popular choice across many applications despite newer designs like OHC.

Maintenance Tips for OHV Engines

Keeping overhead valve engines in great condition ensures optimal performance and longevity. Proper maintenance is vital.

Regular Valve Adjustments

Regular valve adjustments enhance engine efficiency and prevent wear.

- Check Clearances: Inspect valve clearances periodically to maintain proper alignment.

- Adjust as Needed: Use the manufacturer’s guidelines to adjust the valve positioning.

- Monitor Performance: Watch for strange noises or weaker performance, which may indicate valve issues.

Routine adjustments keep the valve system efficient and reduce the risk of damage.

Importance of Oil Changes

Oil is the lifeblood of your engine. Replacing it regularly improves durability and function.

- Lubrication: Fresh oil ensures smooth operation of camshaft, pushrods, and rocker arms.

- Contaminant Removal: Oil changes flush out dirt and metal particles from engine parts.

- Heat Control: Proper oil levels help dissipate heat effectively during operation.

- Schedule: Follow prescribed intervals for oil changes, based on your usage and engine model.

Timely oil changes protect internal components and extend engine life.

Identifying and Fixing Common Issues

Common engine problems can reduce efficiency if left unchecked. Early fixes prevent costly repairs.

- Noise Detection: Unusual clicking sounds signal rocker arm or valve spring issues.

- Power Loss: Check valves and compression if power delivery weakens.

- Overheating: Examine exhaust valves and cooling systems for proper heat dissipation.

- Inspection: Regularly inspect hoses, seals, and filters for wear or leaks.

Addressing these problems promptly ensures smooth engine operation and reliability.

Effective maintenance of overhead valve engines prevents breakdowns and maximizes performance over time.

Future of Overhead Valve Engines

Despite advancements in automotive and machinery technology, overhead valve (OHV) engines continue to evolve. Manufacturers are exploring ways to enhance their efficiency and adapt to modern demands.

Innovations and Modern Adaptations

Overhead valve engines are benefiting from new materials and smarter engineering techniques. These improvements aim to keep OHV engines relevant in a fast-changing industry.

- Advanced Materials: Lighter and stronger materials reduce weight while improving durability and heat resistance.

- Improved Combustion: Enhanced combustion chamber designs increase fuel efficiency and power output.

- Electronic Integration: Modern OHV engines now use electronic ignition and valve control systems to optimize performance.

- Hybrid Adaptations: Some OHV engines are being tailored to work in hybrid powertrains to enhance versatility.

- Emission Controls: New technologies help OHV engines meet stricter emission standards without sacrificing performance.

These innovations make OHV engines more capable in both traditional and evolving applications.

Relevance in a World Shifting Towards Electric Vehicles

The growing shift to electric vehicles (EVs) raises questions about OHV engines’ relevance. However, they continue to hold value in certain niches.

- Long-Distance Use: OHV engines remain ideal for long-haul vehicles requiring extended range and durability.

- Small Machinery: They dominate applications like lawnmowers, generators, and compact farming equipment.

- Developing Markets: In regions with limited EV infrastructure, OHV engines are a practical choice.

- Low Manufacturing Cost: OHV engines are economical to produce, making them accessible in cost-sensitive markets.

- Transition Period: As EV adoption grows, OHV engines provide a reliable solution during the transition phase.

Though the future leans towards electrification, overhead valve engine present a cost-efficient and reliable option for specific needs. Their blend of innovation and practicality ensures their continued utility in a shifting landscape.

Leave a Reply