What is a Valve Engine?

Valve engines are essential components in many internal combustion engine systems. They regulate airflow and fuel mixture into the engine cylinders. These engines also control the exhaust gases leaving the cylinders. Effective valve operation ensures optimal engine performance and efficiency.

Definition and Overview of Valve Engines

Valve engines use mechanical devices called valves to manage gas flow. These valves open and close at precise intervals. This timing ensures the correct intake of air-fuel mixture and exhaust release. Most valve engines operate on either a four-stroke or two-stroke cycle. In both cycles, the valves play a critical role in maintaining engine functionality. Valve engines are commonly found in cars, motorcycles, and power equipment due to their reliability.

Historical Development and Evolution of Valve Engines

Valve engines have been around since the early days of internal combustion technology. Their invention revolutionized the way engines work by replacing inefficient systems. Early designs featured simple mechanisms like manual valves. Over the years, technology improved valve designs for better control and efficiency. Developments like poppet valves and rotary valves advanced the field. Today, modern systems like variable valve timing (VVT) optimize engine performance further. These innovations reflect the continuous evolution of valve engine technology.

Types of Valve Engines

Valve engines come in several types, each suited to specific applications. Understanding these types helps identify their uses and benefits. Below are the main types of valve engines and their unique features.

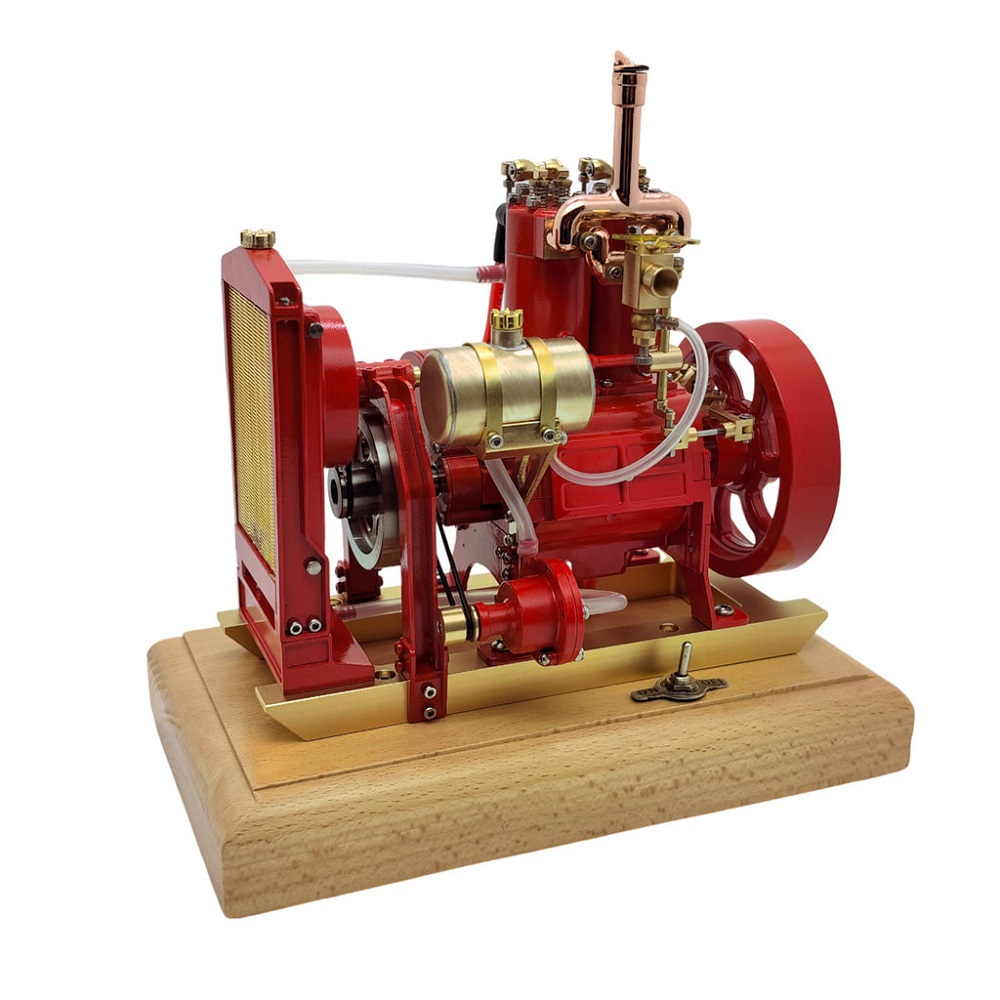

Poppet Valve Engines

Poppet valve engines use mushroom-shaped valves to control air and fuel flow. These valves open and close quickly through spring action. They are common in modern cars due to their efficiency and reliability. Poppet valves are tightly sealed, reducing pressure loss in the combustion chamber. The operation is simple and ensures consistent engine performance. These engines dominate automotive applications because they balance durability and cost-effectiveness.

Sleeve Valve Engines

Sleeve valve engines use a cylindrical sleeve to regulate gas flow. The sleeve moves within the cylinder walls, opening and closing ports. This design reduces moving parts compared to poppet valves, improving smooth operation. Sleeve valves are quieter and provide better fuel distribution. These engines were popular in aircraft and high-performance machines in the past. However, their high maintenance costs made them less common over time.

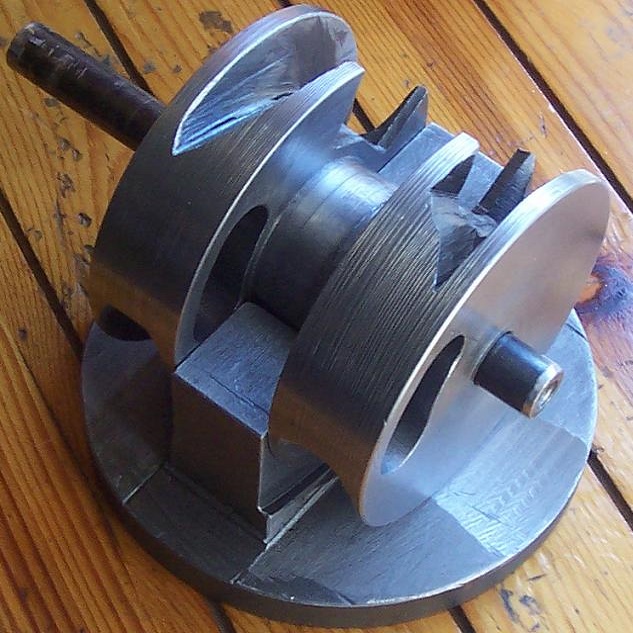

Rotary Valve Engines

Rotary valve engines use spinning discs or cylinders to control airflow. The rotary motion opens and closes the gas passages efficiently. Rotary valves minimize wear since there are fewer components interacting. These engines are highly compact and suitable for small, high-speed machines. Applications include motorcycles and specialty equipment where space-saving designs are critical. Rotary valve designs are innovative yet less widespread due to complex manufacturing.

Key Components of Engine Valve

Valve engines rely on key components for efficient functioning. Each part plays a specific role in gas flow management and engine performance. Understanding these components helps in diagnosing issues and optimizing operation.

Valves and Their Functions

Valves regulate airflow and fuel mixture into and out of the engine. They open during intake and exhaust cycles. Proper sealing prevents pressure loss in the combustion chamber. Common valve types include poppet, sleeve, and rotary valves. Valves ensure the engine runs smoothly and efficiently.

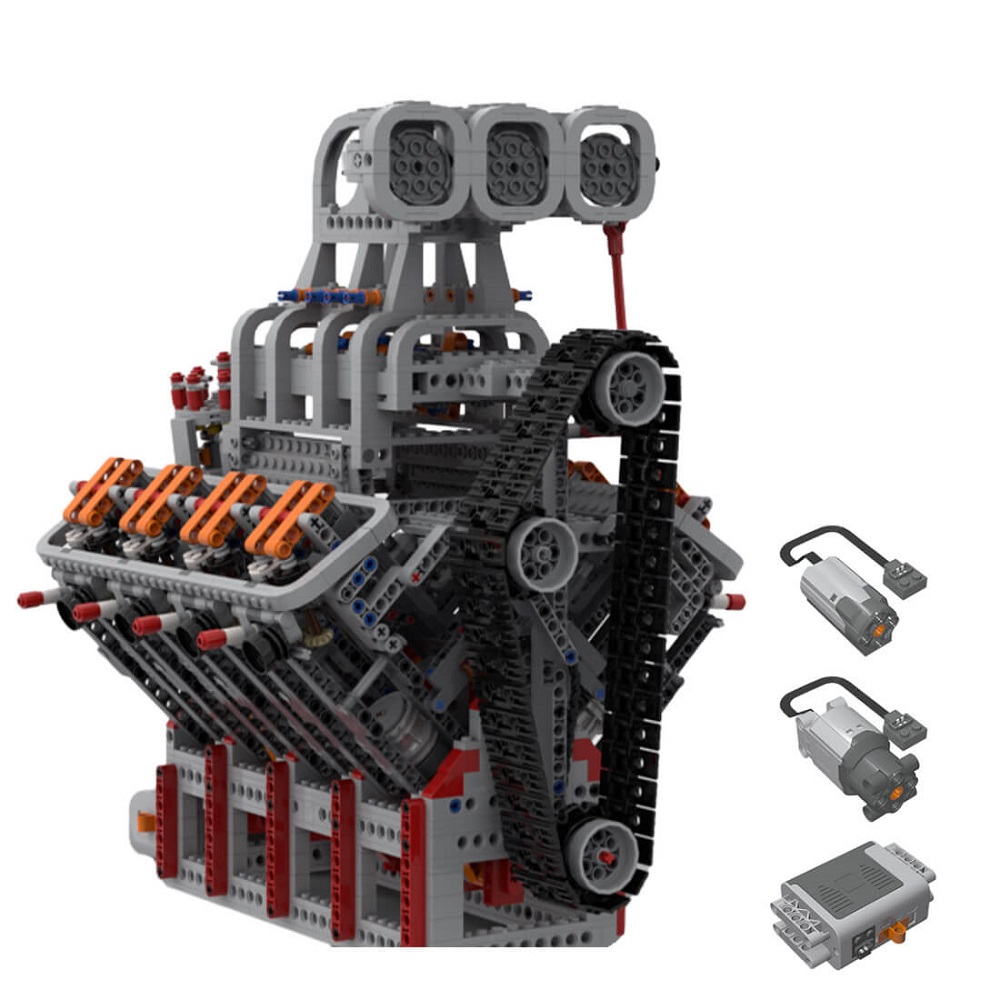

Valve Train Mechanisms

The valve train moves the valves in a synchronized manner. Key parts include the camshaft, lifters, pushrods, and rocker arms. The camshaft controls valve timing and motion. Lifters and pushrods transfer camshaft motion to the valves. Rocker arms help in opening and closing the valves. Together, these mechanisms maintain precise valve movements.

Timing Systems in Valve Engines

Valve timing systems ensure valves open and close at the correct moments. Timing affects fuel efficiency and engine power. Camshaft-driven systems are common in many engines. Variable valve timing (VVT) systems adjust timing for improved performance. Accurate timing reduces emissions and maximizes energy output.

How Valve Engines Operate

Understanding how valve engines work involves exploring their operational cycles and timing systems. Engine cycles and accurate valve timing are essential for efficient and smooth performance.

The Four-Stroke Cycle and Role of Valves

The four-stroke cycle is common in most valve engines. It consists of intake, compression, power, and exhaust strokes. Valves play critical roles in this process.

- Intake Stroke: The intake valve opens, allowing the air-fuel mixture into the cylinder.

- Compression Stroke: Both valves close, sealing the chamber for the mixture’s compression.

- Power Stroke: Ignition occurs, and the exhaust valve remains sealed to contain the expansion.

- Exhaust Stroke: The exhaust valve opens, letting out burnt gases efficiently.

Proper functioning of valves ensures optimal power generation and minimizes fuel wastage during the cycle.

Two-Stroke Valve Engine Operations

Two-stroke engines operate differently from the four-stroke engines. These engines complete a full cycle in two piston movements.

- Intake and Compression: Both intake and exhaust processes occur during the upward piston stroke.

- Power and Exhaust: Combustion and exhaust happen during the downward stroke.

Valve systems in two-stroke engines are simpler but require precise timing for efficient operations. Ports often replace conventional valves, optimizing airflow and fuel delivery.

Importance of Valve Timing

Valve timing ensures valves open and close at precise moments. Incorrect timing impacts engine performance.

- Performance Optimization: Accurate timing boosts power, efficiency, and fuel combustion.

- Emission Control: Optimized timing helps reduce harmful engine emissions.

- Engine Longevity: Proper timing prevents wear and improves overall component durability.

Variable Valve Timing (VVT) is a modern advancement that adjusts timing dynamically. This system offers better efficiency under varying conditions, ensuring peak engine performance.

Advantages and Disadvantages of Engine Valve

Valve engines are widely used due to their efficiency and reliability. However, like all technologies, they have both benefits and challenges. Let’s explore these in detail.

Benefits of Valve Engines

- Efficiency in Gas Flow Management: Valve engines ensure precise control over air and fuel intake.

- Improved Combustion: Proper valve timing leads to efficient combustion, boosting engine performance.

- Wide Applicability: These engines are versatile, used in cars, motorcycles, and industrial equipment.

- Durability: Well-designed valve engines can last long with proper maintenance.

- Enhanced Power Output: Modern advancements like variable valve timing (VVT) maximize power generation consistently.

Limitations and Challenges

- Complexity in Design: Valve engines have numerous components, increasing design and manufacturing complexity.

- Costly Repairs: Components like camshafts and valves can be expensive to repair or replace.

- Timing Sensitivity: Improper valve timing severely affects efficiency and may cause engine damage.

- Wear and Tear: Continuous motion of valves and related parts leads to gradual wear.

- Limited Applications for Certain Types: Some designs, like sleeve or rotary valves, are less practical for modern needs.

While valve engines dominate today’s markets, addressing their challenges continues to drive innovation and improvement.

Applications of Engine Valve

Valve engines are widely used across multiple industries due to their versatility and reliability. Their design supports efficient gas flow management, making them suitable for varied applications. Below, we discuss how valve engines are integral to the automotive, industrial, aviation, and marine sectors.

Valve Engines in Automotive Industry

The automotive industry heavily relies on valve engines for power and efficiency.

- Passenger Vehicles: Most cars use valve engines due to their reliability and fuel efficiency.

- High-Performance Cars: Sports cars utilize advanced valve systems like Variable Valve Timing (VVT) for better performance.

- Commercial Vehicles: Trucks and buses depend on valve engines for their durability and power.

Valve engines help optimize combustion, reduce emissions, and ensure long-lasting performance in vehicles. Their design suits modern automotive needs, balancing power and environmental standards.

Use in Industrial Machinery

Valve engines also find significant applications in industrial settings.

- Construction Equipment: Machines like excavators and bulldozers use valve engines for robust performance.

- Power Generators: Many generators rely on valve engines for consistent and efficient power output.

- Agriculture Machines: Tractors and harvesters benefit from valve engines’ durability and fuel savings.

These engines handle heavy loads and harsh environments effectively, making them ideal for industrial tasks. Their reliability minimizes downtime and boosts productivity.

Integration in Aviation and Marine Industry

Although less common than in other sectors, valve engines are used in aviation and marine applications.

- Small Aircraft: Some light aircraft rely on rotary valve engines for their compact design and efficiency.

- Marine Vessels: Ships and boats use valve engines to power their propulsion systems reliably.

Valve engines in these fields offer smooth operation and control. Their ability to withstand different conditions makes them a dependable choice for specialized applications.

In summary, the adaptability and performance of valve engines ensure their relevance in various industries. Their ability to balance efficiency, durability, and power keeps them indispensable in today’s mechanical landscape.

Maintenance and Troubleshooting of Engine Valve

Proper maintenance is crucial for ensuring valve engines work efficiently and last longer. Regular checks help identify issues early and prevent costly damages. This section covers common engine problems and repair solutions.

Common Issues in Valve Engines

Valve engines, though reliable, may experience various problems during their lifespan. Key issues include:

- Valve Wear and Tear: Continuous operation causes valves to wear out over time, reducing engine performance.

- Overheating: Excessive engine heat can damage valves and surrounding components, leading to lower efficiency.

- Carbon Build-Up: Combustion byproducts can deposit on valves, affecting their ability to seal properly.

- Valve Timing Issues: Incorrect valve timing disrupts airflow, reducing power and fuel efficiency.

- Oil Leaks: Faulty seals or gaskets may cause oil to leak into the combustion chamber.

Addressing these issues promptly keeps the engine running smoothly and prevents further complications.

Valve Adjustment and Repairs

Regular adjustments and repairs are essential to extend the life of valve engines. Here’s a guide to common maintenance tasks:

- Valve Clearance Adjustment: Ensure correct clearance between the valve and camshaft to maintain proper operation.

- Cleaning Deposits: Remove carbon deposits from valves using specialized tools or cleaning agents.

- Replacing Worn Parts: Swap out damaged valves, springs, or seals to restore engine performance.

- Timing Correction: Adjust the timing system to ensure valves open and close at the right moments.

- Oil System Check: Inspect seals and gaskets for leaks and replace them if needed.

Regular engine inspections by professionals can identify minor problems before they escalate. DIY repairs might work for simple issues, but complex problems often require expert intervention.

By addressing common faults and performing regular maintenance, you can maximize the durability of valve engines.

Future Innovations in Engine Valve Technology

Valve engine technology continues to evolve with next-generation materials and advanced systems like VVT. These innovations aim to improve performance, efficiency, and longevity while reducing cost and environmental impact.

Advancements in Materials and Design

New materials and designs are making valve engines more efficient and durable. Here’s how:

- Lightweight Materials: Using materials like titanium reduces engine weight, increasing fuel efficiency and performance.

- Heat-Resistant Alloys: Advanced alloys handle higher temperatures, preventing wear and extending engine lifespan.

- 3D-Printed Components: 3D printing allows precise and complex designs that reduce fabrication time and costs.

- Reduced Friction Designs: Innovative coatings and smoother surfaces cut down friction, improving engine efficiency.

- Simplified Mechanisms: Fewer moving parts mean easier maintenance and lower chances of mechanical failure.

These advances ensure valve engines remain competitive in today’s engineering landscape.

Prospects of Variable Valve Timing (VVT) Systems

Variable Valve Timing (VVT) continues to transform valve engine performance. Key benefits and future prospects include:

- Improved Performance: VVT adjusts valve timing dynamically, ensuring optimal power at all engine speeds.

- Fuel Efficiency Enhancements: By optimizing airflow, VVT reduces fuel consumption in real-time.

- Lower Emissions: Tailored timing improves combustion, producing fewer pollutants.

- Adaptive Driving Support: Systems like cam phasing adapt to driving conditions, offering smoother performance.

- Integration with AI: Future VVT systems may use AI to predict performance needs under various conditions.

VVT technology widens the applications of valve engines while meeting stringent regulatory and efficiency standards.

In summary, advancements in materials, designs, and systems like VVT are paving the way for a more efficient and sustainable future for valve engines. These innovations keep valve engines relevant in a rapidly changing global market.

Conclusion

Understanding valve engine and their functionality provides valuable insights into the performance of internal combustion engines. The 24-valve configuration illustrates the benefits of efficient gas exchange, ultimately affecting the engine’s power output and efficiency. As we explore the intricacies of valvetrains, camshaft profiles, and maintenance practices, it becomes clear that valves play a crucial role in engine health.

With ongoing advancements in valve technology, the future of engine design looks promising. Innovations in control systems and alternatives for fuel and emissions will play pivotal roles in shaping the automotive landscape. The continuous improvement of engine valves indicates that performance, efficiency, and environmental responsibility can coexist.

As automotive enthusiasts and everyday drivers alike appreciate the importance of engine valves, they can better understand the dynamics of their vehicles. Knowledge of valve technology empowers individuals to make informed decisions regarding maintenance, upgrades, and vehicle purchases. This understanding allows riders and drivers to maximize the potential of their engines while enjoying the journey on the road ahead.

Leave a Reply